Abstract

The artificial neural networks (ANN) by their capacities of training, classification, and decision, give a solution to bearing diagnosis problem by the automatic classification of the vibratory signals corresponding to the various states the machines. They are intended to increase the precision(accuracy) and to reduce errors caused by subjective human judgments. However it is important to note that the ANNs in the aids to diagnosis must be set for optimum performance. The non-existence of predefined rules for ANNs parameters setting (number of hidden neurons in each hidden layers etc…) obstruct the achievement of optimal performances. The use of genetic algorithm (GA) can solve this problem by the parameters and structure optimization of ANN. This paper discusses the use of the ANN multilayer Perceptron (MLP), for the diagnosis of electric motor bearings, by the automatic classification of the various operating conditions the machine .The signals taken from the experimental test rig are processed by using various methods of signal processing. The calculated indicators were used to build the patterns vector, which is used for the following to train and test of the network. The GA are used to search(optimize) the structure and the various parameters of the network, which simplifies the neural network structure and makes the training process more efficient and giving the best performances of the network.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Rolling element bearings are widely used elements in electric motors. Their failure is one of the most frequent reasons for electric motor breakdown. In order to enhance motor’s reliability and reduce maintenance cost, bearing condition monitoring becomes an important measure to ensure machine safety [1].

Considerable research has been carried out previously to develop various algorithms and methods for bearing fault detection and diagnosis [2–6].

Nowadays, Artificial Neural Network (ANN) are proving their effectiveness in several research areas especially for classification problems in many different environments, including business, science and engineering. The ANN is an information processing paradigm inspired by biological nervous systems [7]. The human learning process maybe partially automated with ANN’s. It can be configured for a specific application, such as pattern recognition or data classification, through a learning process. As the neural network theory is still in progress, there is not a set of ways to guide the design process. Now, the design of neural network and finding the optimal parameters in order to maximize the performance of ANN is one of the major challenges in the uses of ANN [8].

2 Background

2.1 Rolling Element Bearings

The main components of rolling bearings are: the inner ring; the outer ring, the rolling elements and the cage (Fig. 1). Typically, the inner ring of the bearing is mounted on a rotating shaft, and the outer ring is mounted to a stationary housing. Commonly rolling elements are balls or rollers. The roller elements transfer the load over a very small surface (ideally, point contact) on the raceways [9].

Local or wear defects cause periodic impulses in vibration signals. Amplitude and periodic of these impulses are related to the shaft rotational speed and fault location. The formula for the various defect frequencies is given by:

Ball pass frequency, outer race:

Ball pass frequency, inner race:

Fundamental train frequency (cage speed):

Ball (roller) spins frequency:

where fr is the shaft speed, n is the number of rolling elements, and α is the angle of the load from the radial plane. Note that the ball spin frequency (BSF) is the frequency with which the fault strikes the same race (inner or outer).

2.2 Bearing Fault Diagnosis Techniques

A wide variety of techniques, were developed for the detection and diagnosis of faults in rolling element bearings. They have been introduced to inspect raw vibration signals. These algorithms can be classified into time domain, frequency domain, time- frequency domain, higher order spectral analysis, and model based techniques [10, 11].

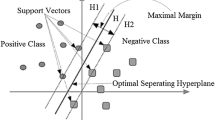

2.3 MultiLayer Perceptron (MLP)

The multilayer Perceptron (MLP) is the simplest and most known type of neural networks. Its structure, showed by Fig. 2, is relatively simple: an input layer, an output layer and one or more hidden layers. Each neuron is connected fully to the neurons of its preceding and the following layers [12].

MLP is one of the most successful feed-forward neural networks for diagnosis. A review of some works on fault diagnosis vibration based on ANN has been presented in [13].

The challenges for constructing a MLP network are: the determination of a sufficient number of hidden layers; neurons within each layer; learning rate; the activation function, and the connections initial weights. These parameters have a great impact on the learning methods convergence. Although a formal methodology to express the number of hidden neurons does not been developed yet. Many studies on this subject were launched [14–20]. However, as a known fact more neurons and layers in the network result a longer training period and convergence problems.

2.4 Genetic Algorithms (GA)

The Genetic Algorithm (GA) has been introduced by J. HOLLAND to solve a large number of complex optimization problems. Each solution represents an individual coded in one or several chromosomes. These chromosomes represent the problem’s variables. First, an initial population composed by a fixed number of individuals is generated; then, an operator of reproduction is applied on a number of individuals selected according to their fitness score. This procedure is repeated until the maximum number of iterations is reached. GA has been applied in a large number of optimization problems in several domains, telecommunication, routing, scheduling, and it proves its efficiency to obtain a good solution [21].

2.5 Artificial Neural Networks Optimized by the Genetic Algorithm

However it is important to note that the ANNs parameters (number of hidden neurons in each layer, number of hidden layers etc.) (Fig. 3), in the aids to diagnosis must be set for optimum performance.

These parameters are often chosen empirically seeking desired results, which makes the use of this method very difficult. In this work GA are proposed for the optimization and the search of the best(optimal)structure and parameters of ANN.

3 Materials and Methods

In this research work, the procedure of diagnosis consists of two stages, namely preprocessing using some signal processing methods for feature extraction, and the design of the appropriate neural network.

3.1 Data Acquisition

The experimented data base was extracted from the test rig shown in Fig. 4.

a The bearing test rig. b The schematic description of the test rig. [22]

The web site provides access to ball bearing test data for normal and faulty bearings [23]. Experiments were conducted using a 2HP Reliance Electric motor, and acceleration data was measured at locations near to and remote from the motor bearings. These web pages are unique in that the actual test conditions of the motor as well as the bearing fault status have been carefully documented for each experiment Motor bearings were seeded with faults using electro-discharge machining (EDM). Faults ranging from 0.17 mm in diameter to 0.71 mm in diameter were introduced separately at the inner raceway, rolling element (i.e. ball) and outer raceway. Faulted bearings were reinstalled into the test motor vibration data was recorded for motor loads of 0–3 horsepower (motor speeds of 1797–1720 RPM).Vibration data was collected using accelerometers, attached to the housing with magnetic bases. Accelerometers were placed at the 12 o’clock position at both the drive end and fan end of the motor housing. The time domain presentation of signal is shown in Fig. 5.

3.2 Fault Diagnosis Scheme

The flow chart of the Bearing fault diagnosis based on ANN is shown as Fig. 6.

4 Results and Discussion

4.1 Preprocessing of Vibration Signals

A signal conditioning step is required to remove useless information, and facilitate the task of indicators extraction from each signal the some of the most commonly used indicators for bearing monitoring were extracted [24–27], namely: the RMS value, crest factor, peak to peak value, kurtosis, and the energy from the spectrum envelope.

After a preliminary analysis [28], we chose to calculate these indicators as follows:

Time domain indicators

Each signal was pass band filtered in four adjacent 1.5 kHz band: [1–1500 Hz], [1500–3000 Hz], [3000–4500 HZ], [4500–6000 Hz] and [1–6000 Hz]. From each filtered signal were extracted: RMS, Crest factor, Crest-Crest Value and Kurtosis. Figure 7 presents the variation of time domain indicators.

Frequency domain indicators

The frequencies domain indicators are calculated from the spectrum envelope in five frequency bands: [1–1000 Hz], [1000–2000 Hz], [2000–3000 Hz], [3000–4000 Hz], [4000–5000 Hz] and [1000–6000 Hz]. The variation of Frequency domain indicators are shown as Fig. 8.

4.2 Constitution of the Patterns Vector (Networks Input)

The patterns vector is consisted of the described above time and frequency domain indicators. The data that have been be treated, categorized, and stored in an observations/variables array.

4.3 Choice of the Classes (Networks Output)

The networks output vector contains the various classes corresponding to each operating conditions from the experimental test rig. five classes fixed, each one of them corresponds to a defect diameter. Table 1 represents the labeling of the various studied classes.

4.4 Data Normalization

To improve the performance of the MLP, normalization of patterns vector data was done. The obtained database was divided in three parts: training set, test and validation set. the used normalization formula is given below,

where

- \(\sigma_{j}\) :

-

is the standard deviation (SD) of du jth parameter

- m j :

-

Is the average

4.5 The Neural Network Configuration

The employed MLP was configured as follow (Table 2) [29, 30].

4.6 The Genetic Algorithms

GA have been used in different ways in optimizing ANN; of the most common seeks the optimization the elements of the pattern vector (training data and test data) [31–33].

In our papers, GAs were applied to optimize the number of neurons in the hidden layer MLP. In this purpose, we created a fitness function whose formula is as follows [34].

- C :

-

is a constant

- E :

-

is the minimum error(performance)

- H :

-

is the number of neurons in the hidden layer

- Hmax:

-

is the maximum value of the neurons in the hidden layer

4.7 Results

The number of hidden neurons in the hidden layer range from 1 to 20, in order to obtain the optimal value that gives the best performance of classification.

So, for the GA we use the following parameters:

-

15 populations

-

mutation rate 0.05

-

crossover rate 0.9

-

binary coding

Figure 9 shows that the value of the objective function is minimal for a number of hidden neuron equal 2.

So we can conclude that the number of neuron in the hidden layer that gives us the best performance is 2 neurons.

5 Conclusion

The present article describes the use of ANN to automate the electric motor bearing diagnosis, based on vibration signal analysis. Initially, the vibration signals collected from the test bench (Bearing Data Center) are preprocessed, to extract the monitoring indicators most appropriate to the health of the experimental device. Then we built the database used to training and testing the MLP. Various possible kinds of faults (five diameters) have been taken into consideration into this work. However, the ANN performance depending on the size of the training data set, the size of the ANN (the number of hidden layers and number of neurons per hidden layer). In order to finding the optimal value of the number of hidden neurons, we use the GA. That allow us to obtain the value that give us the best performance of ANN. We have stressed, that the efficiency of the optimization depends of the choice the GA parameters.

References

Randall RB, Antoni J (2011) Rolling element bearing diagnostics—a tutorial. Mech Syst Signal Proc 25(2):485–520

Howard I (1994) A review of rolling element bearing vibration: detection, diagnosis and prognosis. DSTO-AMRL report, DSTO-RR-00113, pp 35–41

McInerny SA, Dai Y (2003) Basic vibration signal processing for bearing fault detection. IEEE Trans Educ 46(1):149–156

Sawalhi N (2007) Diagnostics, prognostics and fault simulation for rolling element bearings. Ph. D. thesis, School of Mechanical and Manufacturing Engineering, University of New South Wales, Australia

Nataraj C, Kappaganthu K (2011) Vibration-based diagnostics of rolling element bearings: state of the art and challenges. In: 13th world congress in mechanism and machine science, Guanajuato 19–25 June 2011

Kankar PK et al (2011) Fault diagnosis of ball bearings using machine learning methods. Expert Syst Appl 38:1876–1886

Haykin S (2001) Neural Networks—a comprehensive foundation, 2nd edn. Pearson Prentice Hall, India, p 823

Egriogglu E, Aladag CH, Gunay S (2008) A new model selection strategy in artificial neural networks. Appl Math Comput 195:591–597

McFadden PD, Smith JD (1985) The vibration produced by multiple point defects in a rolling element bearing. J Sound Vib 96(1):69–82

Khan AF (1991) Condition monitoring of rolling element bearings: a comparative study of vibration based techniques. PhD Dissertation, University of Nottingham

Chen P (2000) Bearing condition monitoring and fault diagnosis. Master of science thesis, The University of Calgary, Canada

Bishop CM (1995) Neural networks for pattern recognition. Oxford University Press, Oxford

Rao BKN et al (2012) Failure diagnosis and prognosis of rolling—element bearings using artificial neural networks: a critical overview. In: 25th international congress on condition monitoring and diagnostic engineering. Journal of physics: conference series vol 364

Miller GF, Todd PM, Hedge SU (1989) Designing neural networks using genetic algorithms. Proceedings of the 3rd international conference on genetic algorithms, Morgan Kaufmann, San Mateo

Onoda T (1995) Neural network information criterion for the optimal number of hidden units. In: Proceedings of the 1995 IEEE international conference on neural networks, vol 1

Ioan I, Corina R, Arpad I (2004) The optimization of feed forward neural networks structure using genetic algorithms. In: Proceedings of the international conference on theory and applications of mathematics and informatics—ICTAMI, Greece

Curry B, Morgan PH (2006) Model selection in neural networks: some difficulties. Eur J Oper Res 170(2):567–577

Liu Y, Starzyk JA, Zhu Z (2007) Optimizing number of hidden neurons in neural networks. In: Proceedings of the IASTED international conference on artificial intelligence and applications (AIA ’07), pp 121–126

Shibata K, Ikeda Y (2009) Effect of number of hidden neurons on learning in large-scale layered neural networks. In: Proceedings of the ICROS-SICE international joint conference 2009 (ICCASSICE ’09), pp 5008–5013

Sheela KG, Deepa SN (2013) Review on methods to fix number of hidden neurons in neural networks. Math Probl Eng Article ID: 425740, 11 pages, http://dx.doi.org/10.1155/2013/425740

Sivanandam SN, Deepa SN (2008) Introduction to genetic algorithms. Springer, Berlin

Huang Y, Liu C, Zha XF, Li Y (2010) A lean model for performance assessment of machinery using second generation wavelet packet transform and Fisher criterion. Expert Syst Appl 37:3815–3822

Case Western Reserve University, bearing data center (2006) http://www.eecs.cwru.edu/laboratory/bearing/download.htm

Alfredson RJ, Mathew J (1985) Time domain methods for monitoring the condition of rolling element bearings. Inst Eng Aust Mech Eng Trans 10:102–107

Claire B (2002) Éléments de maintenance préventive de machines tournantes dans le cas de défauts combinés d’engrenage et de roulements. INSA Lyon thesis

Chen P (2000) Bearing condition monitoring and fault diagnosis. Master of science thesis, The University of Calgary, Canada

SUN Q, XI F, Krishnappa G (1998) Signature analysis of rolling element defects. In: Proceeding of CSME forum, Toronto pp 423–429

Fedala S (2005) Le diagnostic vibratoire automatisé: comparaison des méthodes d’extraction et de sélection du vecteur forme. Magister thesis, University of Setif

Badri B, Thomas M, Sassi S, Lakis A (2007) Combination of bearing defect simulator and artifical neurl network of the diagnosis of damaged bearings. In: Proceedings of the 20th international congress on condition monitoring and diagnostic engineering management (COMADEM07), Faro, pp 175–185

Fenineche H (2008) Application des réseaux de neurones artificiels au diagnostic des défauts des machines tournantes. Magister Thesis. University of Setif

Li B, Chow MY, Tipsuwan Y, Hung JC (2000) Neural-network based motor rolling bearing fault diagnosis. IEEE Trans Industr Electron 47(51):1060–1067

Samanta B et al (2004) Bearing fault detection using artificial neural networks and genetic algorithm. EURASIP J Appl Signal Process 3:366–377

Jack LB, Nandi AK (2000) Genetic algorithm for feature extraction in machine condition monitoring with vibration signals. IEE Proc Vis Image Signal Process 147:205–212

Shifei D et al (2011) Studies on optimization algorithms for some artificial neural networks based on genetic algorithm(GA). J Comput—Mai

Acknowledgment

The authors would like to thank Kenneth A. Loparo, from Bearing Data Center, Case Western Reserve University, Cleveland, for his experimental data provided.

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this paper

Cite this paper

Hocine, F., Ahmed, F. (2016). Electric Motor Bearing Diagnosis Based on Vibration Signal Analysis and Artificial Neural Networks Optimized by the Genetic Algorithm. In: Chaari, F., Zimroz, R., Bartelmus, W., Haddar, M. (eds) Advances in Condition Monitoring of Machinery in Non-Stationary Operations. CMMNO 2014. Applied Condition Monitoring, vol 4. Springer, Cham. https://doi.org/10.1007/978-3-319-20463-5_21

Download citation

DOI: https://doi.org/10.1007/978-3-319-20463-5_21

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-20462-8

Online ISBN: 978-3-319-20463-5

eBook Packages: EngineeringEngineering (R0)