Abstract

The objective of this paper is to provide a new theoretical basis to localize and quantify sparse damage in a structure based on highly incomplete modal information. Although a large number of papers have been written on the subject, this paper offers a new perspective on the problem by proposing the L-1 norm minimization criteria, in contrast to the more traditional L-2 (Euclidean) norm minimization criterion. The proposed L-1 norm approach enables accurate and robust examination of a number of potential damage locations much larger than the number of frequencies used in the formulation of the modal sensitivity matrix. In addition, it is shown that L-1 minimization leads to sparse solutions, this is in contrast with the L-2 criteria, which leads to disperse solutions. The computational effort necessary to solve the L-1 optimization is significantly larger than in the traditional Euclidean norm and requires the use of convex optimization algorithms. However, given the results that can be obtained, the computational effort is justified. The efficacy of the proposed framework is demonstrated in detecting sparse damage in a simulated 21 degree of freedom shear building structure.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

26.1 Introduction

The use of vibration measurements, and more specifically, identified modal information to detect damage (stiffness reductions) in structures can be traced back almost to the dawn of microcomputers in the late 1970s and early 1980s [1, 2]. The realization that changes in structural properties induce changes in vibration frequencies was the primary impetus for developing vibration-based damage identification technology. Since then, numerous analytical methods and experimental techniques have been developed in order to expand the limits of what can be detected by processing limited vibration measurements [3–5].

Modal information for damage detection includes changes in modal frequencies, modal shapes and(or) modal damping between the assumed healthy state and the potentially damaged state. It has been shown theoretically and verified experimentally that the uncertainty and difficulty to identify modal shapes and damping ratios increases significantly in comparison with that associated with identification of modal frequencies [6, 7]. Therefore, it is highly desirable to develop computational methods that operate solely based on changes of identified modal frequencies as a criterion for damage detection.

While the amount of literature that proposes the use of modal frequency shifts as a feature for damage detection is extense [8, 9], it has not been yet possible to generalize their use in damage detection. Some authors have claimed that the use of modal information, specially modal frequencies is not sufficient to locate damage and that in general, changes in frequencies cannot provide spatial information about structural changes [10].

The main difficulty in localizing damage using modal information, such as changes in mode shapes and frequencies, resides in that the number of potential damage locations is by far larger than the number of identified modal parameters. If a sensitivity method is used, the result is an underdetermined system of linear equations with infinite number of possible solutions. If one decides to use exclusively modal frequencies, the problem is exacerbated even further.

The first objective of this paper is to clarify the mathematical nature of the underdetermined system of equations that arise from the application of the sensitivity method and to show that among the infinite number of possible solutions; in general, there are only a handful of sparse solutions. A sparse solution of degree s is one that only has at most s number of non-zero entries. Since structures are typically damaged in a small number of locations in comparison with the complete domain, we are interested in sparse solutions with low value of s, i.e. solutions with very few and sometimes only one non-zero component. Even though the concept of sparsity has been exploited to solve inverse problems in other disciplines [11, 12], only until very recently it has begun to attract some attention in structural health monitoring applications [13].

The second objective of this paper is to propose a method to find sparse solutions of the underdetermined system of equations that result from formulating the sensitivity method in structural dynamics. The proposed method relies on the use of the l 1 norm as opposed to the traditional l 2 norm. Previous results show that the l 1 minimum solution to a system of under determined system of linear equations is sparse [14]. The computational effort necessary to solve the l 1 optimization is larger than the traditional l 2 optimization and requires the use of convex optimization algorithms [15].

The paper begins with a brief review of the sensitivity method for finite element model updating. This is followed by a section on Banach vector spaces (complete normed vector spaces), with special emphasis on the contrast between l 1 and the l 2 normed spaces. The paper continues with a section describing one possible algorithm to solve the l 1 minimization problem, namely the primal-dual interior point method. We conclude with a section illustrating the proposed methodology in a non-uniform shear beam. In all cases, it is shown that changes in a small subset of the spectrum are sufficient to accurately locate small and localized stiffness reductions at arbitrary locations in the presence of moderate measurement noise.

26.2 Sensitivity-Based Model Updating

The sensitivity approach is one of the most popular and practical frameworks for finite element model updating in structural dynamics [16]. The basic idea is to relate small variations in the stiffness and mass of a finite element model (FEM) to the corresponding variations in the eigenvectors and eigenvalues. In this paper, we seek a relationship between small changes in eigenvalues to small changes in the parameters that define the stiffness matrix, that is

where \(\Delta \theta \in {\mathbb{R}}^{p\times 1}\) is a vector of changes in the parameters that define the stiffness matrix of the structure, \(\mathbf{S} \in {\mathbb{R}}^{n\times p}\) is the sensitivity matrix, and the \(\Delta \lambda \in {\mathbb{R}}^{n\times 1}\) is the corresponding change in the model’s eigenvalues due to \(\Delta \theta\).

In particular, we restrict our attention to the cases where the stiffness matrix \(\mathbf{K} \in {\mathbb{R}}^{n\times n}\) can be expressed as

where E i is an elementary influence matrix corresponding to the ith parameter, \(f_{i}\left (\cdot \right )\) is a differentiable function and p is the total number of independent parameters that define K. Consequently

By taking the first term of the Taylor series expansion around the current parameter value, the partial derivative of the stiffness matrix with respect to any particular parameter θ k can be approximated as

It has been previously shown [16] that

where λ j and ϕ j satisfy

and

where \(\mathbf{M} ={ \mathbf{M}}^{T} \in {\mathbb{R}}^{n\times n}\) is the mass matrix of the model, ϕ j is the mass normalized eigenvector corresponding to the eigenvalue λ j .

If only a subset of q < p < n frequencies is identified from vibration data, then only the corresponding q rows of S can be used in the inversion. Furthermore, since errors in system identification are inevitable and damage produces finite changes in the model parameters, the following approximate underdetermined system of equations results

where \(\Delta \lambda _{q} \in {\mathbb{R}}^{q\times 1}\) is the difference between the q eigenvalues of the damaged and undamaged structures, \(\Delta \theta \in {\mathbb{R}}^{p\times 1}\) is the change in the stiffness parameters and the components of \(\mathbf{S}_{q} \in {\mathbb{R}}^{q\times p}\) are given by Eq. (26.5). The vector \(\epsilon \in {\mathbb{R}}^{q\times 1}\) represents the error in the vector \(\Delta \lambda _{q}\) and it is the byproduct of the combined effect of numerical errors in the system identification algorithms, modeling errors and measurement noise, among others.

In general Eq. (26.8) has infinite number of solutions. In order to obtain a unique solution (or a few feasible solutions) we propose exploiting the fact that damage typically occurs at a very small number of sparse, yet unknown points r within the domain of the structure such that r < q. Traditionally, sparsity has not been exploited in damage identification.

26.3 The l p Norm

A norm is a mapping \(\left \|\cdot \right \|\) from a vector space X into \(\mathbb{R}\) which satisfies the following properties for every x ∈ X and y ∈ X and every \(\alpha \in \mathbb{C}\):

-

1.

\(\left \|x\right \| \geq 0\)

-

2.

\(\left \|\alpha x\right \| = \left \vert \alpha \right \vert \left \|x\right \|\)

-

3.

\(\left \|x + y\right \| \leq \left \|x\right \| + \left \|y\right \|\)

A norm generalizes the concept of distance that we inherit from Euclidean geometry. One of the most commonly used norms are the l p norms, which for a vector space \(X \in {\mathbb{C}}^{n}\) and 1 ≤ p ≤ ∞ is defined as

In the case of p = 2 we obtain the usual l 2 norm or Euclidean distance. For p = 1 we obtain the l 1 norm or the Manhattan distance, which corresponds to the sum of the absolute value of the components. For p = 0, although not a proper norm, since it does not meet requirements (26.2) and (26.3), we obtain the l 0 norm which corresponds to the number of components with non-zero elements (provided one accepts 00 = 0). The l 0 norm defines the sparsity of x ∈ X. A vector \(x \in {\mathbb{R}}^{n}\) is said to be s-sparse, for s < n if it contains s non-zero components and we represent it as \(\left \|x\right \|_{0} = s\).

We define an l p -ball B r p as the closed set whose elements satisfy

To develop some intuition regarding the effect of using different norms as criteria to select solutions to underdetermined system of linear equations consider Fig. 26.1. The line representing all the possible solutions to the generic underdetermined linear equation \(ax_{1} + bx_{2} = c\) is shown (a, b, c are constants). Figure 26.1a depicts the solution that minimizes the l 2 norm. This is obtained by determining the smallest l 2-ball that contains an element that satisfies the equation \(ax_{1} + bx_{2} = c\). By definition, every point in the depicted circle has the same l 2 norm and only one point satisfies the equation. Figure 26.1b depicts the solution that minimizes the l 1 norm. Similarly, in Fig. 26.1b the minimum l 1 solution is obtained by finding the smallest l 1-ball that contains an element that satisfies \(ax_{1} + bx_{2} = c\). As can be seen, the shape of the l 1 ball is very different from its l 2 counterpart. Moreover, except for the trivial cases of lines with slope of ±π∕4 radians, the l 1 solution will always be sparse, i.e., only one component will be non-zero. On the other hand, the l 2 solution, except for trivial cases of vertical and horizontal lines, will always have a non-sparse solution,i.e. all non-zero components. Finally, Fig. 26.1c shows the solutions obtained by minimizing the l 0 norm, as expected two solutions are obtained, one of them is the same that was obtained by minimizing the l 1 norm. Finally, note that proper l p norms are convex, which make them very suitable for solutions using convex optimization algorithms, while the l 0 norm is of combinatorial nature and non-convex.

(a) l 2 solution to an underdetermined linear equation. (b) l 1 solution to an underdetermined linear equation. l 1 solutions will provide the sparsest solution possible, while l 2 solution will provide the least sparse solution possible. (c) Depicts the solutions obtained by minimizing the l 0 norm

26.4 Numerical Methods for l 1 Minimization of Linear System of Equations

In contrast with l 2 minimization, which can be readily solved using well known algorithms such as singular value decomposition, the l 1 minimization requires significantly greater computational effort and no closed form solution exist. There are at least five family of computational methods for obtaining sparse solutions to underdetermined linear set of equations. These are:

-

Greedy pursuit: Iteratively refines a sparse solution by successively identifying one or more components that yield the greatest improvement in quality.

-

Convex relaxation: Replaces the combinatorial l o norm problem with a convex l 1 optimization problem. Solves the convex optimization problem using algorithms that exploit the structure of the problem.

-

Non-convex optimization: relaxes the l 0 problem to a related nonconvex problem and finds an stationary point.

-

Bayesian framework: Assumes a prior distribution for the unknown coefficients that favors sparsity. Develops a posteriori estimates that incorporate observations. After computing the posterior, identifies maximum a posteriori estimate or region with large probability mass.

-

Brute force: Searches through all possible sets. Clearly unfeasible for moderate and large scale problems.

In this paper we concentrate on convex relaxation methods, specifically the primal-dual interior point algorithm [15]. We replace the combinatorial l 0 by the l 1 norm, yielding a convex optimization problem with tractable solution. Intuitively, this makes sense, since the l 1 norm is the closest convex norm to the l 0 norm (see Fig. 26.1).

26.5 Numerical Verification

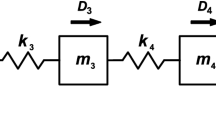

In this section we show numerical results to illustrate the applicability of the proposed methodology and some of the challenges that can be expected. We will simulate a 21 degree of freedom (DoF) shear beam with variable stiffness and mass. The main objectives are: (a) to detect a 1 % stiffness reduction in any single element given a limited number of system frequencies (no noise), (b) to detect multiple damaged elements selected at random given a limited number of identified frequencies of the system in the ideal noiseless case, and finally (c) to detect a 10 % reduction in stiffness in any single element in the presence of noise in the identified frequencies. For all cases the log-barrier interior-point optimization method was implemented using the l1-magic optimization package in MATLAB [17].

The degrees of freedom of the model are numbered from 1 in the first mass closest to the support, to 21 at the free end. The stiffness of the springs varies as follows \(k_{1} =\ldots = k_{7} = 1,000\), \(k_{8} =\ldots = k_{14} = 750\) and \(k_{15} =\ldots = k_{21} = 500\) and masses vary as follows \(m_{1} =\ldots = m_{7} = 1\), \(m_{8} =\ldots = m_{14} = 0.75\) and \(m_{15} =\ldots = m_{21} = 0.50\). All expressed in consistent units. The resulting fundamental frequency of the structure is 0. 436 Hz.

The damage sensitive features are a subset of the differences between the frequencies of the original system and the damaged system. We selected the lower frequencies as these are typically the ones that can be identified from measured vibration data in structures. The objectives here are: (1) to show the number of frequencies required in order to accurately identify the location and intensity of sparse damage, (2) to illustrate the difference between using an l 2 norm minimization criteria versus the proposed l 1 norm criteria for damage detection and (3) to show the effect of identification errors (noise) on the probability of detection (POD) of the proposed method.

To begin consider Fig. 26.2. Here we present the results of one particular ideal case (no noise) in which the damage (1 % stiffness reduction) was present in element No. 6 and the lowest 4 frequencies were selected as damage sensitive features. Thus, the sensitivity matrix \(\mathbf{S}_{q} \in {\mathbb{R}}^{4\times 21}\). In Fig. 26.2a the l 1 norm minimization solution is presented and in Fig. 26.2b the solution obtained using l 2 minimization. As stated previously, the proposed l 1 methodology finds the correct sparse solution, while the l 2 minimization generates an incorrect non-sparse solution.

The damage was identified as 15 units of stiffness reduction, this in contrast with the actual damage of 10 units. This result can be further refined if needed by simply fixing the damage location (found using the proposed algorithm) and optimizing the intensity to match the observed changes in frequency. At this point it is essential to emphasize that no prior information was given to the algorithm as to the potential number or locations of the damage. The method correctly identifies that there is a single element damaged (No. 6) and simultaneously estimates its intensity using changes in the lowest four eigenvalues.

We now proceed to examine the performance of the algorithm in detecting 1 % damage in any single element (taken separately, one at a time). Figure 26.3a presents a plot depicting in the ordinate the required number of frequencies in order to properly identify damage in each element considered (abscissa). In all cases, frequencies were selected starting from the lowest in increments of one until adequate identification was obtained. As can be seen, the number ranges from 2 in order to identify damage in element 15 up to 9 in order to identify damage in element 11. In average the number of frequencies required is close to 4.

Figure 26.3b displays the level of damage quantification accuracy obtained with the proposed method. As can be seen, the actual simulated stiffness reduction was 1 % for each member (considered separately), the proposed algorithm is typically within 0. 5 % of the actual value.

Next we investigate the scenario where multiple elements are damaged. Consider first the specific example where element No. 6 is affected by 1 % stiffness reduction (10 units) and element No. 15 by 5 % stiffness reduction (25 units). A comparison of the results using the l 1 minimization versus the l 2 minimization are shown in Fig. 26.4. For this case the lower 6 frequencies were used as damage sensitive features. As can be seen, the algorithm correctly identifies the locations of damage. The stiffness reduction identified by the algorithm was 1. 6 % (16. 33 units) for element No. 6, and 7. 7 % (38. 82 units) for element No. 15. We can also see from Fig. 26.4 that one could potentially assign some small damage ( < 1 %) to element No. 3 which was not damaged.

To investigate the effect of errors ε in Eq. (26.8) we simulate ε as a realization of an n-dimensional Gaussian random vector with zero mean and standard deviation of each component ε i proportional to the value of the corresponding λ i where n is the number of “identified” frequencies included in the inversion. We varied the number of “identified” frequencies, starting from 2 up to 10. In each case 1, 000 simulations were performed to obtain the corresponding probability of detection (POD). The criteria for detection were: (1) The method correctly identifies the element as damaged (reduced stiffness) and (2) it does not assign any other element a stiffness reduction greater than 20 % of the stiffness reduction assigned to the element with the highest reduction. This last condition assures that the identified damage is indeed sparse. A summary of the results for four selected elements are shown in Fig. 26.5.

By examining Fig. 26.5 in conjunction with Fig. 26.3a one can see that independently of the noise level, if not enough frequencies are included in the analysis, it will not be possible to achieve an accurate damage identification. In general the plots show the expected trend, i.e. the POD increases as the coefficient of variation of the noise decreases and as the number of frequencies included increases beyond those needed in the ideal case. It can also be observed that the POD curves tend to converge and that beyond a certain number of frequencies the increase in accuracy is minimal. An interesting case occurs with spring 2, in this case, when less than the minimal number of frequencies are used, the presence of noise improves the POD up to a certain point. This should be seen as an exception and not as a rule, as can be observed from the other cases. The range of values selected for the coefficient of variation of the “identified” frequencies was taken from uncertainty quantification studies on system identification results of real structures [6].

Finally we proceed to examine the efficacy of the proposed l 1 minimization algorithm as a function of the damage size for a fixed level of noise. Figure 26.6 depicts the POD for 1, 000 independent simulations for each fraction of damage (stiffness reduction) between 0 and 0.20 in increments of 0.02. In all cases a fixed coefficient of variation of 0. 001 was used for each frequency considered. As expected, the POD increases with the number of frequencies included and with the damage size. In majority of cases one can verify that for a damage severity corresponding to a 0. 10 stiffness reduction a POD > 0. 75 can be obtained with eight frequencies (or less in some cases), which is less than half the minimal number of frequencies required for a unique inversion of the sensitivity matrix.

26.6 Conclusions

This paper presents a new framework based on l 1-norm minimization to localize and quantify isolated structural damage in the form of stiffness reduction. The damage sensitive feature is the change in a subset of the eigenvalues of the system. The main contribution of the paper is to show that the l 1 based sensitivity approach is capable of accurately identifying damage using a noise contaminated subset of the spectrum which has significantly fewer elements (sometimes an order of magnitude less) than the set of potentially damaged elements. Furthermore, since the proposed algorithm does not rely on mode shapes, the number of sensors needed to perform the estimation can be relatively small, in many cases a single sensor could suffice.

References

Richardson MH (1980) Detection of damage in structures from changes in their dynamic(modal) properties- a survey. NUREG/CR-1431, U.S. Nuclear Regulatory Commission, Washington, DC

Potter R, Richardson MH (1974) Identification of the modal properties of an elastic structure from measured transfer function data. In: 20th International instrumentation symposium, Albuquerque

Doebling SW, Farrar CR, Prime MB, Shevitz DW (1996) Damage identification and health monitoring of structural and mechanical systems from changes in their vibration characteristics: a literature review. Los Alamos National Laboratory Report, LA-13070-MS

Sohn H, Farrar CR, Hemez F, Shunk DD (2003) A review of structural health monitoring literature: 1996–2001. Los Alamos National Laboratory Report, LA-13976-MS

Yuen K-V (2012) Updating large models for mechanical systems using incomplete modal measurement. Mech Syst Signal Process 28:297–308

Reynders E, Pintelon R, De Roeck G (2008) Uncertainty bounds on modal parameters obtained from stochastic subspace identification. Mech Syst Signal Process 22:948–969

Moser P, Moaveni B (2011) Environmental effects on the identified natural frequencies of the Dowling Hall Footbridge. Mech Syst Signal Process 25(7):2336–2357

Slawu OS (1997) Detection of structural damage through changes in frequency: a review. Eng Struct 19(9):718–723

Wang X, Yang C, Wang L, Yang H, Qiu Z (2013) Membership-set identification method for structural damage based on measured natural frequencies and static displacements. Struct Health Monit 12(1):23–34

Farrar CR, Doebling SW, Nix DA (2001). Vibration-based structural damage detection. Philos Trans R Soc Lond A 359(1778):131–149

Ghosh S, Rudyi Y (2009) Application of L1-norm regularization to epicardial potential solution of the inverse electrocardiography problem. Ann Biomed Eng 37(5):902–912

Candes E, Romberg J (2007) Sparsity and incoherence in compressive sampling. Inverse Probl 23:969–985

Zhou S, Bao Y, Li H (2013) Structural damage identification based on substructure sensitivity and l 1 sparse regularization. In: Proceedings of SPIE 8692 sensors and smart structures technologies for civil, mechanical and aerospace systems

Donoho DL, Elad M (2003) Optimally sparse representation in general (nonorthogonal) dictionaries via l 1 minimization. Proc Natl Acad Sci 100:2197–2202

Boyd S, Vandanberghe L (2004) Convex optimization. Cambridge University Press, New York

Mottershead JE, Link M, Friswell M (2011) The sensitivity method in finite element model updating. A tutorial. Mech Syst Signal Process 25(7):2275–2296

Candes E, Romberg J (2006) l 1-magic: a collection of MATLAB routines for solving the convex optimization programs central to compressive sampling. www.acm.cal-tech.edu/l1magic/

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 The Society for Experimental Mechanics, Inc.

About this paper

Cite this paper

Hernandez, E.M. (2014). Identification of Localized Damage in Structures Using Highly Incomplete Modal Information. In: Wicks, A. (eds) Structural Health Monitoring, Volume 5. Conference Proceedings of the Society for Experimental Mechanics Series. Springer, Cham. https://doi.org/10.1007/978-3-319-04570-2_26

Download citation

DOI: https://doi.org/10.1007/978-3-319-04570-2_26

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-04569-6

Online ISBN: 978-3-319-04570-2

eBook Packages: EngineeringEngineering (R0)