Abstract

Micromanipulation of dielectric objects, from polystyrene spheres to living cells, is achieved when radiation pressure forces create stable trapping by highly focused laser beams through microscopes. However, the impressive history of optical trapping is shadowed by the light diffraction limit, as research currently has focused on materials below the micron scale, requiring stronger optical confinement and higher intensities than can be provided by the conventional optical tweezers. Recently, plasmonic nanostructures have entered the field, either to assist or enhance it. In this study, we present experimental results on using localized fields of metallic structures for efficient trapping, with various patterns (dots, fringes and squares). The patterns were produced by laser interferometry on almost continuous Ag or Au films on glass and glass covered by an amorphous Al\(_{2}\)O\(_{3}\) layer (10 nm thick) respectively. We have calculated the optical forces by measuring the particle’s escape velocity. The results show that the effective quality factor Q in the patterned metal film is enhanced by a factor \(>\)10, with respect to the unpatterned metal film and a factor \(>\)100, with respect to an uncoated glass. In addition, mathematical simulation of plasmonic fields is investigated to confirm and explain theoretically, the experimentally observed plasmonic enhancement.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The field of optical trapping has grown due to implementation in various arenas including physical chemistry, biology and medicine. This success lies in the non-invasive nature of optical forces. Recently, evanescent waves have been employed, instead of conventional propagating waves to form the optical trap. This is expected to allow development of optical traps with sub-wavelength volumes, which could enable direct manipulation of nano-scale objects [1–3]. Moreover, plasmonics involve a wealth of novel promising scientific applications such as the trapping of nanomaterials by an enhanced optical force. Optical trapping based on surface plasmons can potentially overcome the main disadvantage of the conventional optical trapping systems, i.e. due to the diffraction limit of the incident light the spatial resolution in trapping is ordinarily limited to more than several hundreds of nanometers. Nanometric optical tweezers with sub-diffraction-limited trapping volume have been realized by utilizing optical near field between gold nanodots fabricated by electron beam lithography [4, 5]. These studies indicate that such metallic nanostructures (nanogaps, nanoantennas etc.), can function as novel small light sources in the nano-cosmos. Plasmonic traps may play a key role in the development of applications, such as lab-on-a-chip, with increased functionalities. Compared to conventional optical tweezers, plasmonic traps do not require elaborate optical setups. Lately, plasmonic traps have become an important tool for immobilizing nanoparticles or cells on a substrate.

In a previous work [6], we reported that the fabrication of an optical trap with enhanced efficiency could be based on localized plasmonic fields around sharp metallic features. The trap was created near the surface of a laser-structured silicon substrate with quasi-ordered microspikes, coated with a thin silver film.

In this work, we present experimental results on using localized fields of metallic structures for efficient trapping, with various patterns (dots, fringes and squares). The patterns were produced by laser interferometry on almost continuous Ag or Au films on glass or glass covered by an amorphous Al\(_{2}\)O\(_{3}\) layer (10 nm thick) respectively. We have calculated the average of the optical forces by measuring the particle’s escape velocity. An enhancement of the effective quality factor Q is observed for certain patterns with respect to unpatterned metal layers or uncoated glass. In addition, mathematical simulation of plasmonic fields is performed to confirm theoretically the experimentally observed enhancement.

2 Materials and Methods

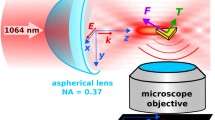

The experimental set-up has been described previously [3] and is only outlined here. The trap was created using a continuous wave Gaussian Nd:YAG laser beam at 1064 nm, focused through an objective onto the sample. The beam radius at the waist was w\(_{0}\sim 500\) nm, corresponding to the focusing lens with numerical aperture N.A. \(=\) 1.25, employed. The substrates were placed on a motorized x-y translation stage (Standa 8MT 167-2S) and the image of the trapped beads was captured on a CCD camera. As trapped objects we used polystyrene beads with mean diameter of 900 nm, suspended in deionized water of refractive index n \(=\) 1.33.

The metallic structures were produced by laser interferometry using phase masks at 193 nm on almost continuous Ag or Au films deposited on glass or glass covered by an amorphous Al\(_{2}\)O\(_{3}\) layer (10 nm thick) respectively. Most results refer to patterns produced with a single pulse of energy density of 58 mJ/cm\(^{2}\). Patterns as those shown in Fig. 24.1 were produced by exposing the films to 5 laser pulses (a, b) and 1 laser pulse (c), each with the phase mask rotated by \(90^{\circ }\) as described in details elsewhere [7, 8]. On the patterns nanoparticles with mean diameters in the range 70–100 nm were formed.

3 Results and Discussion

We determined the effective optical trap force, by performing escape velocity measurements. By translating the structured substrates at a constant velocity, under the focal point of the trapping laser beam, we were able to measure the escape velocity for which the polystyrene beads escaped the optical trap. At the escape velocity, the effective trapping force is considered to be equal to the viscous drag force, described by the modified Stokes law,

where \(\eta \) is the water viscosity, r the bead radius, \(v_{esc}\) the escape velocity of the bead and K (\(\sim \)1.33) a correction coefficient [9]. Figure 24.2 shows the effective force exerted on 900 nm polystyrene beads, optically trapped above the structures as a function of the power of the trapping laser beam. In this graph, we can observe that the trapping force changes with the substrate morphology. The squared and fringed patterns [Fig. 24.1b, c for Ag], show a significant enhancement of the trapping force, compared to that in the dotted pattern or the unpatterned films.

Trapping force on 900 nm polystyrene beads as a function of laser power for different substrates. \(\blacksquare \) squared pattern in Au film, \(\square \) unpatterned Au film, \(\blacktriangle \) dotted pattern in Ag film (SEM image shown in Fig. 24.1a), \(\bullet \) squared pattern in Ag film (SEM image shown in Fig. 24.1c), \(\blacklozenge \) fringed pattern in Ag film (SEM image shown in Fig. 24.1b)

Knowing the trapping force, F, we can evaluate the effective quality factor of the optical trap, Q. The effective quality factor is defined as,

where c is the speed of light, n is the refractive index of the surrounding medium and P is the power of the trapping laser beam. The quality factors for the samples used in this study are given in the following Tables. We note that these are average of the optical force values and should be regarded as approximations, since for some samples the optical force is a nonlinear function of the trapping laser power, as shown in Fig. 24.2. In previous studies [9], it was observed that the increased trapping laser power changes the axial trapping point; hence a single value for the quality factor could not be derived for a given particle over all laser powers.

The calculated quality factors in Table 24.1, for the squared patterns in Au and Ag films, are one or two orders of magnitude larger than the ones of the other patterned substrates and uncoated glass respectively. The evaluated structures of the Table 24.1 have been developed with one laser pulse of energy density 58 mJ/cm\(^{2}\).

Table 24.2 shows the dependence of the quality factor on the average energy density used to produce fringed patterns in Ag films using 5 laser pulses. The patterns produced with the highest energy density show more than twice enhancement of Q, when compared to similar patterns produced with lower energy densities. Generally, lower energies produce less nanoparticles as expected and shown in Fig. 24.3.

A possible explanation for the enhanced efficiency of the described optical trap is based on the action of localized plasmonic fields, created around the patterns covered with metallic nanoparticles [10, 11]. However, the field enhancement is not an inherent property of plasmonics, but rather that of cavity effects as seen in Fabry-Perot interferometers and laser resonances [12]. For this reason more investigation is needed. However, we can conclude that the combination of metallic structures with metallic nanoparticles results in electromagnetic field enhancement, during optical trapping and increases the quality factor of the trap.

As far as the theoretical analysis is concerned, the trapping force shows an enhancement when the substrate is covered with a metal layer, and even more in the presence of nanostructures. The electromagnetic force can be calculated through the gradient of the square of the electric field norm, as described by the formula,

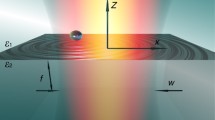

where \(a\) is the polarizability of the particles and \(n_{env} \) is the refractive index of the medium, water in our case (\(n_{env}=1.33\)) [13]. Specifically and in coherence with the experimental parameters, a Gaussian laser beam with wavelength \(\lambda _{0} =1064\) nm was assumed to illuminate the samples, namely an uncoated glass, an unpatterned metal film and a patterned metal film. The beam radius, at the waist was \(\mathrm{{w}}_{0}\sim 500\) nm corresponding to a focusing lens with numerical aperture N.A. \(=\) 1.25, as the one used in the experiments. The diameter of the nanospheres was chosen to be 100 nm, and the distance between them 250 nm, in order to fit best the experimental conditions. The material of the nanospheres was assumed to be gold, although similar results are produced for silver or other metals. The background environment was water, as in the experiments. Then, the Maxwell equation in the form,

was solved through finite element numerical analysis [14], using the COMSOL Multiphysics software package [15]. Here \(k_0\) is the free space wavenumber and \(\varepsilon _r\) the relative permittivity of the material, given by the formula,

where \(n,\kappa \) are the real and the imaginary part of the complex refractive index, respectively. In this way, via (24.4) and (24.5), the electric field distribution in the focal region of the beam was determined, and then (24.3) was applied in order to calculate the trapping force.

The results are shown in Fig. 24.4a. It is clear that the trapping force reaches a maximum when patterned metal film is employed. Figure 24.4b shows the electric field distribution over a metal substrate with nanospheres. It is evident that the nanostructures strongly interact with the electromagnetic field, enhancing its gradient, and consequently the trapping force.

4 Concluding Remarks

In conclusion, we have demonstrated that the measured trapping force exerted on polystyrene beads of 900 nm diameter changes with the substrate morphology. Periodically patterned metal films create a plasmonic optical trap with a larger trapping efficiency, than that of a conventional system, and an additional potential for applications in nanoengineering and nanobiology. The calculated Q factor was almost one or two orders of magnitude larger than the one of a conventional optical trap, with the same objective lens. The maximum trapping force was achieved in squared patterns covered by metal nanoparticles, with gold leading to slightly higher enhancement than silver. The theoretical simulations confirm an optimization in optical trapping when metallic nanospheres are employed. However, as the field enhancement is not an exclusive property of plasmonics, more investigation is under way to establish the contribution of the localized plasmonic field to the total trapping field. In addition, as 1064 nm wavelength was not the optimum for the specific combination of substrate and nanostructures employed, a more favorable combination of all three is studied.

References

M. Gu, J.-B. Haumonte, Y. Micheau, J.W.M. Chon, X. Gan, Laser trapping and manipulation under focused evanescent wave illumination. Appl. Phys. Lett. 84, 4236–4238 (2004)

K. Wang, E. Schonbrun, P. Steinvurzel, K.B. Crozier, Trapping and rotating nanoparticles using a plasmonic nano-tweezer with an integrated heat sink. Nat. Comm. 2, 469-1–469-4 (2011)

D.G. Kotsifaki, M. Makropoulou, A.A. Serafetinides, Efficient and low cost multiple optical trap, based on interference. Optik 124, 617–621 (2013)

A.N. Grigorenko, N.W. Roberts, M.R. Dickinson, Y. Zhang, Nanometric optical tweezers based on nanostructured substrates. Nat. Phot. 2, 365–370 (2008)

M. Righini, G. Volpe, C. Girard, D. Petrov, R. Quidant, Surface plasmon optical tweezers: tunable optical manipulation in the femtonewton range. Phys. Rev. Lett. 100, 186804-1–186804-4 (2008)

D.G. Kotsifaki, M. Kandyla, I. Zergioti, M. Makropoulou, E. Chatzitheodoridis, A.A. Serafetinides, Optical tweezers with enhanced efficiency based on laser structured substrates. Appl. Phys. Lett. 101, 011102-1–011102-3 (2012)

R.J. Peláez, C.N. Afonso, J. Bulíř, J. Lančok, M. Novotný, Diffractive and coloured films by laser interferometry patterning. Surf. Coat. Techn. 211, 205–208 (2012)

R.J. Peláez, G. Baraldi, C.N. Afonso, S. Riedel, J. Boneberg, P. Leiderer, Selective gold nanoparticles formation by pulsed laser interference. Appl. Surf. Sc. 258, 9223–9227 (2012)

W.H. Wright, G.J. Sonek, M.W. Berns, Parametric study of the forces on microspheres held by optical tweezers. Appl. Opt. 33, 1735–1748 (1994)

A. Kinkhabwala, Z. Yu, S. Fan, Y. Avlasevich, K. Müllen, W.E. Moerner, Large single-molecule fluorescence enhancements produced by a bowtie nanoantenna. Nat. Phot. 3, 654–657 (2009)

W. Zhang, L. Huang, C. Santschi, O.J.F. Martin, Trapping and sensing 10 nm metal nanoparticles using plasmonic dipole antennas. Nano. Lett. 10, 1006–1011 (2010)

S. Kawata, Plasmonics: future outlook. Jap. J. Appl. Phys. 52, 010001-1–010001-10 (2013)

J. Wu, X. Gan, Optimization of plasmonic nanostructure for nanoparticle trapping. Opt. Exp. 20, 14879–14890 (2012)

J.-M. Jin, The finite element method in electromagnetics. Wiley-IEEE Press, New York (2002)

Acknowledgments

The authors would like to thank Prof. A. Boudouvis for access to the COMSOL Multiphysics software package. The authors would also like to thank Mr. Sp. Zidropoulos for his help with the SEM imaging. RP acknowledges a grant from the JAE-doc program co-funded by European Social Fund. This work has partially been supported by MAT2011-28345-C02-02 (Spain) projects.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer International Publishing Switzerland

About this paper

Cite this paper

Kotsifaki, D.G. et al. (2014). Enhanced Optical Forces in Plasmonic Microstructures. In: Polychroniadis, E., Oral, A., Ozer, M. (eds) International Multidisciplinary Microscopy Congress. Springer Proceedings in Physics, vol 154. Springer, Cham. https://doi.org/10.1007/978-3-319-04639-6_24

Download citation

DOI: https://doi.org/10.1007/978-3-319-04639-6_24

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-04638-9

Online ISBN: 978-3-319-04639-6

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)