Abstract

Deformation twinning is a mechanism of critical interest in magnesium alloys and other HCP metals, both due to its ability to accommodate strain and its tendency to contribute to failure by providing a preferential crack pathway along twin boundaries. This deleterious behavior is worsened by instances of twin transmission, where a twin impinging on a grain boundary nucleates an adjacent, connected twin in the neighboring grain due to intense local stresses. Many commercial Mg alloys feature coarse grain boundary intermetallic particles in their as-produced state which potentially impede or exacerbate the localized stresses that play a role in both twin transmission and twinning behavior. Combined EDS-EBSD is used to analyze grain boundary particles, deformation twins, and transmission events to determine how particle morphology, position, and grain orientation modify twinning behavior and transmission likelihood, and how these findings compare to computational results from crystal plasticity—fast Fourier transform modeling.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Extended Abstract

Controlling the evolution of crystallographic texture is key to promoting ductility and formability in magnesium alloys. A number of different avenues of texture control have been researched, including novel deformation processes [1, 2], alloying to alter the balance of deformation mode activities [3,4,5,6], and microstructural engineering via grain size reduction [7,8,9,10,11]. One under-studied strategy for control of texture evolution is the introduction of intermetallic particles.

Previous research into the role of coarse, micron-scale intermetallic particles during deformation has indicated that they may promote a more diffuse deformation texture when compared to a similar alloy with a lower volume fraction of particles [12, 13]. Additionally, Berman et al. found that, while the intermetallic particles may fracture, they did not cause premature failure; fractography indicated that most microvoids originated at grain boundaries rather than at particles [14].

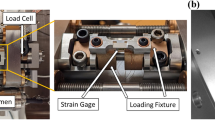

In the present work, the role of intermetallic particles on the active deformation modes and the texture evolution of thixomolded and thermomechanically processed (TTMP) AM60 was studied. Hot-rolled and flattened thixomolded AM60 was subsequently heat treated at 250 ℃ for 48 h followed by 100 ℃ for 24 h to homogenize the microstructure and grow the β-Mg17Al12 intermetallic phase at the grain boundaries. Samples in this as-TTMP condition were compared to samples subsequently heat treated at 450 ℃ for 15 min to partially solutionize the β phase. These two microstructural conditions will be referred to as the “high particle fraction” and “low particle fraction” samples, respectively. While the low particle fraction samples admittedly contain a greater fraction of Al in solid solution, Al solute has not generally been found to significantly weaken the formation of a basal texture. Tensile specimens were produced from each of the microstructural conditions along both the rolling and transverse directions (RD and TD). These samples were pulled in tension to strains of 5%, and then the as-deformed specimens were characterized via combined electron backscatter diffraction (EBSD) and electron dispersive spectroscopy (EDS). While EBSD identified the orientations of the grains, EDS identified the locations of the intermetallic particles.

The viscoplastic self-consistent polycrystal plasticity model (VPSC) [15] was used to predict the tensile behavior along the RD and the TD based on the starting textures. Based on the VPSC modeling results, tension along the TD is predicted to result in deformation dominated by extension twinning, while tension along the RD is more favorable for dislocation slip.

The textures of the undeformed as-TTMP material and specimens pulled in tension are shown in Fig. 1. The as-TTMP material has a moderate basal texture with significant TD spread. Tension along the RD resulted in the weakening of the basal texture and an increase in the extent of TD spread. This evolution was more pronounced in the high particle fraction specimen. In the low particle fraction specimen pulled along the TD, the basal peak weakened but became more symmetrical. In the high particle fraction specimen, a clear split basal texture was produced.

In this talk, twinning analysis and intragranular misorientation analysis conducted using the MTEX toolbox for MATLAB [16] are used to examine the microstructural mechanisms that result in this disparate texture evolution. The implications for alloy design and microstructural engineering of magnesium alloys are discussed.

References

Mathaudhu, S. et al. Novel Magnesium Alloy Processing via Shear-Assisted Processing and Extrusion (ShAPE). in Magnesium Technology 2019 (eds. Joshi, V. V., Jordon, J. B., Orlov, D. & Neelameggham, N. R.) 65–67 (Springer International Publishing, 2019). doi: https://doi.org/10.1007/978-3-030-05789-3_11.

Zhang, D., Darsell, J., Overman, N., Herling, D. R. & Joshi, V. V. Eliminating Yield Asymmetry and Enhancing Ductility in Mg Alloys by Shear Assisted Processing and Extrusion. in Magnesium Technology 2021 (eds. Miller, V. M., Maier, P., Jordon, J. B. & Neelameggham, N. R.) 91–99 (Springer International Publishing, 2021). doi: https://doi.org/10.1007/978-3-030-65528-0_15.

Hantzsche, K. et al. Effect of rare earth additions on microstructure and texture development of magnesium alloy sheets. Scr. Mater. 63, 725–730 (2010).

Hadorn, J. P. et al. Role of Solute in the Texture Modification During Hot Deformation of Mg-Rare Earth Alloys. Metall. Mater. Trans. A 43, 1347–1362 (2011).

Al-Samman, T. & Li, X. Sheet texture modification in magnesium-based alloys by selective rare earth alloying. Mater. Sci. Eng. A 528, 3809–3822 (2011).

Jin, Z.-Z. et al. Alloying design and microstructural control strategies towards developing Mg alloys with enhanced ductility. J. Magnes. Alloys 10, 1191–1206 (2022).

Xu, J. et al. A weak texture dependence of Hall-Petch relation in a rare-earth containing magnesium alloy. J. Mater. Sci. Technol. (2021) doi: 10/gmdfd2.

Wang, Y. & Choo, H. Influence of texture on Hall–Petch relationships in an Mg alloy. Acta Mater. 81, 83–97 (2014).

Yamashita, A., Horita, Z. & Langdon, T. G. Improving the mechanical properties of magnesium and a magnesium alloy through severe plastic deformation. Mater. Sci. Eng. A 300, 142–147 (2001).

Liao, J., Hotta, M., Kaneko, K. & Kondoh, K. Enhanced impact toughness of magnesium alloy by grain refinement. Scr. Mater. 61, 208–211 (2009).

Somekawa, H. & Mukai, T. Effect of grain refinement on fracture toughness in extruded pure magnesium. Scr. Mater. 53, 1059–1064 (2005).

Decker, R. F. et al. Alloy Design and Processing Design of Magnesium Alloys Using 2nd Phases. JOM 71, 2219–2226 (2019).

Miller, V. M. & Pollock, T. M. Texture Modification in a Magnesium-Aluminum-Calcium Alloy During Uniaxial Compression. Metall. Mater. Trans. A 47, 1854–1864 (2016).

Berman, T. D., Pollock, T. M. & Jones, J. W. Texture, Second-Phase Particles, and the Anisotropy of Deformation Behavior in TTMP AZ61. Metall. Mater. Trans. A 46, 2986–2998 (2015).

Lebensohn, R. A. & Tomé, C. N. A self-consistent anisotropic approach for the simulation of plastic deformation and texture development of polycrytsals: application to zirconium alloys. Acta Metall. Mater. 41, 2611–2624 (1993).

Bachmann, F., Hielscher, R. & Schaeben, H. Texture Analysis with MTEX—Free and Open Source Software Toolbox. Solid State Phenom. 160, 63–68 (2010).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Anthony, B.T., Miller, V.M. (2024). Quantifying the Role of Coarse Intermetallic Particles on Deformation Behavior. In: Leonard, A., Barela, S., Neelameggham, N.R., Miller, V.M., Tolnai, D. (eds) Magnesium Technology 2024. TMS 2024. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-50240-8_17

Download citation

DOI: https://doi.org/10.1007/978-3-031-50240-8_17

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-50239-2

Online ISBN: 978-3-031-50240-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)