Abstract

The design of a magnetic field sensor system based on clad-etched fiber Bragg grating (FBG) sensors is presented in this chapter. When magnetic field monitoring is performed in electronically harsh environments, conventional measurement systems may not be reliable due, for example, to the effects of high levels of ionizing radiation or electromagnetic fields. Fiber Bragg gratings (FBGs) have features that lend these devices suitable to operate in harsh environments, but an appropriate design of the optoelectronic device is needed in order to work as a magnetic field sensor, since FBGs are natively insensitive to magnetic fields. Using magnetic fluids as sensing materials, FBGs can be used to detect magnetic field.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

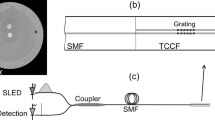

1 FBG-Based Magnetic Field Sensor

The design concept of such magnetic field sensor lies in the integration of a clad-etched fiber Bragg grating (FBG), which is sensitive to surrounding refractive index (SRI), with a magnetic-fluid coating as sensing element.

1.1 Magnetic Fluid

Magnetic fluid is a stable colloidal solution of ferromagnetic nanoparticles. The behavior of magnetic fluid depends on the external magnetic field and its refractive index shown to be magnetic field dependent [1–3]. The refractive index of a generic material n mat is given by

where ε r is the dielectric constant and χ m is the electric susceptibility of the material. The selected magnetic fluid consists of an aqueous solution of iron (II, III) oxide (Fe3O4—magnetite) magnetic nanoparticles (>50 nm) prepared by the chemical coprecipitation method [4]. Fe3O4 has a cubic inverse spinel structure which consists of a cubic close packed array of oxide ions where all of the Fe2+ ions occupy half of the octahedral sites and the Fe3+ are split evenly across the remaining octahedral sites and the tetrahedral sites. In this material, when the external magnetic field is perpendicular to the propagation direction of light, we have

Then, the refractive index of the magnetic-fluid coating will decrease when the magnetic field increases.

1.2 FBG as Surrounding Refractive Index (SRI) Sensor

If the FBG is designed as a SRI sensor, the reflection spectra of the FBG will show a dependence on the refractive index of the media surrounding the fiber. A way to achieve sensitivity to changes in surrounding refractive index (SRI) is to excite evanescent waves in the media surrounding the fiber [5]. It has been proven that by etching the fiber in the grating region to reduce its diameter, SRI significantly affects the effective refractive index of the core, causing the Bragg wavelength to shift [6]. The Bragg wavelength is given by

where n eff is the effective refractive index of the core and Λ is the grating period. Studying the dependence of the effective refractive index of the propagating mode, n eff , on the design parameters of the FBG, in particular cladding diameter and SRI, is possible to find the relation between a shift in λ B and the variation in the SRI that caused the shift. In the case of a magnetic-fluid coating, it is furthermore possible to establish a correspondence between the shift in the Bragg wavelength and the magnetic field the coating is subjected to.

2 Device Modeling

In order to study the wavelength shift, a structure with a uniformly thinned cladding along the grating was assumed and a model of doubly clad fiber defined for the cross section [7, 8]. The dependence of the effective refractive index on both the cladding diameter and SRI was evaluated by numerically solving the dispersion equation of the double cladding fiber mathematical model. A two-dimensional mode analysis has been performed on a single-mode optical fiber defined by CAD with a fixed core radius of 4.1 μm and refractive index n core = 1.460 RIU, cladding refractive index n clad = 1.455 RIU and a variable cladding radius from 4.2 to 62.5 μm, and refractive index of the surrounding media SRI in the range of 1.33–1.45 RIU. The model was simulated in the COMSOL ambient, a commercial multiphysics FEM simulator, connected to MATLAB to sweep in cladding radius and SRI. The outputs of the electromagnetic analysis are the electric field distribution and the effective refractive index of the propagating mode, n eff .

3 Results

The results show the effects of SRI and cladding radius on the electromagnetic properties of the device (Fig. 1). The Bragg wavelength of the thinned FBG shifts to higher wavelengths by increasing the SRI. The Bragg wavelength of the thinned FBG shifts sharply when the SRI is close to the cladding refractive index of the thinned FBG, near 1.460 RIU (Fig. 2). Moreover, the thinned FBG with the smaller radius has a higher sensitivity for the same SRI value (Fig. 3).

4 Conclusions

The results obtained encourage our design concept and the development of a low-cost class of magnetic FBG sensors suitable for several kinds of applications, for low-intensity and high-intensity magnetic fields. The preliminary design and optimization phases carried out by means of the 2D FEM analysis permit to significantly reduce the cost and the development time of the sensor and to manufacture a customized device for each application.

References

S. Y. Yang, Y. F. Chen, H. E. Horng, C. Y. Hong, W. S. Tse, and H. C. Yang, “Magnetically-modulated refractive index of magnetic fluid films,” Applied Physics Letters, Vol. 81, No. 26 (2002), pp. 4931–4933.

H. E. Horng, C. Y. Hong, S. Y. Yang, and H. C. Yang, “Designing the refractive indices by using magnetic fluids,” Applied Physics Letters, Vol. 15, No. 15 (2003), pp. 2434–2436.

C. Y. Hong, S. Y. Yang, H. E. Horng, and H. C. Yang, “Control parameters for the tunable refractive index of magnetic fluid films,” Journal of Applied Physics, Vol. 94, No. 6 (2003), pp. 3849–3852.

Y. Laiqiong, Z. Luji, and Y. Jixiao, “Study of preparation and properties on magnetization and stability for ferromagnetic fluids,” Materials Chemistry and Physics, Vol. 66, No. 1 (2000), pp. 6–9.

A. Cusano, G. Breglio, M. Giordano, M. Russo, J. Nasser, “Optoelectronic refractive index measurements: application for smart polymer processing,” Sensors, 2002. Proceedings of IEEE, Vol. 2 (2002), pp. 1171-1175.

A.N. Chryssis, S.M. Lee, S.B. Lee, S.S. Saini, M. Dagenais, “High Sensitivity Evanescent Field Fiber Bragg Grating Sensor,” IEEE Photonics Technology Letters, Vol. 17, No. 6 (2005), 1253-1255.

M. Monerie, “Propagation in Doubly Clad Single-Mode Fibers,” IEEE Journal of Quantum Electronics, Vol. QE-18, No. 4 (1982), 535-542.

A. Iadicicco, A. Cusano, S. Campopiano, A. Cutolo, M. Giordano, “Thinned Fiber Bragg Gratings as Refractive Index Sensors,” IEEE Sensors Journal, Vol. 5, No. 6 (2005), 1288-1295.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer International Publishing Switzerland

About this paper

Cite this paper

Saccomanno, A., Pagnano, D., Irace, A., Cusano, A., Giordano, M., Breglio, G. (2014). On the Design of a Clad-Etched Fiber Bragg Grating Sensor for Magnetic Field Sensing Applications. In: Di Natale, C., Ferrari, V., Ponzoni, A., Sberveglieri, G., Ferrari, M. (eds) Sensors and Microsystems. Lecture Notes in Electrical Engineering, vol 268. Springer, Cham. https://doi.org/10.1007/978-3-319-00684-0_43

Download citation

DOI: https://doi.org/10.1007/978-3-319-00684-0_43

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-00683-3

Online ISBN: 978-3-319-00684-0

eBook Packages: EngineeringEngineering (R0)