Abstract

In order to improve the availability and cost effectiveness of products over their service life there is a need to improve levels of service knowledge and provide better linkages between that knowledge, the engineering designers, and those providing ‘through-life’ engineering services and maintenance support. This paper considers what is meant by both design knowledge and service knowledge before offering definitions which are grounded in the literature that will underpin the development of the research in this area. How service knowledge obtained during maintenance, repair and overhaul might be used to increase a product’s availability for use in service is considered using a Gas Turbine High Pressure Nozzle Guide Vane as an example case study. It is chosen as it is a complex product using state of the art materials and offers design and manufacturing challenges that are informed by service performance. A greater understanding of the required content, drivers, and inhibitors relative to service knowledge informed design is established together with how service driven design knowledge might be better informed. The paper proposes that existing service knowledge can be used to inform the design of selected complex manufactured components such as those found in aero-engines. A system architecture or framework for a ‘design for service’ programme which would facilitate greater whole-life component availability, reduced costs due to downtime and potentially much leaner logistics is proposed.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

It is concluded that in the future, there is the ability to develop systems and algorithms which have the ability to apply usage and maintenance knowledge, thereby promoting a greater understanding and characterisation of degradation mechanisms and to use this information to proactively inform the design process.

1 Introduction

The ‘servitization’ of manufacturing organisations is well documented in the literature [1–3]. As organisations are exposed to the twin drivers of global competition and the requirement to provide sustainable solutions [4] relative to both product and process one sees the emergence of Product-Service Systems (PSS) and an alternative business paradigm [5–8]. This has seen the increasing requirement to develop aligned product support and asset management strategies which span the whole life-cycle of the manufactured product [9–12]. Underpinning all of these initiatives is the role of applied technology, systems, and data harvestings techniques which are used to acquire product condition, usage data, degradation status and mechanisms, and service history. The data acquired can then offer information relative to the product which if used appropriately can generate knowledge of use, failure, and required remaining ‘in service’ life.

Data obtained from Integrated Vehicle Health Management (IVHM) generic applications [13, 14], typically Condition Based Maintenance (CBM) [15–17], and Health and Usage Monitoring (HUMS) [18, 19], together with data which is, or could be obtained from the maintenance, repair, and overhaul (MRO) facilities within the service delivery system and infrastructure offers immense potential to improve the products availability for use throughout its life-cycle. Recognition of this is well documented in the ‘Asset Management’ (AM) [20–22], ‘Product life-cycle Management’ (PLM) [23–25] and the emerging ‘Through-life Engineering Services’ (TES) [26–28] literature.

This paper presents ongoing research which seeks to understand how service knowledge can be used to inform design thus enabling the reduction of mean time to failure thereby increasing product availability. To gain this understanding a case study method is applied centred on the design, manufacture and the service support of an aero-engine component, namely a high pressure nozzle guide vane (HPNGV).

2 Research Methodology

In seeking to gain a more comprehensive understanding of the role of service knowledge when used to inform design the research sought to identify a high value manufactured component which was part of complex assembly/product, which should it fail, would have a major impact to the assembly’s availability for use and thus revenue. Within the lens of manufacturing organisations who compete by offering high levels of service in support of their manufactured products (i.e. availability contracting) much is found within the literature relating to the aerospace sector. Typically gas turbines (aero-engines) manufactured by leading organisations (GE, Rolls Royce, and Pratt and Whitney) feature heavily as high risk items to the manufacturer’s revenue should they fail. To focus this study the High Pressure Nozzle Guide Vane (HPNGV) was selected as it is a complex product which exhibits a state of the art application relative to materials, design, and production/service methods (Fig. 1).

The aim of the research presented in this paper is to: define what is meant by design knowledge and service knowledge relative to through-life engineering services in the context of the through-life service support offered by OEM’s relating high pressure nozzle guide vanes, and to investigate the role of service knowledge as obtained during maintenance repair and overhaul (MRO) in informing the design of HPNGV’s thereby increasing the product’s availability for use.

In order to achieve the research aim several questions are presented which serve as way marks to achieving the aim. Namely:

-

i.

What is knowledge in the context of this research?

-

ii.

What is meant by design knowledge in the context of this research?

-

iii.

What is meant by service knowledge in the context of this research?

-

iv.

How can service knowledge obtained from the MRO function inform the engineering design content and process for the HPNGV?

In order to answer the questions proposed and thus achieve the research aim a three stage research programme is presented.

- Stage 1::

-

A review of the literature (Question 1–3)

- Stage 2::

-

To apply IDEF0 and IDEF3 modelling techniques to gain a thorough understanding of the ‘AS-IS’ condition for the whole life support of the HPNGV supplied by the host manufacturer (Question 3)

- Stage 3::

-

Presentation of how service knowledge may be used to inform design (Question 4)

The next section of the paper will review the literature relative to questions (way marks) posed from which definitions for design knowledge and service knowledge will be offered.

3 The Role of Data, Information and Knowledge in Support of Design: Literature Perspectives

With increasing levels of data being acquired from the aforementioned technical applications the importance of effective data, information, and knowledge management becomes increasingly apparent and the volume of data is becoming incalculable. This has led to a plethora of research initiatives with an emergent focus upon ‘Big Data’ [29]. The technology, manufacturing, and engineering sectors are no exception to this exponential growth in data generation and acquisition. Data however is just that, data. Of itself it is inert and has little use in its acquired form. It is only when data is reviewed and given context does it acquire value by being information, and ultimately through understanding, it becomes knowledge.

In seeking to understand the distinction between data, information, and knowledge one finds guidance from the literature. Reference [30] states that data is comprised of text and numbers whilst information is the alignment of the data to the context in which it was acquired [30]. Within service delivery systems and product MRO support functions the initial performance and degradation data from service activities and condition monitoring applications can be viewed as data. It is only when the data is aligned to the context from which it is acquired can it be termed information, and only once analysed does this information gain understanding and thus it becomes knowledge. It can be seen that a hierarchy of data, information, and knowledge exists which forms the building blocks for various levels of product support offered by way of a service delivery system. Typically this hierarchy is seen in the fields of Control Engineering, Systems Engineering, and Information and Knowledge Management Systems. It forms the basis of such technical support applications as Condition Based Management (CBM1) [31], Condition Based Maintenance (CBM2) [32, 33], and IVHM [34, 35] systems facilitated by the Open-System Architecture–Condition Based Management (OSA–CBM) framework [34, 36].

In consideration of the concepts identified the research questions (way marks) posed in the previous section of this paper emerge.

3.1 What Is Knowledge and How Is It Represented?

Much has been written in the literature relative to the definition, content, context and dimension of knowledge. Most contributions tend to be philosophical in nature rather than focusing on application. The authors have resisted the temptation to just adopt a definition, choosing to illustrate the grounding of the definitions offered in this paper. This section of the paper re-visits elements of the literature (not exhaustive) in order to develop definitions for ‘design knowledge’ and ‘service knowledge’. In seeking to address the questions posed the authors initially sought guidance from the Oxford English Dictionary which defines the concept as:

-

i.

“Facts, information, and skills acquired through experience or education; the theoretical or practical understanding of a subject.

-

(a)

The sum of what is known: the transmission of knowledge

-

(b)

Information held on a computer system

-

(c)

Philosophy, true justified belief; certain understanding as opposed to opinion

-

(a)

-

ii.

Awareness of familiarity gained by experience of a fact or situation” [Oxford English Dictionary]

Knowledge can be either tacit or explicit [30, 37]. Explicit knowledge can be articulated and codified by way of formal language which may be textual, numeric, and/or alpha-numeric [38]. This ability results in the capability to share knowledge content, context, and meaning with other sources without losing its integrity. This for the authors is critical to the process of servitization supported by product/asset condition and degradation knowledge. As manufacturing organisations move from offering base services, through intermediate level service provision, to advanced services offerings and availability contracting [39] supported by monitoring technologies [40] and MRO functions [41, 42], the ability to develop, store, and recall knowledge relative to product usage and performance becomes essential in order to deliver timely service response.

Tacit knowledge is the collection of understanding and experiences which reside within the individual person or entity as a collective. It comprises of two distinct elements. The technical component of such knowledge resides in the practical skills and product/process know-how which is employed in the understanding of tasks but is not codified. The second element of tacit knowledge is cognitive and is evolved from the beliefs and viewpoints of the individual and makes it difficult to codify and disseminate.

Information is defined as the flow of messages (data) which may have syntactic and semantic elements [43]. This is of particular importance when considering Information Retrieval Systems (IRS) which deal with the “searching, retrieving, clustering, and classifying the data, particularly text and other structured forms” [44]. Here such systems offer the semi-structured searching and clustering of text records based upon the classification of data. Reference [44] state that semantic retrieval systems identify and make sense of the data returned based upon the context to which the data refers by identifying the concepts which structure the text. The IRS do this by having ‘built in’ understanding of the ‘ability to learn’ syntax (how to say something) and the semantic (the meaning behind the text) [44].

Barons Business Directory defines syntax or (syntactic information) as relating to rules governing the information of statements within a programming language relative to computer science. It therefore facilitates the location, sharing, and combination of datasets thus enabling greater understanding and the derivation of knowledge. It is seen that information is the flow and exchange of data [45, 46] which facilitates the formulation of knowledge through the meaning of the data (message) and the mode and context in which it is acquired [43].

A further categorization of knowledge is that it is either ‘Declarative’ or ‘Procedural’ [47]. In the aforementioned categories it is seen that both tacit and explicit knowledge focuses upon the explanation of the concept of knowledge relating to its definition, transformation, dissemination, and application. For Zack [47] an alternative view is that of the application of knowledge. Here, declarative knowledge relates to the content of knowledge (the ‘know what’), whilst procedural knowledge relates to the processes required to use the knowledge (the ‘know how’). In addition a third element is found which is ‘Causal knowledge’ (the ‘know why’) [43]. For Mountney [43] causal knowledge refers “… to the underlying recognition of where it is appropriate to apply … . [the content] … . knowledge” [43]. Finally knowledge can be either, broad and easy to codify and thus disseminate, or specific with results in greater difficulty in codification due to lack of a common synta32 and/or domain.

All of these theories have strengths and weaknesses and the literature has many contributions that attempt to understand the comparisons and interactions to which the reader could refer. For the focus of this paper the authors suggest that each of the aforementioned lenses is equally valid and the choice of theory depends upon the aspect of the study. When seeking to understand the holistic nature and identity of knowledge and its application to industrial cases the research (and reader) should be fully aware of each of these dimensions.

3.2 Design and Service Knowledge and the Product Innovation Process

References [48, 49] propose that the effective use of knowledge is essential to the success of any organisation. Mountney’s [43] study on innovative manufacturing knowledge reviews how contributions to the literature relative to knowledge for innovation align with the theories discussed earlier. In observing the interaction of differing types of knowledge Mountney refers to the SECI model for the dynamic theory of knowledge creation (Fig. 2) [46].

The socialisation phase represents the knowledge transfer by face to face exchange and the sharing of mutual or collective experience (i.e. the craftsman and his apprentice). This knowledge exchange is difficult to formalise and is context specific. The second phase in organisational learning is the externalisation phase. Here tacit knowledge is typically codified and published by way of textual records, drawings and other means of recording, communicating and disseminating learning. When tacit knowledge is codified and made explicit it is crystallised and facilitates the sharing of its contents to third parties enabling new knowledge to be generated. The product design process is an example of this as ideas move through concept, initial design, feasibility analysis, to final design.

Combination is the third phase of knowledge creation. Here differing types of explicit knowledge is combined to yield new solutions and learning. In today’s operating companies this is typically facilitated by the use of computer based technologies and digital networks which offer large scale data bases. The advent of cloud computing and the issues of ‘Big Data’ offer immense opportunities and challenges in the field of organisation learning. Such explicit knowledge is harvested from many sources, processed and then disseminated throughout the host organisation. The final stage in the model is that of Internalisation. Explicit knowledge is received by the user and then applied. Quite simply it becomes part of the individual’s knowledge and experience and is then ready to be passed on in the next iteration of the model.

Technical (design and service support) knowledge is defined as “the knowledge associated in realising products and services” [50]. For Stokes [51] the requirement to “design and manufacturer for service is … essential … . ” and implied within their assertion are the benefits by way of increased service life (availability for use) that can be obtained when service knowledge becomes an input to the design process, thus enhancing design knowledge.

Design knowledge can be classified as having two dimensions, namely

Product knowledge includes geometric modelling techniques (CAD systems and simulation packages) which can support the detailed design of the product, whilst knowledge modelling (capture and dissemination of what is known) is used when developing designs from concept to detail. In contrast, Design Process Knowledge is also described as existing in two levels

-

i.

design activities, and

-

ii.

design rationale [52].

Typically design activities for a given product are requirement and specification specific, and are represented and guided by coded procedure (explicit/declarative/procedural knowledge) and the experience of the designer (tacit/causal knowledge). The design rationale is informed by the collective body of knowledge and understanding of the collective (stakeholder requirements, standard practice, legislation, standards, knowledge of use, knowledge of failure and degradation, and methods of repair).

When considering design knowledge for any product is also relates to three primary attributes of the product

-

i.

“the physical layout of the product (form)”,

-

ii.

“the function of the product and the effect of that function”,

-

iii.

“the causal effect of the use of the function of the product (behavior)” [52]

In consideration of these attributes relating to design knowledge the following definition is offered which seeks to cover the full scope of the concept.

Design knowledge is the summation of understanding relative to product form, function, and the causal effect of a products usage, supported by both explicit and tacit knowledge which can be either declarative or procedural, and an understanding by feature and/or attribute of the modes of manufacture, mechanisms of degradation and failure, and modes of repair.

The research aim seeks to investigate how service knowledge may be used to inform design. In so doing a definition of service knowledge is required. Again the Oxford Dictionary is consulted to understand what is meant by service within the context of this work. Upon review it is found that ‘service’ in this context is defined as the act of “… perform[ing] routine maintenance or repair work on a … . [product/asset] …”. Clearly to undertake such an undertaking there is a requirement for knowledge and understanding as to the mode of use, mechanism of degradation, cause and effect of such degradation supported by route cause analysis of the failure, supported by knowledge and understanding of the mode of repair. It is important to note that to conduct a service activity is to change the state of the component. This can be either physically (by restoring original condition), or/and improving the operational life (increasing the mean time before failure (MTBF)). In acknowledging these elements of service activities the following definition for service knowledge is offered which is grounded in the literature.

Service knowledge is the ability to initiate a change of state in a product or asset, facilitated by the awareness of the current condition of that product or asset, its historical usage, and the means of restoring the ‘as designed’ functionality supported by explicit (codified) and tacit knowledge of the degradation and failure mechanisms of that component.

4 The Requirement for a Formal MRO Knowledge Capture, Storage, and Retrieval System to Inform Design for High Pressure Nozzle Guide Vane

Having offered reviewed the definition for ‘knowledge’, and offered definitions for ‘design knowledge’ and ‘service knowledge’, which are both grounded in the literature the research sought to gain understanding of the state of the art relative to service knowledge informed design. To gain such understanding will ultimately require sector and industry based cross-sectional and longitudinal case studies informed by a pilot study. In order to develop greater understanding of the required content, drivers, and inhibitors of service knowledge informed design, a pilot exploratory case study was carried out with an aerospace OEM manufacturing HPNGVs.

The first stage was to understand the ‘AS-IS’ condition of the ‘through-life’ cycle process which included design, manufacture and service support for the chosen part. Following direct observation, semi-structured interviews, informal discussions, and document audit (route and process data sheets) functional and knowledge models were constructed in IDEF0 and IDEF3 formats respectively [52]. A typical section of the IDEF0 model is shown in Fig. 4. Whilst the full details of the IDEF models are not reported within this paper the work highlighted that the ‘AS-IS’ position relative to service knowledge feedback to design was not integrated by default within the case study organisation.

First level decomposition of IDEF0 diagram for design, manufacture, and service support of HPNGV [52]

Upon examination of the design sections of the models it was observed that the design process is split into three sections

-

i.

concept stage,

-

ii.

preliminary design stage,

-

iii.

full designs accompanied by Bill of Materials (BOM), Bill of Process (BOP) and relevant data sheets.

It is observed that there is significant input from the manufacturing function (example section shown in Fig. 5) into all stages of the design process which takes the form of codified and tacit knowledge with all elements of the design knowledge model (Fig. 3) being easily identifiable. However, the same was not observed when considering the service knowledge feedback into the design of the product. Whilst there is a plethora of evidence to illustrate that service data is being gathered by the MRO functions (Fig. 6), upon discussion with the commodity design team there appeared to be no default position adopted by all, whereby the design process was directly informed by the service data (and subsequent knowledge) as a default definition of the design process (i.e. stage gate control). In contrast to the manufacturing inputs, service inputs (knowledge) were, whilst supported by the engine manuals for the generic engine sets, limited to key performance parameters which were both explicit and tacit in nature.

Partial fourth level decomposition intermediate design stage of IDEF0 diagram for design, manufacture, and service support of HPNGV [52]

This observation is supported by the organisation’s own internal review findings and formed the justified rationale for the selection of the case study.

5 Discussion

In reviewing the MRO functions for the chosen aero-engine component it is observed that the procedures and systems are well defined and advanced in content and application. The IDEF3 modelling activities illustrate that from component receipt by the MRO facility, through sentencing, repair, and refit, there are much data collected, trended and stored. The authors suggest that this is typical of most OEM’s manufacturing complex engineering products. However when seeking to understand the feedback mechanism and content of service acquired knowledge to design developments are not so established or mature.

The typical MRO function within a service delivery system possesses both explicit and tacit knowledge relative to mechanisms of failure, repair technologies and methodologies, and ‘lifing’ decisions. Upon receipt of HPNGVs the maintenance subjects the component to various dimensional, visual, and non-destructive techniques (typically X-ray and Die Penetrant tests) from which the results (data) are recorded in line with written procedures, standards, and requirements as directed by statutory authorities. Such data is often input into various analytical software tools (e.g. FRACAS) so as to offer trend data (and information) by way of PARETO analysis and WEIBULL data. Whilst these initiates offer information relative to frequency of occurrence and the information (and occasionally knowledge) reported via SAPP and PLM software portals, seldom is the technical and engineering knowledge relating to failure modes and the ‘cause and effect’ parameters affecting the component’s degradation mechanism fed back into the design process by default.

Typically in components of generic design and particularly when produced by a single manufacturer, such components (ref HPNGVs) are the sum of standard features which are imported into the design around common reference planes only to then be connected by defined ‘filleting’ through the use of ‘Non-Uniform Rational B-Spline’ (NURBS) applications. In doing this, there is the risk of ‘carrying over’ design faults and degradation mechanism which exist at the feature level from one engineering issue level to the next. This results in continuing failed components presenting due to ‘engineered in’ degradation mechanisms which may have been eliminated if only the ‘voice’ of the service function was given equal consideration to the design process from conceptual stage to issue of final designs.

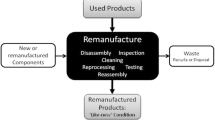

There are many ‘off the shelf’ software platforms that can be applied to the problem but they all rely on the correct ontology and taxonomy relative to failure/degradation event/mechanism—the problem of applying the correct and a standard set of definitions, language and syntax throughout the service delivery system. When seeking to establish this all too often does the solution base itself on codified (explicit) standard data. Upon visit to the asset by the service engineer, or presentation of the component to the MRO facility, a standard engineer’s report (or component inspection report) is completed which has pre-defined fields for the input. These fields are dependent upon the correct descriptors being identified and entered. Additionally, one often finds a section of the report in which the engineer/inspector is allowed to enter ‘free text’ into the field describing the failure mode, degradation mechanism, usage data, and or repair process applied or decision to scrap. This is a rich source of data (information and knowledge) which is seldom mined. In the case of an established OEM the amount of data that it holds can be substantial and an inhibitor to analysis. How much better would it be if a system which was self-learning (descriptions, ontologies, etc.) based upon actual inputs from text data which could inform the design process was developed. The final goal of the research programme is the development of such a system. This paper reports the vision and rationale of the undertaking and sets the initial prototype specification for such development (Fig. 7).

When reviewing the figure it can be seen that as the component arrives at the MRO facility data from inspection, observation, and sentencing activities is acquired. By applying software analytics by way of trending tools (FRACAS, RCI, and DFMEA) information and knowledge becomes available for use by the service support and design functions. Such data and information recording forms both the explicit and tacit knowledge asset base of the organisation and through effective system architectures which enable capture, storage, and easy retrieval by the service and design functions can assist in knowledge based learning. Parallel research is currently being undertaken to develop knowledge based learning by way of ‘Term Recognition Software’ and supporting algorithms which can collect data from text rich qualitative data contained within service reports, and by ‘self-learning’ differing descriptors and ontologies for the same degradation mechanisms, offer enhanced knowledge to the overall experience base repository.

The benefit of such a system is clear. The development and application of such a system architecture offers the potential for a single point search for all those who have access to the system. The designer would be able to enter the product he wishes to design (HPNGV) and then the feature (RODN Holes–Fig. 1) and by doing so would be able to get full state-of-the-art knowledge relative to the performance, failure mode, degradation mechanism, and ‘life’ considerations (cost etc.) when adding the feature to the component design. In the servitized world of the 21st Century where consideration has to be given to global commercial and environmental pressures, the importance of component life and therefore the product’s availability for use cannot be overstated.

6 Conclusions

This research seeks to understand, develop, and enhance the role of maintenance, repair and overhaul knowledge in facilitating service led design for gas turbine high pressure nozzle guide vanes. In seeking to define what is meant by service knowledge the research posed several research questions which would act as waymarks towards meeting the research aim. In addressing these questions and after consulting the literature for a definition for ‘knowledge’, definitions for ‘design knowledge’, and ‘service knowledge’ are offered which are grounded in the literature. The research uses this understanding (definitions) and by use of a case study identifies the ‘AS-IS’ condition relative to the use of service knowledge to inform the design of a selected complex manufactured component for an aero engine. This service knowledge assists in the definition of a system architecture (framework) to deliver for a ‘design for service’ prototype solution facilitating greater whole-life component availability, reduced costs due to downtime, and potentially lean logistics

This work has formed the exploratory stage of a larger research programme which seeks to develop systems and algorithms which have the ability to apply ‘usage’ and ‘maintenance’ knowledge thereby promoting a greater understanding of the characterisation of component feature based degradation mechanisms, and the use of this information to proactively inform the design process. The work has further defined design and service knowledge aligned to the focus of the study. Future research initiatives will include the data-mining of text rich qualitative maintenance data in support of codified explicit service knowledge and through the application of novel analysis and synthesis methods, the knowledge gained will be used to inform an design through a developed integrated system architecture.

References

Vandermerwe S, Rada J (1988) Servitization of Business: adding value by adding services. Eur Manage J 6(4):314–324

Neely A (2008) Exploring the financial consequences of the servitization of manufacturing. Oper Manage Res 1:103–118

Baines TS, Lightfoot HW, Benedettini O, Kay JM (2009) The servitization of manufacturing: a review of literature and reflection on future challenges. J Manuf Technol Manage 20(5):547–567

Stiassnie E, Molcho G, Shpitalni M (2009) Holistic design of sustainable systems with improved lifecycle performance: Paper No. ESDA2008-59207. ASME 9th Biennial conference on engineering systems design and analysis. Design, Tribology, Education. Haifa, Israel. 7–9 July 2008. Vol 3 pp 111–119

Mont O (2000) Product service systems 2000; Final Report for IIIEE, Lund University, Lund

Tukker A, Tischner U (eds) (2006) New business for old Europe—product-service development, competitiveness and sustainability. Greenleaf Publishing Ltd, Sheffield

Tukker A, Tischner U (2006) Product-services as a research field: past, present and future. Reflections from a decade of research. J Clean Prod 14(17):1552–1556

Baines TS, Lightfoot HW, Evans S, Neely A, Greenough R, Peppard J et al (2007) State-of-the- art in product-service systems. Proc Inst Mech Eng Part B J Eng Manuf 221:1543–1552

Meier H, Roy R, Seliger G (2010) Industrial product service systems—IPS2. CRIP Ann Manuf Technol 59(2):607–627

Ponsignon F, Smart PA, Maull RS (2012) Service delivery systems: a business process perspective. http://edututors.info/view/d3d3LnBvb32Mub3JnL2NvbmZlcmVuY2VzL2NzbzIwMDcvdGFsa3MvNDQucGRm/service-delivery-systems-a-business-process-perspective-f.html. Accessed 26 March 2012

Charns MP (1997) Organization design of integrated delivery systems. Hosp Health Serv Adm 42(3):411–432

Roy R, Shaw A, Erkoyuncu JA, Redding L (2013) Through-life engineering services. Meas Control 46(6):172–175

Jennions IK (ed) (2011) integrated vehicle health management: perspectives on an emerging field. SAE International, Warrendale

Benedettini O, Baines TS, Lightfoot HW, Greenough RM (2009) State-of-the-art in integrated vehicle health management. Proc Inst Mech Eng Part G J Aerosp Eng 223(No 2/2009):157–170

Gulledge T, Hiroshige S, Iyer R (2010) Condition-based maintenance and the product improvement process. Comput Ind 61(9):813–832

Kurfess TR (2007) Detecting trouble early with CBM. Control Eng 54(7):36

Holguin L (2005) IEEE. Conditioned based maintenance (CBM). Autotestcon 2005:188–193

Parker S (2011) IHUMS and real results: a case study from the UK. In: Jennions IK (ed) Integrated vehicle health management: perspectives on an emerging field warrendale. SAE Int, PA, pp 125–140

Land JE (2001) IEEE, IEEE. HUMS—The benefits—Past, present and future. In: 2001 IEEE Aerospace conference proceedings, vols 1–7, pp 3083–3094

New PHM Techniques and Trends for Asset Life Cycle Management (2012) Proceedings of the 1st international conference on through-life engineering services: enduring and cost-effective engineering solutions

Kumar S, Kruth J, Van Humbeeck J, Voet A (2009) A study of degradation of laser-sintered moulds using wear tests. Rapid Prototyp J 15(2):104–110

Banks J, Merenich J (2006) IEEE. Cost benefit analysis for asset health management technology. In: 2007 proceedings of the annual reliability and maintainability symposium, pp 95–100

Liping Z, Jun W, Pingyu J, Yongtao Q (2008) Service design for product lifecycle in service oriented manufacturing. Intelligent robotics and applications. In: Proceedings first international conference, ICIRA 2008, Jan 2008

Teresko J (2005) Building PLM’s potential [product lifecycle management]. Industry Week 2005, vol 254, issue 8

Stark J (2011) Product lifecycle management: 21st century paradigm for product realisation, 2nd edn. Springer, London

Roy R, Shehab E, Hockley C, Khan S (eds) (2012) Proceedings of the 1st international conference on through-life engineering services: a. Enduring and cost-effective engineering support solutions. Cranfield University, Cranfield, Bedfordshire

Through-life Engineering Services Standards Development (2012) Proceedings of the 1st international conference on through-life engineering services—enduring and cost-effective engineering support solutions

Identifying the Challenges in Through-life Engineering Services (2012) 1st International conference on through-life engineering services: enduring and cost-effective engineering support solutions

Manyika J, Chui M, Braun B, Bughin J, Dobbs R, Roburgh C et al (2011) Big data: the next frontier for innovation, competition, and productivity. http://www.mckinsey.com/insights/business_technology/big_data_the_next_frontier_for_innovation. 2013

Young B, Cutting-Decelle AF, Guerra D, Gunendron G, Das B, Cochrane S (2005) Sharing manufacturing information and knowledge in design decision support. Advances in integrated design and manufacturing in mechanical engineering, Springer, Netherlands, pp 173–185

Chatterjee SK (2008) Condition-based maintenance management: enhances reliability. Chem Eng 115(12):46

Greenough RM, Grubic T, Modelling condition-based maintenance to deliver a service to machine tool users. Int J Adv Manuf Technol 2011 FEB 52(9–12):1117–1132

Staller C., Condition based maintenance—what is its condition? http://www.mimosa.org. Accessed Feb 2009

Poll S, Iverson D, Patterson-Hine A (2003) Characterization of model-based reasoning strategies for use in IVHM architectures. Syst Diagn Prognosis Secur Cond Monit Issues Iii 5107:94–105

Embedded Reasoning Supporting Aerospace IVHM (2007) AIAA Infotech aerospace 2007 CONFERENCE and Exhibit. American Institute of Aeronautics and Astronautics, 7–10 May 2007

Redding LE (2011) An introduction to integrated vehicle health management—a perspective from literature. In: Jennions IK (ed) Integrated vehicle health management: Perspective on an emerging field warrendale. SAE International, PA, pp 17–26

Polanyi M (1966) The tacit dimension. Doubleday, New York

Easterby-Smith M, Lyles MA (eds) (2011) Handbook or organizational learning and knowledge management, 2nd edn. Wiley, New York

Baines T, Lightfoot H, Peppard J, Johnson M, Tiwari A, Shehab E et al (2009) Towards an operations strategy for product-centric servitization. Int J Oper Prod Manage 29(5):494–519

Anon (2012) GE’s IVHM technology for business aviation. https://www.youtube.com/watch?v=bSbReXT_bBs. Accessed 06 Jan 2012

Ramudhin A, Paquet M, Artiba A, Dupre P, Varvaro D, Thomson V (2008) A generic framework to support the selection of an RFID-based control system with application to the MRO activities of an aircraft engine manufacturer. Prod Plan Control 2008 19(2):183–196

Jackson C, Mailler B (2013) Post-servicing failure rates: optimizing preventive maintenance interval and quantifying maintenance induced failure in repairable systems. New York; 345 E 47TH ST, 10017 USA: IEEE; 2013

Mountney (2009) Acquisition and shaping of innovative manufacturing knowledge for preliminary design. Cranfield University, Cranfield, Bedfordshire

Gupta S, Garg D (2011) Comparison of semantic and syntactic information retrieval system on the basis of precision and recall. Int J Data Eng 2(3):93–101

Nonaka I (1994) The dynamic theory of organizational knowledge creation. Organ Sci 5(1):14–37

Nonaka I, Toyama R, Konno N (2000) SECI, Ba, and leadership: a unified model of dynamic knowledge creation. Long Range Plan 33:5–34

Zack MH (1999) Managing codified knowledge. Sloan Manag Rev 40(4):45–58

Grant RM (1996) Prospering in dynamically-competitive environments: organizational capability as knowledge as knowledge integration. Organ Sci 7(4):375–387

Grant EB, Gregory MJ (1997) Tacit knowledge, the lifecycle and international manufacturing transfer. Technol Anal Strateg Manag 9(2):149–162

Bohn RE (1994) Measuring and managing technological knowledge. FALL Magazine, October 15. http://www.sloanereview.mit.edu/article/measuring-and-managing-technological-knowledge/. Accessed May 2014

Stokes M (2001) Managing engineering knowledge: MOKA methodology for knowledge based engineering applications. MOKA Consortium, London

Szykman S, Sriram RD, Regli W (2001) The role of knowledge in next generation product development systems. ASME J Comput Inf Sci Eng 1(1):3–11

Acknowledgment and Funding

This research is funded by the Through-life Engineering Services based at Cranfield University which in turn is funded by the UK Engineering and Physical Sciences Research Council

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Redding, L.E., Hockley, C.J., Roy, R., Menhen, J. (2015). The Role of Maintenance, Repair, and Overhaul (MRO) Knowledge in Facilitating Service Led Design: A Nozzle Guide Vane Case Study. In: Amadi-Echendu, J., Hoohlo, C., Mathew, J. (eds) 9th WCEAM Research Papers. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-319-15536-4_31

Download citation

DOI: https://doi.org/10.1007/978-3-319-15536-4_31

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-15535-7

Online ISBN: 978-3-319-15536-4

eBook Packages: EngineeringEngineering (R0)