Abstract

Since the early 1980s, the longwall method has developed into the safest, highest producing and most productive form of underground coal mining, rivalling the performance of many surface mining operations. This is due in large part to the rapid uptake of computer based technologies for automation and monitoring; improved reliability and performance of longwall mining equipment; and the adoption of plant management and loss control principles. This situation has many important implications for the geoscience and geotechnical engineering professions. For example, lost opportunity costs associated with loss of ground control are now so high that many of the simple observational and empirical approaches traditionally applied to geotechnical designs and operational aspects in longwall mining are no longer commensurate with the business risks that have to be managed. There is an increased need for geotechnical input to be based on sound engineering principles that encapsulate measured ground behaviour, applied mechanics, and numerical modelling. Ongoing research is important to support this need.

This chapter addresses geotechnical principles and practices relevant to satisfying these engineering requirements, making extensive use of figures and photographs to illustrate important concepts. It considers panel layout options and associated chain pillar design; traces the history of powered support design to draw learnings about their static and kinematic requirements; identifies and assesses operational variables, including cutting and support techniques, powered support maintenance, and face operational practices. It then reviews face behaviour and ground control requirements and practices; and evaluates the design and support of installation roadways and longwall recovery roadways, including pre-driven roadways.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Abutment loading

- Bidirectional cutting

- Caliper shield

- Canopy ratio

- Chain pillar design

- Chain pillar function

- Chock shield

- Conventional mode

- Cutting technique

- Cyclic loading

- Double chock

- Floor heave

- Gateroad orientation

- Ground control

- Ground response curve

- Half web cutting

- Horizontal stress

- Lemniscate linkage

- Longwall

- Longwall installation roadway

- Longwall recovery

- Longwall top coal caving

- Miniwall

- One web back

- Periodic weighting

- Powered support

- Powered support hydraulics

- Pre-driven roadway

- Sacrificial roadway

- Shield

- Skew roof

- Strata control

- Stress notch

- Stress relief

- Support resistance

- Tailgate abutment loading

- Tip-to-face

- Unidirectional cutting

- Yield pillar

9.1 Introduction

Since the early 1980s, longwall mining has developed into the safest, highest producing and most productive form of underground coal mining, rivalling the performance of many surface mining operations. In Australia, for example, advances in technology, geotechnical engineering and work practices over that period have resulted in more than a three-fold increase in the average productivity of longwall mining, with some newer operations achieving up to an eight-fold increase. Subject to adequate coal reserves, environmental constraints, and access to capital, it is the method of choice for new underground operations.

The significant increases in longwall productivity are due in large part to rapid uptake of computer based technologies for automation and monitoring; improved reliability and performance of longwall mining equipment; and the adoption of plant management and loss control principles, leading to both increased rates of production and reduced labour requirements. In terms of production, average daily output of the top performers in Australia has increased from, typically, 5,000 t/day in 1985, to 20,000 t/day in 2013. Incremental cost savings associated with these rates of production, supported by increased coal selling prices, meant that delayed profit opportunity for each day of unplanned stoppage of a longwall face increased from as little as A$10,000/day in 1985, to in excess of A$500,000/day for some premium coking coal operations in 2013, with non-recoverable fixed costs sometimes being of the order of A$150,000/day.

This has important implications for the geoscience and geotechnical engineering professions. Firstly, operations are now in a better position to justify the engagement of geotechnical professionals, with the annual salary of one such person being recouped if their input avoids just one or two days of lost production per annum. Secondly, the lost opportunity costs are now so high that many of the simple observational and empirical approaches traditionally applied to geotechnical designs and operational aspects in longwall mining are no longer commensurate with the business risks that have to be managed. There is an increased need for geotechnical input to be based on sound engineering principles that encapsulate measured ground behaviour, applied mechanics, and numerical modelling. Ongoing research is required to support this need. This chapter addresses geotechnical principles and practices relevant to satisfying these engineering requirements.

9.2 Panel Layout

9.2.1 Basic Longwall Mining Methods

There are two basic types of longwall mining, namely, ‘longwall mining on the advance’ and ‘longwall mining on the retreat’. Longwall mining on the advance involves developing the maingate and tailgate entries just ahead of the longwall face as it is being advanced, with these gateroads being maintained in the goaf of the panel using various combinations of pack walls and arch support systems. The primary advantage of the method is that the single entry gateroads are located in stress relieved zones. Disadvantages include slow mining rates due to gateroad advance and longwall face advance being interdependent; restricted access for ventilation and supplies; ongoing roadway maintenance requirements; increased propensity for spontaneous combustion due to air ingress into the goaf; and no second independent means for egress in an emergency situation.

Longwall mining on the retreat is the most common type of longwall mining. It involves driving one, two or three gateroads down both flanks of a panel to its extremity, and then connecting these two sets of gateroads (Fig. 2.3). The longwall equipment is installed in this connecting roadway and the block is progressively extracted on the retreat. The method is not subject to many of the impediments associated with longwall mining on the advance and has a lower exposure to others. However, serious ground control difficulties can be associated with supporting and maintaining gateroads, cut-throughs and pillar ribs. Longwall mining on the retreat finds extensive application in Australia, South Africa and the USA at depths ranging from as low as 15 m, down to around 700 m. In these countries, it is premised on multiple entry longwall development that requires leaving one or two rows of interpanel pillars (chain pillars) between longwall panels. The method finds application using single entry gateroads at depths exceeding 1,200 m in Europe. It is also used extensively in China, including to recover coal from the goaf in thick seams (see Sect. 9.9.1).

The number of gateroads utilised in longwall mining is a function of many factors including egress requirements, ground conditions, gas and ventilation regimes, panel dimensions, production rate and propensity to spontaneous combustion. Three gateroads are always required when there is a requirement for two independent means of egress from the mining face. High gas regimes may also require three gateroads in order to provide a sufficient quantity of air to dilute the gas to safe and prescribed levels. Gas pre-drainage does not necessarily remove this requirement because rib emissions in the gateroads can still result in gas content in intake airways exceeding permissible levels (typically, no more than 0.25 % CH4 equivalent in intake roadways) before the air reaches the mining face. This situation is aggravated in long panels, some of which can exceed three kilometres, due to the increased roadway surface area.

In any case, air quantity requirements at the working face may require three gateroads in very long panels in order to compensate for reduced air flow due to increased resistance associated with surface friction and shock losses. The relationship between ventilation pressure, air quantity and airway resistance is given by Eq. 9.1:

where

-

P = fan pressure (pa)

-

Q = air flow quantity (m3/s)

-

R = roadway resistance (Ns2/m8)

The installation of standing support in roadways, especially tailgates, increases the resistance of the ventilation circuit considerably and can make the difference between requiring two or three gateroads in order to deliver the required quantity of air to the face. This is especially the case in coal seams prone to spontaneous combustion, as increasing fan pressure to compensate for increased airway resistance encourages air leakage between intake and return airways and across goaves, thereby promoting the development of spontaneous combustion. The basic principles for managing spontaneous combustion in these situations are presented in a range of literature, including Humphreys and Richmond (1986), Cliff et al. (1996) and MDG-1006 (2011).

Production rate also has a significant bearing on the number of gateroads required for longwall production. Gas emissions, dust make and heat generation increase with rate of retreat and, therefore, a higher quantity of air at an adequate velocity is required to safely manage these factors. The trend towards wider and higher longwall faces and higher capacity longwall production equipment also has a significant effect on heat production at the working face, with the power requirements of some installations exceeding 6 MW. Where conditions permit, consideration can be given to constructing a small diameter shaft at the inbye end of each panel as an alternative to driving extra gateroads for ventilation purposes.

Multiple gateroads aggravate ground control difficulties in longwall mining because the second and subsequent gateroads are exposed to longwall abutment stress. This necessitates that these roadways are either sufficiently remote from a longwall panel that abutment stress impacts on them can be safely and productively managed or else, in the case of a twin gateroad situation, the second maingate roadway is located in the yield zone of the abutment stress profile. These options, illustrated in Fig. 9.1, determine the type and width of the chain pillars. Hence, chain pillars can range from squat pillars in the former case to yield pillars in the latter case.

A raft of additional ground control difficulties can be experienced in driving and supporting cut-throughs. Problems can arise on development when preference is given to orientating headings rather than cut-throughs in the more favourable direction for managing horizontal stress. They can arise on extraction because the cut-throughs are located within the abutment stress front. For these reasons and in order to minimise roadway drivage, the distance between cut-throughs is usually maximised, thus resulting in the length of chain pillars typically being two to five times their width.

Many of the basic ground engineering principles relevant to designing roadways, pillars and support systems in these circumstances are presented in Chaps. 2, 3, 4, 5, and 6. Aspects of these specific to longwall interpanel pillars (chain pillars) are developed in more detail in this chapter.

9.2.2 Gateroad Direction and Layout

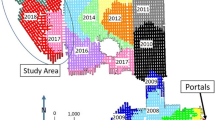

Factors which need to be considered in optimising gateroad direction and layout include surface constraints; lease boundaries; coal quality consistency; coal thickness consistency, dip and dip direction; cleat intensity and direction; and horizontal stress magnitude and direction. Conflicts between these factors require design compromises, with high horizontal stress tending to be the most important and dominant factor controlling design. Figure 9.2 shows the three general design options for managing this factor.

For the purpose of this text, the layout shown in Fig. 9.2a is referred to as a 0/90/90 layout, indicating that the gateroads are orientated parallel to the major horizontal stress direction and the cut-throughs and longwall installation face are at right angles to this stress direction. This layout minimises the adverse impact of horizontal stress on the gateroads and maximises it on the cut-throughs and installation face. Therefore, it has the advantage of optimising conditions during longwall retreat at the expense of potentially difficult development conditions when driving cut-throughs and the longwall installation roadway. Conditions can be particularly adverse at the point of backholing a cut-through that has been developed from both directions.

Figure 9.2b depicts a 0/60/90 layout in which the gateroads continue to be orientated in the optimum direction and the installation face in the most adverse direction, but the cut-throughs are now orientated at 60° to the horizontal stress field to mitigate its impacts on them. The benefits of this option have to be weighed up against a range of operational impediments that can be associated with angling cut-throughs in this manner. These include:

-

Cut-throughs can only be driven from one direction. This introduces scheduling restrictions and reduced operational flexibility, both of which may retard advance rates.

-

Mobile plant cannot turn left and right into and out of cut-throughs, again reducing operational flexibility.

-

There is a higher likelihood that one mining direction will not be optimum for controlling the impact of cleating and jointing, thereby elevating the risk of injury and causing an increase in mining spans due to rib spall.

-

Two corners of the chain pillars are acute, resulting in them having a reduced strength, being susceptible to damage by equipment, and prone to fall along cleat and joint planes. In turn, these factors elevate the risk of injuries due to risk of rib fall and result in increased intersection spans and, hence, exposure to roof control problems.

The compromise situation of a −30/30/60 layout, in which horizontal stress impacts on headings, cut-throughs and the installation roadway are all reduced but not eliminated, is depicted in Fig. 9.2c. This layout can be difficult to implement due to other competing mining considerations and constraints, such as lease boundaries, seam dip, and gas management.

Other stand-alone or complementary options for managing horizontal stress in roadways during gateroad drivage and longwall extraction include primary and secondary support strategies and stress relief roadways. These aspects are discussed in more detail in Sects. 3.4 and 5.2 and Chaps. 6 and 7.

9.2.3 Chain Pillar Life Cycle

Longwall interpanel pillars, or chain pillars, can perform a variety of functions, some of which change over the life of the pillars. Essentially, the pillars are required to remain structurally stable and functional until at least the passage of the second longwall. In designing a chain pillar, consideration should be given to its life cycle, which can be broken down into five stages on the basis of pillar loading (Fig. 9.3). The stages are described in respect of a two heading development but the principles also hold true for a three heading development.

-

Stage I. Two gateroads are developed into what, for practical purposes, could be considered virgin ground. Pillars are surrounded by solid in all four quadrants (that is, for 360°). Unless the depth of mining is very shallow, the overall width-to-depth ratio, W/H, of the gateroad panel is too small to result in full tributary load acting on the chain pillars. Depending on depth and horizontal stress magnitude and direction, the goaf of an adjacent longwall panel may cause the gateroad development panel to be shielded to some extent from horizontal stress.

-

Stage II. The longwall face reaches the chain pillar and the pillar is now surrounded by solid in only three quadrants (270°). The abutment load of the goaf in the fourth quadrant is distributed between the longwall block and the side abutment, which includes the chain pillar, resulting in an increase in chain pillar load.

-

Stage III(a). As the longwall retreats past a chain pillar, the abutment load carried by the longwall face is progressively transferred onto the chain pillar, or side abutment. Ultimately, the side abutment falls beyond the influence of the longwall face and the chain pillar is subjected to full maingate abutment loading arising from the goaf, which now occupies two adjacent quadrants of the pillar (180°). This situation is referred to as single sided abutment loading. The magnitude and distribution of the abutment stress profile and the width of the chain pillar determine the proportion of abutment load carried by the chain pillar.

-

Stage III(b). The chain pillar occupies the same relative position as in stage III(a) and so, in theory, the abutment loading acting on it should be unchanged. However, because the strength of rock can decrease over time, especially under high load, the stability of both the chain pillar and the adjacent gateroad (tailgate) may deteriorate in the time interval between the passage of the two longwalls. Ongoing mining-induced changes in the stress field can also contribute to this deterioration.

-

Stage IV. The chain pillar is now surrounded by solid in only one quadrant (90°). The abutment load of the second goaf is distributed between the second longwall block and the chain pillar, resulting in a further increase in chain pillar load. This situation is sometimes referred to as tailgate abutment loading.

-

Stage V. As the second longwall retreats beyond the chain pillar, the abutment load carried by the longwall face is again progressively transferred onto the tailgate side abutment, with the chain pillar now surrounded by goaf in all four quadrants. This situation is referred to as double sided abutment loading. Due to the stiffness of the superincumbent strata, the load acting on a double abutment loaded chain pillar may not initially be double that for a single sided abutment loading situation, especially at depth. A number of additional panels may have to be extracted before this state is reached, as evident from the profiles of vertical surface displacement depicted in Figs. 3.16 and 3.19.

9.2.4 Chain Pillar Design

Chain pillars constitute interpanel pillars, with the basic principles pertaining to their function and design introduced in Sect. 5.2. There is no single correct design method for longwall chain pillars, particularly since the roles of chain pillars in a mine layout may be quite diverse (Hebblewhite and Galvin 1996). Nevertheless, in nearly all cases, a primary function of chain pillars is to provide a buffer of sufficient width between the goaf of the previous longwall panel and the gateroads of the current longwall panel in order to shield the gateroads from high abutment stress. Therefore, chain pillar design should include consideration of the abutment stress that gateroads can tolerate, having regard to the local geology, the type and density of support to be installed in the gateroads, and the level of serviceability required of them (Galvin et al. 1982).

A variety of empirical and numerical approaches are currently utilised to design chain pillars. Many of the empirical approaches rely on the concepts of angle of break and abutment angle and a single sided abutment load multiplying factor to estimate pillar load at the tailgate/face corner. This load is then compared to pillar strength calculated using an empirical equation derived for bord and pillar mining situations. The two most common means of calculating chain pillar width utilising these empirical approaches are:

-

To work backwards from a design pillar safety factor that is judged to produce a safe working environment, acceptable tailgate conditions and, where required, adequate surface subsidence control. In some circumstances where only minimal surface subsidence is tolerable, UNSW power safety factors of 2.2 or more based on double sided abutment loading have been used with the intent of preventing pillar failure in the long term. Otherwise, the design safety factor is usually based on the notion of preventing pillar failure until after the second longwall face has passed by the pillar. in which case the maximum pillar load is taken to be that acting on the chain pillar at the tailgate end.

-

To work backwards from a design stability factor selected on the basis of its empirical relationship to some measure of tailgate serviceability. The stability factor is equated to the ratio of chain pillar strength to chain pillar load, with the latter usually estimated at the tailgate corner. A number of permutations of abutment angle and single sided abutment loading multiplication factors can be associated with the calculation of pillar load in some approaches, for example, ALTS (M. G. Colwell et al. 1999). The philosophy of NIOSH (2008) in respect of ALPS and ARMPS needs to be borne in mind, this being that since these are empirical models derived from real-world data, they do not require a full understanding of the mechanics of pillar behaviour. This is an important consideration when applying the formulations at sites other than from where the data was sourced. Risk is always associated with situations where there may be a lack of understanding of the mechanics underpinning behaviour or where loading conditions are significantly different to the cases in the underpinning databases (for example, in multiseam mining situations).

Limitations are associated with both empirical approaches. For example, the concept of an abutment angle does not reflect the mechanics of overburden behaviour as depth increases (Sect. 3.2), while none of the empirical pillar strength formulae applied in the various design procedures were derived on the basis of the behaviour of pillars that abutted caved ground or for pillars in the high width-to-height ratio range of many chain pillars.

In Sect. 5.2.2 it was noted that numerical modelling has been promoted for designing chain pillars since at least the early 1980s. Nevertheless, limitations can still be associated with these approaches, especially in regard to quantifying pillar load, the effect of caving on pillar strength, and goaf reconsolidation characteristics. Notwithstanding this, the cost of undertaking parametric and sensitivity analysis utilising sensible numerical models in order to give confidence to chain pillar design is minor to trivial in comparison to the adverse safety, productivity and financial risks associated with a poor chain pillar design in longwall mining. The various ways in which numerical modelling finds application to chain pillar and gateroad design and support are reflected, for example, in the approaches of Salamon (1991), Gale (2004), Peng (2008), and Esterhuizen et al. (2010b).

As the depth of mining increases, strength considerations result in an increase in chain pillar width-to-height ratio. This has implications for both the pillar width required to provide an adequate buffer from abutment stress and for the propensity for pressure bursts within the chain pillars. A situation is also reached where, irrespective of the width of the pillar, induced stress levels at the pillar ribsides result in deformations sufficient to threaten safety and the serviceability of the gateroad. Longwall mining on the advance is uneconomic for mitigating these impacts. Hence, the concept of yield pillars has found application in designing chain pillars in deep longwall retreat operations in attempts to ameliorate pressure bursts, severe rib spall, and pillar punching of the roof and floor strata. The concept is also used in the USA to minimise coal sterilisation and to provide optimum geometries for place changing in three heading developments, and in South Africa to provide more uniform surface subsidence profiles.

The concept of a yielding coal pillar is based on the controlled unloading of a coal pillar once its peak load carrying capacity has been exceeded. It has been applied in the USA in two, three and four heading gateroad layouts. It relies on utilising the post-failure strength of a yielded pillar to provide local ground support, while transferring (shedding) the majority of the overburden and abutment load to adjacent, stiffer, non–yielding pillars. The terminology is sometimes confused, with a yield pillar also referred to as a crush pillar. Hebblewhite and Galvin (1996) report that many so-called yield pillars are, in fact, stable load-bearing pillars of very low height in benign roof strata conditions. It is important to appreciate the distinction since the penalty for poor design is severe in the form of sudden and unpredictable pillar collapse.

A review of gateroad yield pillar design approaches and applications in USA longwall operations by NSA Engineering (2000) found that yield pillars at that time were generally 6–9 m wide and ranged in width-to-height ratio from 3 to 5. No ‘entirely successful’ yield pillar designs were achieved when width-to-height ratio exceeded 5, nor were any ‘operationally successful’ full-yielding gateroad systems achieved in ground where the CMRR was less than 50. Measurements suggested that full yielding of a pillar seldom occurred until after the first adjacent panel has been extracted well outbye of the pillar and the majority of peak side abutment stress has been attained. Badr et al. (2002) reported similar findings, noting that previous designs have enjoyed mixed success and that load shedding requires three criteria to be satisfied, namely:

-

there are load bearing areas (unmined seam or compacting goaf) nearby which can sustain the transferred load;

-

the roof and floor are sufficiently competent to facilitate the load transfer without debilitating roof falls or floor heave; and

-

the stiffness of the surrounding rock mass is sufficiently high to ensure that the equilibrium of the rocks remains stable.

Salamon et al. (2003) undertook numerical simulation of longwall chain pillars of width-to-height ratios 3, 5 and 10 at a depth of 700 m. The authors noted that their discussion of results deliberately avoided the quantification of the terms ‘narrow’, ‘intermediate’ and ‘squat’. The research indicated that for narrow pillars, pillar deformation is controlled; the yielding zones progress towards the centre of the pillar smoothly; and a pillar that is yielding throughout its width can readily be created. If the depth of mining is great, this full yielding state can be reached during the development of the gateroad entries. The desktop analysis concluded that such narrow pillars make ideal yield pillars, their only shortcoming being that their load bearing capacity is low. This limits the spans over which they should be applied.

The study concluded that it appears pillars with an intermediate width-to-height ratio cannot be brought into a fully yielding state because their failure process becomes unstable when yielding penetrates to a certain depth. This critical depth could be reached either during primary development or during secondary longwall extraction. The instability may induce a pressure burst-like event and even a total collapse of the pillar. Therefore, the utilisation of yield pillars of this size should be restricted to relatively shallow cover.

Salamon et al. (2003) also concluded that squat pillars have the potential for sudden seismic events in their outer zone but, because of the large width of the remaining inner core, the rubble around the pillar sides provides sufficient confinement to enable stability to be re-established. These pillars were not considered ideal chain pillars in deep longwall mining situations.

A feature of most successful yield pillar and crush pillar outcomes to date has been the presence of very stiff immediate roof strata. This is not surprising, as the high stiffness of this strata regulates both the magnitude and rate of load transfer to pillars adjacent to the longwall block, thus controlling the rate of yield and failure mode of these pillars.

9.2.5 Chain Pillar/Gateroad Behaviour

9.2.5.1 Stage I – Development

During gateroad development, roadway and pillar behaviour are governed by the same principles that apply to bord and pillar mining. The main difference between bord and pillar main development and gateroad development, which is unlikely to be detectable in practice, is that the load acting on the gateroad pillars may be lower because the narrower gateroad panel width results in a smaller reduction in the stiffness of the overburden. Nevertheless, this load can still be expected to result in extensive fracturing of gateroad sidewalls as depth of mining increases.

In the case of intermediate depth longwall panels, actual pillar stresses may be comparable to those encountered at the shallower depths of typical bord and pillar mining. In deeper longwall situations, pre-mining rock stress will already be higher than pillar stresses normally encountered in bord and pillar mining and, therefore, extensive fracturing of gateroad sidewalls can be expected even at narrow panel widths.

9.2.5.2 Stage II – Maingate/Face Corner

As the goaf approaches a chain pillar at the maingate face corner, the pillar is subjected to increased abutment load. The presence of the goaf also causes a change in the state of horizontal stress in the immediate roof and floor of the gateroad. Primary factors that determine the magnitude of this change include the direction of the major horizontal stress relative to the gateroad direction; the composition of the immediate roof strata; the elastic modulus and Poisson’s ratio of the immediate roof strata; and whether caving develops at the face or is delayed. Figure 9.4 shows an example of the manner in which a horizontal stress notch developed around the maingate end of a longwall face when the in situ major horizontal stress was approximately twice the primitive vertical stress high and orientated at around 30° to the maingate.

A widely-employed relationship between the horizontal stress concentration factor and the angle of the maingate to the major horizontal stress direction is plotted in Fig. 9.5a. It is based on stress measurements in stone strata some 5 m over the rib of chain pillars and 2.5 m above the mining horizon. Horizontal stress is shown to peak at almost 2.2 times primitive (virgin) stress at this horizon when the gateroad is orientated at approximately 65° to the major horizontal stress direction. The end user of the relationship shown in Fig. 9.5a needs to be cognisant that it is based on limited data, with the shape at higher stress angles being determined by just one data point (Cook Colliery ). Furthermore, it has no regard to the impact on ground behaviour of the ratio between the two principal lateral stress directions.

An update of this relationship developed by Gale (2014) is shown in Fig. 9.5b. This revision has regard to some new data, face position and numerical modelling. Both relationships shown in Fig. 9.5 indicate that maingate stress conditions will be optimised when the gateroads are orientated within approximately 25° of the direction of the major horizontal stress. Stress relief is very well developed in stiff materials but not well developed in thick coal or soft materials (Gale 2014).

Stress notching tends to develop once the extraction face approaches to within about 30 m of an intersection but can be present over the full panel length and, if the stress is sufficiently high, extend into the companion gateroad (travelling road). In some instances, the intermediate/minor horizontal stress may also be of sufficient magnitude to result in stress notching. There is usually a marked increase in the impact of a stress notch when the extraction face is within 20 m of a maingate intersection, before the stress is relieved at the intersection. This stress relief is conducive to the unravelling of the strata fractured by the notching, resulting in intersection roof falls to a considerable height if pre-emptive support measures are not in place. Typically, these measures need to include long cables installed well ahead of the stress notch together with some form of surface support system. It is preferable to install this additional support prior to advancing the conveyor belt during gateroad development so that the placement of the support is not constrained at a later date by equipment, lack of access, or lack of space.

The floor is also subjected to the stress notching, which can result in floor heave making a substantial contribution to convergence. This may necessitate the installation of standing support, the leaving of additional coal in the floor, concreting of the floor and, in some cases, the bolting of the floor.

9.2.5.3 Stage III – Travel Road/Tailgate Single Abutment

The significantly increased loading on the pillars and the presence of the adjacent goaf create the potential for a number of interactive behaviour modes to impact on pillar and roadway stability in single abutment loading situations. In the first instance, the increased pillar load results in compression of the pillar and its roof and floor strata. The strata adjacent to the goaf are free to dilate but this freedom progressively reduces with distance from the goaf edge back into solid abutment as self-confinement is restored. This generates an increase in horizontal stress in the immediate roof and floor strata due to the Poisson’s effect. Depending on mining geometry, the Poisson’s effect may be substantially recovered at the site of the travelling road (maingate companion road, which subsequently becomes the tailgate), thus subjecting the roof and floor strata of this roadway to elevated horizontal stress from this contributing factor.

If the increase in abutment stress is sufficiently large, it can initiate or aggravate yielding and crushing of the outer portions of the coal pillars. This results in an increase in the effective span of the travel road, thus reducing the resistance of both the roadway roof and floor to bending and buckling forces.

Crushing and yielding of the outer portions of a pillar give rise to a second source of induced horizontal stress in the roof and floor strata of the travel road/tailgate. The confined core concept for explaining pillar strength (Chap. 4) is premised on the outer crushed and yielding zones of a coal pillar providing confinement to the elastic core of the pillar (Fig. 4.22). In accordance with Newton’s law of action and reaction, these restraining forces have to be balanced by compressive forces induced in the roof and floor strata. These compressive forces may induce the buckling and failure of the roof strata and/or the buckling and heaving of the floor beds (Salamon 1991) (Fig. 9.6).

A schematic of pillar edge crushing showing the influence of the associated dilation and yielding on the lateral loading of the immediate roof and floor strata (Modified from Salamon 1991)

In addition to the coal pillar element of the pillar system, consideration has to be given to the mechanical properties of the immediate roof and floor strata of the pillar system. Possible behaviour modes under the effect of high abutment stress include bearing capacity failure of the roof or floor strata and extrusion of soft roof or floor layers.

It has been suggested by some researchers that the immediate roof of a longwall travelling road/tailgate can be put into tension following the formation of the first adjacent longwall goaf. They attribute this to horizontal stress relief resulting from one or a combination of the presence of the goaf and differential pillar compression either side of the gateroad. The concept of horizontal stress relief due to the formation of a goaf is discussed in Sect. 5.2.5 and illustrated in Figs. 5.12, 5.13, and 5.14. The deviation of the in situ stress field around the zone of softening overlying a goaf may result in a reduction in lateral stress in the roof and floor of a travel/tailgate roadway but, in most cases, the residual component of lateral stress is still likely to be significant.

The concept that differential pillar compression associated with yielding coal pillars could contribute to the immediate roof of a tailgate being placed in tension (for example, as proposed by R. W. Seedsman 2012) appears to have its origins in stability concepts put forward by Diederichs and Kaiser (1999b) in relation to mining beneath blocky hanging walls in hard rock mines. The end-user is advised to carefully review the source publication to determine the relevance of the concept to their conditions.

In some situations, roof displacement and floor heave can be associated with the failure and dilation of stiff, thin layers within the immediate roof or floor strata. These strata attract stress because of their stiffness before shearing and bulking so as to drive the roof down or the floor up, often in a rapid manner. This behaviour mode can be difficult to distinguish from pure buckling failure and from general bearing capacity failure. Two or more modes may be interactively in play at the same time.

Figure 9.7 shows an example of floor heave that developed dynamically in a tailgate companion roadway. The coal roof and pillar ribs were bolted and strapped. As the pillars dilated under high abutment load, the supported rib line remained intact but started to ride over the W straps and rock bolts installed in the roof. Ultimately and without warning, the coal floor uplifted. Vasundhara et al. (2003) provide more detailed discussion on weak floor failure mechanisms associated with longwall mining operations.

A range of operational benefits is associated with not installing standing support in a longwall travelling road/tailgate. These relate to ventilation efficiency, inspections, material and equipment access, and labour requirements. Hence, there has been a focus on replacing standing support systems with long tendons. This has met with success at some mines. However, standing support continues to be required in those mining environments where floor uplift constitutes a significant component of seam convergence and where the effectiveness of tendon support systems is adversely affected by shear displacement on bedding planes. The timing of the installation of standing support is a matter for site management, as dictated by local conditions and mining priorities. However, when standing support is required, it is strongly advisable to always have it in position for 100 m outbye of the longwall face and, preferably, for at least 200 m.

9.2.5.4 Stage IV – Tailgate/face

Ground behaviour in the vicinity of the tailgate end is complicated further by two factors. Firstly, the chain pillars are subjected to additional increases in abutment stress. Secondly, the immediate and upper roof strata have another degree of freedom, with the opportunity to displace both transversely into the existing adjacent goaf and longitudinally into the approaching new goaf. Weak bedding planes in the roof facilitate large scale slip of the roof strata towards the goaf, as measured for example by Fabjancyk et al. (2006). Assessment of strata deformation modes and impacts in these environments falls outside the scope of empirical and semi-empirical approaches to pillar stability assessment.

One type of behaviour specific to this environment is the so-called skew roof mechanism, which Tarrant (2005a) and Fabjancyk et al. (2006) associate with a change in the profile of a tailgate from rectangular to rhomboidal as shown in Fig. 9.8. The behaviour, which can vary in magnitude and direction between mine sites, has been attributed to the reorientation of the stress field around the goaf generating shear couples on bedding planes and other structures in the roof and floor. These shear couples result in differential shear within the strata, leading to high levels of strata failure in the roadway. According to Fabjancyk et al. (2006), once a skew roof mechanism is initiated, it is likely to extend a substantial distance into the goaf. The magnitude and direction of pre-mining horizontal stress is believed to have a major impact on the direction of the skew and the extent that the skew process impacts on the roadway. Tarrant (2005a) lists the key factors driving skew roof behaviour as:

Concepts developed by Tarrant (2005a) relating to the skew roof mechanism in longwall tailgates. (a) Simplified model of stress/displacement changes adjacent to goaf. (b) Relative movement as monitored at Metropolitan Colliery, Australia

-

the absolute and relative magnitudes of the vertical and horizontal stresses;

-

the shear modulus of the strata pile (shear deformability); and

-

the extent of overburden bridging.

Tarrant credits shear stress damage due to skew roof behaviour with being capable of destroying intrinsic support, including cable bolts. Hence, standing support rather than cables is considered the most appropriate stabilisation strategy, with Tarrant (2005b) providing a range of recommendations in that regard.

Fabjancyk et al. (2006) provide further discussion of the skew roof mechanism, concluding that the range of strata deformation mechanisms that can occur around goaves warrants that the positioning of roadways in the vicinity of goaves is based on a higher level of assessment than that used for traditional pillar stability approaches. Moodie and Anderson (2011) report on similar behaviour associated with longwall top coal caving at Austar Coal Mine, Australia , where change in vertical stress was measured to be higher on the travel road side of a chain pillar rather than on the goaf side.

In summary, pillar and roadway behaviour about a tailgate can be complex. It can involve a range of stress paths and mechanisms. All may have application in some situations but none are exclusive. Different mechanisms and combinations of mechanisms operate in different environments and at different points in time in the mining process. As already noted in Sect. 5.2.5, each situation should be individually assessed, with consideration given to utilising numerical modelling to predict principal stress magnitudes and profiles and to give insight into strata behaviour modes.

9.2.5.5 Stage V – Double Abutment Loading

Full double abutment loading situations are not usually of interest other than if the chain pillars have a role to play in restricting surface subsidence or if multiseam mining is contemplated. In the case of surface subsidence, the structural integrity of the coal pillar and the compression of the chain pillars and surrounding strata take on added significance. It should be noted that surface subsidence above a chain pillar is not necessarily an indicator of the state of stability of the pillar. This is because elastic strata compression, especially at depth, can make a major contribution to surface subsidence.

Particular care is required when using surface subsidence behaviour above chain pillars to draw conclusions about their state of stability. Some vertical surface displacement will occur over any chain pillar simply due to elastic compression of the coal pillar and surrounding strata in response to mining-induced stress. This compression can be quite considerable at depth. Lateral displacement of the overburden towards the goaf is another factor that contributes to the development of vertical displacement above chain pillars.

9.3 Longwall Powered Supports

9.3.1 Development

Longwall mining of coal originated in the 1800s as a so-called ‘hand-got’ mining method (pick and shovel) using timber props with headboards as face support. Hand-got mining was progressively replaced with shotfiring, ploughs and shearers. Support progressed to rows of friction props with connecting bars that were leapfrogged forward with face advance. Hydraulic props were introduced in the 1940s, followed by the Eastern European concept of a shield support comprised of a rigid, half-arch, frame to protect the face from goaf flushing. These early support systems provided the basis for the first longwall powered supports, so-called because they were connected to a hydraulic power supply and capable of self advancing.

In Russia, the rigid shield was developed into a hydraulic shield support by pinning a canopy to the flushing shield and connecting the flushing shield to a base by a simple hinge and one or two hydraulic legs (Figs. 9.9a and 9.10). These supports were often referred to as caliper or arc shields since the canopy tip followed a circular pathway as the support was raised or lowered. The concept was developed further in Germany in the 1960s, with these shield supports being characterised by rear-facing angled legs; a relatively high tip load capacity; a low rear load carrying capacity; good protection against goaf flushing; and a high longitudinal stiffness to resist horizontal displacement towards the goaf. Because the legs of a shield support are angled, the vertical support provided to the roof is less than the rated capacities of the legs and reduces as the legs become more inclined when the support yields.

2 leg caliper shield powered supports, shearer and AFC for the longwall face reported by Cloete (1980) to have set a world record of a monthly production of 162,557 tonnes at Sigma Colliery, South Africa , in June 1980

The first hydraulic supports in Britain were installed in 1951. These comprised hydraulic legs mounted on a base, with connecting bars replaced with a solid canopy to produce a so-called hydraulic chock support (Fig. 9.9b). The British National Coal Board (NCB) stipulated a maximum distance between the coal face and the front support leg of 2 m, which effectively precluded the use of 2 leg shield supports. The NCB also dictated that the full face height had to be cut in one pass (bi-directional shearing) and that the face was operated in so-called conventional mode, whereby the supports were set up against the armoured face conveyor (AFC) prior to the passage of the shearer and advanced immediately after its passage.

The British powered supports were characterised by four or more vertical hydraulic legs, a high rear load carrying capacity, a low tip load carrying capacity, poor protection from flushing of the goaf, and poor longitudinal stability, the latter making them prone to collapse in a scissor-like manner as the immediate roof strata moved towards the goaf. In order to address the low tip load capacity and to satisfy NCB specifications, additional hydraulic legs were fitted to the front of some supports (Figs. 9.9c and 9.11).

A major design development in longwall hydraulic supports occurred when the German coal industry replaced the simple hinge on the shield support with a lemniscate linkage . The lemniscate linkage caused the canopy tip to travel in a near vertical plane as the support was raised and lowered and imparted high longitudinal stability to the support (Fig. 9.9d). This addressed the concern that the arc motion of a caliper shield resulted in an unfavourable reduction in confinement to the immediate roof when the support was set and a favourable increase in confinement as the support yielded and converged. Subsequently, the concept was incorporated into chock supports to prevent them from collapsing into the goaf, thereby giving rise to the chock shield (Fig. 9.9e).

In the meantime, shield supports were fitted with a rigid canopy instead of a pinned canopy and forward angled legs became the norm, with both features increasing tip load capacity (Figs. 9.9g and 9.12). In the 1970s, in response primarily to a marketing ploy by some chock shield manufacturers that supports with four legs ‘obviously’ had to offer support benefits over shields with only two legs, an additional pair of legs began to be incorporated into shield supports (Fig. 9.9h). These supports were short-lived, with engineering analysis by McKay (1978) and others of the heavier, more complex and more costly 4 leg supports, concluding that the additional legs offered little, if any, additional support benefits and, in some instances, reduced performance.

Up until the late 1970s, many chock shields employed a hinged canopy, also referred to as a split or cantilevered canopy. The location of the hinge point ranged from between the front and back legs to well in front of the front legs, although the hinge point immediately in front of the front legs was most common (Figs. 9.9e and 9.13). This allowed the canopy to adapt better to the shape of the roof, which often contained vertical steps because the shearer cutting horizon was controlled manually. The tip load capacity of these supports was independent of the leg capacity, being determined by the cantilever cylinder capacity and its lever arm distance. The supports generated low tip loads, typically one-tenth of the nominal support capacity and, with the onset of yielding, the cantilever extensions were prone to a domino collapse along the face. A failure of this type involving supports with a tip capacity of only 100 kN (10 t) occurred on the first longwall face at Coalbrook Colliery , South Africa, in 1979 (Henderson 1980; personal experience). These types of incidents contributed to cantilevered canopies being phased out in favour of rigid canopies (Fig. 9.14).

Major advances in extrusion technologies in the 1990s enabled hydraulic leg capacity to be more than doubled, from typically 2–5 MN (~200 to 500 t). Leg capacity has continued to increase, approaching 0.9 MN (900 t) by 2010, with corresponding increases in tip load capacity and in leg stiffness due to the larger bore area. The configuration and high tip load capacity of shield supports has enabled the length of the rigid canopy section to be extended while maintaining a very high tip load capacity, so that longwall faces are now operated routinely with the powered supports set back from the AFC a distance of one cutting web. The additional space gained in this so-called one-web back mode provides a number of operational benefits, such as improved ventilation, larger face conveyors, and a second travel (walk) way along the face. In the event that face conditions deteriorate and/or the face spalls excessively, the option still exists to ‘close up the face’ by advancing the supports a distance of up to one web, although care is then required when taking the next shear to avoid cutting into the support canopies. Closing up the face in this manner is referred to as double chocking.

The substantial improvements that have been achieved in tip support capacity and minimisation of the area unsupported between support tips and the face can be negated if the coal face spalls, especially in thicker seams. To address this problem, it is now very common for powered supports utilised in thicker coal seams to be fitted with an hydraulically activated extension, or flipper, that can be deployed as either or both an extension to the canopy to confine the immediate roof and a face sprag to confine the coal face (Figs. 9.9i and 9.15).

In order to accommodate larger diameter legs and longer canopies and flippers and to improve the lateral and torsional stability of shield supports in thick seam mining operations, the width of powered supports has progressively increased from the traditional 1.5 m to upwards of 2.0 m. Hence, shield supports now offer advantages over chock shield supports in terms of higher tip load capacity; increased vertical stiffness; reduced number of components; less structural complexity; and reduced size and reduced weight, while at least matching the rear support capacity of chock shields. Shield supports are standard on all new longwall faces in Australia and the USA. However, 4 leg chock shields continue to be utilised in longwall top coal caving operations in thick seams.

9.3.2 Basic Functions

Effectively, powered supports are located in the goaf and, therefore, are surrounded by strata that have already been impacted by mining-induced fracturing. The basic ground control functions of a powered support are to maintain this fractured strata in a confined and interlocked state; control convergence in the face area to limit further localised fracturing and bedding plane movement; and provide a goaf break off line. These functions are not mutually exclusive.

Excessive convergence generates additional fracturing and leads to increased rib spall and guttering at the face, and bed separation and block detachment above the supports, all of which are conducive to roof falls on the longwall face. Face spall increases the unsupported distance between the tip of the longwall supports and the face. Guttering results in roof cavities and, together with bed separation and block detachment, increases the load acting on the supports. In turn, this increases the likelihood and magnitude of support yield, resulting in more convergence. The process can become self perpetuating as yielding of the powered supports results in increased face load, bed separation, and fracturing. Failure to induce caving of the immediate roof at the rear of the powered supports aggravates these conditions.

In addition to providing support to the roof, a powered support assists in sustaining horizontal stress in the immediate roof strata to confine the fractured rock and maintain it in an interlocked state so that it does not unravel on the face line. This is accomplished by sandwiching the immediate roof between the support canopy and the upper strata, thereby maintaining bedding planes in a clamped state to resist horizontal displacement and dilation as the strata subsides onto the goaf pile. This function requires the support to have the capacity to transfer horizontal thrust to the floor, which is achieved through the lemniscate linkages.

9.3.3 Static and Kinematic Characteristics

The performance of a powered support is dependent on its static and kinematic characteristics. Two conditions must be satisfied for a powered support to be in a state of equilibrium, namely, the algebraic sum of all forces acting on it must be zero, and the algebraic sum of all moments about any point must be zero. Other parameters of particular importance to shield performance are:

-

total roof support resistance of the support;

-

support resistance of each load bearing member;

-

stiffness of the support;

-

canopy ratio (or canopy balance, being as discussed later, the ratio of canopy face tip to leg distance to canopy rear end to leg distance);

-

capacity to vary canopy attitude;

-

immediate roof and floor bearing pressure and capacity; and

-

the kinematic properties of the support for adapting to various roof geometries.

The computation of load acting on a longwall powered support is complex and statically indeterminate. It is a function of the stiffness of the powered support and the stiffness of the surrounding strata, both of which can vary during the mining process and be time dependent. There are numerous permutations in the factors that determine the system stiffness. These include:

-

depth of mining;

-

mining height;

-

composition, thickness and caveability of the immediate roof strata;

-

composition, thickness and caveability of the upper roof strata;

-

relative location and thickness of particularly weak, strong or extrusive strata;

-

strength of the floor strata;

-

joint direction, dip and density;

-

density of mining-induced fracturing;

-

configuration of the powered support;

-

stiffness of the powered support; and,

-

setting and yield pressure of the powered support.

Hence, no geotechnical model finds universal application and each site has to be assessed in its own right using tools such as surface to seam displacement instrumentation; microseismic monitoring; powered support pressure and convergence monitoring; surface subsidence monitoring; numerical modelling; and observation and deduction. The four models depicted in Fig. 9.16 provide a basis for conceptualising powered support statics across the range of conditions most commonly encountered.

There is no unique definition of total roof support resistance, also referred to as total support density, but it is most commonly defined as the ratio of the total normal thrust applied by the support to the roof, to the area of roof supported by each powered support unit. This area is measured from the coal face to the edge of the last supporting element on the goaf side of the face. The total thrust is based on the sum of the nominal yield loads of all the hydraulic support elements in the system. The support resistance is a minimum immediately after the passage of the shearer and a maximum once the support has been advanced.

Early developments in determining total support resistance were based around British views that support resistance need only be sufficient to prevent excessive convergence and European views that it had to be as high as possible to prevent bed-separation over the face area. Many of the European views related support resistance to mining height, reasoning that the greater the mining height, the greater the caving height and, therefore the thicker the strata bed resting on the longwall face supports. At the time, minimum support resistances on installed faces ranged from 100 kN/m2 to 1.2 MN/m2 (10–120 t/m2), the latter associated with strong massive roof strata situations. With the benefit of hindsight, it appears that the difference between the two philosophies was simply a reflection that typical British strata behaved in a more plastic manner and, therefore, was more tolerant of convergence than the more massive and brittle strata associated with European conditions.

Since the early 1990s, it has become common practice in weak to moderately strong roof strata in Australia and the USA to operate powered supports at a set pressure of 0.6–0.8 MN/m2 (60–80 t/m2) and a yield pressure of 1–1.1 MN/m2 (100–110 t/m2). Some operations use a higher set pressure of 90 % of yield pressure. These appear to be limiting values when the contact strength of the roof strata is taken into account and to be supported by numerical modelling outcomes. Gale (2009), for example, has concluded on the basis of numerical modelling that support resistances over 1.2 MN/m2 (120 t/m2) would be considered excessive and not required in weak environments. In stronger and more massive roof strata, higher values for support resistance, setting and yield pressure prevail. As at 2010, the highest capacity shield supports in the world had a total support resistance of 1.6 MN/m2 (160 t/m2) (Winter et al. 2010). These were employed at Moranbah North Mine, Australia, beneath a weak immediate roof overlain by a strong massive roof prone to periodic weighting.

It is important to appreciate that the total support resistance is not uniformly distributed over the roof and the values quoted earlier and those provided in manufacturer’s specification sheets are averaged over the full roof area. In the ideal case of the powered support being sandwiched between two rigid plates, the maximum support resistance is generated at the end points of the hydraulic legs, as illustrated in Fig. 9.17. Load transfer to the roof reduces with distance along the canopy from the legs. A similar load transfer profile exists in the floor. This situation approximates to that associated with the bulking model depicted in Fig. 9.16a.

The bulking model can be conceptualised as a displacement controlled system, with irresistible strata convergence of the upper roof strata loading the coal face, the powered supports and the goaf. The powered supports represent very soft springs located between stiff springs, being the adjacent goaf, and very stiff springs, being the coal face. The stiffness of the legs of the powered supports and their setting load determine the overall stiffness of the powered support and, therefore, the amount of convergence that can occur prior to the supports reaching yield. In this setting, powered supports only have the capacity to influence strata behaviour in their immediate vicinity. The concept of ‘bigger is better’, in terms of support resistance, does not necessarily deliver improved face control. Rather, the more critical controlling factors may be the point of application of support resistance; load distribution within the canopy and the base; support stiffness; the integrity of the immediate roof to function as a fractured but interlocked beam or cantilever; and roof and floor contact strengths.

The behaviour of the bulking model is changed significantly if a face break occurs, resulting in a detached block above the powered support (Fig. 9.16b). The detached block causes the system to revert from being displacement controlled to being load controlled. Ashwin et al. (1970), Whittaker (1974) and Wilson (1975) proposed similar simple analytical models for determining the distribution of forces and moments for this situation. While there are a number of limitations associated with these models (see for example, Smart et al. 1982; Aziz and Porter 1985) which have resulted in modifications by Smart and Redfern (1986), Barczak and Tadolini (2007), and others, they still give valuable insight into the basic behaviour of powered supports and provide a reasonably accurate analysis of one extreme condition.

The detached block models assume that the legs of the powered support are rigid and that the support is uniformly loaded by the dead weight of the detached block of strata of mass, W. The block can be of any size and shape, although some models define its geometry on the basis of caving height, caving angle and overhang distance into the goaf. Geometry determines where the centre of gravity, or centroid, of the detached block acts on the powered support. This may be on the face side of the legs, the goaf side of the legs, directly over the legs of a shield support, or between the front and back legs of a chock shield. In order to prevent rotation, a fictitious balancing or stabilising force, S, has to be introduced to mimic the resistance to rotation provided by the roof strata (Fig. 9.18).

For the case where the centre of gravity acts between the face and the front legs of a rigid canopy chock shield (Fig. 9.18a), the maximum weight, W, of loosened strata that can be supported is found by taking moments about the rear of the support and is given by Eq. 9.2.

where

-

F = normal component of combined capacity of front legs

-

B = normal component of combined capacity of rear legs

-

s, w, f and r = lever arm distances

Assuming that the yield ratings of the front and back legs of the chock shield are equal, it follows from Equation 9.2 that because (s-w) is greater than (s-f), the actual support resistance is less than one half of the nominal support resistance. A similar static analysis can be performed for 2 leg shields and for 4 leg chock shields when the centre of gravity of the load acts between the two sets of legs or behind the rear set of legs. The periodic weighting model (Fig. 9.16c) represents an extreme case of the detached model in which the centre of gravity of the load acting on the support is some distance back into the goaf.

The model demonstrates that the total thrust of a support system is only ever equal to the sum of the nominal thrust of the system components when the centre of gravity of the load acts directly over the legs on a 2 leg shield support or at the mid-point between the front and back legs on a four leg chock shield. Longwall support manufacturers utilise the detached block model to compute and specify the tip and rear load capacities of powered supports, examples of which are presented in Table 9.1. This table shows that when the centre of gravity of the supported load acts at the tip, the actual load carrying capacity of the powered support is of the order of only 25 % of the its nominal support capacity.

The detached model highlights the importance of considering not only total support resistance when selecting powered supports but also the location and distribution of turning moments that may be generated within the support. However, the model has limitations, as becomes evident when it is applied to high capacity shield supports. The model cannot cause the supports to yield under any realistic detached block configuration other than one which cantilevers at least 10–15 m into the goaf, such as encountered in some periodic weighting situations. The model is unable to account in its own right for other situations in which shield supports yield. This partially reflects the fact that powered supports do not have the capacity to resist all mining-induced convergence, with the level of convergence required to cause yield decreasing with increase in powered support stiffness associated with higher set pressures and stiffer hydraulic legs.

The unconfined model represents the situation where the caving line progresses over the top of a powered support (Fig. 9.16d). This is more likely to occur at larger mining heights in weak strata environments. It results in a relaxation in lateral confining stress at the face, allowing the fractured strata between the tip of the support and the face to unravel. Factors which aggravate the situation include the presence in the immediate roof of low friction bands and bands prone to extrude under load; an irregular roof cutting profile; the presence of a cavity associated with a previous face fall; sloppy lemniscate linkages; and inadequate support resistance.

The progression of the caving line towards the face increases the turning moments at the tip of the support because it simultaneously removes counter balance from the rear of the canopy and moves the centre of gravity of the load towards the tip. Once the cave line reaches the front legs, the canopy is free to rotate about these legs, allowing the tip to drop into the working place and reducing tip capacity to zero. Face falls are inevitable without intervention to fill voids and reconsolidate the fractured strata.

The load distribution profile, maximum tip capacity, and maximum rear capacity of a shield support are very sensitive to the canopy ratio, or canopy balance, defined by Eq. 9.3 as:

A misconception sometimes associated with a shield support is that angling of the legs towards the face introduces a horizontal component of stress to confine the immediate roof, with this confinement increasing as the support yields. This is not the case as the lemniscate linkage causes the support canopy to travel in a straight vertical trajectory (Fig. 9.9).

In addition to maintaining forces and moments in equilibrium, the capacity of a support to control convergence depends on the stiffness of its hydraulic system and on its setting and yield loads. Hydraulic system stiffness is determined primarily by the height and area of the fluid column in the legs, with a component also associated with expansion of the leg tubes and hoses. In accordance with Eq. 2.3, everything else remaining unchanged, the higher the fluid column in the legs, the less pressure (or support resistance) developed per unit of convergence. The setting load corresponds to a prestress applied to resist convergence, while the yield load determines the peak resistance to convergence. Although longwall mining height has increased substantially and now approaches 6 m, the corresponding reduction in leg stiffness has been offset to some degree by the larger bore diameter of the hydraulic legs associated with modern thick seam supports. In the case of double telescopic legs, the load generated by the support is determined by the cross-sectional area of the smallest cylinder in the telescopic leg.

Care has to be exercised in relying on some stiffness values and concepts for longwall supports presented in the literature as there is a mix of definitions of stiffness, some computations are flawed, and some concepts are confused. Typically, a load increment of 1 MN (100 t) with its centre of gravity acting in the thrust line of the legs of a modern 2 leg shield support extended to 3 m will result in 5–7 mm of convergence up to the yield point of the support, corresponding to a support stiffness of 0.14–0.2 MN/mm.

However, a lower load is required to produce the same convergence if the centre of gravity of the load acts in front of or behind the thrust line of the legs, or if the support operates at a greater height. If the effective area supported by a 2 leg shield is approximated to be 10 m2, then a 1 MN (100 t) load increment acting over the same shape and size area on a 3 m high coal face would result in around only 0.6 mm of convergence. Hence, the effective stiffness of a powered support is an order of magnitude less than that of the coal that it replaces, meaning that even in the most favourable circumstances, a powered support only makes a small contribution to controlling the overall stress and convergence distribution about a longwall face.

If debris accumulates over or under a powered support, it acts as a soft inclusion and can negate the benefit of high leg stiffness to control convergence. Good housekeeping to minimise the accumulation of this material, high setting pressures, and maintenance of setting pressures to compact the material are important in minimising convergence. Skimming the roof with the canopy of a powered support as it is advanced also assists in minimising debris on top of the canopy.

In specifying the support resistance for a longwall powered support, careful consideration needs to be given to the contact strength and bearing capacity of the immediate roof and floor strata and to the loading profile of the support canopy and base. Contact pressures are higher at the floor than at the roof due to the smaller load bearing area of the support base and the effect of turning moments (Fig. 9.17). The combination of leg configuration and high tip load capacity of a shield support can generate high turning moments and, therefore, concentrate loadings at the toe of these types of supports. Hence, the bearing capacity of the floor is an important consideration when designing a powered support for a specific site or assessing if a powered support is suitable to a different site. It has a significant influence on powered support design in respect of:

-

the overall geometry of the powered support and AFC so that base loading profiles do not exceed the bearing capacity of the floor;

-

the type of base fitted to the support (solid or split); and

-

the fabrication of the base to tolerate bending and torsion over its planned operating life.

A range of approaches can be adopted to assessing the bearing capacity of the floor, with the most common being the application of bearing capacity formulae of the type presented in Appendix 4 and numerical modelling. Solid bases to maximise load carrying area and base lifting rams to raise the front (toes) of the powered supports when advancing them are two controls utilised in weak floor strata to mitigate against bearing capacity failure. If the bearing capacity of the floor is exceeded, powered supports start to rotate towards the face, resulting in the unloading of the canopy at its tip. In these situations, shield supports are prone to topple towards the face, especially once mining height exceeds about 3 m. On the other hand, uneven, hard floor conditions can subject the base of a support to excessive bending and torsion, leading to the failure of welds. Split base support systems offer some advantages in these conditions because torsional forces on the base are greatly reduced.

The computation of load and turning moments acting on a longwall support is complicated because in addition to being statically indeterminate, it is also time dependent. Medhurst (2005) proposed that the ground response curve concept provided a convenient means to graphically show ground behaviour, its relationship to powered support performance, and roof stability. The basis of this approach is shown in Fig. 9.19. It is premised on roof behaviour being convergence controlled, with a unique ground response curve applying to each combination of mining conditions (geology, depth, geometry etc.).

In practice, considerable uncertainty is associated with the calculation of a ground response curve for a longwall face environment because of the numerous complex permutations of strata behaviour about a longwall face, their time dependency, and a lack of data over the full range of a ground response curve. Medhurst (2005) proposed that a strata-support interaction relationship of the type defined by the curve AD in Fig. 9.19 could be derived by considering:

-

routine geotechnical data;

-

leg convergence/stiffness test results;

-

monitoring data relating to leg pressures, surface subsidence, surface to seam extensometers and microseismics; and

-

underground observations.

A limitation with this approach, as recognised by Barczak (2006) and others, is that the mine loading conditions are not sufficiently comprehensive and controlled to develop a full curve. Numerical modelling can assist but it is still constrained by the variable and complex behaviour modes and failure states of strata that fall within the zone of influence of a powered support. Gale (2009) utilised the ground response curve concept in a general form to define three stages in the ground response to longwall mining, shown imprinted on Fig. 9.19. These stages are:

-

Stage (i) – An elastic “intact” mass whereby the amount of support to resist ground movement is well outside the capability of any face support.

-

Stage (ii) – A fractured interlocked mass that has some remaining confined strength but is typically still outside the capacity of face supports.

-

Stage (iii) – Fractured ground which starts to lose its interlocking nature, resulting in a reduction in confinement leading to unravelling and falls of ground.

The role of powered supports in this scenario is envisaged as maintaining the remaining ground strength in Stage (ii) and stopping the transition to Stage (iii). Typically, setting load is intended to provide adequate control against progression to Stage (iii).

As the fractured rock mass unravels, the situation progressively changes to a load controlled system. The stiffness of the powered supports then becomes variable, depending on where the centre of gravity of the load acts on the support. At that point, the application of a strata-support interaction curve of the type shown in Fig. 9.19 becomes problematic.

Irrespective of its static characteristics and capabilities, a longwall powered support system has limited practical value if the geometric proportions of the system and its kinematic characteristics limit contact of the canopy with the roof. It is important that the support is in good contact with the roof and that the span between the coal face and the area of application of the main thrust of the support system is small. The introduction of shearer technology that senses and remembers mining profiles along the face has aided in reducing the frequency of large vertical steps in the floor and roof caused by loss of horizon control. However, poor roof contact conditions can still occur in the presence of geological disturbances, excessive loose material on the canopy of a powered support, and roof cavities.

Rigid canopies limit the options for maximising canopy contact area when the roof profile is irregular and for applying support where it may be most needed. The two leg configuration of a shield support in association with the compensating, or canopy tilt, cylinder connecting the canopy to the flushing shield provides some potential to optimise canopy orientation and, therefore, contact area. However, this canopy orientation may not be maintained under load. It must be remembered that the effective tip distance is that distance from the face back to where the immediate roof strata comes into contact with the canopy of the powered support. Some support designs promote tip contact by curving the canopy tip upwards.

9.4 Operational Variables

In addition to equipment selection and mine design, there are a range of operational variables that are important for managing ground control about a longwall face. The timely and effective use of these is vulnerable to the vagaries of human performance. Therefore, they need to be underpinned by a robust Trigger Action Response Plan (TARP) .

9.4.1 Cutting Technique and Support Configuration

There are three basic techniques for cutting coal from a longwall face, namely, bidirectional (bi-di), unidirectional (uni-di) and half web, and a range of permutations within each.

In bi-di mode, the face is cut from both directions to its full height and width (one web) with each pass of the shearer. This enables the AFC to be advanced immediately behind the shearer. The AFC has a limited degree of articulation and so is advanced incrementally over a distance of 15–20 powered supports, with this transition section being referred as the snake. It also enables the face to be double chocked (closed up) in poor ground conditions immediately after each pass of the shearer. The potential disadvantages of this cutting technique are loss of floor horizon control because it is not easy to see and monitor this horizon when cutting; poor floor cleanup leading to debris ingress under the powered supports; and extended time for the shearer to double shuffle at each end of the longwall face in order to cut out the bottom section of the face right up to the gate end.