Abstract

In this paper, an adaptive finite-time tracking control scheme is proposed for uncertain robotic manipulators. The controller is developed based on combination of terminal sliding mode control technique and radian basis function neural networks (RBFNNs). The RBFNNs are used to directly approximate individual element of the inertial matrix, the Coriolis matrix and gravity torques vector. The adaptation laws are derived to adjust on-line the parameters of RBFNNs. Finally, the simulation results of a two-link robot manipulator are presented to illustrate the effectiveness of the proposed control method.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Nonsingular terminal sliding mode control

- Radial basis function neural network

- Adaptive control

- Finite-time convergence

- Robot manipulator

1 Introduction

In recent decades, robot manipulators were applied widely in various fields, in which many tasks require high-speed and high-precision trajectory tracking. However, robotic manipulators are generally nonlinear and involve many uncertainties and external disturbances in their dynamics, such as payload variations, friction, external disturbances, and sensor noise etc. Therefore, designs of a controller that can attenuate the effects of robotic uncertainties have become the subject of many researches. In order to deal with this problem, many control approaches have been proposed such as proportional-integral-derivative (PID) control [1], robust control [2, 3], adaptive control [4, 5], sliding mode control [6–11], and neural network control [12–16].

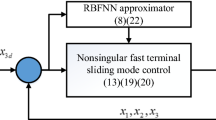

In this paper, an adaptive terminal sliding mode control based on local approximation method is proposed for trajectory tracking of uncertain robotic manipulators. At first, the controller is developed based on terminal sliding mode technique. Then, in order to improve the system performance and attenuate the effects of uncertainties, the RBFNNs are used to directly approximate individual element of the inertial matrix, the Coriolis matrix and gravity torques vector. Finally, a simulation study is performed on a two-link robot manipulator to prove the effectiveness of the proposed control method.

The rest of this paper is arranged as follows. The system dynamics and problem formulation are described in Sect. 2. The structure of terminal sliding mode neural networks controller is presented in Sect. 3. In Sect. 4, simulation results for a two-link robot manipulator are provided to demonstrate the performance of the proposed controller. Finally, some important remarks are concluded in Sect. 5.

2 System Dynamics and Preliminaries

The dynamics of a serial n-links robot manipulator can be written as [17]

where \( q(t),\dot{q}(t),\mathop q\limits^{..} (t) \in {\mathbf{R}}^{n} \) are the vector of joint accelerations, velocities and positions, respectively. \( M(q) \in {\mathbf{R}}^{n \times n} \) is the inertial matrix, \( C(q,\dot{q}) \in {\mathbf{R}}^{n \times n} \) expresses the centripetal and Coriolis matrix, \( G(q) \in {\mathbf{R}}^{n} \) represents the gravity torques vector, \( \tau \in {\mathbf{R}}^{n} \) is the control torque, and \( \tau_{d} \in {\mathbf{R}}^{n} \) is the bounded external disturbance vector.

For convenience, the above dynamic equation has the following useful structural properties;

Property 1:

\( M(q) \) is a symmetric positive definite matrix.

where \( m_{1} ,m_{2} \) are known positive scalar constants, \( x \in R^{n} \) is a vector, \( \left\| {} \right\| \) denotes the Euclidean vector norm.

Property 2:

\( M(q) - 2C(q,\dot{q}) \) is a skew symmetric matrix.

for any vector \( x \in {\mathbf{R}}^{n} \).

The control objective of this paper is to design a stable control law to ensure that the tracking error between joint position vector \( q \) and desired joint position vector \( q_{d} \) converge to zero in finite time.

3 Controller Design

In order to apply the terminal sliding mode control, it is necessary to define the terminal sliding surface \( s(t) \) for n-link robot manipulator as

where \( \beta = diag(\beta_{1} ,\beta_{2} , \ldots ,\beta_{n} ) \), \( \beta_{1} ,\beta_{2} , \ldots \beta_{n} \) are positive constants, \( 0 < \varphi < 1 \), \( sig(\dot{e})^{\varphi } = \left( {\left| {\dot{e}_{1} } \right|^{\varphi } sign(\dot{e}_{1} ),\left| {\dot{e}_{2} } \right|^{\varphi } sign(\dot{e}_{2} ), \ldots ,\left| {\dot{e}_{n} } \right|^{\varphi } sign(\dot{e}_{n} )} \right) \), \( s = \left[ {s_{1} ,s_{2} , \ldots, s_{n} } \right] \), \( e(t) = q(t) - q_{d} (t) \), \( \dot{e}(t) = \dot{q}(t) - \dot{q}_{d} (t) \).

According to the sliding mode design procedure, the control input \( u \) consists of the components

where \( K_{SW} = diag(k_{SW1} ,k_{SW2} , \ldots ,k_{SWn} ) \), \( k_{SW1} ,k_{SW2} , \ldots, k_{SWn} \) are positive constants. The equivalent control can be interpreted as the continuous control law that is obtained by equation \( \dot{s} = 0 \) for nominal system in the absence of the uncertainties and external disturbances.

From (1), the \( \mathop e\limits^{..} \) is given by

Multiplying both sides of Eq. (6) by \( M(q) \) and substituting (7) into it yields

Define \( \dot{q}_{s} = s + \dot{q} \), then \( \mathop {q_{s} }\limits^{..} = \dot{s} + \mathop q\limits^{..} \), \( \dot{q}_{s} = \dot{q}_{d} + \beta sig(e)^{\varphi } \), \( \mathop {q_{s} }\limits^{..} = \mathop {q_{d} }\limits^{..} +\,\varphi \beta \left| e \right|^{\varphi - 1} \dot{e} \). From (8), we have

If the nonlinear robot dynamic functions \( M(q) \), \( C(q,\dot{q}) \), \( G(q) \) are clearly known, then the equivalent control can be defined as

where \( K = diag(k_{1} ,k_{2} , \ldots ,k_{n} ) \), \( k_{1} ,k_{2} , \ldots, k_{n} \) are positive constants.

The stability of the close loop system (10) can be easily proved by Lyapunov theory if the gains of the switching controller are bigger than the upper bounds of uncertainties. However, robot manipulators are complex nonlinear systems which involve many uncertainties and external disturbances. Therefore, the RBFNNs are used to directly approximate individual element of the inertial matrix, the Coriolis matrix and gravity torques vector of the robot. Therefore Eq. (9) becomes.

where \( \hat{M}(q) \), \( \hat{C}(q,\dot{q}) \), and \( \hat{G}(q) \) be the estimates of \( M(q) \), \( C(q,\dot{q}) \), and \( G(q) \), respectively. For the system (11), the proposed controller is expressed by the following equation

where \( \hat{M}(q) = \left[ {\hat{W}_{M}^{T} \bullet \sigma_{M} (q)} \right] \), \( \hat{C}(q,\dot{q}) = \left[ {\hat{W}_{C}^{T} \bullet \sigma_{C} (q,\dot{q})} \right] \), \( \hat{G}(q) = \left[ {\hat{W}_{G}^{T} \bullet \sigma_{G} (q)} \right] \). The neural network weight vectors are designed as follows.

where \( k = 1,2, \ldots, n \). \( \varGamma_{Mk} \), \( \varGamma_{Ck} \), and \( \varGamma_{Gk} \) are constant symmetric positive definite matrices. \( \hat{W}_{Mk} \),\( \hat{W}_{Ck} \), and \( \hat{W}_{Gk} \) are column vectors with their elements being \( W_{Mkj} \), \( W_{Ckj} \), \( W_{Gkj} \), respectively.

4 Simulation Results

In this section, to verify the validity and effectiveness of the proposed method, the performance of the proposed controller is tested via simulation on a two-link planar robotic manipulator. The simulations are performed in the MATLAB-Simulink environment using ODE 4 solver with a fixed-step size of \( 10^{ - 4} \,s \).

The dynamic equation of the two-link robot is described as follows

where the inertia matrix \( M_{ij} (q) \) is given by

The Coriolis and centrifugal matrix \( C_{ij} (q,\dot{q}) \) is given by

The gravity torques vector \( G_{i} (q) \) is given by

The parameters values employed to simulate the robot are given as of \( l_{1} = 1\,{\text{m}} \), \( l_{2} = 0.8\,{\text{m}} \), \( m_{1} = 1\,{\text{kg}} \), \( m_{2} = 1\,{\text{kg}} \), \( \beta = diag(12,12) \), \( \varphi = 0.8 \), \( K = diag(150,50) \), \( K_{SW} = diag(5,5) \). The external disturbances are selected as

The reference trajectories are given by

The initial states are chosen as

The simulation results are shown in Figs. 1 and 2. It can be observed that the controller can track the desired trajectory very well, the controller brings very small tracking errors, and the state trajectories reach to the origin in a finite amount of time. Thus, the simulation results demonstrate that the proposed controller can effectively control the unknown nonlinear dynamic system.

5 Conclusion

In this paper, an adaptive terminal sliding mode control based on local approximation method is proposed for trajectory tracking of uncertain robotic manipulators. The controller is developed based on the combination of terminal sliding mode control technique and radian basis function neural networks (RBFNNs). Adaptive learning laws have been derived to adjust on-line the output weights of the RBFNNs during the trajectory tracking control of robot manipulators without any offline training phases. In the simulation example, the proposed control is applied to a two-link robotic manipulator. The simulation results are given to demonstrate the effectiveness of the proposed method.

References

Arimoto, S., Miyazaki, F.: Stability and robustness of PID feedback control for robot manipulators of sensory capability. In: Brady, M., Paul, R.P. (eds.) Robotic Research. MIT Press, Cambridge (1984)

Spong, M.W.: On the robust control of robot manipulators. IEEE Trans. Autom. Control 37(11), 1782–1786 (1992)

Abdallah, C., Dorato, D.M., Jamishidi, M.: Survey of the robust control robots. Control Syst. Mag. 12(2) (1991)

Slotine, J.J.E., Li, W.: On the adaptive control of robot manipulators. Int. J. Robot. Res. 6(3), 49–59 (1987)

Ortega, R., Spong, M.W.: Adaptive motion control of rigid robot: a tutorial. Automatica 25(6), 877–888 (1989)

Utkin, V.I.: Variable structure systems with sliding modes. IEEE Trans. Autom. Control 22, 212–222 (1997)

Man, Z., Paplinski, A.P., Wu, H.R.: A robust MIMO terminal sliding mode control scheme for rigid robotic manipulators. IEEE Trans. Autom. Control 39(12), 2465–2469 (1994)

Wu, Y., et al.: Terminal sliding mode control design for uncertain dynamic systems. Syst. Control Lett. 34(5), 281–287 (1998)

Yu, X., Man, Z.: Fast terminal sliding-mode control for nonlinear dynamic systems. IEEE Trans. Circ. 49(2), 261–264 (2002)

Yu, S., et al.: Continuous finite-time control for robotic manipulators with terminal sliding mode. Automatica 41(11), 1957–1964 (2005)

Slotine, J.J.E., Li, W.: Applied Nonlinear Control, pp. 41–190. Prentice-Hall, EngleWood Cliffs (1991)

Wang, L., Chai, T., Zhai, L.: Neural network-based terminal sliding mode control of robotic manipulators including actuator dynamics. IEEE Trans. Ind. Electron. 56(9), 3296–3304 (2009)

Ge, S.S., Hang, C.C.: Direct adaptive neural network control of robots. Int. J. Syst. Sci. 27, 533–542 (1996)

Ge, S.S., Lee, T.H., Harris, C.J.: Adaptive neural network control of robot manipulators. World Scientific, London (1998)

Ge, S.S., Hang, C.C., Woon, L.C.: Adaptive neural network control of robot manipulators in task space. IEEE Trans. Ind. Electron. 44, 746–752 (1997)

Woon, L.C., Ge, S.S., Chen, X.Q., Zhang, C.: Adaptive neural network control of coordinated manipulators. J. Robot. Syst. 16(4), 195–211 (1999)

Craig, J.J.: Introduction to Robotics Mechanics and Control, 3rd edn. Prentice Hall, EngleWood Cliffs (2005)

Khalil, H.K.: Nonlinear Systems, 3rd edn. Prentice Hall, EngleWood Cliffs (2002)

Girosi, F., Poggio, T.: Networks and the best approximation property. In: Artificial Intelligence Lab. MIT, Cambridge (1989)

Acknowledgments

This work was supported by the Research Fund of University of Ulsan.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Tran, MD., Kang, HJ. (2015). A Local Neural Networks Approximation Control of Uncertain Robot Manipulators. In: Huang, DS., Han, K. (eds) Advanced Intelligent Computing Theories and Applications. ICIC 2015. Lecture Notes in Computer Science(), vol 9227. Springer, Cham. https://doi.org/10.1007/978-3-319-22053-6_58

Download citation

DOI: https://doi.org/10.1007/978-3-319-22053-6_58

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-22052-9

Online ISBN: 978-3-319-22053-6

eBook Packages: Computer ScienceComputer Science (R0)