Abstract

The distance from extreme compression fiber to neutral axis (c) is depended to combinations of axial load and flexural moment capacities of reinforced concrete (RC) columns. Since c is depended to different internal forces, the value of c cannot be found without assuming the final design. Thus, it can be iteratively searched in order to find the flexural moment capacity of columns under an axial loading. By using the presented method, the solution with the minimum cost ensuring maximum flexural moment and axial load is found. A random search technique is explained in this chapter for optimum design of uniaxial RC columns with minimum cost. In optimization, design of RC columns is done by considering the design rules described in ACI 318- Building Code Requirements for Structural Concrete. The random search technique (RST) for optimization of RC uniaxial columns is effective on finding optimum cross-sections and reinforcement design with minimum cost.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

In design of reinforced concrete (RC) structures, structural members are defined according the architectural designs. The main goal of the design engineer is to find the solution by considering security measures given in design codes, esthetic and comfort requirements of people and economy in material. Although the architectural projects limit the independent design of engineer, the design is done by assuming the design variables between these limits. Then, the assumed design is modified according to design codes if the dimensions of the member are not suitable to carry out internal forces resulting from static and dynamic sources. The economy of the design is depended to the experience of design engineers. Although the cross-section dimensions are precisely assumed for RC members, the required reinforcement bar can never be provided as calculated since the bars in the market are constant in size. For these reasons, optimization is important for RC members. This chapter represents a numerical optimization technique for uniaxial RC columns. The design variable of RC columns such as cross-sectional dimensions and amount of steel bars (detailed design with diameter size and numbers) are randomly searched in the presented method for the minimum material cost ensuring the ACI-Building Code Requirements for Structural Concrete requirements. For several RC structural members, several optimization methodologies have been proposed. The reviews of several studies are presented in Sect. 2.

2 Literature Survey for Optimization of RC Members

The recent approaches contain optimization of RC structures (2D or 3D) or a detailed optimization of a member of a RC structure. Metaheuristic based methods are the leading ones for the last 15 years in search several design variables of the optimized RC member. The following contributions to the optimization science for RC application are given in this section.

Coello et al. employed genetic algorithm in development of an optimization approach for RC beams [1]. Genetic algorithm is also used in the approach of Rafiq and Southcombe for optimization biaxial RC columns [2]. Several RC member was optimized by genetic algorithm based approach of Koumousis and Arsenis [3]. The detailed reinforcement design of RC frame structure employing genetic algorithm was done by Rajeev and Krishnamoorthy [4]. By employing sequential quadratic programing technique, shape optimization of RC members was done and genetic algorithm was employed in cost optimization by Rath et al. [5]. By considering slenderness of the columns, RC frames was optimized by Camp et al. by employing genetic algorithm and the optimization process was carried out by grouping several members of RC structures [6]. Ferreira et al. optimally designed T-shaped RC beams according to different design codes [7].

Genetic algorithm was also combined with other metaheuristic method inspired from natural phenomena and these hybrid algorithms have been used in the optimization of RC members. A hybrid algorithm, which is combination of genetic algorithm and simulated annealing, was used by Leps and Sejnoha for optimum design of continues beams [8]. By considering lateral equivalent static earthquake loads at the joints, Lee and Ahn optimized RC frame by using a genetic algorithm based method and a database including possible desing of RC members [9].

Three dimensional RC frame structure under excitation of dead, live, snow and earthquake load was optimized by the method of Balling and Yao [10]. Ahmadkhanlou and Adeli proposed an optimization method with two stages for optimization of RC slab. The neural dynamics model [11, 12] for the optimum solution of continuous variables and perturbation technique modify the values to practical ones were used in the optimization method [13]. Barros et al. developed expressions for the bending moment, steel area and ratio for singly or doubly RC beams for optimum design [14]. Optimum cost design of pre-stressed concrete bridges were done by Sirca Jr. and Adeli [15]. RC continuous beams were optimized by using a genetic algorithm based method and selecting design variables from a database in the study of Govindaraj and Ramasamy [16]. By combining genetic algorithm and discretized form of the Hook and Jeeves method, a hybrid algorithm was used in the optimization of RC flat slab buildings [17]. RC frames were optimized by the genetic algorithm based method of Govindaraj and Ramasamy [18]. Single-bay multi-story and multi-bay single story RC frames were optimized by Guerra and Kiousis [19]. A multi objective optimization approach for RC frames was developed by Paya et al. by employing a metaheuristic method called simulated annealing [20]. Two heuristic methods such as random walk and descent local search and two metaheuristic methods such as the threshold accepting and the simulated annealing based optimization was proposed for optimization of RC frames of bridges [21].

Generally RC member optimization studies consider the minimization of the cost. Several studies considered the value of embedded CO\(_{2}\) emission. Two different approaches using simulated annealing algorithm [22] and big bang-big crunch optimization [23] were used for the optimization of RC frames in order to reduce cost and embedded CO\(_{2}\) emission.

Gil-Martin et al. developed a reinforcement sizing diagram approach for RC beams and columns [24]. Barros et al. investigated the optimum depth and reinforcement of RC beam in rectangular shape [25]. According to Eurocode 2, Fedghouche and Tiliouine optimized singly reinforced T-shaped RC beams by employing genetic algorithm [26].

Several approaches employing metaheuristic algorithms such as simulated annealing [27, 28], harmony search [29], big bang-big crunch [30] and charged system search [31] have been used in the optimization of RC retaining walls. The music inspired metaheuristic algorithm called harmony search have been used in the optimization of several RC members such as continuous beams [32], T-shaped RC beams [33], columns [34] and frames [35]. Kaveh and Sabzi optimized RC frames by using several metaheuristic algorithms [29]. Optimum design of RC beams were done by Kaveh and Sabzi and big bang-big crunch was employed in their approach [36]. Rama Mohan Rao combined several algorithms such as simulated annealing and tabu search for optimization of hybrid fiber-reinforced composite plates [37]. A random search technique for the optimization of RC beams [38] and columns [39] was developed. In the following section, random search technique for optimization of RC columns is summarized.

3 Random Search Technique for Optimum Design of RC Columns

A RC column with a cross-sectional dimension and reinforcements can carry different combination of axial force and flexural moment. This reason is resulting from the change of stresses on the cross-section and location of steel reinforcements. Thus, the distance from the extreme compression fiber to the neutral axis (c) changes according to loading conditions. In design of RC members, a reinforcement ratio is calculated for a constant cross-section. When the cross-section is assumed, the reinforcements for the axial force can be found and the flexural moment capacity can be calculated according to the value of c For the ratio of reinforcements the moment capacity may be very different than the required one. In order to find the closest flexural moment value to the required one optimization techniques must be used.

The presented method; random search technique is numerical algorithm which iteratively search the best design of RC member according to design constraints, member loadings and objectives. The objective of the optimization is explained as material cost in this chapter. ACI-318 Building Code Requirements for Structural Concrete [40] rules were taken into consideration.

As mentioned in the introduction section of the chapter, design engineers are depended to architectural project. For that reason or esthetics of the building, the cross-section dimensions are limited with the ranges. These ranges may be also selected as practical dimensions for shortening the optimization process. Also, ranges for steel reinforcement must be used to shorten the optimization process and consider the supplying of the steel bars. The bar with big diameter sizes may not be found near to the construction. For that reason, the price of the steel may increase because of transportation costs.

Generally, concrete is a cheap material comparing to steel but cost ratio of concrete to steel may change according to the region of the construction yard. Transportation and import costs play a great role in this factor. Also, if the travel time of the concrete form facility to construction yard is long, the use of admixture may increase the cost of the concrete. For that reason, numerical optimization of RC member must be done by considering specific conditions. Mathematic optimum result may not be optimum for all specific conditions.

Before the random search of design variables of RC columns, several design constants given in Table 1 are defined. These design constants are length of column (\(l\)), clear cover (\(\mathrm{c}_\mathrm{c})\), maximum aggregate diameter (\(\mathrm{D}_{\max })\), elasticity modulus of steel (\(\mathrm{E}_\mathrm{s}\)), specific gravity of steel (\(\upgamma _\mathrm{s}\)), specific gravity of concrete (\(\upgamma _\mathrm{c})\), yield strength of steel (\(\mathrm{f}_\mathrm{y}\)), compressive strength of concrete (\(f_{c}^{\prime }\)), cost of the concrete per m\(^{3}\) (\(\mathrm{C}_\mathrm{c}\)), cost of the steel per ton (\(\mathrm{C}_\mathrm{s}\)). Also, loading conditions such as axial force (N), shear force (V) and flexural moment (M) are defined. In the Fig. 1, the loading of the column is shown.

The ranges of design variables are also defined. The design variables are breadth of column (\(\mathrm{b}_\mathrm{w}\)), height of the column (h), number and diameter size of longitudinal reinforcement bars in two lines (including web reinforcements) and diameter size and distance of shear reinforcements. In Fig. 2, the design variables are shown. Symmetrical design is done for upper and lower section of the column.

After the design constants, loadings and ranges of design variables are defined, cross-section dimensions (\(\mathrm{b}_\mathrm{w}\) and h) are randomly defined by considering the selected range. For productivity of the column in the construction yard, dimensions are assigned with productivity values which are multiple of a value. The ductile fracture conditions given in Eq. (1) and (2) are checked for randomly selected dimensions. The first condition is a shear force criterion with two inequalities while second condition is related with the axial capacity of columns.

In Eqs. (1) and (2), \(\mathrm{A}_\mathrm{c}\) represents the cross-sectional area (\(\mathrm{b}_\mathrm{w}\)h) of column. If these conditions are not suitable for selected cross-section, \(\mathrm{b}_\mathrm{w}\) and h are iteratively randomized.

After cross-section dimension supporting ductility conditions, reinforcement design is started. Number and diameter size of the longitudinal reinforcement are randomly defined for upper and lower faces of column. In order to carry flexural moment in opposite directions, the same reinforcements were used for both faces of column. ACI-318 rules are checked for the orientation of reinforcement bars. If needed, the reinforcements are positioned in two lines. Placement condition defined in ACI-318 [40] for columns are shown in Eq. (3). \(\upphi _\mathrm{average}\) is the average of the diameter sizes in a line where the placement condition is checked. \(\mathrm{a}_{\upphi }\) is the clear distance between reinforcements. The reinforcements are iteratively randomized until placement condition is satisfied.

In the methodology, web reinforcements are also assigned with randomization. Also, minimum and maximum reinforcement conditions are also checked. Reinforcement ratio (\(\uprho \)), which is calculated by the ratio of all longitudinal reinforcements to cross-sectional area, must be between 0.01 and 0.06. If the limit conditions are not satisfied, iterative randomization of reinforcements continue.

After all design variable related with axial forces are randomly assigned with a practical value, the distance from extreme compression fiber to neutral axis (c) is scanned for axial force capacity. Then, flexural moment capacity of random design is found. If the flexural moment capacity is lower than the required one or more than a defined percentage of the required value, the iterations are repeated. In the present method used in the optimization of the numerical example, this percentage is taken as 100 %. For every 500 iteration, it is iteratively increased with 1 %.

After the random design of cross-section and longitudinal reinforcement, the design of shear reinforcements was done. Iteratively, diameter sizes are assigned with the values within the range and the required distance of shear reinforcement (stirrups) are found according to nominal shear strength of concrete (\(\mathrm{V}_\mathrm{c}\)) and nominal shear strength of reinforcement (\(\mathrm{V}_\mathrm{s}\)) given in Eqs. (4) and (5), respectively.

\(\mathrm{A}_\mathrm{v}\) and s represents shear reinforcement area and distance between them. d is the effective depth of the concrete. Also, the \(\mathrm{V}_\mathrm{s}\) value must not exceed \(0.66\sqrt{\mathrm{f}_\mathrm{c}^{'}}\mathrm{b}_\mathrm{w} \mathrm{d}\). In that situation, the objective function is penalized with a very big value. Also, the calculated results are compared with the minimum shear reinforcement (\(\mathrm{A}_\mathrm{v,min}\)) value and maximum shear reinforcement distance (\(\mathrm{s}_{\max })\) defined in Eqs. (6) and (7), respectively. The result of shear reinforcements with the minimum cost is taken into consideration and the results modified according to Eqs. (6) and (7).

After a suitable design is found, the maximum material cost which is the objective function of the optimization is calculated. The objective function which is minimized is given in Eq. (8). The parameters used in Eq. (8) are listed in Table 2.

The objective function is calculated by repeating the optimization process for several iteration numbers and design with the minimum cost is found. The flowchart of the optimization methodology is given Fig. 3.

Also, the strength of material such as \(\mathrm{f}_\mathrm{y}\) and \(\mathrm{f}^{'}_\mathrm{c}\) may taken as a design variable, but in construction of a structure, using different material types may not be practical. The methodology is applied for different loading condition of axial force and flexural moment in Sect. 4.

4 Numerical Example

The optimum design of uniaxial columns was investigated for different flexural moment and axial force values. Design constant, shear force value (V) and ranges of design variables used in the numerical examples are given in Table 3.

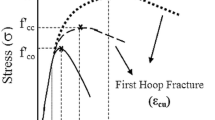

In the calculations, the compressive stress block to neutral axis depth was assumed as equivalent rectangular. The \(\upbeta _{1}\) value, which is a factor relating depth of equivalent rectangular stress block, was calculated as given in Eq. (9).

If the value of \(\upbeta \) \(_{1}\) is lower than 0.65, \(\upbeta _{1}\) is taken as 0.65. The elasticity modulus of concrete was calculated by using Eq. (10).

In searching of design variables, the values of b\(_\mathrm{w}\) and h were chosen from (or rounded to) values which are divisible to 50 mm in order to produce a RC structure member practical in construction yard. Because of constant size of steel reinforcements, even integers are assigned for the diameter sizes. The optimum results of several M-N cases (Table 4) are given in Table 5.

The optimum cross-section dimensions of Case 1 such as \(\mathrm{b}_\mathrm{w}\) and h are 250 and 300 mm, respectively. In this case, reinforcement positioned in one line is suitable to carry the internal forces. Two reinforcements with the minimum diameter range (16 mm) is found for the optimum results. Also, cross-section dimensions are found as the range minimums. For that reason, the most shear reinforcement is needed for Case 1 since the nominal shear strength of concrete \((\mathrm{V}_\mathrm{c})\) is low for the design with small cross-section dimensions. The total material cost of the Case 1 is 19.61$ as seen in Table 5.

In Case 2, the optimum height of the column is 450 mm while b\(_\mathrm{w}\) is 250 mm which is also minimum value as found as Case 1. In order to carry more flexural moment, h value is increasing. Longitudinal reinforcements are also found as minimum values for allowed range. The total cost of the optimum design is 28.05$ for Case 2.

In Case 3, increase of height of the column is also seen according to previous cases. Single line design of steel reinforcement is also possible for Case 3 in order to position the required optimum steel reinforcements. But in Case 3, the longitudinal reinforcements are not assigned with minimum range size.

In Case 4, the optimum height of the column is the maximum allowed value. In that case, the reinforcements or the breadth of the column must be increase. The breadth of the column has effective on placing more reinforcements in a line, but using the reinforcements in two lines for a section with 300 mm breadth is the optimum solution. By the increase of the cross-section dimensions, optimum shear reinforcement is getting lower and the distance between stirrups are increasing. The same shear reinforcement is optimum for the last three cases (Case 4–6).

For Cases 5 and 6, the cross-section is assigned with the range maximums. For these cases, the longitudinal moments were positioned in two lines. The cost of Case 5 and 6 are 55.12$ and 67.11$, respectively. In Case 6 comparing to Case 5, the longitudinal reinforcements are significantly increasing because of the limit of cross-sectional dimensions.

In the conclusion section, results for additional M-N combinations were given in several grafts in order to discuss the results of the proposed method. The optimum results were searched for flexural moment values between 100 kNm and 700 kNm by 100 kNm differences. In that cases, five different axial force value (500, 1000, 1500, 2000 and 2500 kN) were used.

5 Conclusion

The optimum cost of different M-N combinations are plotted in Fig. 4. As seen in the graph, the optimum costs are near to each other for 400 kNm flexural moment. This situation is also observed for flexural moment more than 400 kNm, but not for 500 kN axial force. For the flexural moments below 400 kNm, ACI-318 rules are critical constraints in design. Especially for 2000 and 2500 kN axial force, the optimum costs for flexural moment between 100 and 300 kNm are nearly equal to each other.

In Fig. 5, the optimum total reinforcement ratio of longitudinal reinforcements to cross-sectional area are plotted for M-N combinations. As seen in the Fig. 5, ranges of design variables are more critical than the minimum required reinforcement ratio defined as 0.01 in ACI-318 for 500 kN axial force and 100 kNm flexural moments. In the cases with 500 kN axial force, the optimum cost and total reinforcement ratios are very big compared to other axial force values. Since the compressive forces are low in the section, these forces are not so effective to reduce tensile forces resulting from flexural moments. To carry tensile stresses, steel reinforcement bars are needed. In most flexural moment cases of 2500 kN axial force, minimum reinforcements are optimums while big cross-sections are enough to carry compressive forces.

By using the presented approach, optimum solutions of RC uniaxial columns can be found for different M-N combinations. As seen in the optimum results, cross-sectional area of column was enlarged in order to carry more internal forces. This situation is originated from the big cost difference of steel and concrete. The proposed method can assign reinforcements in two lines in order to ensure positioning rules about adherence between steel and concrete. Because of this ability, the optimum results are ready for production in construction yards without modification. In M-N combination with low internal forces, longitudinal reinforcements are positioned in single line. This results shows the effectiveness of the proposed method. As a conclusion, random search technique for the optimization of RC columns is a feasible approach.

References

Coello CC, Hernandez FS, Farrera FA (1997) Optimal design of reinforced concrete beams using genetic algorithms. Expert Syst Appl 12:101–108

Rafiq MY, Southcombe C (1998) Genetic algorithms in optimal design and detailing of reinforced concrete biaxial columns supported by a declarative approach for capacity checking. Comput Struct 69:443–457

Koumousis VK, Arsenis SJ (1998) Genetic algorithms in optimal detailed design of reinforced concrete members. Comput-Aided Civil Inf 13:43–52

Rajeev S, Krishnamoorthy CS (1998) Genetic algorithm-based methodology for design optimization of reinforced concrete frames. Comput-Aided Civ Inf 13:63–74

Rath DP, Ahlawat AS, Ramaswamy A (1999) Shape optimization of RC flexural members. J Struct Eng ASCE 125(12):1439–1446

Camp CV, Pezeshk S, Hansson H (2003) Flexural design of reinforced concrete frames using a genetic algorithm. J Struct Eng-ASCE 129(1):105–11

Ferreira CC, Barros MHFM, Barros AFM (2003) Optimal design of reinforced concrete T-sections in bending. Eng Struct 25:951–964

Leps M, Sejnoha M (2003) New approach to optimization of reinforced concrete beams. Comput Struct 81:1957–1966

Lee C, Ahn J (2003) Flexural design of reinforced concrete frames by genetic algorithm. J Struct Eng-ASCE 129(6):762–774

Balling R, Yao X (1997) Optimization of reinforced concrete frames. J Struct Eng-ASCE 123(2):193–202

Adeli H, Park HS (1995) Optimization of space structures by neural dynamics. Neural Netw 8(5):769–781

Adeli H, Park HS (1998) Neurocomput Des Autom. CRC Press, Boca Raton, FL

Ahmadkhanlou F, Adeli H (2005) Optimum cost design of reinforced concrete slabs using neural dynamics model. Eng Appl Artif Intell 18(1):65–72

Barros MHFM, Martins RAF, Barros AFM (2005) Cost optimization of singly and doubly reinforced concrete beams with EC2-2001. Struct Multidiscip \(O.\), 30(3):236–242

Sirca G Jr, Adeli H (2005) Cost optimization of prestressed concrete bridges. J Struct Eng, ASCE 131(3):380–388

Govindaraj V, Ramasamy JV (2005) Optimum detailed design of reinforced concrete continuous beams using genetic algorithms. Comput Struct 84:34–48

Sahab MG, Ashour AF, Toropov VV (2005) Cost optimisation of reinforced concrete flat slab buildings. Eng Struct 27:313–322

Govindaraj V, Ramasamy JV (2007) Optimum detailed design of reinforced concrete frames using genetic algorithms. Eng Optim 39(4):471–494

Guerra A, Kiousis PD (2006) Design optimization of reinforced concrete structures. Comput Concr 3:313–334

Paya I, Yepes V, Gonzalez-Vidosa F, Hospitaler A (2008) Multiobjective optimization of concrete frames by simulated annealing. Comput-Aided Civ Inf 23(8):596–610

Perea C, Alcala J, Yepes V, Gonzalez-Vidosa F, Hospitaler A (2008) Design of reinforced concrete bridge frames by heuristic optimization. Adv Eng Softw 39:676–688

Paya-Zaforteza I, Yepes V, Hospitaler A, Gonzalez-Vidosa F (2009) CO\(_{2}\)-optimization of reinforced concrete frames by simulated annealing. Eng Struct 31:1501–1508

Camp CV, Huq F (2013) CO\(_{2}\) and cost optimization of reinforced concrete frames using a big bang-big crunch algorithm. Eng Struct 48:363–372

Gil-Martin LM, Hernandez-Montes E, Aschheim M (2010) Optimal reinforcement of RC columns for biaxial bending. Mater Struct 43:1245–1256

Barros AFM, Barros MHFM, Ferreira CC (2012) Optimal design of rectangular RC sections for ultimate bending strength. Struct Multidiscip Optim 45(6):845–860

Fedghouche F, Tiliouine B (2012) Minimum cost design of reinforced concrete T-beams at ultimate loads using Eurocode2. Eng Struct 42:43–50

Ceranic B, Freyer C, Baines RW (2001) An application of simulated annealing to the optimum design reinforced concrete retaining structure. Comput Struct 79:1569–1581

Yepes V, Alcala J, Perea C, Gonzalez-Vidosa F (2008) A parametric study of optimum earth-retaining walls by simulated annealing. Eng Struct 30:821–830

Kaveh A, Abadi ASM (2011) Harmony search based algorithms for the optimum cost design of reinforced concrete cantilever retaining walls. Int J Civil Eng 9(1):1–8

Camp CV, Akin A (2012) Design of retaining walls using big bang-big crunch optimization. J Struct Eng-ASCE 138(3):438–448

Talatahari S, Sheikholeslami R, Shadfaran M, Pourbaba M (2012) Optimum design of gravity retaining walls using charged system search algorithm. Math Probl Eng 2012:1–10

Akin A, Saka MP (2010) Optimum detailed design of reinforced concrete continuous beams using the harmony search algorithm. In: Topping BHV, Adam JM, Pallarés FJ, Bru R, Romero ML (eds) Proceedings of the tenth international conference on computational structures technology, Civil-Comp Press, Stirlingshire, UK, Paper 131, doi:10.4203/ccp.93.131

Bekdaş G, Nigdeli SM (2013) Optimization of T-shaped RC flexural members for different compressive strengths of concrete. Int J Mech 7:109–119

Bekdaş G, Nigdeli SM (2014) Optimization of slender reinforced concrete columns. 85th annual meeting of the international association of applied mathematics and mechanics, Erlangen, Germany, 10–14 Mar

Bekdaş G, Nigdeli SM (2014) Optimization of RC frame structures subjected to static loading. In: 11th world congress on computational mechanics, Barcelona, Spain, 20–25 July

Kaveh A, Sabzi O (2012) Optimal design of reinforced concrete frames using big bang-big crunch algorithm. Int J Civil Eng 10(3):189–200

Rao Rama Mohan AR, Shyju PP (2010) A meta-heuristic algorithm for multi-objective optimal design of hybrid laminate composite structures. Comput-Aided Civil Infrastruct Eng 25(3):149–170

Nigdeli SM, Bekdas G (2013) Optimization of RC beams for various cost ratios of steel/concrete. In: 4th European conference of civil engineering ECCIE’13, Antalya, Turkey, 8–10 Oct

Bekdaş G, Nigdeli SM (2014) Optimum design of uniaxial RC columns. In: An international conference on engineering and applied sciences optimization, Kos Island, Greece, 4–6 June

ACI 318M–05 (2005) Building code requirements for structural concrete and commentary. American Concrete Institute, Farmington Hills, MI

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Bekdaş, G., Nigdeli, S.M. (2015). Optimization of Reinforced Concrete Columns Subjected to Uniaxial Loading. In: Lagaros, N., Papadrakakis, M. (eds) Engineering and Applied Sciences Optimization. Computational Methods in Applied Sciences, vol 38. Springer, Cham. https://doi.org/10.1007/978-3-319-18320-6_21

Download citation

DOI: https://doi.org/10.1007/978-3-319-18320-6_21

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-18319-0

Online ISBN: 978-3-319-18320-6

eBook Packages: EngineeringEngineering (R0)