Abstract

Since the introduction of ionic liquid matrices (ILM) for matrix-assisted laser desorption/ionization (MALDI) mass spectrometry, manifold applications for a range of different substance classes (e.g., amino acids, peptides or proteins) were described. ILM are composed of an equimolar mixture of classically used acidic MALDI matrices and organic bases, which allows for an almost infinite number of combinations with different properties. A major advantage offered by many ILM compared to classical crystalline matrices is a highly homogeneous sample distribution, which is especially important in regard to quantification.

In general the concentration of an analyte can be determined based on the intensity of its corresponding ion in the mass spectrum (MS1 quantification). For this purpose the use of an internal standard with a high similarity to the analyte of interest is usually recommended. However, in certain cases it is possible to quantify the analyte without the use of an internal standard. Here we describe two exemplary applications of MALDI MS using ILM for the determination of enzyme activities.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- MALDI MS

- Quantification

- Matrix

- Hot spot

- Sweet spot

- Ionic liquid matrix

- Internal standard

- Standard-free

- Enzyme screening

- Substrate screening

1 Introduction

Matrix-assisted laser desorption/ionization (MALDI) mass spectrometry (MS) has become a major analytical technique in various sectors of scientific research, industrial applications and pharmaceutical or food quality control. Low molecular weight compounds (Cohen and Gusev 2002), e.g., amino acids, lipids, sugars, or vitamins, can be analyzed as well as molecules of higher molecular weight such as peptides, proteins, or oligonucleotides (Karas and Hillenkamp 1988). Key features of this technology are its relatively simple and fast sample preparation, a comparatively high tolerance towards impurities (e.g., salts or detergents), low sample consumption as well as straightforward interpretable spectra. The latter is mainly caused by the preferred formation of singly charged ions.

The careful choice of a suitable matrix for a certain application is of fundamental importance for the success of an experiment as the matrix can influence the ionization/desorption behavior, trigger the formation of adducts or may affect the stability of the analyte of interest. This fact concerns qualitative as well as quantitative applications of MALDI MS. In general MALDI matrices must fulfill several criteria: they have to be stable under high vacuum conditions (low vapor pressure), and absorb the laser light at the emitted wavelength. Additionally, matrices should be inert towards the analyte and either co-crystallize (solid matrices) with the analyte or solubilize (liquid matrices) the latter (Fig. 1).

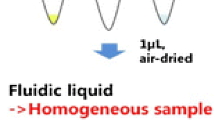

Whereas qualitative measurements are applied routinely, quantification by MALDI MS is hampered by several challenges . First, signal intensities are not only dependent on the amount of analyte present in the sample but also of its chemical composition. The ionization behavior of peptides, for example, is influenced by the basicity of the single amino acids, certain amino acid modifications and the sequence itself. Internal standards with high chemical similarity to the analyte, at best stable isotope-labeled counterparts of the analyte, are required for quantification. Second, complex samples or impurities can favor ion suppression effects. Accordingly, analytes have to be purified prior to MALDI MS measurement or the sample complexity has to be reduced, e.g., by offline-LC separation and subsequent spotting onto the target. Last, sample spots using classical crystalline MALDI matrices such as α-cyano-4-hydroxycinnamic acid (CHCA), 2,5-dihydroxybenzoic acid (DHB) or sinapinic acid (SA) are indicated by rather inhomogeneous distribution of the analyte over the spot. These so-called ’hot spots’ or ‘sweet spots’ trigger a poor spot-to-spot and shot-to-shot reproducibility of the measurement, substantially hampering quantification. Consequently, protocols using conventional MALDI matrices have to average a representative amount of spectra over the whole spot area by automated laser movement to achieve reliable results. In addition the homogeneity of the matrix-analyte co-crystal has to be optimized, e.g., by fast evaporation of the matrix solvent (Nicola et al. 1995) or the addition of co-matrices (Gusev et al. 1996; Distler and Allison 2001) such as fucose. Another possibility for improved sample homogeneity is the application of liquid matrices. Glycerol-based liquid matrices , for example, are composed of crystalline matrices dissolved in a highly viscous and vacuum stable liquid, such as glycerol, by the help of a solubilizing reagent (Sze et al. 1998). A second approach, which will be focused on in the following chapter, is the direct application of liquid components, e.g., ionic liquids, as MALDI matrices.

Ionic liquids are defined as salts with melting points below 100 °C. Due to their outstanding properties, these compounds have gained widespread applications in almost all disciplines of analytical chemistry in recent years (Sun and Armstrong 2010). In 2001, the use of ionic liquids as MALDI matrices was reported for the first time by Armstrong and coworkers (Armstrong et al. 2001). However, it turned out, that so-called room-temperature ionic liquids (RTIL) were not generally suitable as MALDI matrices; one reason was the lack of suitable UV-absorption. Therefore, the authors introduced a novel class of ionic liquids, which they synthesized by the equimolar combination of classical acidic MALDI matrices (e.g., CHCA, DHB, SA) with different organic bases (e.g., pyridine, tributylamine, 1-methylimidazole). These novel matrices, which showed comparable or in some applications even improved MALDI matrix properties, were later called ionic liquid matrices (ILMs) (Zabet-Moghaddam et al. 2004; Tholey and Heinzle 2006). As several of these ILMs crystallize at room temperature, they are termed ion matrices as well (Lemaire et al. 2006). Two methods for the preparation of ILMs will be described in the practical part of this chapter.

The option of choosing different acidic matrix compounds and organic bases for the preparation of an ILM allows for an almost infinite number of combinations (Berthod et al. 2009; Crank and Armstrong 2009; Towers et al. 2010; Gabriel et al. 2014) with unique properties, giving the opportunity of creating tailor-made matrices. However, unlike demonstrated for crystalline matrices (Jaskolla et al. 2008), up to now no prediction of final properties of a particular acid–base combination is possible. Thus, the test of properties is still a matter of trial-and-error experiments. Despite this, ILMs provide a number of interesting features. Even after salt formation the suitability of the parent acid compound for a distinct class of analytes persists; e.g., CHCA, which is one of the best suited matrices for the analysis of peptides, retains this property after conversion to an ILM. A second feature of ILM is the strong reduction of matrix signals in the low m/z region (Vaidyanathan et al. 2006). In contrast to the crystalline acidic parent matrices, only weak or even no signals of the ILM itself are usually present in the mass spectrum; only the base compound of the ILM forms a strong signal. This creates an inherent advantage for the analysis of low molecular weight compounds by MALDI MS.

ILMs are not superior over their classical crystalline counterparts in every respect. The formation of sodium or potassium adducts in many ILMs is increased compared to the use of solid matrices. This feature is in particular useful for the analysis of carbohydrates (Harvey 1999). However, in case of peptides, alkali adducts hamper data interpretation as spectra become more complex. The simultaneous occurrence of different species of the analyte (e.g., [M + H]+, [M + Na]+, [M + K]+) causes sensitivity loss and consequently increases the limit of detection. It has to be noted, that the introduction of the so-called substoichiometric ILM , composed by a 2:1 ratio of CHCA and pyridine, can lead to improved spectra qualities in the analysis of peptide mass fingerprint spectra (Zabet-Moghaddam et al. 2006). Furthermore the addition of ammonium salts such as ammonium phosphate, as employed in glycerol-based liquid matrices (Cramer and Corless 2005) and previously introduced for the reduction of alkali adduct ion formation in nucleotide analysis, also enhances spectra quality. In case of intact proteins, the formation of alkali adducts leads to significant peak broadening, thus making ILMs less suitable for this application.

Sample spots using ILMs appear like a viscous film on the target after sample preparation. Within this film the analyte is very homogenously distributed (Zabet-Moghaddam et al. 2004; Mank et al. 2004; Tholey et al. 2006; Tholey 2006). Thus, the formation of ‘hot spot s’ is widely suppressed. Even in acid–base combinations which appear to be crystalline at room temperature the sample distribution is improved compared to conventional crystalline MALDI matrices. This feature renders ILMs useful especially in regard to quantification based on MS1 signal intensities (Zabet-Moghaddam et al. 2004; Li and Gross 2004). Principally quantification can be performed on the level of MS or MS/MS (aka MS2 or tandem MS) spectra. In this chapter we will only focus on the quantification based on MS1.

In the following sections we describe the use of ILMs for the quantification of low molecular weight biomolecules (carbohydrates) and of biopolymers (peptides). We present two applications for the determination of enzyme activities by quantitative MALDI MS. However, the principles elucidated in the two examples are easily transferrable to a number of other applications.

2 Applications

Enzyme-catalyzed reactions play a central role in various fields of biotechnology and scientific research. Novel enzyme variants, either from natural sources or created by means of directed evolution (e.g., site-directed mutagenesis) of existing biocatalysts, are constantly requested. This creates a high demand for powerful screening technologies for the most active candidates within a selection of enzymes (enzyme screening ) and accordingly for the determination of the product and/or substrate concentration of the enzyme-catalyzed reaction. Typically, optical methods relying on UV/Vis absorption or fluorescence are the method of choice for this purpose. However, these approaches are restricted to the monitoring of reactions in which either the substrates or products of the reactions show alterations in terms of absorption/fluorescence. As substrates of interest often do not contain the latter, artificial substrates are applied, which can falsify results by affecting the enzymatic reaction. In addition optical methods are sensitive towards impurities, such as buffers or cofactors. Other methods applied in enzyme screening are HPLC, GC/MS, or NMR. Mass spectrometric methods gained increasing importance for biocatalyst screening in the last years (Tholey and Heinzle 2002; Reetz 2003; Greis 2007; de Rond et al. 2015). Mass spectrometry can provide not only quantitative information, but is also suitable for unambiguous identification and structural analysis of the investigated molecules, which is an advantageous key feature of this technology compared to optical screening methods. This property of mass spectrometry is especially beneficial for the understanding of unknown conversion pathways by new enzymes.

Quantitative MALDI MS has been demonstrated to be a powerful technology for the determination of enzyme activities, as it provides easy and straightforward sample preparation and at least a moderate tolerance against salts, which allows for a direct monitoring of reaction mixtures without prior purification steps (Kang et al. 2000; Wittmann and Heinzle 2001).

In many cases substrates and products of enzyme-catalyzed reactions are compounds with molecular weights below 500 Da. Prerequisites for qualitative and quantitative analysis of low molecular weight compounds by MALDI MS in general are (1) a clear distinction of matrix and analyte signals in the low m/z region of the spectrum, and (2) the use of a molar matrix-to-analyte ratio (M/A ratio) of approximately 10:1 to 100:1 (Kang et al. 2000). Furthermore (3) suitable internal standards have to be applied to prevent errors deriving from signal suppression effects. These standards should either exhibit physicochemical similarity to the analyte of interest, as in case of peptides achieved by the exchange of a single amino acid for example, or at best should be its isotopically labeled counterpart (e.g., 2H, 13C, 15 N, 18O). Last, (4) poor reproducibility caused by ‘hot spot ’ formation should be minimized by automated measurement protocols and by increasing the sample homogeneity as far as possible. As ILMs are characterized by a strong reduction of matrix signals in the lower mass region and the formation of highly homogeneous sample preparations, they offer reasonable properties for the quantitative analysis of low molecular weight compounds, e.g., the substrates and products of enzyme-catalyzed reactions.

Quantification using internal standards — enzyme screening for the identification of the most active biocatalyst.

In 2004, Bungert and coworkers presented a method to identify the most active variant of the enzyme pyranose oxidase (POx) using ILMs and quantitative MALDI MS (Bungert et al. 2004). This enzyme catalyzes the conversion of glucose into glucosone (Fig. 2a). During this reaction, hydrogen peroxide is liberated as a by-product, which can be degraded into water and oxygen by catalase (Giffhorn 2000). For the screening, ten different variants of POx, overexpressed in Peniophora sp., were incubated with the substrate glucose in 96-well microtiter plates. To prevent an inactivation of POx by increasing concentrations of hydrogen peroxide, catalase was added to the mixture as well.

(a) Reaction scheme of the pyranose oxidase-catalyzed conversion of d-glucose into 2-keto-d-glucose (glucosone). (b) MALDI MS spectrum of low molecular weight substrates and products of the pyranose oxidase-catalyzed reaction. Sodium ([M + Na]+) (m/z 203.05) and potassium Fig. 2 (continued) adducts ([M + K]+) (m/z 219.03) of glucose and its fully 13C-labeled analogue ([U-13C]) (m/z 209.05 and 225.03) as well as of the product glucosone (m/z 201.05 ([M + Na]+), 217.03 ([M + K]+)) were detected in positive mode. All other peaks not assigned here belong to matrix components. Figure with permission from (Bungert et al. 2004). (c) Schematic time-dependent change of substrate and product concentrations during an enzymatic reaction. The sum of substrate and product concentrations at a certain time-point is constant all over the curve

MALDI MS-based quantification of the substrate glucose was achieved by using fully 13C-labeled glucose as an internal standard. An ILM composed of equimolar amounts of DHB and pyridine was used as matrix. Prior to determination of enzyme activities, a calibration curve was measured, monitoring the relative intensities of analyte to internal standard in dependence of the molar ratio of these two compounds. This step is the most critical and time consuming in the overall screening process. Major goals are to elucidate the range of linear correlation and to fit the analyte amounts with the needs of the enzymatic reaction. For the screening of the enzymatic activity, at certain time points, aliquots were taken and the enzymatic reaction was stopped by the addition of trifluoroacetic acid (TFA). Afterwards the solution was mixed with the internal standard. After sample preparation using the dried-droplet technique, samples were spotted each five times on the target for MALDI MS measurement.

Spectra of the experiments showed alkali adducts of the substrate and product (Fig. 2b). As the [M + K]+ signals were more intense in comparison to the [M + Na]+ signals, potassium adducts were chosen for quantification. Concentrations of glucose were assigned by comparing the signal intensity of the POx substrate to the intensity of the added internal standard 13C-labeled glucose. Based on the calibration curve, the concentration of the substrate glucose could be determined easily based on the signal intensity ratio of the analyte and internal standard. The product concentration was calculated based on 13C-labeled glucose as well, because isotopically labeled glucosone was not commercially available. As the ion response of glucosone in comparison to glucose was unknown, a correction factor to transform glucosone signals into the scale of glucose signals was determined. This was possible under the assumption that the sum of substrate and product amount is constant throughout the enzymatic reaction (Fig. 2c).

Monitoring substrate degradation and subsequent product generation enabled the identification of the most active variant of POx easily. The determination of glucose and glucosone by HPLC proved the reliability of the MALDI MS-based method. Compared to HPLC runs, which took 22.0 min for each sample, the fast measurement by MALDI MS took only 3.5 min for five replicates of each sample (42 s per spot), using a 20 Hz laser. Contemporary MALDI mass spectrometers can even manage the same workload with significantly reduced measurement times.

In summary, enzyme screening using MALDI MS exhibits various different advantages. Besides the benefits already mentioned in the introduction, such as simple sample preparation or low sample consumption, samples can be stored for re-measurement for a certain period of time.

Standard-free quantification — substrate screening in monitoring trypsin-catalyzed peptide degradation .

While for the quantification of low molecular weight compounds isotopically labeled standards are available, for more complex biomolecules, e.g., peptides and polynucleotides, this can be a limiting factor, in particular in large-scale screening processes. Although in most cases the application of structural homologous standards can deliver satisfying quantitative results, peak suppressing effects and potential peak overlapping should always be taken into account (Gusev et al. 1996). Despite all achievements made by using relative quantification methods, standard-free and absolute quantification, e.g., for the analysis of enzyme activities as well as for proteomics-related applications, is still of high interest.

However, absolute quantification in MALDI MS is hampered by the dependence of the ion formation on the applied laser energy/fluence (Dreisewerd 2003), the appearance of spatially isolated ‘hot spot s’ in the sample due to the inhomogeneous incorporation of analytes into the matrix crystal lattice and a typically nonlinear increase of signal intensities; the latter can usually be observed over a broad range of matrix-to-analyte (M/A) ratios (Dreisewerd 2003). Furthermore a reduction of sample complexity, e.g., by solid phase extraction or chromatographic fractionation, might be necessary to reduce ion suppression effects (Dreisewerd 2014). Replacement of crystalline matrices by ILMs can circumvent the mentioned drawbacks to some extent. It was shown that the homogeneous sample preparations achievable by the use of ILMs are also suitable for quantitative analysis using MALDI MS and allow the direct quantification of peptides (Tholey et al. 2006). The correct adjustment of molar M/A ratios was identified as major critical parameter in this respect.

Typical M/A ratios used for the analysis of peptides are in the range of 103–105 (Hillenkamp et al. 1991). However, for the absolute quantification of peptides the M/A ratio has to be noticeably increased, which was shown by the analysis of neurotensin measured with an ILM consisting of an equimolar ratio of CHCA and 3-(dimethylamino)-1-propylamine (DMAPA) . Using M/A ratios of 35,700–500,000 a linear correlation between the amount of peptide on target and signal intensity was observed (Tholey et al. 2006). The dynamic range of linearity was determined to one order of magnitude. This range is slightly lower compared to those achievable with relative quantification using an internal standard (Li and Gross 2004). Using glycerol-based liquid matrices, Palmblad and Cramer have shown a linear dynamic range of more than two orders of magnitude without the use of an internal standard (Palmblad and Cramer 2007). When using an internal standard, the ratio between the analyte and the internal standard is the critical parameter (Kang et al. 2000). In addition several factors influence the dynamic range, e.g., (1) the applied laser energy/fluence, (2) the limitation of applicable matrix amount onto the target and (3) the limit of detection as well as (4) the ionization efficiency of the analyte itself. However, in case of unknown analyte concentrations the elucidation of the best M/A ratio is a prerequisite task; but if the sample complexity hampers this first step, relative quantification with an internal standard is the method of choice. For the screening of enzyme reactions, where the initial substrate concentration is a known parameter, the absolute quantification without an internal standard is possible as long as the number of analytes to be detected simultaneously is low enough to minimize peak suppressing effects.

Nevertheless, this method enabled to monitor enzyme-catalyzed reactions, e.g., the time-dependent degradation of peptides and peptide mixtures by trypsin (Tholey et al. 2006). This model situation represents a method for enzyme screening, e.g., when a set of different isoforms of an enzyme is screened to determine the most active one by conversion of the same substrate. By acquisition of a calibration curve, variation of the initial substrate concentration of neurotensin and the application of a classical enzyme kinetic method (Lineweaver-Burk plot ) the K M- and v max-value of the proteolytic reaction were determined. Results obtained in parallel by relative quantification using a homologous internal standard (Trp11-neurotensin ) and HPLC-UV (at 214 nm) as an orthogonal method were in good agreement to those achieved by absolute quantification. This confirms the application of standard-free analysis by MALDI MS as a compatible quantitative method.

Considering the previously mentioned ion suppressive effects, if more than one substrate is analyzed simultaneously, this method can still be used for monitoring multisubstrate conversions in a rather semi-quantitative way. Therefore the authors investigated the evolution of tryptic digestion of an equimolar mixture of five peptides (angiotensin II, substance P, neurotensin, ACTH (1–17) and ACTH (18–39)). This more complex analyte environment impeded the direct determination of kinetic parameters for substrates with more than one cleavage site as different cleavage sites with different surrounding amino acid sequences result in various kinetic parameters. Once products are generated from the first proteolysis event they can serve as substrates for the following reactions and therefore can be consumed during the reaction. Additionally, the same problems of peak suppression (Knochenmuss and Zenobi 2003) hampered the overall accuracy. Therefore the authors chose the signal intensities rather than calculated concentrations to monitor the reaction, which means kinetic parameters, e.g., v max and K M, could not be determined in this experiment. However, the evolution of signal intensities was considered to be sufficient enough for a semi-quantitative method capable of screening several substrates for an enzyme.

In conclusion, ILMs applied with elevated M/A ratios allow for the direct quantification of peptides without the need of an internal standard. As for the understanding of enzyme activities the initial conversion velocity is the most relevant parameter, the limitation of the dynamic range to one order of magnitude also does not hamper the substrate screening. The described method is not limited to monitor proteolytic reactions but also applicable for most enzyme-catalyzed reactions as well. The key prerequisite is obviously a detectable difference in mass for substrate and product molecules.

3 Materials and Protocols

3.1 Materials

3.1.1 Laboratory and Technical Equipment

-

Pipettes and pipette tips, reaction tubes

-

Sonication bath

-

Flash evaporator/rotary evaporator

-

Vacuum oven/vacuum centrifuge

-

Stainless steel MALDI MS target

-

MALDI-TOF mass spectrometer

3.1.2 Chemicals

-

MALDI matrix compound (e.g., CHCA, DHB, or SA)

-

Organic base compound (e.g., pyridine, tributylamine or 1-methylimidazole)

-

Methanol, ethanol, or acetonitrile

-

Deionized water (18.2 MΩ/cm)

-

Trifluoroacetic acid (TFA)

-

Internal standard

-

Mass calibration standard

3.2 Preparation of ILMs

In general, two different protocols are available for the preparation of ILMs. The major difference between both protocols is the performance of a solvent evaporation step as suggested in the original protocol (Armstrong et al. 2001). In the second protocol the acidic and basic component are simply premixed in appropriate solvents and are immediately used for further sample preparation (Zabet-Moghaddam et al. 2004). The original method is in particular suited for longer storage of the prepared ILM. No significant differences in the MALDI behavior have been observed for the two protocols up to now.

3.2.1 Preparation with Solvent Evaporation (Armstrong et al. 2001)

-

Prepare the ILM by dissolving the crystalline matrix (~0.5 g) in methanol (15 mL) and add an equimolar amount of organic base.

-

Sonicate the mixture for 5 min, filtrate and remove the solvent by evaporation.

-

Dry the product in a vacuum oven at room temperature in order to remove residual solvent traces. The resulting organic salt can be stored at 4 °C in the fridge for a few days and can be dissolved freshly in the required solvents prior to measurement.

3.2.2 Fast Preparation (Zabet-Moghaddam et al. 2004)

-

Alternatively, prepare the ILM by dissolving the crystalline matrix directly in the solvent mixture, which is used for sample preparation, e.g., 70% acetonitrile, and add the equimolar amount of pure organic base.

-

Sonicate the mixture for 5 min.

-

ILMs prepared in this way should be made freshly on each day of measurement as degradation occurs faster in dissolved than in solid form of the matrix.

3.3 First Step Towards Quantification

-

Analyze the ion response of your analyte of interest by MALDI MS and identify the amount on target required to get a reasonable signal-to-noise ratio in the mass spectrum.

-

Assign the linear range for the analyte by plotting the signal intensities for a broad variety of concentrations around the amount on target determined in the previous step. The linear range of an analytical method is defined as the range in which the signal intensity increases directly proportional with the analyte concentration.

-

For highly contaminated samples it is recommended to purify the samples prior to MALDI MS measurement. Due to sample losses during purification the internal standard should be added beforehand.

3.4 Setting up a Calibration Curve

3.4.1 General Rules

-

In general, a suitable calibration curve can either span the whole linear range or can be limited to the region of interest in case your experimental setup allows you to estimate the approximate concentration of analyte a priori.

-

As a general rule, the more data-points you collect to set up the curve, the more accurate the determination of the unknown concentration of the analyte. The final concentration of the analyte should be determined in the central part of the curve.

3.4.2 Setting up a Calibration Curve Using an Internal Standard

-

Prepare dilution series of the analyte covering the concentration range of interest. Use the same buffer solutions as in your final experiment before mixing the analyte solution with matrix as this influences the ion response. Finally, spike the calibration solutions with a constant amount of internal standard, dry (e.g., 5 min under air stream or under vacuum) and measure the calibration solutions (each concentration at least three times) by MALDI MS.

-

Generate the calibration curve by plotting analyte concentrations on the x-axis and signal intensity ratios of analyte and internal standard on the y-axis of the diagram.

3.4.3 Setting up a Calibration Curve Without an Internal Standard

-

Proceed as described above with the preparation of the analyte dilution series but without the addition of an internal standard.

-

Generate the calibration curve by plotting analyte concentrations on the x-axis and signal intensities of the analyte on the y-axis of the diagram.

3.5 Sample Preparation for MALDI MS Measurement and Data Analysis

-

Mix the sample (with internal standard) and the ILM of choice at a suitable molar M/A ratio. Spot at least three replicates of the sample on the target, dry the sample spots as described in Sect. 3.4.2, and acquire the MALDI MS data.

-

Calculate the signal intensity ratio of analyte and internal standard or, in case of standard-free quantification, simply determine the signal intensity of the analyte from the mass spectrum. Use the calibration curve to determine the unknown concentration of the analyte.

3.6 General Remarks

-

Note that certain ILM preparations lead to the formation of small crystals after ejecting the target out of the high vacuum. This effect does usually not hamper the quality of a potential re-analysis of the sample preparations.

-

Addition of small amounts of acids can help to promote ionization of different analytes. For example, the analysis of phosphopeptides can be facilitated by the addition of 1% H3PO4 to the ILM (Tholey 2006).

References

Armstrong DW, Zhang LK, He LF, Gross ML (2001) Ionic liquids as matrixes for matrix-assisted laser desorption/ionization mass spectrometry. Anal Chem 73(15):3679–3686

Berthod A, Crank JA, Rundlett KL, Armstrong DW (2009) A second-generation ionic liquid matrix-assisted laser desorption/ionization matrix for effective mass spectrometric analysis of biodegradable polymers. Rapid Commun Mass Spectrom 23(21):3409–3422

Bungert D, Bastian S, Heckmann-Pohl DM, Giffhorn F, Heinzle E, Tholey A (2004) Screening of sugar converting enzymes using quantitative MALDI-ToF mass spectrometry. Biotechnol Lett 26(13):1025–1030

Cohen LH, Gusev AI (2002) Small molecule analysis by MALDI mass spectrometry. Anal Bioanal Chem 373(7):571–586

Cramer R, Corless S (2005) Liquid ultraviolet matrix-assisted laser desorption/ionization—mass spectrometry for automated proteomic analysis. Proteomics 5(2):360–370

Crank JA, Armstrong DW (2009) Towards a second generation of ionic liquid matrices (ILMs) for MALDI-MS of peptides, proteins, and carbohydrates. J Am Soc Mass Spectrom 20(10):1790–1800

de Rond T, Danielewicz M, Northen T (2015) High throughput screening of enzyme activity with mass spectrometry imaging. Curr Opin Biotechnol 31:1–9

Distler AM, Allison J (2001) Improved MALDI-MS analysis of oligonucleotides through the use of fucose as a matrix additive. Anal Chem 73(20):5000–5003

Dreisewerd K (2003) The desorption process in MALDI. Chem Rev 103(2):395–426

Dreisewerd K (2014) Recent methodological advances in MALDI mass spectrometry. Anal Bioanal Chem 406(9–10):2261–2278

Gabriel SJ, Pfeifer D, Schwarzinger C, Panne U, Weidner SM (2014) Matrix-assisted laser desorption/ionization time-of-flight mass spectrometric imaging of synthetic polymer sample spots prepared using ionic liquid matrices. Rapid Commun Mass Spectrom 28(5):489–498

Giffhorn F (2000) Fungal pyranose oxidases: occurrence, properties and biotechnical applications in carbohydrate chemistry. Appl Microbiol Biotechnol 54(6):727–740

Greis KD (2007) Mass spectrometry for enzyme assays and inhibitor screening: an emerging application in pharmaceutical research. Mass Spectrom Rev 26(3):324–339

Gusev AI, Wilkinson WR, Proctor A, Hercules DM (1996) Direct quantitative analysis of peptides using matrix assisted laser desorption ionization. Anal Bioanal Chem 354(4):455–463

Harvey DJ (1999) Matrix-assisted laser desorption/ionization mass spectrometry of carbohydrates. Mass Spectrom Rev 18(6):349–450

Hillenkamp F, Karas M, Beavis RC, Chait BT (1991) Matrix-assisted laser desorption/ionization mass spectrometry of biopolymers. Anal Chem 63(24):1193A–1203A

Jaskolla TW, Lehmann WD, Karas M (2008) 4-Chloro-alpha-cyanocinnamic acid is an advanced, rationally designed MALDI matrix. Proc Natl Acad Sci U S A 105(34):12200–12205

Kang MJ, Tholey A, Heinzle E (2000) Quantitation of low molecular mass substrates and products of enzyme catalyzed reactions using matrix-assisted laser desorption/ionization time-of-flight mass spectrometry. Rapid Commun Mass Spectrom 14(21):1972–1978

Karas M, Hillenkamp F (1988) Laser desorption ionization of proteins with molecular masses exceeding 10,000 daltons. Anal Chem 60(20):2299–2301

Knochenmuss R, Zenobi R (2003) MALDI ionization: the role of in-plume processes. Chem Rev 103(2):441–452

Lemaire R, Tabet JC, Ducoroy P, Hendra JB, Salzet M, Fournier I (2006) Solid ionic matrixes for direct tissue analysis and MALDI imaging. Anal Chem 78(3):809–819

Li YL, Gross ML (2004) Ionic-liquid matrices for quantitative analysis by MALDI-TOF mass spectrometry. J Am Soc Mass Spectrom 15(12):1833–1837

Mank M, Stahl B, Boehm G (2004) 2,5-Dihydroxybenzoic acid butylamine and other ionic liquid matrixes for enhanced MALDI-MS analysis of biomolecules. Anal Chem 76(10):2938–2950

Nicola AJ, Gusev AI, Proctor A, Jackson EK, Hercules DM (1995) Application of the fast-evaporation sample preparation method for improving quantification of angiotensin II by matrix-assisted laser desorption/ionization. Rapid Commun Mass Spectrom 9(12):1164–1171

Palmblad M, Cramer R (2007) Liquid matrix deposition on conductive hydrophobic surfaces for tuning and quantitation in UV-MALDI mass spectrometry. J Am Soc Mass Spectrom 18(4):693–697

Reetz MT (2003) An overview of high-throughput screening systems for enantioselective enzymatic transformations. Methods Mol Biol 230:259–282

Sun P, Armstrong DW (2010) Ionic liquids in analytical chemistry. Anal Chim Acta 661(1):1–16

Sze ET, Chan TW, Wang G (1998) Formulation of matrix solutions for use in matrix-assisted laser desorption/ionization of biomolecules. J Am Soc Mass Spectrom 9(2):166–174

Tholey A (2006) Ionic liquid matrices with phosphoric acid as matrix additive for the facilitated analysis of phosphopeptides by matrix-assisted laser desorption/ionization mass spectrometry. Rapid Commun Mass Spectrom 20(11):1761–1768

Tholey A, Heinzle E (2002) Methods for biocatalyst screening. Adv Biochem Eng Biotechnol 74:1–19

Tholey A, Heinzle E (2006) Ionic (liquid) matrices for matrix-assisted laser desorption/ionization mass spectrometry-applications and perspectives. Anal Bioanal Chem 386(1):24–37

Tholey A, Zabet-Moghaddam M, Heinzle E (2006) Quantification of peptides for the monitoring of protease-catalyzed reactions by matrix-assisted laser desorption/ionization mass spectrometry using ionic liquid matrixes. Anal Chem 78(1):291–297

Towers MW, McKendrick JE, Cramer R (2010) Introduction of 4-chloro-alpha-cyanocinnamic acid liquid matrices for high sensitivity UV-MALDI MS. J Proteome Res 9(4):1931–1940

Vaidyanathan S, Gaskell S, Goodacre R (2006) Matrix-suppressed laser desorption/ionisation mass spectrometry and its suitability for metabolome analyses. Rapid Commun Mass Spectrom 20(8):1192–1198

Wittmann C, Heinzle E (2001) MALDI-TOF MS for quantification of substrates and products in cultivations of Corynebacterium glutamicum. Biotechnol Bioeng 72(6):642–647

Zabet-Moghaddam M, Heinzle E, Tholey A (2004) Qualitative and quantitative analysis of low molecular weight compounds by ultraviolet matrix-assisted laser desorption/ionization mass spectrometry using ionic liquid matrices. Rapid Commun Mass Spectrom 18(2):141–148

Zabet-Moghaddam M, Heinzle E, Lasaosa M, Tholey A (2006) Pyridinium-based ionic liquid matrices can improve the identification of proteins by peptide mass-fingerprint analysis with matrix-assisted laser desorption/ionization mass spectrometry. Anal Bioanal Chem 384(1):215–224

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Tucher, J., Somasundaram, P., Tholey, A. (2016). Quantitative MALDI MS Using Ionic Liquid Matrices. In: Cramer, R. (eds) Advances in MALDI and Laser-Induced Soft Ionization Mass Spectrometry. Springer, Cham. https://doi.org/10.1007/978-3-319-04819-2_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-04819-2_5

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-04818-5

Online ISBN: 978-3-319-04819-2

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)