Abstract

Physicochemical effect on the corrosion process of API X60 steel exposed to five types of soils from south of México at different moisture content was carried out. Two soils were collected in the state of Veracruz (clay of high plasticity and silt) and three soils from the state of Campeche (clay, sand, and clay-silt). Moisture values were determined by addition of 0, 20, 40, and 60 mL of deionized water in a volume of 125 cm3 of each soil. Physicochemical effect of the different soils on the corrosion process of X60 steel was evaluated through electrochemical impedance spectroscopy (EIS) and potentiodynamic polarization curves (PCs). Effect of the damage on the coating when the steel is exposed to corrosive soils was studied. The three more corrosive soils (clay, sand, and clay-silt) were used to evaluate the corrosion behavior with a viscoelastic coating with a simulated damage. The higher corrosion rate obtained from polarization curves for uncoated X60 steel was found in the clay (0.379 mm/year) with 39.7 wt.% of moisture content. Steel coated with a simulated damage indicates that the clay-silt (52.3 wt.%) was the most aggressive soil for X60 steel (0.0029 mm/year).

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- X60 steel

- Soils

- Corrosion

- Electrochemical impedance spectroscopy (EIS)

- Potentiodynamic polarization curves

1 Introduction

External corrosion and stress corrosion cracking (SCC) phenomena are the main deterioration mechanism of the buried pipelines. The origin of these damages is due to coating failure and inefficient cathodic protection, which can reduce the structural integrity of buried pipelines. To preserve the external integrity, pipeline systems are designed and built with two protection systems: one physical (coating) and other electrochemical (cathodic protection) that can be performed by impressed current or sacrificial anodes.

The various phenomena that damage the external surface of pipelines are developed in a complex process, mainly due to the heterogeneity of the soils [1]. The corrosivity of a specific soil generally is determined by soil type, moisture content, soil resistivity, soluble ion content, pH, oxidation–reduction potential, and the role of microorganism in the soil. Soil properties depend on soil particle size distribution, organic content, mineralogical composition, structure and moisture content, that all of them can change inclusive at short distances. There are some mathematical models that use physical parameters measured in field, such as resistivity, pH, redox potential, and level of cathodic protection, to determine the corrosion susceptibility of pipelines [2]. The model is based upon the concept that damage evolution is an irreversible process. These models provide general guidance for materials selection and for the location and design of underground pipelines.

Deterioration by external corrosion in buried pipelines occurs due to formation of corrosion cells between the metallic structure and the soil [3, 4]. The severity of this deterioration is determined by the level of environmental corrosivity. The investigation and studies on SCC originated by the soils in the current days have become of interest in the oil industry and for the researchers in the area of the preservation of materials. SCC can develop in pipelines under normal operating condition when a coating disbonded and groundwater comes into contact with the outside surface of the pipe.

The concern with the environment is very important and a better understanding of the soil as a corrosive agent becomes necessary to optimize the cathodic protection systems in the pipelines. Steel pipelines corrode in soil by complex electrochemical processes because of a different soil electrolytes nature. The corrosion process of X60 pipeline steel using various aqueous solutions representatives of a one type of soil has been developed [5]. As well as some SCC studies using the X60 steel have been developed [6–10]. On the other hand, some studies about mechanical and environmental effects on SCC of low carbon pipeline steel in a soil were carried out [11]. The electrochemical impedance spectroscopy (EIS) results showed that the highest corrosion of the steel sample was obtained when the highest cathodic over potential was applied. Corrosion phenomena are accentuated by the influence of soil parameters such as resistivity, pH, temperature, moisture content, and chemical composition of electrolytes contained in the soil.

It was found that the presence of hydrogen in the steel changes the fracture mode, passing from the microvoid coalescence to quasi-cleavage, accelerating the fracture process [11]. The non-metallic inclusions in the steel act as trap sites of hydrogen. When a critical concentration of hydrogen is reached the crack propagates, following a transgranular path due to the embrittlement of the steel.

Studies associated with the effect of temperature on corrosion process of carbon steel in contact with saline soils and solutions representative of soils suggest that the effect of depth and type of soil are relevant factors to activate the oxidation of steel [12–14]. Some studies use different representative aqueous solutions of soils that are in contact with metal surfaces in a particular geographical area [5, 15], which are used for the characterization of the external corrosion process in different carbon steel. In this study we use directly the collected samples of soil as a corrosive environment. The synthetic solutions of soils do not correspond to the environmental systems of all the types of soils in each geographic region and environmental conditions. Due to the soils diversity that exist in México, this work is proposed to use the EIS and PC to study the corrosion behavior of the API X60 pipeline with and without coating in contact with five different soils types with different moisture content. Two soils were collected in the state of Veracruz and three soils from the state of Campeche in México.

2 Experimental

2.1 Steel Used

The steel sample used as working electrode was made of API 5L X60 pipeline steel with 42 in. (106.6 cm) in diameter and 0.5 in. (1.27 cm) in thickness. Table 11.1 shows the chemical composition of this steel.

Some of the most important mechanical properties for the API X60 pipeline steel are shown in Table 11.2.

The working electrodes for the electrochemical techniques were machined to obtain steel plates with 2 × 2 × 0.5 cm. The working electrode was mechanically polished up to 600 grit SiC paper, cleaned, and degreased with acetone prior to perform the tests.

2.2 Soils Characterization

Physicochemical and electrical properties of the soils collected in the south of México were characterized. Two soils were collected in Veracruz State and three soils in Campeche State in México. These soils were characterized as was found in the field, after they were prepared in lab. First the soils were dried at 60 °C for 3 days, after that the soils were subjected to grinding in order to homogenize the particle size. Subsequently, a constant volume of 125 cm3 sample of each dried and sieved soil was selected. Then in each soil sample different volumes of deionized water were added (0, 20, 40, and 60 mL), in order to dissolve soluble salts and other ionic species. Subsequently, the physicochemical properties were determined again. Thus, moisture content was determined according to ASTM D4959 [16], using a furnace to dry the soils at 110 °C during 1 h. Redox potential was evaluated according to ASTM G200 [17], as well as using an Ag/AgCl electrode redox potential and pH was measured directly in the soil samples.

2.3 Electrochemical Evaluations

Electrochemical tests were performed in a cell of acrylic as is shown in Fig. 11.1. Steel plates with 1.13 cm2 of total exposure area from API X60 steel were used as working electrode (WE); a graphite rod was used like the auxiliary electrode (AE); a saturated calomel electrode (SCE) as the reference electrode (RE). API X60 steel samples were exposed to the five soils and it was evaluated by EIS and potentiodynamic polarization curves (PCs). The impedance spectra were performed in the frequency range of 10 kHz–10 mHz with an amplitude of 10 mV, recording ten points per frequency decade. Potentiodynamic polarization curves were recorded at sweet rate of 0.001 V/s and the polarization potential range used was ±0.3 referred to E corr. Electrochemical evaluations with samples uncoated and coated with a Potentiostat–Galvanostat were carried out. Samples were coated with a viscoelastic polymer. The coating has a mechanical damage around 0.3 cm in diameter (0.282 cm2 exposure area).

3 Results and Discussion

3.1 Microstructure of the Steel Used

The API X60 steel microstructure consisted of fine pearlite and ferrite with a grain size around 10–15 μm as is shown in Fig. 11.2. Low carbon steels tend to have a ferrite–pearlite structure containing little pearlite in the grain boundaries mainly. In addition, some globular inclusions containing Mn, S, and Al were observed. It is important to point out that the inclusions are considered as preferred locations for corrosion initiation sites or propagation of pre-existing defects [6–8, 11].

3.2 Physicochemical Characterization of the Soils

Figure 11.3 shows images of the five soils collected in south of México. Two soils were collected in the state of Veracruz (clay of high plasticity and silt) and three soils from the state of Campeche (sand, clay, and clay-silt). As can be noted, the soils present colorations and particle size different, which could be associated with changes in the physicochemical properties.

Table 11.3 shows the physicochemical properties of the soils measured in field directly (0 wt.% of water added) and the properties after 20, 40, and 60 mL of water added. Table 11.3 presents the values of moisture, pH, redox potential, and geographical location of the five soils collected in southern México. The soils evaluated in field show that the moisture content was highest in the clays.

After measurements of the physicochemical parameters of the soils under field conditions (0 wt.% water added), the samples were dried and grinded in order to sieve to have a particle size more homogeneous. From these soils was took 125 cm3 of each soil and was added 20, 40, and 60 mL of deionized water and again physicochemical parameters were measured. The results of these measurements are shown in Table 11.3. Each type of soil absorbs different amount of water. It is observed that most of the soils from the state of Campeche have near neutral pH; soils obtained from Veracruz have pH values with acid trend. The clay from Campeche (Clay-C) provides the maximum value of redox potential (−411 mV) and moisture of 20.35 wt.%. This indicates that the clay should act as real ionic conductor and its behavior could affect metal oxidation.

The moisture, pH, and redox potential presented in Table 11.3 show the complexity of physicochemical phenomena that provide the soils when they are subjected to the presence of water, which indicates that this variation significantly affects the coating and consequently corrosion process of steels.

3.3 Corrosiveness of the Soils Analyzed by EIS

Figure 11.4 shows the Nyquist plots obtained for X60 steel exposed to the five types of soils at the maximum water content added. This figure shows that the X60 steel is susceptible to corrosion in these soils. It is important to point out that the impedance spectra were fitting by a simple equivalent electric circuit. According to this it is possible to say that the corrosive effect of soils is as follows: Clay-C>Sand-C>CS-C>Silt-V>CHP-V.

The lowest resistance values correspond to Clay-C and the highest resistance values correspond to CHP-V. This behavior indicates that the corrosion rate (CR) of the X60 pipeline steel is more aggressive in Clay-C than other soils. It is important to point out that the impedance spectrum corresponding X60 pipeline steel in sand of Campeche (sand-C) presents an inductive loop, which it can be associated with the film adsorbed on surface steel. The solution resistance (R s, or conductivity of the soil) in Silt-V and CHP-V is really affected because the values of these R s are high. This behavior should be attributed to the low concentration of salts in the soils, for that reason they are poor ionic conductors and consequently the CR of the pipeline steel decreased. In addition, two time constants are possible to observe in these soils, where the time constant at low frequency is attributed to the charge transfer resistance and at high frequency is attributed to the transfer of the oxygen through of the soil.

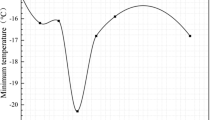

3.3.1 Effect of Moisture Content on Soils

In order to get a better analysis of the soils corrosion on the X60 steel, a depth analysis of the most aggressive soil (Clay-C) was carried out. Figure 11.5 shows the impedance spectra of the X60 steel exposed to Clay-C at three moistures content. It is important to note that the electrochemical phenomenon of Fig. 11.5 reveals the complexity of corrosion process in steel. Because the clays behave as ionic conductors in presence of water, but when the water begins to evaporate (low humidity), this soil will probably not permit the flow of current cathodic protection. In field, this phenomenon could be dangerous because dry clay does not allow adequate cathodic protection, however, when the clay changes from dry to wet clay, it could cause an over potential that would harm the coating and anode beds.

In Fig. 11.5 it is possible to observe that the highest values of real and imaginary impedance for the X60 exposed to Clay-C corresponding to 20.35 wt.% of moisture, this fact indicates that at this moisture, the corrosion rate is low, may be attributed to the soil resistance that limited the corrosion process. However, the moisture value of 39.71 wt.% in the clay activates the corrosion process due to low impedance values.

3.3.2 Effect of Coating

The underground pipelines are protected by two forms, one mechanical barrier with a coating and the other electrochemical with galvanic anodes or impressed current. However, there is a high probability of finding damages on the coating with different geometry and morphology (by mechanical damage, bad application or degradation). For that reason it is useful to understand the effect of the damage on the coating when the steel is exposed to a corrosive soil. Thus, were selected the three more corrosive soils (Clay-C, CS-C, Sand-C) to carry out electrochemical evaluations and study of the corrosion process on X60 pipeline steel. Plates from X60 steel were coated and, one damage on the coating was produced (0.3 cm in diameter) prior to electrochemical assessment. The EIS spectra were obtained after X60 steel was exposed 30 days to the soils.

Impedance spectra obtained for X60 steel coated with a commercial coating exposed to the three soils from Campeche are shown in Fig. 11.6. In this figure it is possible to observe that X60 steel is more susceptible to corrosion when it is exposed to CS-C. It is important to mention that the electrochemical phenomena shown in these curves are associated with the response of the induced damage area. Thus, considering the defect on the coating has the same area, the electrochemical changes are attributed to the damage and the loss of the coating adherence due to the presence of these types of soils, so the coating causes different type of corrosion forms likely pitting and crevice corrosion.

3.3.3 Quantitative Analysis of EIS Spectra

In order to carry out a quantitative analysis of the impedance spectra, an adjustment of the experimental data was performed by means of equivalent circuits and the program nonlinear least squares fit of Boukamp [18]. Due to the existence in the majority of the spectra of at least a semicircle, for adjustment of the experimental data an equivalent circuit of a single time constant R s (R ct C EDL) was used, where R s is the resistance associated with the conductive properties of soil used, R ct is the charge transfer resistance, and C EDL is the capacitance associated with the electrical double layer. The capacitance values shown in Table 11.4 for the properties of the electric double layer were calculated using Eq. (11.1) [19, 20]:

It is known that depending on the value of capacitance, the active area of the metal is changed [18]. The capacitance assessment (C) was carried out in function of the area (A), charge (q), the dielectric constant (ε), the disturbance voltage (E), and the spacing between the parallel flat plates as described in Eqs. (11.2) and (11.3), where C i is the capacitance value of an i (μF) system; ε o is the vacuum dielectric constant (8.85 × 10−14 F cm−1); ε i is the dielectric constant of the i system; A and δ correspond to the area and thickness; dq is the change of the charge (Coulomb); dE is the change in potential (Volts).

If the charge transfer properties retain the same value ε, then the next analysis is carried out:

-

If R ct is high, then C EDL is low

-

If R ct is low, then C EDL is high

This indicates that a greater charge transfer resistance (R ct) a lower contribution of C is generated, indicating the existence of a lower electrochemical activity in the electrical double layer and a suitable electric field oriented in the steel–soil interface, which control the corrosion process. The greater value of C indicates a greater corrosion due to a lower contribution of the charge transfer resistance in the steel–soil interface.

Table 11.4 shows the values of the electrical parameters obtained by the best fit of the experimental data obtained from the X60 steel exposed to the five soils. According to this table it is observed that X60 steel is more susceptible to corrosion in Clay-C with R ct = 371.78 Ω cm2 at a moisture content of 39.71 wt.%. While C EDL values associated with faradaic charge transfer on the Steel Surface indicate that corrosiveness of X60 steel is in the following order: Sand-C, Clay-C, CS-C, Silt-V and finally CHP-V.

3.4 Polarization Curves for Uncoated Steel

Figure 11.7 shows polarization curves obtained for X60 steel exposed to five soils studied at maximum moisture content (adding 60 mL of deionized water). In this figure, it is observed that in all PCs of the X60 steel samples, the anodic branches have high slopes. This behavior indicates that the oxidation reaction (charge transfer polarization) is influenced by a mass transfer process; it is attributed to the wet soil adsorbed on surface of the steel samples. On the other hand, the cathodic branches in all PCs have high slopes too. This fact indicates that a diffusion process also influenced in the cathodic reaction. According to the behavior observed in the PCs it is possible to mention that the corrosive effects of each soil are in the following order: Clay-C>CS-C>Sand-C>Silt-V>CHP-V.

The electrochemical responses in the qualitative analysis show that there are at least three types of soils those are corrosives to steel, these are the soils from Campeche. Furthermore, it is well known that the external surfaces of the buried steel pipeline often are exposed to different environmental conditions that may change the corrosiveness of the soils.

3.4.1 Quantitative Analysis of PCs

Table 11.5 shows the corrosion rates values obtained from polarization curves for X60 steel exposed to saturated soils (Fig. 11.7). From these results it is observed that X60 steel is more susceptible to corrosion in Clay-C with a corrosion rate of 0.3796 mm/year; followed by CS-C (0.3475 mm/year), Sand-C (0.3013 mm/year), Silt-V (0.2700 mm/year), and finally the CHP-V (0.1813 mm/year).

The qualitative and quantitative analyses show the complexity of the corrosion process of steels in soils, because each type of soil has different physicochemical properties, such as color, pH, redox potential, corrosion potential, particle size, ions and moisture retention, which must be considered in electrochemical assessment.

3.5 Polarization Curves for Coated Steel

Figure 11.8 shows potentiodynamic polarization curves obtained for X60 steel coated with a viscoelastic polymer having a simulated damage and exposed to three soils from Campeche at maximum moisture content (adding 60 mL of water). The clay-silt has a greater retention of water (52.3 wt.%) due to the physicochemical properties [19, 20]. In addition, this type of soil increases the current values in the branch of the anode and cathode, respectively. This behavior suggested that the CS-C is more corrosive than Sand-C and Clay-C for the X60 steel. It is important to mention that the anodic branches for the X60 steel in the three soils have slopes that belong at not pure charge transfer process. It is to say, a passivation process is influenced in the oxidation reaction of the X60 steel corrosion. It is important to point out that the anodic branches also have a slight decrease in the value of the oxidation current of about 100–120 mV from E corr, then after these potential values is observed a significant increase in the current response. The slight decrease in current indicates that the formation of corrosion products and the wet soil absorbed on surface of the steel could have produced a passivation behavior that it can have limited the charge transfer between the steel-coating-soil. In addition, the cathodic branches show the contribution of the diffusion process overall in the CS-C soil.

3.5.1 Quantitative Analysis of PCs for Coated Steel

Table 11.6 lists physicochemical parameters and corrosion rate obtained from polarization curves for X60 steel (Fig. 11.8) exposed to the soils from Campeche after 30 days. It is observed that the X60 showed the biggest corrosion rate when is exposed to CS-C, which corroborates with the impedance diagrams of Fig. 11.6. It is observed that Clays in general are more corrosive soil and probably modify the properties of adhesion of the coating to the metal. It is observed that the same coating on the steel acts different, it could be that the different soil modifies its adhesion properties changing the exposure area and the corrosion process, demonstrating the complexity of the corrosion process of steel in contact with different soils even with the presence of coatings.

4 Conclusions

Physicochemical effect on the corrosion process of API X60 steel exposed to five types of soils from south of México at different moisture content was carried out. The soils evaluated have different water retention and each soil has a moisture content in which the corrosion process is more active. The greater corrosion rate, do not belong necessarily in saturated soils. The higher corrosion rate obtained from polarization curves for uncoated X60 steel was found in the Clay-C (0.379 mm/year) with 39.7 wt.% of moisture content. Steel coated with a simulated damage indicates that the Clay-Silt (52.3 wt.%) was the most aggressive soil for X60 steel (0.00295 mm/year). These results are agreed with the results obtained by EIS. In addition, it is important to point out that a not pure charge transfer process is developed in the corrosion of the X60 steel; it is to say, a diffusion process influenced the activation corrosion process. The results suggest the use of EIS and PC in the cathodic protection study is a really important tool for the analysis of the corrosion process in underground pipelines at different stages of season of the year (dry and rainy), due to the cathodic potential variations in different types of soils and different moisture contents.

References

Wilmott MJ, Jack TR (2000) Corrosion by soils. In: Winston Revie R (ed) Uhlig’s corrosion handbook, 2nd edn. Wiley & Sons, Inc., ISBN 0-471-15777-5

Alamilla JL, Espinosa-Medina MA, Sosa E (2009) Modeling steel corrosion damage in soil environment. Corros Sci 51:2628–2638

Beavers JA, Thomson NG (2006) External corrosion of oil and natural gas pipelines. ASM Handbook, vol 13C, Corrosion: environments and industries (#05145). ASM International, Materials Park, 44073-0002, 1021–1022

Uhlig HH (1971) Corrosion and corrosion control. Introduction to corrosion science and engineering, 2nd edn. Wiley, New York

Benmoussat A, Hadjel M (2005) Corrosion behavior of low carbon line pipe steel in soil environment. J Corros Sci Eng 7:1–19

Velazquez Z, Guzman E, Espinosa MA, Contreras A (2010) Stress corrosion cracking behavior of X60 pipe steel in soil environment, Mater Res Symp Proc 1242:69–78 [Pérez R, Contreras A, Esparza R (eds)]

Contreras A, Hernández SL, Galvan R (2011) Effect of pH and temperature on stress corrosion cracking of API X60 pipeline steel. Mater Res Symp Proc 1275:43–52 [Pérez R, Contreras A, Esparza R (eds)]

Pan BW, Peng X, Chu WY, Su YJ, Qiao LJ (2006) Stress corrosion cracking of API X-60 pipeline in a soil containing water. Mater Sci Eng A 434:76–81

Trejo-Atecas B, Orozco-Cruz R, Contreras A, Galvan-Martinez R (2014) Electrochemical characterization of the X60 steel corrosion at different overvoltages: a cathodic protection study. Mater Sci Forum 793:59–66

Quej-Aké LM, Galvan-Martinez R, Contreras A (2013) Electrochemical and tension tests behavior of API 5L X60 pipeline steel in a simulated soil solution. Mater Sci Forum 755:153–161

Contreras A, Hernández SL, Orozco-Cruz R, Galvan-Martinez R (2012) Mechanical and environmental effects on stress corrosion cracking of low carbon pipeline steel in a soil solution. Mater Design 35:281–289

Nie XH, Li XG, Du CW, Cheng YF (2009) Temperature dependence of the electrochemical corrosion characteristics of carbon steel in a salty soil. J Appl Electrochem 39:277–282

Gervasio D, Song I, Payer JH (1998) Determination of the oxygen reduction products on ASTM A516 steel during cathodic protection. J Appl Electrochem 28:979–992

Murray JN, Moran PJ (1989) An EIS study of the corrosion behavior of polyethylene coating holidays in natural soil conditions. Corrosion 45:885–895

Fitzgerald JH (1993) Evaluating soil corrosivity-then and now. Mater Perform 49:17–19

ASTM D 4959 (2007) Standard test method for determination of water (moisture) content of soil by directs heating. ASTM International, West Conshohocken, PA, 2007

ASTM G 200-09 (2014) Standard test method for measurement of oxidation-reduction potential (ORP) of soil. ASTM International, West Conshohocken, PA, 2014

Boukamp BA (1989) Equivalent Circuit (EQUIVCRT.PAS), User Manual, University of twente, Netherlands

Quej-Ake L, Marín-Cruz J, Galván-Martínez R, Contreras A (2014) Corrosion behavior of low carbon steel exposed to different soils. Mater Sci Forum 793:169–179

Pech-Canul MA, Chi-Canul LP (1999) Investigation of the inhibitive effect of N-phosphono-methyl-glycine on the corrosion of carbon steel in neutral solutions by electrochemical techniques. Corrosion 55:948–956

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Quej, L.M., Míreles, M.J., Galvan-Martinez, R., Contreras, A. (2015). Electrochemical Characterization of X60 Steel Exposed to Different Soils from South of México. In: Pérez Campos, R., Contreras Cuevas, A., Esparza Muñoz, R. (eds) Materials Characterization. Springer, Cham. https://doi.org/10.1007/978-3-319-15204-2_11

Download citation

DOI: https://doi.org/10.1007/978-3-319-15204-2_11

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-15203-5

Online ISBN: 978-3-319-15204-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)