Abstract

In recent times, in the field of manufacturing, due to the continuously changing market demand, the concept of reconfigurable manufacturing systems emerged. This requires a process plan along with the machinery (kinematic configuration) to produce the part. When the product is changed, consequently the process plans and the kinematic configurations change accordingly as well. The change in the basic machinery seriously affects the overall profit of the industry. This paper presents an approach to minimize this cost while still providing a suitable process plan for the associated kinematic configuration. The algorithm to implement this approach is also the part of this paper. A sample part is taken as an example to illustrate the use of this approach. The results are compared with the existing data for the part. The applicability, uses and future trends have been discussed in conclusion.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Process Plan

- Operation Sequence

- Reconfigurable Manufacturing System

- Machine Structure

- Machine Configuration

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

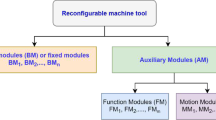

Reconfigurable manufacturing system (RMS) due to less lead time and the ability to adapt to changing market trends is an effective and successful manufacturing system of the current era, where tough competition and unanticipated customer requirements is a regularity. RMS can convert its production methodology from a low volume single batch production to the high volume line production without many issues, thus its usefulness is obvious. RMS is basically for automated industries, therefore it has two levels of configuration; the system level and the machine level, i.e., tooling and tool positioning. Therefore, there is a two level control of RMS as well: software control at the system level and a G&M code (CNC) control at the hardware or machine level.

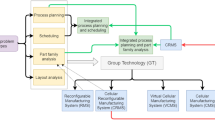

The main purpose of this paper is to introduce an approach which can select from the generated process plans the most feasible process plan (in terms of time as well cost of production) for the current available machinery, to reduce the overall initial cost of production. To achieve this, initially the developed process plans are required and to develop those, it is important to understand the manufacturing system. The conventional approaches use computer aided process planning systems (CAPP) in which, the machine components are considered static and only one process plan is developed for the system (Dedicated Manufacturing System). On the other hand, recently most of the research is been carried out to develop multiple process plans and a system to implement them. The CAPP for RMS, known also as Reconfigurable process planning (RPP) allows much freedom in this regard and therefore multiple process plans can be developed and multiple machine configurations can be deducted from those process plans. This concept is illustrated in Fig. 1.

A considerable amount of work has been done on the machine structure reduction [1]. The approach used was machine structure configuration approach. Also, there have been various attempts to develop and improve the operational sequences to achieve the maximum production that can be achieved [2, 3]. But; in general, it has been directed toward the development and the selection of the most optimum process plan based on cost of production, the production rate, and so on. The research work in this regard is shown in Table 1.

The set of operations which are achieved in RMS if compared with the rigid DMS sequences, enable us to reconfigure the sequences on different machines as per our requirement [4], as well as quickly reconfiguring process plans [5] and developing new ones as well [6]. Nonlinearity plays a serious role in the development of part programs and has been utilized by developing the concept of Network Part Program (NetPP) [7]. This was implemented by machine tool builders (e.g., by MCM S.P.A.). A number of studies throughout the world are focused on developing the part programs which develop the machine sequences. These studies are mostly focused on identifying similarity between new or evolved products and existing ones as well as on algorithms for optimizing the process precedence charts. A generic constraint-based model for CAPP was proposed [8] along with some appropriate solution methods and applied to different industrial domains [9, 10]. Another step further would be an approach which (a) minimizes part handling and re-fixturing time and (b) minimizes the cost of changes in the evolved process plans referring to setups, tools, re-programming costs [7]. In addition, evolving process plans have an impact on device configuration, especially in reconfigurable manufacturing systems. On the basis of this and some other issues/limitations associated with reconfigurable manufacturing systems, the concept of co-evolution emerged [11]. This concept introduces the development of product, processes, and structures simultaneously instead of developing one with reference to the other (process dependent on structure etc.).

From this, it can be inferred that the issue of manufacturing systems’ recurring and initial cost has been discussed many times since the first introduction of RMS in 1999. But, the concept of reducing them by co-relating the existing and the new parts’ process plan, is a new one. Even the concept of co-evolution does not cater for these costs. These costs, when reduced, can boost the profits of the machining wing of the manufacturing setup. To address this issue, the methodology is discussed in Sect. 2.

2 Methodology

Machine Adaptive Retainability Approach (MARA) is presented in this paper. The flow chart of the algorithm is shown in Fig. 2. The assumptions made during this approach are presented later on. The inputs of the approach include: the dimensions of the work-piece, the tool approach directions, the previously employed process plans and the feasible process plans for the new part. The approach consists of a comparison stage, after that the decision making and finally the selection of the process plan. The output is: the proposed machine configuration in case the current configuration is not sufficient, the candidate operation sequences and their tool approach directions. If it is sufficient however, then the same plan is maintained.

2.1 Assumptions

-

All the machines are reconfigurable.

-

All machine structures have the basic three translations, i.e., x, y, and z axis.

-

Since the basic translations are present, therefore the rest of the combinations which can be produced are ignored. And only the two possible rotations are considered.

The inputs required for this approach are as follows:

2.2 Tool Approach Directions

The direction from which the tool can approach to perform the specified task, is called the tool approach direction. The tool approach direction for some common tasks is shown in Fig. 3. The method by which they can be represented in a table is shown in Table 2. Further details can be found in [7, 12].

-

1 represents the possible TAD for the respective operation.

-

0 represents that TAD which cannot be used for the corresponding operation.

2.3 Previously Employed Process Plan

The data required is the tool approach directions, the operation sequences, the tools used, and the machinery utilized. This approach using the previously employed process plans for any specified part, selects from the new feasible process plans for the new part the one which is nearest (with conditions explained later in this paper) to the previously employed process plans to reduce costs in machinery.

2.4 Feasible Process Plans

Developing all the feasible process plans has been accomplished by many authors (El Maraghy 2007, T. Tolio 2002 etc.). Therefore, this is not a part of this research. Whatever means may have been adapted to develop the process plans, the feasible process plans for the part are taken as an input for the approach.

The algorithm for the approach is presented in Fig. 4. The abbreviations and the terminologies used in the flow chart are as follows:

- Tad:

-

Tool approach direction

- PEPP:

-

Previously employed process plans

- PPP:

-

Proposed process plan

- L, j, k, I:

-

Variables initialized as 0

- Reftadop:

-

TAD of the operation of the reference or previously employed process plan

- Tadop:

-

TAD of the operation of the proposed process plan. It should be noted that the operation should have the same serial wise location as the corresponding Reftadop

- CPP:

-

Counter for the difference in PPP and PEPP’s operations

- CKC:

-

Counter for the overall kinematic configuration difference between PPP and PEPP

The algorithm starts off with the inputs (previously employed process plan, proposed process plans, and work piece dimensions) and then moves on to the size check. If the machine workspace is not sufficient for the work piece then the algorithm stops then and there. After this step the algorithm moves into the first loop. Here, it compares the first operation of the first feasible process plan with the previously employed process plan. In the second iteration of the loop, the second operation is compared and after that, the third, and so on. If the operation has the same tool approach direction as that of the subsequent operation of the old process plan then the algorithm moves on to the next operation. In case they are different, a counter counts the change. When all of the operations have been compared; the changes in the process plan as a whole are saved.

Next, the algorithm moves on to the second proposed process plans, comparing it again with the previously employed process plan. The result may be a different number of changes. Later, the algorithm moves on to the third proposed process plan, and then to the fourth up to the final proposed process plan. It should be noted that if the number of operations is different for the previously employed and the proposed process plans then the excess operations will automatically have a counter change of 1, each. For example; if the new process has 10 operations as compared to the previously employed plan with 5 operations then the counter will have the value of the difference 5 stored in it due to this difference. The next step in the algorithm is the comparison of the overall tool approach directions of the proposed process plans with the overall tad of the PEPP. The algorithm first calculates the overall tool approach directions of the previously employed process plan. Then, it moves on to the first proposed process plan, then to the second, after that to the third continuing up to the final proposed process plan. A stepwise check of the process plans is made moving from one operation to the next. Initially, the TAD of the first operation of the process plan is saved into memory then it is compared with the TAD of the second operation. If both are the same then the counter remains 1. If not; then the counter counts 2 and the TAD of the 2nd operation is saved as well.

Later, in the algorithm, both these TADs are compared with the TAD of the third operation; which, if different, is again saved in the memory and in case of being same as either of the operations, is ignored. In this way the algorithm compares all the operations of the process plan and finally the overall TAD of each process plan is now stored in the memory. The algorithm has now stored the TAD of each operation as well as the overall TAD of the operational sequences. An overall TAD comparison is made between the proposed and the previously employed process plan. In case there is no difference between the previously employed and the proposed process plan, the algorithm saves the difference as 0; if there is a single change the algorithm stores it as 1, and so on. The further explanation of the complete algorithm is made in the section ‘case study’. The final stage in the algorithm is the utilization of the data stored. For each proposed sequence, there are currently two sets of information (1) the difference in the proposed and the previously employed sequence and (2) the overall TAD difference. The plan having an overall TAD change of 0 is the most preferred process plan for that particular RMS machine. If the number of plans having 0 overall TAD change is more than 1, then, the difference in the sequence separates them. The plan having least differences in the sequence will be selected.

3 Case Study

MARA is implemented on parts ANC-090 and ANC-101. For the case study, it is assumed that a certain industry has been producing the part ANC-090 and now it intends to switch to the production of part ANC-101. The parts are shown in Fig. 5 and Error! Reference source not found. A considerable amount of similarity exists between the two parts. The operation sequence along with the TAD of the operation for part ANC-090 which the company has been using is presented in Table 3. The proposed process plan is shown in Table 4. A comparison is made between these two in the following text to convert the differences into a numeric and thus, a calculable form. This numeric form can then be used to gauge the level and the cost that will be incurred by the new process plan.

To explain the algorithm’s working, it is implemented on the case study: Initially, a comparison is made between the first operation of the first proposed process plan and the first operation of the previously employed process plan. Form Tables 3 (Row 2) and 4 (Row 2), it can be seen that both of these have the same tool approach direction, i.e., +z. Therefore there is no addition to the value of CPP (initially 0). Then, it compares the second operation in the sequence. These too have the same TAD as well. Therefore, the algorithm moves on to the third and then the fourth and so on up to the twelfth operation all of which have the same TAD (−z). After this operation, the PEPP ends and for the comparison with the new process plan, the rest of the operations of the new process plan are compared with a 0 TAD. Therefore, all of these provide an increase in CPP. For example, operation 13 has TAD +x and in PEPP there is no operation 13 therefore it is compared with TAD: 0 and the CPP automatically increases by 1. The same is repeated for operation 14, 15 up to operation 20 increasing the CPP to 8. Therefore the total CPP for this sequence is 8.

Now, the ‘overall TAD’ of the PEPP and the new process plan is compared. The overall TAD is used to identify the machines capable of performing all the operations of a certain process plan. For example, if the overall TAD is 1 (−z), then a 3-axis machine is sufficient to perform all the operations of the process plan, if it is 2 (−z and +z), then a rotation will also be required and the minimum requirement will be a 4-axis machine. In this case however, the PEPP has an overall TAD of 3, (x, y axis are for positioning of the tool on the surface and −z for the TAD). While the Overall TAD of the new process plan is 4, (x and y are for positioning of the tool while −z and +x are the TAD. The –a direction is the new axis of motion for the angular hole). To achieve all of this a 4-axis machine at least with one axis of rotation is required. Hence, this concludes that the CKC is 1 for this process plan because a new axis is required as well. (CKC remains 0 if the previous and the new machines require same axis machines).

4 Results and Discussion

The results and the priority analysis is this approach is carried out only when there are at least 2 proposed process plans. The priority of one over the other through the MARA can then be developed. Hence, two of the PPP’s for the new part is shown in Tables 5 and 6.

The 2nd and the 3rd proposed process plans have different operation sequences as compared to the 1st (Table 4). In the 2nd PPP, the angular hole and its features have precedence over other operations. Thus, they moved up to the 2nd, 3rd, 4th, and 5th operation in the operation sequence. These are the operations numbered form 14 to 17. Now, in this situation, when the each operation is sequentially compared with the operations of PEPP, the case is considerably different. In this case when the 2nd operation in the sequence is compared with the same in Table 3, the CPP is increased by 1. It is further increased when the 3rd, 4th, and 5th operations are compared. Hence, this PPP has a considerably higher CPP in comparison with the first PPP. The overall TAD of this PPP is same (Overall TAD = 4) as that of the first PPP. The result is that this will also require a rotation axis (not some different axis) for the operations to be performed. In this regard both these PPP’s remain the same. The results drawn from the case study with different PPP’s are shown in Table 7. It can be seen that the PPP#1 has less CPP as compared with the other PPP’s while the CKC remains the same. Therefore the PPP#1 should be preferred over the other process plans.

5 Conclusion

A number of techniques are available for the problems associated with RMS, but are generally focused on either the development of the process plans for a certain machine configuration or try to find the most candidate configuration for a certain process plan. The issue which is generally not considered is the cost of changing the configuration as well as the process plan for new part. The concept of co-evolution which does consider this, was presented only recently. The major issue which co-evolution does not consider is the initial cost of production for any new part. MARA following the concepts presented in machine structure configuration approach was presented in the paper. It introduced the concept of developing the new part’s process plans and kinematic configurations using the previous part’s information. The kinematic configuration includes the machine’s capability and the reconfigurable machine tools required to develop the part. The complete part information plus the previous part’s knowledge is used as an input to initially develop a comparison between the currently employed process plan and the proposed process plans. This generated a deciding factor for the proposed process plans and concluded whether any one of these is a suitable candidate for the new part basing upon the current scheme. The required machine capabilities were then generated, helping in understanding the machine structures required for the subsequent process plans, thus prioritizing the most suitable one. The approach is more suitable if the both the previous and the new part to be produced belong to the same part family.

Finally, utilizing this information and including the previous data in the analysis, a suitable process plan along with the machine structure is proposed. This should not only help in the selection of the process plans but also significantly reduce the cost of the new machine structure which may have been required in case the previous information is ignored. This approach will help in automating and improving the process of machine as well as the process plan selection in commercial computer aided manufacturing (CAM) systems. It should be noted however, that this approach may be applied after some sort of sorting is done to select only the best few proposed process plans, if that is not the case, the approach will become tedious and redundant. In the current CAM systems the current machines and their configurations, plans are completely ignored when a new part is presented for manufacturing. This can be an important step in further developing the artificial intelligence (AI) of the current automated RMS. In the future this work will be taken further to develop the complete generation of suitable process plan for certain configurations.

References

Shabaka AI, ElMaraghi HA (2007) Generation of machine configurations based on product features. Int J Comput Integr Manuf 20(4):355–369

Kruth J, Detand J (1992) A CAPP system for nonlinear process plans. CIRP Ann Manufact Technol 41(1):489–492

Kim YS, Wang E, Rho HM (2001) Geometry-based machining precedence reasoning for feature-based process planning. Int J Product 2001 Res 39(10):2077–2103

Gologlu C (2004) Machine capability and fixturing constraints-imposed automatic machining set-ups generation. J Mater Process Technol 148(1):83–92

Colosimo BM, Semerar Q, Tolio T (2004) Rule based system for nonlinear process plan generation. Stud Inf Control 9:13–43

Grieco A, Matta A, Nucci F, Tolio T (2000) New policy to manage tools in flexible manufacturing systems using network part program. In: Proceedings of ASME 3rd conference on intelligent systems in design and manufacturing, Boston

Azab A, ElMaraghy HA (2007) Mathematical modeling for reconfigurable process planning. CIRP Ann Manufact Technol 56(1):467–472

Ma’rkus A, Va’ncza J (2001) Process planning with conditional and conflicting advice. CIRP Ann Manufact Technol 50(1):327–330

Ma′rkus A, Va’ncza J, Kova’cs A (2002) Constraint-based process planning in sheet metal bending. CIRP Ann Manufact Technol 51(1):425–428

Duflou JR, Va’ncza J (2005) Computer aided process planning: a state of the art. Comp Ind 56(7):747–771

Tolio T, Ceglarek D, ElMaraghy HA, Fischer A, Hu SJ, Laperrie` re L, Newman ST, Va’ncza J (2010) Co-evolution of products, processes and production systems. CIRP Ann Manufact Technol

Youssef AMA, ElMaraghy HA (2007) Optimal configuration selection for reconfigurable manufacturing systems. Published online: 30 June 2007 @ Springer Science+Business Media, LLC

Chu C-CP, Gadh R (1996) Feature-based approach for set-up minimization process design from product design. Comput-Aid Des 28:321–332

Cochran DS, Arinez JF, Duda JW, Linck J (2001) A decomposition approach for manufacturing system design. J Manuf Syst 20(6):371–438

ElMaraghy HA (1992) Integrating assembly planning and scheduling—CAPP related issues. Annls CIRP 41:11–14

Saygin C, Kilic SE (1999) Integrating flexible process plans with scheduling in flexible manufacturing systems. Int J Adv Mfg Technol 15:268–280

ElMaraghy HA (2005) Flexible and reconfigurable manufacturing systems paradigms. Int J Flex Manuf Syst 17(4):261–276 (Special issue on Reconfigurable Manufacturing Systems)

Acknowledgments

The moral, financial, and the knowledge-based support of NUST is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer International Publishing Switzerland

About this paper

Cite this paper

Hasan, S.M., Baqai, A. (2013). An Approach for the Selection of Process Plans Based on Part Family Changes. In: Azevedo, A. (eds) Advances in Sustainable and Competitive Manufacturing Systems. Lecture Notes in Mechanical Engineering. Springer, Heidelberg. https://doi.org/10.1007/978-3-319-00557-7_6

Download citation

DOI: https://doi.org/10.1007/978-3-319-00557-7_6

Published:

Publisher Name: Springer, Heidelberg

Print ISBN: 978-3-319-00556-0

Online ISBN: 978-3-319-00557-7

eBook Packages: EngineeringEngineering (R0)