Abstract

The removal of the antibiotic compound tetracycline hydrochloride (TC) was investigated by using goethite/H2O2 as a heterogeneous Fenton reagent. At pH 3.0–4.0, although presenting the lowest adsorption capacity of TC to goethite, the TC removal can be still greatly promoted by the reductive transformation of Fe(III) to Fe(II) with TC in the solution over goethite. A rapid initial TC decay was observed at the first 5 min, followed by a much slower retardation stage. This reason was likely that the reductive transformation of Fe(III) to Fe(II) was inhibited with the proceeding of the Fenton reaction. However, all the goethite-catalyzed Fenton reactions responsible for the TC removal were well fitted to pseudo-first-order kinetics (R 2 > 0.99), and their apparent activation energy (E a) for this Fenton-like reaction was 31.86 kJ·mol−1. This low value of E a was very consistent with the TC Fenton removal significantly enhanced with the temperature increase and simultaneously mediated by the surface-controlled homogeneous and heterogeneous reactions.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In the last decades, there had been growing concern focusing on the release of antibiotics in the environment [1]. Tetracyclines (TCs) were among broad-spectrum antibiotics extensively used for the disease control in human and animals due to their great therapeutic values. This good behavior made TCs to rank the second most in both output and usage globally [2] and thus led to high TCs residues in the environment [3–5]. Most of the used antibiotics were water soluble, and as much as 90 % of one dose can be excreted in urine and up to 75 % in animal feces, resulting in their frequent detection in surface, ground, and wastewaters [6]. Up to date, even though TCs presented just at trace levels in the environment, they had been characterized as “pseudo-persistence” due to their continuous introduction into the environment [7], posing potential hazard to public health [4]. Therefore, it was very important to develop a process to partially or totally eliminate these pollutants from the environment [7–10].

Due to their antibacterial nature, conventional biological methods and adsorption methods can’t remediate antibiotic-contaminated waters effectively at low cost [11, 12]. In contrast, advanced oxidation methods were suitable alternatives for rapid degradation of recalcitrant and nonbiodegradable compounds in wastewater [13]. Compared to the homogeneous Fenton reaction, the heterogeneous Fenton reaction had its unique advantage since it can be efficiently operated in a wide range of pH values. The heterogeneous Fenton reaction process was preferred as a suitable treatment method for its capability of complete mineralization of organic compounds at ambient temperature and also its benefit from the easy separation of solid catalysts from treated wastewater [14, 15].

In the context, environmentally friendly iron oxides involving magnetite (Fe3O4), hematite (Fe2O3), goethite (α-FeOOH), and lepidocrocite (γ-FeOOH) had attracted much more concern because they were widespread in the natural environment and can be easily applied to in situ soil remediation processes [16]. Among iron minerals, goethite is the most abundant poorly crystalline mineral in natural environments, which has a low solubility (pKsp = 14.7), and it generally possesses huge surface areas. Using goethite as a heterogeneous Fenton catalyst had already received a great deal of attention due to its proven highly excellent catalytic reactivity toward H2O2 [17, 18]. Simultaneously, the goethite-catalyzed Fenton reaction had been found to be effective in aspect of oxidizing many kinds of organic compounds [19, 20]. Especially under acidic solution condition at pH below 4.0, there existed the potential for the combination of both heterogeneous and homogeneous Fenton reactions in the presence of goethite/H2O2 reagent, which may obviously promote the oxidative decomposition for those recalcitrant organic pollutants containing certain reductive active groups. For instance, tetracycline hydrochloride (TC) contained a reductive phenolic diketone moiety.

In addition, TCs used in common involve tetracycline (TC), oxytetracycline (OTC), and chlortetracyclines (CTC) [21, 22]. They were active against a range of organisms such as Myco-plasma and Chlamydia, as well as a number of gram-positive and gram-negative bacteria. However, it should be noted that TCs generally have strong affinity to clay and oxide minerals, humic substances, and soils and sediments due to their highly hydrophilic nature [23–25]. Therefore, TCs’ good adsorptive behaviors can somewhat enhance its Fenton removal rates over relevant iron minerals. However, unlike the well-characterized adsorptive interactions of TC with minerals, TC’s Fenton decomposition had received less concern. So far, the TC degradation via the mentioned heterogeneous Fenton reaction by using goethite as a catalyst had not yet been reported in the literature, with the exception of the homogenous photo-Fenton reaction process [7]. Consequently, it was essential to develop an efficient treatment method to degrade TC via a heterogeneous Fenton process by utilizing the low cost and efficiently catalytic active goethite. In this study, the goethite-catalyzed heterogeneous Fenton process for TC removal from wastewater was investigated in detail via a series of batch experiments, with emphasis on the optimization of the TC Fenton oxidation process kinetic parameters and further the discussion of the Fenton reaction degradation mechanisms.

2 Materials and Methods

2.1 Chemicals and Materials

The antibiotic tetracycline (TC) was purchased from Alading Chemicals Co., Shanghai, China, and used without further purification. All other used chemicals, including hydrogen peroxide (H2O2, 30 %), sulfuric acid (H2SO4, 96 %), ferric nitrate (Fe(NO3)3, p.a.), ferrous sulfates (FeSO4·7H2O, p.a.), potassium hydroxide (KOH, p.a.), and sodium hydroxide (NaOH, p.a.), were supplied by Guangzhou Chemicals Co., China. Duplicate-deionized water was used to make the dye solutions of desired concentration. Goethite was prepared in our laboratory based upon the synthesis methods reported by Wu et al. [16].

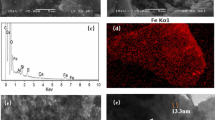

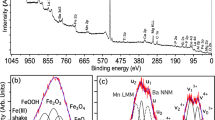

2.2 Characterization of Materials

The specific surface area (BET), pore size (BJH), and pore volume (V p) of the catalysts were determined by the N2 adsorption–desorption method at liquid nitrogen temperature (at 77 K) using an ASAP2020M apparatus (Micromeritics Instrument, USA). The XRD patterns of the samples were recorded on D-MAX 2200 VPC X-ray diffractometer equipped with Cu Kα radiation (Rigaku, Japan). The size and morphology of goethite were characterized by scanning electron microscopy (SEM) (ZEISS Ultra 55, Carl Zeiss of Germany).

2.3 Experimental Procedure for Fenton Reaction

All the experiments were conducted in a double glass cylindrical jacket reactor with a total volume of 0.5 L under dark. Before the reactions, TC solutions were adjusted to desired initial pH value (i.e., pH = 4.0) via the addition of NaOH or H2SO4 of 0.1 mol·L−1. Next, catalyst of a given amount was added into 0.4 L of TC solution, which was equilibrated with goethite within 1 h (reaching over 80 % of adsorptive maximum), then the determination of its adsorption removal efficiencies for TC was done, followed by the addition of H2O2 into the TC and goethite mixed suspensions. Four constant temperatures in the range of 25–50 °C were obtained through a thermostat by using a magnetic stirrer to stir the suspensions during the reactions.

2.4 Analytical Methods

The aqueous concentration of TC was monitored by UV–vis spectrophotometer (Unico 3802; Shanghai instrument Co.) at a maximum absorption wavelength of 357 nm to determine the TC removal and decomposition. The TC’s degradation was determined by a TOC analyzer (TOC-V, Shimadzu, Japan), and its products were determined by a high-performance liquid chromatography (HPLC, LC-20AT, Shimadzu, Japan). At regular time intervals, 2.5 mL solution samples were taken out and the solid was removed from the solution by using 0.45 μm cellulose acetate syringe membrane filter. TC’s Fenton oxidative removal efficiencies were determined based on a calibration curve, which was obtained by a batch of standard TC solutions with defined concentrations. As such, the TC’s Fenton oxidative removal efficiencies may be determined as Eq. 1:

where C t and C 0 were the solution TC concentrations at time t and initial time, respectively. The standard deviations (P) for the concentration measurement were small with most P < 0.05. The initial and final solution pH values were measured by a PHS-3C pH meter (Shanghai instrument Co., China).

3 Results

3.1 Characterization of Iron Oxide Catalysts

The XRD pattern of the as-synthesized goethite in this study (Fig. 1) well corresponded to the standard card for α-FeOOH (goethite, JCPDS No. 29-0713) [16], with the main reflection peaks at 2θ = 21.23, 33.28, and 36.67°. This confirmed that a highly purified α-FeOOH was obtained. An SEM image of goethite was shown in Fig. 2, revealing that the crystalline needle-like goethite was very small with typical lengths in the range of 1–5 μm and an average pore width around 10.0 nm. In addition, the BET surface area and pore volume of the as-synthesized goethite were 33.66 m2·g−1 and 0.078 cm3·g−1, respectively.

3.2 Effect of Initial pH

The effects of initial pH on the removal efficiency of TC were studied at an initial pH ranging from 3.0 to 10.0, and the results were shown in Fig. 3. At pH above 5.0, the removal rate of TC increased while the initial pH increased, and the final removal efficiency rose to over 95 % with an initial pH of 10.0 and a reaction time of 240 min. On the other hand, as the initial pH dropped below pH 4.0, the removal efficiencies of TC may also reach above 95 % within the same reaction time of 240 min, even though the TC adsorption capacity was relatively lower than at higher pH values. Our obtained results were very different from those of Wang et al. (2011) via an ultrasound-enhanced catalytic ozonation process by also using goethite as a catalyst (US/goethite/O3) [8], where the removal rate of TC via oxidative degradation increased with the increase of initial pH in the pH range from 2.0 to 9.0. As a result, it can be concluded that at low pH 3.0–4.0, the Fenton degradation process presenting high TC’s removal rates was mainly attributed to the aqueous homogeneous reactions related to dissolved iron species rather than the solid surface reactions, whereas at high pH around 8.0, the process was attributed mainly to the heterogeneous reactions occurring on the surfaces enhanced by the TC’s strong adsorption besides the potential H2O2-enhanced adsorption able to benefit for the generation of •ΟΗ, which would be further discussed in detail later. On the other hand, at circumneutral pH (pH 5.5–7.4), the lower TC but higher Cl− (chloride ion) adsorptions led to the relatively lower TC’s removal rates. The Cl− may inhibit the generation of •ΟΗ over goethite. However, these processes were different from the decolorization of the azo dye Orange G using goethite as a Fenton catalyst [16].

3.3 Effect of the Catalyst Dosage

The effect of the initial dosage of goethite on Fenton oxidation of TC was investigated in the range of 0.4–1.2 g·L−1. As clearly seen in Fig. 4, the removal efficiencies of TC gradually increased as the goethite dosage increased from 0.4 to 1.0 g·L−1. This can be also explained by the heterogeneous generation processes of •ΟΗ taking place directly at the goethite/water interface (Eqs. 7–9) [17]. The increase of goethite dosage may increase the amount of adsorption sites for TC as well as generating more hydroxyl radical. However, further increase of goethite dosage up to 1.2 g·L−1 can decrease the Fenton removal efficiency, potentially due to the proven “unproductive destruction of the reactant” effect [26]. This reason was that excessive goethite may catalyze H2O2 to produce more O2 and less •ΟΗ, leading to an obvious decrease in the TC removal efficiency. Based on the observation in this study, the optimum goethite dosage was determined to be 1.0 g·L−1.

3.4 Effect of the Hydrogen Peroxide Concentration

The influence of the H2O2 concentrations from 10 to 40 mmol·L−1 on the removal efficiency of TC decomposition via the heterogeneous Fenton processes was investigated and the results were present in Fig. 5. As the H2O2 concentrations increased from 10 to 20 mmol·L−1, the TC removal efficiency displayed a slight increase from 91.8 to 97.2 % after 240 min owing to an enhancement in the quantum yield of formation of •ΟΗ. However, further increase of the H2O2 concentration caused an obvious decrease in the removal efficiency of TC, due to the scavenging effect of H2O2 as described in Eqs. 2 and 3 [27]:

3.5 Effect of the TC Concentration

As can be seen in Fig. 6, the TC’s initial concentrations substantially affect its removal rates. An increase in initial concentration led to a decrease in TC’s removal rate. When the TC concentrations decreased from 60 to 10 mg·L−1, its removal efficiencies relevantly increase from 35.7 to 92.3 % at the end of 30 min. But still, all the removal efficiencies can reach 98 %, providing enough reaction time.

3.6 Influence of Reaction Temperature

The impact of temperature on the removal of TC via the Fenton reaction process catalyzed by goethite was studied at 25, 30, 35, and 40 °C, respectively, and the obtained results were presented in Fig. 7. As shown in Fig. 7, reaction temperature has a significant influence on the TC Fenton removal rate. The TC’s removal efficiencies increase from 49.2 to 92.1 % within 120 min when the reaction temperature rose from 25 to 40 °C. The results indicated that higher temperature favors the Fenton oxidation of TC, potentially due to the acceleration of Fenton’s reaction with increasing temperature [28]. Higher temperature may also enhance the adsorption rates of both TC and H2O2 as well as the release rate of iron ions to some extent from goethite surfaces mainly through improving their interfacial diffusion rates at the goethite/water interface. Thus, increasing the temperature greatly improved the generation rate of the •OH radical. Therefore, the removal rates of TC’s Fenton oxidation were highly accelerated with increasing temperature, especially under the acidic condition at low pH 3.0–4.0.

4 Discussion

4.1 Effects of Adsorptive Behaviors of Tetracycline to Goethite on the TC Fenton Removal

TC has a pKow of 1.19, indicating that TC is relatively hydrophilic as a result; the removal of TC mainly relies on its adsorption by goethite before the addition of H2O2, but the removal of TC by adsorption was below 20 % during the Fenton process as shown earlier. Tetracycline molecule presents very polar and has three proton-active groups, including a dimethylammonium, a tricarbonylamide group, and a phenolic diketone [23]. The distribution of tetracycline species depends upon solution pH conditions. These structural characteristics are favorable for its adsorption and oxidative degradation. On the other hand, the potential three different surface species, that is, FeOH2+, FeOH0, and FeO−, on goethite can greatly mediate its surface adsorptive activities toward TC that is significantly controlled by the solution pH because these surface functional groups of goethite may transform subjected to the following two equations [8]:

Due to its pHpzc (the point of zero charge) around 8.0, the goethite surface was presumably positively charged in acidic and neutral solution (pH < pHpzc) and negatively charged in alkaline solution (pH > pHpzc). Hence, it was deserved to especially note that goethite possesses a high surface-site density of Bronsted acid sites at the pH range of 3.0–4.0 that decrease adsorption of positively charged TC onto goethite for the reason of TC’s strong protonation under the acidic low pH condition. For example, Tanis et al. [29] investigated the interactions of TC with goethite- or ferrihydrite-coated quartz and found that their maximum adsorption capacity for TC occurred at about pH 8.0, and the effect of ionic strength was of less importance. As such, previous studies indicated that the potential for TC strong adsorption onto the minerals greatly depends upon TC’s charge nature that is highly related to the protonation–deprotonation interactions of its three reactive surface functional groups [30–32].

The addition of H2O2 alone without goethite into the solution almost did not contribute to the removal of TC by direct oxidation. However, the strong adsorption of TC to goethite substantially enhanced the goethite-catalyzed heterogeneous Fenton oxidation in terms of TC’s removal efficiency. There exist three different functional groups in TC molecule structure corresponding to its three different pKa values of 3.3, 7.7, and 9.7, and thereby TC may present varied predominant species of H4TC2+, H3TC, H2TC−, and HTC2− at pH 3, 6, 8, and 10, respectively. Hence, it should be noted that the four different species of TC can undergo protonation–deprotonation reactions depending upon aqueous solution pH value [33]. For this reason, electrostatic repulsion between TC and goethite surfaces both with similarly charged groups is much stronger at either lower pH value (positive–positive repulsion) or higher pH value (negative–negative repulsion).

However, especially in the case of pH value around 8.0, the interactions of TC with goethite surfaces may create a maximum electrostatic attraction. Hence, it was expected that there should exist a positive relationship between the increase in adsorption capacity of TC onto goethite and the relevant promotion of the TC removal as the pH values increased from 5.0 to 8.0. An the same time, it had been proven that H2O2 favors to be adsorbed onto the more negatively charged oxide surfaces because of its capability of forming strong complexes with those compounds with weak base properties [34]. As such, higher concentration of •OH can be generated with the increase of the solution pH value. Moreover, the electrophilic •OH radical will tend to attract negatively charged TC molecule with high electrical density on the ring system [35], thus leading to the enhanced Fenton catalytic activities in the alkaline conditions.

As a result, we can conclude that the alkaline pH condition (i.e., pH 8.0–10.0) was very favorable for the Fenton catalytic degradation of TC. On the contrary, the higher removal rate of TC also occurring at a low initial solution pH values (i.e., pH 3.0–4.0) was mainly due to the leaching of iron ions from goethite to the solution further to enhance the homogeneous Fenton oxidation in improving removal rate of TC mainly via raising the concentration of ferrous/ferric ions in the suspension. As acidic low pH values corresponded to the low adsorption of TC on to goethite, apparently it can not account for TC’s displaying high removal rate from the suspension. This should be ascribed mainly to the homogeneous Fenton decomposition catalyzed by dissolved iron ions, which may be further explained in the following.

4.2 Effects of Reductive Behaviors of Tetracycline to Goethite on the TC Fenton Removal

The group of phenolic diketone in TC molecule was proven to benefit the iron ions to be released from goethite [19]. As shown in Fig. 8, the total iron concentration was obviously increased especially at pH 3.0, while TC was added into goethite containing suspension. As for blank suspension case with goethite only (not shown in the figure), the iron concentration below 0.5 mg·L−1 even cannot be detected at pH 4.0, so the leaching of iron to the suspension was negligible above pH 4.0.

Actually, the reductive activity of TC may improve the generation of ferrous ions either on the goethite surfaces or in the solutions prior to the addition of H2O2. Generally, the dissolved iron is expected to be much more released under acidic solution condition potentially due to existing three heterogeneous reaction processes at the goethite/water interface, namely, a proton-induced solubilization (Eq. 6), a reductive dissolution (Eqs. 7 and 8), and a non-reductive release [19]. A rapid initial TC decay observed at the first 5 min may be mainly ascribed to homogeneous Fenton reaction caused by high dissolution of iron in the suspension (Eq. 8), while the heterogeneous Fenton oxidation directly occurring over goethite (Eqs. 9–11) can be simultaneously strengthened by the reductive transformation of surface ferric ions caused by TC itself (Eq. 7) besides H2O2 (Eq. 9).

4.3 Fenton Oxidation Kinetics

As can be seen in the aforementioned figures, a rapid initial TC decay was observed at the first 5 min, followed by a much slower retardation stage, which was likely because the reductive transformation of Fe(III) to Fe(II) by TC in the solution over goethite was inhibited with the Fenton reaction proceeding. However, the surface-controlled Fenton oxidation reaction generally follows the Langmuir–Hinshelwood model [14], which was typically described as a second-order reaction. But in this study, as the TC concentration in the solution did not decrease quickly during the degradation, its instantaneous adsorbed amount can be assumed as constant, and the TC decomposition via the combination of both homogeneous and heterogeneous Fenton reactions can be described by the following pseudo-first-order equation [36]:

where C 0 and C t were the TC concentrations (mg·L−1) at the initial time and reaction time t, K app was the pseudo-first-order rate constant (min−1), and t was degradation time (min). The K app constant can be obtained from the slope of the straight lines by plotting −ln(C t/C 0) as a function of time t, through regression. As can be seen in Fig. 9, the rate constant of TC decomposition, K app, was found to be 0.0128 min−1 under the reaction conditions given in the figure caption. In addition, similar reasonable results can also be obtained for other cases as listed in Table 1. As seen, all the goethite-catalyzed Fenton-like reactions responsible for TC removal are greatly efficient under the optimal reaction conditions as described earlier, and in most situations they may be well fitted to the pseudo-first-order kinetics (R 2 > 0.99).

Based upon the apparent kinetic rate constants at different temperatures, the value of apparent activation energy for the TC Fenton removal can be computed with the Arrhenius equation. A good linear relationship was obtained in the Arrhenius plot of lnk versus 1/T. The value of the activation energy (E a) was determined to be 31.86 kJ·mol−1. Since activation energy of ordinary thermal reactions was in general between roughly 60 and 250 kJ·mol−1 [37], apparently our obtained low value of E a in this study was well in agreement with the given relevant higher removal rates measured in the Fenton-like reaction.

4.4 Decomposition of TC

The UV–vis spectra of the TC removal evolution versus the reaction time were shown in Fig. 10, where the absorption spectra of TC in the aqueous solution were scanned in the range of 200–500 nm. As can be observed from these spectra, the absorbance of TC was characterized by two main wavelengths before the initiation of the heterogeneous Fenton-like oxidation. One band was located at 357 nm with a maximum absorption in the visible region, while another band was located at 275 nm with a relatively weaker absorption in the ultraviolet region. Moreover, the characteristic absorption peak at 357 nm decreased more rapidly as the reaction proceeded and essentially disappeared at the end of 240 min, whereas the later characteristic absorption peak at 275 nm decreased relatively slowly.

Since tert-butanol (TBA) is a strong radical scavenger, it can terminate radical chain reactions via generating inert intermediate radicals [8, 10]. As can be seen in Fig. 11, TBA can effectively inhibit the TC Fenton oxidation in the presence of goethite/H2O2 reagent. And, hence, the TC removal efficiencies obviously exhibit the decrease to some extent with the increase of TBA concentrations in the range from 5 to 20 mg·L−1 in the solution. Consequently, the TC removal, which was mainly dependent upon the Fenton oxidation reaction with the requirement of •OH, clearly differed from the direct oxidation by H2O2 only. Furthermore, it had been determined that the peak at 275 nm was associated with aromatic ring A structure involving acylamino and hydroxyl in the molecule and that the peak at 357 nm was originated from aromatic rings B-D comprising the extended chromophores (Fig. 12). Hence, the progress of the TC Fenton decomposition can be easily monitored by the absorption peaks at λ = 357 and 275 nm. Very interestingly, our obtained result was very similar to a previous research report by Wang et al. (2011) using another advanced oxidation method (ultrasound-enhanced catalytic ozonation) [8].

4.5 Evaluation of the Mineralization of TC

The concentration of total organic carbon (TOC) is generally chosen as a mineralization index of the degradation. The TC mineralization catalyzed by goethite was monitored via TOC analyzer, and the obtained result was shown in Fig. 13. Please note that the highest TOC removal efficiency for TC (just about 50 % TOC) after 240 min was much lower than its decomposition removal efficiencies (over 95 %), and this suggested that there still existed some intermediates in the solution. The HPLC chromatograms of the TC solution at varied reaction times were present in Fig. 14, where TC (R.T., 9.2 min) rapidly disappeared as the reaction progressed. This was well in agreement with the observation from the UV–vis spectra evolution. However, its degradation products need to be further tested by LC–MS analyses in future.

4.6 Recycle of Goethite Catalyst

Numerous previous studies had clearly indicated that in a particular heterogeneous Fenton process using various small crystal size iron oxides as catalysts, the separation of these small particles from suspension after reaction may be very difficult for the recycle use [10]. Due to its relative larger size in micrometer scale, goethite mineral can be easily separated by simple filtration or even natural sedimentation at the end of the heterogeneous Fenton process.

To investigate the recyclability of the goethite particles, sample powders after TC Fenton reactions were collected by naturally settling and reused in the Fenton reaction for three times under the same conditions. As illustrated in Fig. 15, goethite displayed a good stability and maintained high removal rates during three reaction cycles, with removal efficiency at 96.5, 95.1, and 93.8 % after 240 min under the conditions employed (60 mg·L−1 TC, 20 mmol·L−1 H2O2, 1.0 g·L−1 α-FeOOH, and volume 400 mL, pH 4.0 and T 35 °C).

5 Conclusions

Goethite can be effectively applied for the degradation of tetracycline (TC) by the combination of both heterogeneous and homogeneous Fenton processes in a wide range of pH values. In addition, goethite may catalyze all the Fenton reactions responsible for TC removal following the pseudo-first-order kinetics (R 2 > 0.99) with a lower value of activation energy (31.86 kJ·mol−1). More importantly, TC’s good adsorptive and reductive activities for goethite were by far the predominant factors to TC’s Fenton oxidation removal that can greatly promote the surface-controlled reactions involving the reductive dissolution and transformation of Fe(III) because they were highly consistent with the TC removal enhanced with the increase of temperature. Therefore, tetracycline may be effectively eliminated through the heterogeneous Fenton oxidative process with multimode reaction mechanisms by using the low-cost and efficient goethite.

References

Jones OAH, Voulvoulis N, Lester JN (2001) Human pharmaceuticals in the aquatic environment—a review. Environ Technol 22:1383–1394

Gu C, Karthikeyan KG (2005) Sorption of the antimicrobial ciprofloxacin to aluminum and iron hydrous oxides. Environ Sci Technol 39:9166–9173

Sarmah AK, Meyer MT, Boxall ABA (2006) A global perspective on the use, sales, exposure pathways, occurrence, fate and effects of veterinary antibiotics (VAs). Chemosphere 65:725–759

Kümmerer K (2009) Antibiotics in the aquatic environment—a review. Part I. Chemosphere 75:417–434

Kümmerer K (2009) Antibiotics in the aquatic environment—a review. Part II Chemosphere 75:435–441

Halling-Sørensen B (2001) Inhibition of aerobic growth and nitrification of bacteria in sewage sludge by antibacterial agents. Arch Environ Contam Toxicol 40:451–460

Bautitz IR, Nogueira RFP (2007) Degradation of tetracycline by photo-Fenton process—solar irradiation and matrix effects. J Photochem Photobiol A Chem 187:33–39

Wang Y, Zhang H, Chen L (2011) Ultrasound enhanced catalytic ozonation of tetracycline in a rectangular air-lift reactor. Catal Today 175:283–292

Chen WR, Huang CH (2011) Transformation kinetics and pathways of tetracycline antibiotics with manganese oxide. Environ Pollut 159:1092–1100

Hao R, Xiao X, Zuo XX, Nan JM, Zhang WD (2012) Efficient adsorption and visible-light photocatalytic degradation of tetracycline hydrochloride using mesoporous BiOI microspheres. J Hazard Mater 209–210:137–145

Chen Y, Hu C, Qu J, Yang M (2008) Photodegradation of tetracycline and formation of reactive oxygen species in aqueous tetracycline solution under simulated sunlight irradiation. J Photochem Photobiol A Chem 197:81–87

Zhang H, Liu F, Wu X, Zhang J, Zhang D (2009) Degradation of tetracycline in aqueous medium by electrochemical method. Asia Pac J Chem Eng 4:568–573

Hou LW, Zhang H, Xue XF (2012) Ultrasound enhanced heterogeneous activation of peroxydisulfate by magnetite catalyst for the degradation of tetracycline in water. Sep Purif Technol 84:147–152

Liang XL, Zhong YH, He HP, Yuan P, Zhu JX, Zhu SY, Jiang Z (2012) The application of chromium-substituted magnetite as heterogeneous Fenton catalyst for the degradation of aqueous cationic and anionic dyes. Chem Eng J 191:177–184

Zhong YH, Liang XL, Zhong Y, Zhu JX, Zhu SY, Yuan P, He HP, Zhang J (2012) Heterogeneous UV/Fenton degradation of TBBPA catalyzed by titanomagnetite: catalyst characterization, performance and degradation products. Water Res 46:4633–4644

Wu HH, Dou XW, Deng DY, Guan YF, Zhang LG, He GP (2012) Decolourization of the azo dye Orange G in aqueous solution via a heterogeneous Fenton-like reaction catalysed by goethite. Environ Technol 33:1545–1552

Lin SS, Gurol MD (1998) Catalytic decomposition of hydrogen peroxide on iron oxide: kinetics, mechanism, and implications. Environ Sci Technol 32:1417–1423

Hermanek M, Zboril R, Medrik I, Pechousek J, Gregor C (2007) Catalytic efficiency of iron (III) oxides in decomposition of hydrogen peroxide: competition between the surface area and crystallinity of nanoparticles. J Am Chem Soc 129:10929–10936

Ortiz de la Plata GB, Alfano OM, Cassano AE (2010) Decomposition of 2-chlorophenol employing goethite as Fenton catalyst. I. Proposal of a feasible, combined reaction scheme of heterogeneous and homogeneous reactions. Appl Catal B 95:1–13

Ortiz de la Plata GB, Alfano OM, Cassano AE (2010) Decomposition of 2-chlorophenol employing goethite as Fenton catalyst. II: reaction kinetics of the heterogeneous Fenton and photo-Fenton mechanisms. Appl Catal B 95:14–25

Hirsch R, Ternes TA, Haberer K, Mehlich A, Ballwanz F, Kratz KL (1998) Determination of antibiotics in different water compartments via liquid chromatography-electrospray tandem mass spectrometry. J Chromatogr A 815:213–223

Ma Y, Gao NY, Li C (2012) Degradation and pathway of tetracycline hydrochloride in aqueous solution by potassium ferrate. Environ Eng Sci 29:357–361

Zhao YP, Geng JJ, Wang XR, Gu XY, Gao SX (2011) Adsorption of tetracycline onto goethite in the presence of metal cations and humic substances. J Colloid Interface Sci 361:247–251

Li ZH, Schulz L, Ackley C, Fenske N (2010) Adsorption of tetracycline on kaolinite with pH-dependent surface charges. J Colloid Interface Sci 351:254–260

Chang PH, Li ZH, Jiang WT, Jean JS (2009) Adsorption and intercalation of tetracycline by swelling clay minerals. Appl Clay Sci 46:27–36

Pignatello JJ, Oliveros E, MacKay A (2006) Advanced oxidation processes for organic contaminant destruction based on the Fenton reaction and related chemistry. Crit Rev Environ Sci Technol 36:1–84

Chou S, Huang C (1999) Application of a supported iron oxyhydroxide catalyst in oxidation of benzoic acid by hydrogen peroxide. Chemosphere 38:2719–2731

Sun SP, Li CJ, Sun JH, Shi SH, Fan MH, Zhou Q (2009) Decolorization of an azo dye Orange G in aqueous solution by Fenton oxidation process: effect of system parameters and kinetic study. J Hazard Mater 161:1052–1057

Tanis E, Hannaa K, Emmanuel E (2008) Experimental and modeling studies of sorption of tetracycline onto iron oxides-coated quartz. Colloids Surf A Physicochem Eng Asp 327:57–63

Chen WR, Huang CH (2010) Adsorption and transformation of tetracycline antibiotics with aluminum oxide. Chemosphere 79:779–785

Essington ME, Lee J, Seo Y (2010) Adsorption of antibiotics by montmorillonite and kaolinite. Soil Sci Soc Am J 74:1577–1588

Chang PH, Li ZH, Jean JS, Jiang WT, Wang CJ, Lin KH (2012) Adsorption of tetracycline on 2:1 layered non-swelling clay mineral illite. Appl Clay Sci 67–68:158–163

Parolo ME, Savini MC, Vallés JM, Baschini MT, Avena MG (2008) Tetracycline adsorption on montmorillonite: pH and ionic strength effects. Appl Clay Sci 40:179–186

Wallace JG (1975) Hydrogen peroxide in organic chemistry. E.I. du Pont de Nemours, Wilmington

Khan MH, Bae H, Jung JY (2010) Tetracycline degradation by ozonation in the aqueous phase: proposed degradation intermediates and pathway. J Hazard Mater 181:659–665

Matta R, Hanna K, Kone T, Chiron S (2008) Oxidation of 2,4,6-trinitrotoluene in the presence of different iron-bearing minerals at neutral pH. Chem Eng J 144:453–458

Kasiri MB, Aleboyeh H, Aleboyeh A (2010) Mineralization of C.I. acid red 14 azo dye by UV/Fe-ZSM5/H2O2 process. Environ Technol 31:165–173

Acknowledgment

This work was funded by National Natural Science Foundation of China (Grant Nos. 41072034, 41372050 and 40773080).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Wu, H., Jiang, F., Lu, S., Guan, Y., Deng, D., Chen, X. (2015). Using Goethite as a Heterogeneous Fenton Catalyst for the Removal of Tetracycline Hydrochloride: Effects of Its Adsorptive and Reductive Activities. In: Dong, F. (eds) Proceedings of the 11th International Congress for Applied Mineralogy (ICAM). Springer Geochemistry/Mineralogy. Springer, Cham. https://doi.org/10.1007/978-3-319-13948-7_41

Download citation

DOI: https://doi.org/10.1007/978-3-319-13948-7_41

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-13947-0

Online ISBN: 978-3-319-13948-7

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)