Abstract

Electric discharge machining (EDM) is commonly used to machine precise and tiny parts when conventional cutting methods face difficulty in meeting productivity and tolerance requirements. Die-sinking EDM works well to machine micro-parts and perpendicular walls of die and molds, whereas EDM drilling is excellent for machining deep and narrow holes regardless of material hardness and location. However, EDM electrode wear is rapid compared to conventional cutting and makes it difficult to control the electrode feed and machine precisely. This paper presents an efficient method to estimate electrode wear through a hole pass-through experiment while a stochastic method is adopted to compensate the estimation model. To validate the proposed method, a commercial EDM drilling machine was used. The experimental results show that the electrode wear amount can be predicted acceptably.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

EDM (Electric Discharge Machining) is widely used in manufacturing mechanical parts, molds, die, and aerospace parts when it is difficult to machine via conventional cutting methods. EDM can be classified according to its electrode; die-sinking EDM uses a machine-feature shaped electrode and EDM drilling uses a round, hollow electrode. Due to Computer Numerical Control (CNC) integration into EDM, the electrode motion is controlled precisely and micro-feature machining is possible regardless of material type.

Since productivity and quality depend upon EDM conditions, many studies have been carried out to discover reciprocal relationships. The EDM condition effects and discharge oil on machining quality have been studied experimentally [1, 2]. However, EDM parameter interaction is correlated therefore more complex methods, such as Taguchi method [3] and fuzzy theory [4], are utilized for analysis. Hybrid methods were studied to enhance EDM quality; Jia et al. [5] combined laser and EDM to increase straightness and Kremer et al. [6] studied ultrasonic vibration [6]. Recently, EDM was applied to micro-feature machining [7–10] and EDM drilling is preferred over conventional drilling for machining deep and tiny holes. Many applications are possible, such as air coolant holes in turbine blades, start holes of wired EDM, injection nozzle holes, to name a few. EDM drilling may make micro-hole drilling easier but debris should be removed efficiently for successful EDM. Much research has reported on the relationship between product characteristics and debris elimination methods [11–13].

Together with EDM condition optimization, electrode wear is also a significant consideration in EDM drilling. The electrode of EDM drilling wears out rapidly compared to that of a conventional cutting tool. Mohri et al. [14] analyzed electrode wear against machining time and showed the electrode wear rate (EWR) might reach an equilibrium state. Electrode wear makes it difficult to precisely control electrode motion. EWR can be estimated by a hole pass-through experiment while the wear amount is calculated via hole depth and total machining feed amount. However, EWR depends on the EDM environment. An accurate estimation model might offer basic information for efficient machining in EDM drilling as well as die-sinking EDM. Thus, this paper presents an electrode wear estimation method while the model is adjusted according to EDM conditions. The paper is organized as follows: Sects. 2 and 3 present the EWR estimation model and its compensation methods. Section 4 contains the proposed method which is validated through a discharge experiment. Finally, Sect. 5 presents the conclusion as well as possible future extensions of the proposed method.

2 Electrode Wear Estimation

2.1 EDM Drilling

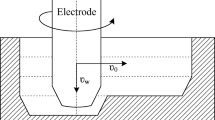

EDM drilling differs from die-sinking EDM in that it machines deep holes via a hollow electrode and spindle rotation in order to remove debris. The negative effects of debris are well known [1]: disturbance of dielectric oil flow, quality deterioration caused by second discharge, electrode wear promotion, etc. Therefore, effective debris removal in EDM drilling, via high-pressure discharge oil and spindle rotation, determines if machining of deep and tiny holes is successful. An EDM drilling illustration is shown in Fig. 1.

2.2 EDM Drilling

Unlike a general-purpose drill, EDM drilling machines a deep hole via oil discharge from a thin, hollow electrode. The discharging process causes severe electrode wear and the electrode wear amount depends on the EDM conditions and machining time. The initial vertical cross section of the electrode is rectangular and wears down into a round cone-like shape (Fig. 2). The variation in electrode edge shape leads to different electrode wear. The electrode wear rate (EWR) can be evaluated by dividing the wear amount (D-T) by hole depth (T) where D is the distance the electrode passes through the hole (Fig. 3). EWR is

However, the electrode wear amount varies according to machining time and hole count though the EDM conditions remain the same. As shown in Fig. 2, the electrode shape changes and therefore affects efficiency. The wear amount increases in proportion to the hole machining and convergence. The convergence speed may differ with the EDM environment but the wear amount pattern is analogous with Fig. 4b. Therefore, the electrode wear model should reflect the wear pattern even when multiple holes are machined. The electrode wear model can be transformed into Eq. (2) and the total wear amount can be calculated with Eq. (3) where αn and λn are the coefficients and n equals the hole machining count.

The hole machining count (n) can be converted into time by dividing the wear amount with the machining time (Fig. 4b). Thus, Eqs. (2) and (3) may be substituted with Eqs. (4) and (5), respectively.

To find the electrode wear amount for the nth hole machining, w t (n), subtract the wear amount until the (n − 1)th hole machining (W(n − 1)) from the wear amount until the nth hole machining (W(n)). The equation for w t (n) is

3 Stochastic Compensation Method

Real time measurement of the electrode wear amount is almost impossible so an estimation model is used instead to predict the machining state. Moreover, the EDM conditions affect the electrode shape causing different machining situations as well as different electrode wear. Consequently, the proposed estimation model in Eqs. (2) and (4) requires adjustment.

Considering that the EWR of the current hole machining is not influenced by the electrode wear history, but only the previous electrode shape, the estimation model can be compensated using the discharge time (T s ) until the (n − 1)th hole machining and machining time (t m ) for the current hole (nth). In other words, the EWR of the (n + 1)th hole is estimated using Eqs. (7) or (8) and the estimation model is compensated again for the EWR of the (n + 2)th hole.

4 Experiment and Results

Experiments were carried out to validate the proposed electrode estimation model using a commercial EDM drill EDB-435F of KTC Co. Ltd (Fig. 5). The electrode is copper and its outer (inner) diameter is Ø0.7 (Ø0.25) mm. The EDM conditions are shown in Table 1. For the electrode wear model, an off-line experiment was carried out to obtain the reference curve of the electrode wear while 10 identical holes were machined with a new electrode 10 times each. 11-hole machining was used for automatic data collection. As shown in Table 2, the electrode wear amount and machining time increases, converging on the constant wear amount and ratio. The electrode wear models using the averages are

The square sums of the estimation errors are 0.191 and 0.602 respectively, and Fig. 6 shows the fitted curves. An additional experiment was carried out to ensure the wear models share the same EDM conditions while the workpiece thickness was changed to 10t (Fig. 7a). As shown in Table 3, the difference between estimation and actual wear amount is large during the first hole machining, which was caused by the longer engaged discharge area (Fig. 7b). Thus, the changed EDM environment is reflected in the estimation model (reference curve). Comparing the converging speed of the two models, the wear ratio based model [Eq. (4)] is more efficient. Table 3 shows that the estimation error is decreased by Eq. (8), and is less than 3 % after the third compensation.

5 Conclusion

Electric discharge machining is widely used to manufacture precise parts. Compared to conventional cutting, the EDM electrodes wear out more. The electrode wear amount of micro-EDM drilling is greater, making it difficult to control electrode feeding. Therefore, this study proposes an electrode wear estimation model and compensation method using a hole pass-through experiment. First, the exponential wear curve is fitted to the machining hole count based model and machining time based model. After that two models are compensated in accordance with the EDM environment, the memory-less property is adopted.

The proposed methods were validated by machining the holes with a commercial micro-EDM drill. The experiments show that the machining time based model more rapidly converges. After three compensations, the model estimates the electrode wear ratio within a 3 % error margin. A future study may apply the proposed method to blind hole machining when high accuracy is required.

References

Lee C-S, Kim J-M, Heo E-Y, Kim B-M, Kim D-W (2011) A study on the machinability of micro channels using micro-EDM. In: The 21st international conference on flexible automation and intelligent manufacturing, TAIWAN, pp 401–408

Lee C-S, Heo E-Y, Hong M-S, Kim J-M (2011) A study on the optimal machining conditions of micro holes in micro-EDM processes. In: The 21st international conference on flexible automation and intelligent manufacturing, Taiwan, pp 409–414

Masuzawa T, Kuo CL, Fujino M (1994) A combined electrical machining process for micro-nozzle fabrication. CIRP Ann Manuf Technol 43(1):189–192

Lin JL, Wang KS, Yan BH, Tarng YS (2000) Optimization of the electrical discharge machining process based on the Taguchi method with fuzzy logics. J Mater Process Technol 102:48–55

Jia ZX, Zhang JH, Ai X (1997) Study on a new kind of combined machining technology of ultrasonic machining and electrical discharge machining. Int J Mach Tools Manuf 37(2):193–197

Kremer D, Lhiaubet C, Moisan A (1991) A study of the effect of synchronizing ultrasonic vibrations with pulses in EDM. CIRP Ann Manuf Technol 40(1):211–214

Kim YT, Park SJ, Lee SJ (2005) Micro/meso-scale shapes machining by micro-EDM process. Int J Precis Eng Manuf 6(2):5–11

Masuzawa T, Fujino M, Kobayashi K (1985) Wire electro-discharge grinding for micro-machining. CIRP Ann Manuf Technol 34(1):431–434

Masuzawa T, Kuo CL, Fujino M (1994) A combined electrical machining process for micro-nozzle fabrication. CIRP Ann Manuf Technol 43(1):189–192

Yu ZY, Masuzawa T, Fujino M (1998) Micro-EDM for three dimensional cavity development of a uniform wear method. CIRP Ann Manuf Technol 47(1):169–172

Lonardo PM, Bruzzone AA (1999) Effect of flushing and electrode material on die sinking EDM. CIRP Ann Manuf Technol 48(1):123–126

Kim BH (1999) Micro-hole machining using MEDM with a screw-type electrode. Master’s Thesis, Seoul National University

Masuzawa T, Ku CL, Fujino M (1990) Drilling of deep micro-holes by EDM using additional capacity. Int J Jpn Soc Precis Eng 23(4):275–276

Mohri N, Suzuki M, Furuya M, Saito N (1995) Electrode wear process in electrical discharge machining. CIRP Ann Manuf Technol 44(1):165–168

Acknowledgments

This research was supported by the Converging Research Center Program through the Korean Ministry of Education, Science and Technology (Grant Number: 2012K001051).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer International Publishing Switzerland

About this paper

Cite this paper

Lee, CS., Heo, EY., Kim, JM., Choi, IH., Kim, DW. (2013). Electrode Wear Estimation and Compensation for EDM Drilling. In: Azevedo, A. (eds) Advances in Sustainable and Competitive Manufacturing Systems. Lecture Notes in Mechanical Engineering. Springer, Heidelberg. https://doi.org/10.1007/978-3-319-00557-7_43

Download citation

DOI: https://doi.org/10.1007/978-3-319-00557-7_43

Published:

Publisher Name: Springer, Heidelberg

Print ISBN: 978-3-319-00556-0

Online ISBN: 978-3-319-00557-7

eBook Packages: EngineeringEngineering (R0)