Abstract

Life cycle assessments (LCAs) of power plants and energy conversion systems currently incorporate more granular spatial and temporal information, aimed at increasing the accuracy of inventories and the results. The power grid comprises highly diverse generation power generation technologies from radioactive nuclear to clean renewables and polluting fossil fuels which leads to electricity mixes. These differences among technologies highly influence the LCA results, hence the need to better characterize the spatial and temporal characteristics for accuracy. This study presents the environmental impacts of power generation technologies based on life cycle assessments (LCAs). The assessments cover impacts from extraction, processing and transportation of fuels, construction of power plants, and power generation. Life cycle assessment (LCA) to power generation technologies is very useful as the world seeks ways to meet growing electricity demand with less health and environmental impacts. LCA is an evolving methodology with several barriers and challenges but has helped in improving the understanding of the lifecycle energy, greenhouse gas emissions, air pollutant emissions, and water-use implications to power generation. The application of LCA tools facilitates an analytically thorough and environmentally holistic approach in assessment and comparison of power generation technologies. Most LCAs show that the best power plants are hydropower, both run-of-river and with reservoir, nuclear energy, and wind power. Fuel combustion directly leads to emissions and potential environmental harm. The cradle-to-grave approach considers all steps between material and fuel extraction from the environment until they are returned to the environment.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Energy payback ratio

- Energy sustainability

- Emissions factor

- Greenhouse gas emission

- Life cycle assessment

- Environmental impact

1 Introduction

Life cycle assessment (LCA) is an important decision support tool used to evaluate the environmental impacts of different products or processes from extraction to disposal of waste, i.e., cradle-to-grave or cradle-to-cradle. The lifecycle assessment has increasingly addressed environmental impacts of various technologies energy technologies [1]. Energy is an essential resource for modern society used for many applications like lighting, transport, communication, heating, air conditioning, and manufacturing, among others. The evaluation of energy production technologies considers all aspects such as energy and raw materials consumptions, energy efficiency, and environmental impacts. The environmental impact is an important factor in the evaluation of power generation technologies [2]. Electricity systems account for 38% of primary energy use globally and are set to rapidly grow as demand for electricity-based services increases such as looking, lighting, sanitation, heating and cooling, and information and communications. The current global electricity mix is dominated by fossil fuels led by coal, natural gas, nuclear, and petroleum which are all nonrenewable [3].

Life cycle assessment (LCA) is a holistic approach applied in evaluating the environmental impacts of products and systems through their entire life. Life cycle analysis is needed to foster the development of energy technologies in a sustainable manner [4]. Life cycle assessment (LCA) is a decision support tool which assesses environmental burdens of products and processes right from materials extraction to disposal popularly referred to as cradle-to-grave or even cradle-to-cradle. For accuracy, the power generation life cycle assessments should better characterize spatial and temporal characteristics [1]. A life cycle assessment is regarded as an environmental assessment of all steps used in production and delivery whose goal is to present a holistic and inclusive picture of environmental impacts by considering all significant downstream and upstream activities and their impacts [5]. The commitment to reduce greenhouse gas emissions by reducing the consumption of fossil fuel sources of energy has driven many countries toward the increased use of low-carbon electricity systems. Nevertheless, reducing greenhouse gas emissions (GHG) may be achieved at the expense of other environmental impacts, like higher depletion of abiotic resources [6, 7].

Selection of generation technologies is coming complex and involves economic, operational, siting, social, and policy constraints [3]. Since the environmental impacts and benefits tend to occur at different phases of the power plant life cycle, it is very important to consider the entire lifecycle. When comparing two options, important phases may not be the same. Therefore, the life cycle approach, i.e., life cycle assessment (LCA) methodology, is preferred. The LCA is a methodology for the evaluation of environmental impact of a product, process, or an activity in the course of its life cycle by quantitatively and qualitatively identifying and describing energy and materials requirements, and associated emissions and wastes generated and released to the environment [8].

As a powerful decision support tool, life cycle assessment (LCA) evaluates the environmental burdens products cross the life cycle. LCA is increasingly being used to address environmental impacts of energy systems and technologies. A typical life cycle analysis is neither spatially explicit nor temporally resolved; hence, it represents a snapshot in space and time or with general data that is not representative of a location at a particular time. Occasionally, LCA results are impactful to the energy sector evolution through knowledge improvement of energy systems and influence policy decisions [1, 9]. LCAs are however challenged by economically powerful and highly innovative energy sectors, more so high regional and temporal variability of operations. These variabilities contribute to unresolved problems in LCA notably the highly diverse generation technologies, leading to different regional mixes which are highly influential in LCA results. Therefore, life cycle assessment for power generation should adequately characterize spatial and temporal characteristics for accuracy and reliability [1, 10].

This review assesses the state of the art of LCA applied in power generation technologies and systems with emphasis on areas like methodological issues, challenges associated with power generation technologies, quantitative results obtained from the literature, and improvement opportunities for LCA applied in power generation.

1.1 Problem Statement

Life cycle analysis for power generation technologies increasingly addresses the environmental impacts of energy technologies. As LCA’s role continues to grow as a decision support tool for energy policy, lingering questions remain on how results can be applied in the face of uncertain assumptions in an ever-evolving energy sector. Typical LCA is neither spatially explicit nor temporally resolved and therefore it represents a snapshot in space and time or with general data that do not represent a location and particular time. Although the life cycle results are impactful to the evolution of the energy sector through enhanced knowledge of energy systems and influence policy, the assessments are challenged by economically powerful, fast-paced, and highly innovative energy sector mainly by high regional and temporal variability of operations. The variability contributes to unresolved problems in life cycle analysis. Different regions have different regional energy mixes since the power grid consists of highly diverse power generation technologies [1, 9].

1.2 Rationale of the Study

The transition to renewable energy sources and “green” technologies for power generation and storage should mitigate the climate change resulting from greenhouse gas emissions. The main sustainability challenge for the transition is the dependency on critical materials, processes, and other resources that have significant environmental impacts. Beyond global warming concerns, we have serious sustainability concerns such as loss of biodiversity, water scarcity, environmental pollution, and energy security that should equally be addressed during the transition [11, 12].

Energy and environment issues are seriously interconnected and need comprehensive analysis and understanding of resource management strategies and their consequences. As an example vital water resource depletion and contamination is related to possible shortages in power generation, distribution, and use while the supply of water needs energy [11].

Therefore, there is a need for a system perspective to locate and quantify the impact of human activities and processes on the environment. The life cycle assessment (LCA) is one of the most inclusive analytical techniques to analyze sustainability trade-offs and benefits resulting from complex energy and environmental systems [11, 13].

For accuracy, power generation LCA analysis should better characterize spatial and temporal characteristics [2]. The comparison of power generation technologies is considered generic because it presents a general overview of environmental and economic impacts that are generally expected. Specific impacts can be smaller or greater based on site-specific conditions or mitigation measures put in place [5]. The comparisons help decision makers as follows:

-

(i)

Policy decisions may be needed before site-specific information is available; hence, “generic” comparisons can be used in decision making.

-

(ii)

Many energy system analyses do not consider the impacts of entire energy systems from extraction and processing, operation and disposal.

-

(iii)

Many assessments neglect sustainability and reliability aspects, yet they are important in sustainable development.

-

(iv)

There is a need for generic data at the planning level for power generation technologies but is not a substitute for detailed and careful analysis of site-specific conditions. However it provides indication of impacts and choices that need more careful detailed consideration [5].

1.3 Potential Uses of Life Cycle Assessment

The life cycle assessment (LCA) is designed to fulfill different functions and objectives. The various applications include [5]:

-

(i)

Analysis of the performance of modern commercial technologies even when the performance of older technologies is totally different.

-

(ii)

LCA can be used to present short-term performance, not necessarily the long-term or expected future performance.

-

(iii)

LCAs can effectively use typical conditions of region or technology [5].

2 Generation Options

Power generation systems do not have equal capability to provide energy services which are variable and time varying. Reliable power systems cannot rely on the “must-run” power systems such as geothermal and nuclear energy or on intermittent power systems like solar and wind alone, but rather an optimized mix of different sources. Energy sources like hydropower with storage can service all electricity needs and maintain system balance. Likewise is oil or diesel, or gas fired power plants which have desirable flexibility, due to the ability to store the energy resource for later use without loss. Intermittent sources constantly require a “backup” system to compensate for fluctuations and storage to store excess when generation for use during high electricity demand [5, 14].

2.1 Analysis of Intermittent Sources

Two approaches can be applied for analysis of intermittent generation systems: for fair comparison.

-

(i)

The systems can be combined for analysis with a typical backup system, which provides the same reliability as other stand-alone systems. Though technically challenging, it can be done, adding wind energy to hydropower.

-

(ii)

Where the system does not consider the required backup, then can be recognized clearly that the assessment is not at par with other “stand-alone” systems [5].

2.2 Main Types of Electricity Generation Systems

Power generation technologies vary greatly but can be grouped on their ability to meet fluctuating electricity demand. Electricity demand as shown in Table 1.

3 Life Cycle Inventory Analysis

LCI involves the compilation and quantification of natural resources consumed and substances released into the environment. In the life cycle inventory (LCI) analysis, the life cycle is drawn with all energy and material requirements such as air, water, soil, and land, as well as their environmental releases which are quantified. The steps in an LCI analysis are the development of a flow diagram, collection of data, multi-output processes, and results reporting [15]. Life cycle inventory (LCIs) are generally based on average data of energy and material inputs and outputs collected from the site or estimated from literature or from modeling studies. To construct an LCI, all inputs and outputs for all processes should be identified and quantified. An LCI process should be at an industrial scale for the modeled system to be as close as possible to a real process. In the case of an ongoing development and low technology readiness level (TRL) of a new process, there should be a scale-up modeling to determine material and energy flows for the desired real scale [16].

3.1 Development of a Flow Diagram

A flow diagram is used to reflect processes making up the product system and the inputs and outputs of the processes within the system. The boundaries are defined by the scope and goal of the analysis. Almost all processes in a system involve a form of transport between processes which requires energy. Processes relate to flows of intermediate products while elemental flows are shown to and from the environment. The elemental flows are material or energy flows entering or leaving the system drawn from the environment or discarded to the environment. Therefore the elemental flows originate directly from the environment. e.g., energy and material resources and land use; or they are discharged directly to the environment like emissions, heat, radiation, and sound [15].

From Fig. 1, it is noted that a system has boundary with product inflow from other systems and direct elemental flow from the environment. Main processes in the energy system are transportation, energy supply, waste treatment, production, acquisition of raw materials, material, recycling, and consumption. The system outputs include product flows to other systems, elementary flows to the environment.

The elementary flows originate from processes within the energy system boundary, as is shown in Fig. 2.

From Fig. 2, it is noted that there are elementary flow-specific unit processes that have their own elementary flows. Intermediate flows occur between various units in the system data collection.

The most time-consuming system in the life cycle inventory assessment is data collection. Data collected should be accurate and relevant for this purpose. Quite often, data is a mix of site-specific data which is obtained by measurements and calculations from measurement and generic, non-site-specific data which is obtained from databases or expert estimates [15].

3.2 Multi-output Processes

Energy systems have many processes that have a single useful output. In such multi-output processes, just one of the outputs may be used in the life cycle. The systems can also have outputs useful to other life cycles that are not under investigation. Material and energy inputs and the elementary flows of the processes under study are allocated among the useful outputs. An example of a multi-output process is cogeneration processes and products where fuel input in combined heat and power (CHP) plants is divided between electricity generation and heat production. In this case, the system can be extended by introducing reference technology for either product; e.g., for heat production, fuel input for heat production can be computed as the fuel required for heat production in a reference boiler. The fuel consumption for power generation is then determined by deducting the fuel input for heat production in the cogeneration system. The reverse can also be done where a reference electricity plant is introduced instead of a reference boiler and the process repeated. In another approach, physical properties of products like mass or energy content are applied as the allocation factor. Mass allocation may not however work for a CHP plant; instead energy content either on a heat/enthalpy basis or on an exergy basis is more realistic and is more meaningful. In the third approach, the economic value of the individual products can be applied for proper allocation factor. The three approaches have been widely used in LCAs [15].

3.3 Reporting

The LCI outcome is a list of all elementary flows to or from the environment for each energy system study resulting from the functional unit provided by the energy systems. They can be organized based on the life cycle stage and/or media like air, water, or land. These results can be used in further analysis like comparison of energy alternatives and identification of life cycle stages with significant environmental releases. These releases do not however express potential environmental impacts [15].

4 Life Cycle Impact Assessment Method

A life cycle impact assessment provides a more meaningful basis for comparisons; e.g., we may know that 8500 tons of carbon dioxide (CO2) and 5000 tons of methane are released to the atmosphere; both being potentially harmful greenhouse gases, it is through a life cycle impact assessment (LCIA) we can determine that the gases have a greater impact. In terms of smog formation? Or which is worse than the other? Or what are the potential impacts on global warming? The LCIA uses science-based characterization factors to determine the impacts of each emission to the environment [17].

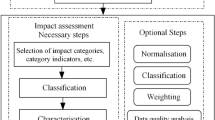

Life cycle impact assessment (LCIA) is part of life cycle assessment (LCA) whose objective is to evaluate and understand the magnitude and significance of environmental impacts for a product system across its life cycle [18]. Life cycle impact assessment involves characterization of impacts and selection of impact assessment categories based on their contribution to normalized and weighted analysis results. There are two basic approaches that can be used to characterize environmental impacts:

-

(i)

The midpoint approach and midpoint indicators recommended by the EC Environment Footprint Guidelines [12, 13].

-

(ii)

The endpoint approach and endpoint indicators.

These approaches are different in terms of objectives and robustness. A comprehensive LCA may display the results using both midpoint and endpoint approach and the endpoint and endpoint indicators approach; but the conclusions remain the same. The term “impact” is generally used as the shorthand for “potential impact,” as it is defined in the ISO standards. Therefore, in the life cycle assessment (LCA), “impact-“associated terms like “impact assessment” or “impact category” is associated with the potential detrimental effects that a substance or a stress can leave on the environment, resources, or human health. Therefore, only potential environmental impacts are regarded as real impacts influenced by factors usually not included in the study. “The LCIA does not have to quantify any actual, specific impacts associated with a product, process, or activity, but seeks to establish a linkage between a system and potential impacts” [19].

Although much can be learned about a process through the life cycle inventory data. An impact assessment is used to provide a more informed basis to make comparisons. It is through an impact assessment we can establish environmental releases with greatest impact. A life cycle impact assessment is used to compute impacts of the environmental releases like global warming and smog [17]. In this regard, the LCI is converted in environmental impacts by category. The impact categories include toxicity, climate change, respiratory effects, acidifications, ozone layer depletion, acidification, eutrophication, natural resources depletion, etc. The substances in the life cycle impact assessment have one or more impact categories; e.g., NOx is responsible for respiratory effects, acidification, and eutrophication [16]. Environmental models can be used to establish specific parameters that quantify the effects of a substance. The result of the impact is proportionally linked to the mass of the substance released to the environment [16]. The environmental gains of energy technology substitution can be determined through complete analyses of LCA and LCI using data from pilot and industrial–scale studies [16].

5 Exergetic LCA Studies

Exergetic life cycle assessment (ExLCA) can be used to quantify the environmental impacts associated with the exergy losses and exergy destruction in an energy system, process, or product. Environmental impact is reduced by increasing exergy efficiencies [20]. The framework of ExLCA is similar to LCA with main steps summarized in Table 3.

Figure 3 shows a flow diagram with inputs and outputs of matter, energy, and exergy at various steps in the life cycle of a product or process.

Exergy and its methodological advancements can be used in LCA studies. Exergy analysis is a multi-disciplinary and emerging field, with applications in resources used in both energetic and non-energetic resources. The exergy is applied in sustainability assessment for thermodynamic properties and parameters, which require less subjective choices as compared to fate, exposure, and effects models applied in most LCA methods. The measurement would make characterization independent of reference substances like carbon dioxide for global warming potential which enables a combination of the results of different impact categories into a cumulative value by using the same unit of exergy. Extensive application of exergy analysis to conventional LCA is done through a systematic and comprehensive determination of exergies which considers standard thermodynamic conditions, emissions, pure state of resources, and individual emission amounts [11].

6 Results of Life Cycle Assessments

Life cycle assessments are applied to analyze the environmental costs and benefits of climate mitigation measures which are usually static in nature and address specific power plants and technology. This study presents the general life cycle assessment of climate mitigation technologies [21].

6.1 Greenhouse Gas Emissions and Environmental Impacts

The following are the environmental impacts of greenhouse gas emissions and global warming:

-

(i)

More intense precipitation events cause flooding, landslides, avalanche, and mudslide damage.

-

(ii)

Increased summer drying over most mid-latitude continental interiors and associated risk of drought.

-

(iii)

Increase in tropical cyclone peak wind intensities, mean, and peak precipitation intensities.

-

(iv)

More intense droughts and floods associated with El Nino events in many different regions.

-

(v)

Rise in the sea level and an increase in the intensity cyclones which can displace millions of people in lowlands.

6.2 Understanding the Studies on Greenhouse Gas Emissions

The potential impacts of climate change have led to many studies focused on greenhouse gas emission assessment which have produced data on emissions of CO2 equivalent; therefore, CO2 and other greenhouse gases are captured in the assessment. Greenhouse gases have different effects on the climate with different life spans in the atmospheric. The global warming potential is used to assess the greenhouse effect of various substances and different substances have different greenhouse gas potential; e.g., a gram of CH4 has a global warming potential of 23, relative to a gram of CO2 assessed over a 100-year period [5, 22].

6.3 Main Findings Concerning Greenhouse Gas Emissions

Based on greenhouse gas emissions, run-of-river hydropower presents the best performance among all systems, followed by nuclear, reservoir-based hydropower and wind power. Run-of-river hydropower with no upstream reservoir and nuclear energy are less flexible, and wind power is intermittent. A backup system is needed for these energy systems and maybe fossil fuel, which significantly increases the final emission factor of the overall electricity system. Coal has the highest emission factor which is about twice the emissions of natural gas combined cycle [5].

For hydropower, a common source of greenhouse gas emissions is the decay of flooded biomass whose assessment is site specific based on factors like reservoir per kWh which varies with topography. The amount of flooded biomass, per unit of area, varies by a factor of 5 (500 t/ha for tropical forest versus 100 t/ha for boreal climate. For average size reservoir per kWh, in boreal or mountain regions, the emission factor for hydropower is approximately 60 times lower than the modern coal-fired generation [5].

Greenhouse gas emissions from hydropower reservoirs resulting from decaying biomass in hydropower reservoirs have persistent uncertainties. Reservoirs in boreal or mountain regions have a small amount of flooded biomass, but reservoirs in tropical environments have higher emission factors, depending on many site-specific conditions [5].

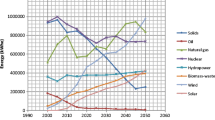

6.4 Future Performance of Energy Systems Concerning Greenhouse Gas Emissions

The global expectations over issues like climate change are high since many studies target only one stage of the life cycle, yet life-cycle assessment may show different expectations since some technologies emit less greenhouse gas at one stage of their life cycle, only to emit more at another stage. Alternative fuels such as ethanol coming from crops may have lower emissions at combustion compared to oil, but crop production-related emissions offset these benefits. In another example, fuel cells have almost zero emissions, but hydrogen production has higher level than natural gas turbines. For carbon sequestration, scrubbing of CO2 emissions from flue gas is complex and expensive. For sulfur, the benefits of scrubbing technologies are justifiable by the fact that the waste generated by these technologies are manageable, but for CO2 emissions, it is complex because carbon is responsible for about 50% CO2 emissions of the coal, while sulfur is 1% or 2% in coal. Capturing all this carbon and pumping it in deep underground reservoirs is energy intensive, polluting, expensive, and relatively fewer benefits. Therefore, the next few decades may not see major technologies to solve the climate change challenges. Therefore, energy efficiency measures and renewable energy technologies will remain the best options to reduce greenhouse gas emissions in the near future [5, 23].

6.5 Acid Precipitation

Environmental Issues

Acid precipitation remains a major environmental concern. SO2 and NOx emissions acidify lakes, rivers, and forests and affect their productivity. It is, however, difficult to identify the direct link between ecosystem impacts and atmospheric emissions. Additionally, vulnerability of forests varies based on soil types. It is generally difficult to establish a direct link between one specific emission and the ultimate environmental damage they cause. Therefore, emission factors may be considered as indicators of “potential” impacts [5].

For forest productivity, impacts of pollutants include the following:

-

(i)

Acid will remove essential nutrients from soils like K, Ca, Mg.

-

(ii)

Acid may mobilize toxic metals like aluminum which damage crops or plant roots.

-

(iii)

Nitrogen from pollutants, although the main nutrient of plants, can create resource imbalance and make trees more vulnerable to frost and diseases.

-

(iv)

Emissions cause photochemical smog which can cause damage.

-

(v)

They contribute to climate change which can cause heat stress or intensity of droughts [5].

Sulphur dioxide leads to formation of sulfuric acid while NOx leads to the formation of nitric acid before contributing to the formation of acid precipitation. NOx also contributes to smog formation from related chemical reactions [5].

Fuels have different sulfur compositions with coal having sulfur content varying between 0.5% and 5% even more in exceptional cases. The average sulfur content for oil and diesel is about 0.2% for light oil/diesel and 2% for heavy fuel, but the percentages vary significantly from one region to another. Natural gas has virtually no sulfur content as it is removed in processing plants after extraction. Various technologies are available for the removal of sulfur dioxide with some capable of scrubbing as high as 90% of SO2 emissions. Technologies that involve high pressure and temperature combustion like diesel engines generate high levels of NOx emissions. Coal, which has significant amounts of nitrogen, is also part of the fuel, leading to high NOx emission factors.

Emission factors for hydropower and nuclear energy are hundreds of times lower than those of fossil fuel–based technologies like coal power generation systems without scrubbing. Therefore, based on SO2 and NOx emissions produced, coal, oil and diesel-based power generation systems are significant contributors to acid. Biomass has low SO2 but a very high factor for NOx, hence a significant source of acid precipitation. Natural gas is also a significant contributor to acid precipitation because of NOx emissions. Wind power can reduce the use of fossil fuel–fired plants by substituting them, leading to reduction in net emissions, although in some cases wind power may increase the use of oil-fired plants as backup.

Future Performance of Energy Systems Concerning Acid Precipitation

The main source of SO2 is fossil fuels, particularly coal and oil-fired power plants. Through scrubbing technologies, SO2 emissions can be reduced by more than 90%, but the technologies are expensive and reduce the power plant efficiency. Burning low sulfur fuels is another option, but these fuels are costlier, needing longer transportation [5].

Land Requirements

Environmental Issues. Emerging renewable energy technologies like wind and solar have large land requirements. Land demand continues to grow due to use in agriculture, cities, and industries, and land for other uses. The alternative sources of biofuels, like ethanol from crops, need large areas of farmland [5].

Understanding the Studies on Land Requirements

For many countries including the United States, most reservoirs were built for irrigation and water supply. Several reservoirs are small or have no power generation function and would have even higher land use factors per TWh. Fossil fuels have less data available and hence some upstream activities are not considered; e.g., surface mining of coal requires more land than underground mining, but no data is available to distinguish them [5, 24].

Main Findings Concerning Land Requirements

Nuclear power plants have the lowest land requirements, if the land required for long-term nuclear waste disposal is neglected. However, inclusion of disposal land requirements seriously increases the nuclear energy land requirements since less land is needed but over a very long time in many thousands of years e.g. 0.1 km/TWh is required for waste disposal, multiplied by 30,000 years, for 30 years of generation, the factor would increase from 0.5 km/TWh to 100 km/TWh) [5].

Renewable energy sources led by biomass plantation have the highest land requirements per unit of energy. This is followed by renewable sources, i.e., hydropower, wind power, and solar power, with almost similar requirements with significant variations based on site-specific conditions. Coal requires much less land than any renewable source of energy in an assessment based on direct land requirements only, i.e., power plants and mining activities. Land-related indirect use is not included in the data. Yet these areas are huge and can multiply the land use factors of energy sources [5].

6.6 Future Performance of Energy Systems Concerning Land Requirements

There is little likelihood that technological development will lead to significant land use reductions. No new technology may be needed to reduce areas affected by acid precipitation for coal and oil. For hydropower, the size of reservoir is important and reservoir areas are about five times smaller than existing ones per unit of energy. Future development of renewables could be significantly constrained by land requirements. Compatibility with existing land uses differ widely and is guided by factors like population density [5, 25].

Hydropower may have other water uses like irrigation, water supply, or flood control. In terms of competition with food production, many renewable energy projects have little negative impacts on agriculture; e.g., land around windmills can still be used for agricultural production while solar energy can be developed on rooftops and over water masses like reservoirs as well as non-arable land. Hydropower can be developed in mountainous or rocky terrain while water from hydro reservoirs can be used for irrigation [5].

However, future energy options like biomass plantations for energy production through direct combustion or bio refinery and anaerobic digestion can be severely limited by the availability of land and hence feedstock [5, 6].

Energy Payback Ratio

Energy payback ratio is the ration of energy produced during the power plants normal life span, divided by the energy required to pay for the construction, maintenance, and fuel for the power generation facility [5].

6.7 Environmental Issues and Payback Ratio

A system with a low payback ratio requires much more energy to maintain it, which generates more environmental impacts. The environmental impacts for fossil fuels are realized during extraction, transportation, and processing of fuels, while for renewable sources, the main impact is from building or facility construction. A payback ratio of close to one implies that the system consumes as much energy as it produces and hence does not need to be developed [5].

LCAs have focused mainly on greenhouse gas emissions from energy in the recent context of climate change commitments. The emissions vary dramatically based on factors like materials used and how they are produced, e.g., aluminum from smelters using hydropower as electricity and smelters using fossil fuels like natural gas and coal to produce the same [1, 5].

The main benefit of using energy payback ratios as a metric is that it is less affected by upstream choices of energy supply, which minimizes the fluctuation in the evaluation of greenhouse gas emissions energy payback ratio, one of the most reliable indicators of environmental performance. Energy payback ratio as an indicator minimizes fluctuations in the results of studies without eliminating them. Renewable energies can have very large variations in energy payback ratios. due to a wide variation of site-specific conditions, i.e., topography for the case hydro, quality of the wind for wind energy, and solar intensity of solar radiation for solar energy [5].

Payback Ratio of Energy Sources

Various analyses show hydropower clearly has the highest performance, with energy payback ratios of 205 to 267 while fossil fuels have payback ratio of 5–7. The payback ratio value for hydropower with reservoir is 205 while the run-of-river has a payback ratio of 267. Best wind sites have payback ratio of about 80 without backup. Biomass has about 27 for power from forestry waste and 5 for planted trees due to higher energy inputs. The higher the distance of the power plants from biomass sources, the lower the payback ratio. Natural gas has a payback ratio of about 5 with some energy being spent on transportation over long distances. The ratio for natural gas power plants located close to the source of natural gas is higher. With high investment on transportation, the payback ratio for coal is also low at about 5 as well as investment on scrubbing of SO2, which requires lime and other resources that need transportation and other investment in production and delivery on site and disposal [5]. Table 2 shows the payback ratios for different generation technologies.

From Table 2, it is observed that hydro with reservoir has the highest payback ratio, followed by wind. Coal, natural gas, and cultivated biomass have the lowest payback ratios.

6.8 Future Performance of Energy Systems Concerning the Payback Ratio

Fossil fuel sources of energy have low energy payback ratios which continue to decline due to reasons like depletion of reserves which tend to be replaced by oil wells that have higher energy requirement like those wells located deep into the sea. Exploitation of fossil fuel resources like coal located far away from load centers and power stations increases transport costs by road and rail. Further investment in emission reduction technology like scrubbing of SO2 can reduce the overall efficiency of coal generation and hence reduce payback ratio while capture and sequestration of CO2 will require huge investment in capital and energy for the operation of scrubbing and disposal equipment while noting that sulfur is about 1% of coal and carbon is more than 50% of the coal. Therefore, mandatory investment in emission reduction technologies will reduce the overall efficiency and feasibility of coal and other fossil fuel power plants [5].

6.9 The Atmospheric Emissions

Health Issues

Emission factors are mainly concerned with climate change and acid precipitation, while other types of air emissions have local and direct effects on health. They include particulate matter, toxic metals like mercury, and non-methane volatile organic compounds (NMVOC) which directly contribute to smog formation [5]. Table 3 shows other atmospheric emissions from power plants.

From Table 3, it is noted that different energy technologies have difference range of values for NMVOC emissions (t/TWh), particulate matter emissions (t/TWh), and mercury emissions (kg Hg/TWh). However, the limitation of the data is that some emissions represent direct emissions from power plants and not life cycle assessment values. The analysis shows hydropower, wind power, nuclear energy, and natural as energy sources and technologies with lowest emissions [5].

Comparing Mercury Contamination

Some hydro reservoirs are known to release mercury in the food chain; the impact can be compared with that of coal or oil-fired mercury emissions, which contaminate the food chain of many lakes. On average, hydro reservoirs can generate 0.07 kg Hg/TWh can be calculated while coal is about 200 times more. However, further analysis shows that about half of mercury released by hydro reservoirs is mercury emitted by coal-fired plants and smelters [5].

7 Carbon Capture and Sequestration

There is continuing and increasing demand for clean coal technologies which are environmentally acceptabler since fossil fuel power plants have environmental impacts like formation of acid rains and photochemical smog formation. Emissions that need control include particulates, NOx and Sox, and trace elements, polycyclic aromatic hydrocarbons, and, importantly, CO2. This has led to technologies that are more environmentally friendly, by reducing pollutant emissions, called clean coal technologies [2].

The two ways of reducing coal emissions are efficiency improvement which improves output and lower emissions per unit of energy output and application CCS technologies to reduce CO2 emissions by 80–90%. CCS is an arrangement between further use of fossil fuels to satisfy increasing energy demand and reduction in CO2 emissions. Carbon capture is not a single technology; instead it is a suite of technologies, some of which can be applied to existing coal-fired power stations, while other technologies are still new technologies and are evolving [2, 26].

There are different techniques used to capture CO2 released by fossil fuel plants, especially coal plants, and to sequester it in storage sites. Three approaches used to integrate CO2 capture technologies with power generation systems are post-combustion, pre-combustion, and oxy-fuel combustion [2].

In post-combustion technology, carbon dioxide is removed after the combustion of fossil fuel. This technology can be implemented as a retrofit option for operating or existing power plants. Technologies that could be employed with post-combustion CCS include adsorption, i.e., physical absorption, cryogenics separation, chemical absorption, and membranes technology [2].

Chemical absorption for CO2 capture can be applied to post-combustion systems, due to low CO2 partial pressure in the flue gas in coal power plants. The amine technology is generally dedicated for retrofitting of existing power plants. The major challenge remains minimizing the operation and investment costs related to the technologies [2]. The alternative chemical absorption in aqueous ammonia solutions can be used to selectively capture the CO2 from the flue gases by the use of an ammonia-based solution at reduced temperature in an absorption column. The ammonia solution is regenerated in a desorption column, and the cycle is repeated. The advantages of ammonia-based technology include low reboiler regeneration energy, high CO2-carrying capacity, low cost, and low power consumption in compression of carbon dioxide [2].

The Ca-looping (CaL) technology is post-combustion CO2 capture technology suitable for integration in power plants and other large CO2 emission industrial plants, e.g., cement industry and steel plants. CAL is based on the multi-cyclic carbonation/calcination of CaO at a high temperature range of 800–950 °C, whereas CO2 in flue gases reacts with the solid sorbent (CaO) at about 500–650 °C, forming calcium carbonate formation. The carbonate product is then decomposed to produce CaO which is recycled back in the carbonator in order to absorb more CO, and a CO2 stream which is dried and compressed for storage and the cycle process is repeated [27].

In the study by [28] focusing on supercritical pulverized coal, a natural gas combined cycle (NGCC), and an integrated gasification combined cycle (IGCC), with and without CCS, it was observed that for a 90% CO2 capture efficiency, life cycle GHG emissions are reduced by 75–84% based on the technology applied, the global warming potential reduced when MEA-based CO2 capture is employed, and other air pollutants such as NOx and NH3 increase leads to higher eutrophication and acidification potentials.

In another study, the LCA study of three pulverized coal power plants with/without post-combustion CCS was undertaken. Two reference chains considered were subcritical and ultra-supercritical pulverized coal-fired electricity generation. In this study, it was observed that the global warming potential reduced by over 70% when CCS were applied, but notable environmental trade-offs encountered are increased—ozone layer depletion, human toxicity, and fresh water ecotoxicity potential. State-of-the-art power plants having no CCS perform better in eutrophication, acidification, and photochemical oxidation although we have deeper reduction in emissions in the form of Sox and NOx in the CCS power plant [2, 29].

In the study by [30], which compared fuel technologies, i.e. IGCC, NGCC, oxy-fuel, and pulverized coal (PC) coupled with CCS, it was observed that carbon capture and sequestration (CCS) results in a net reduction of the GWP by 65–84% by power plants in their life cycle, i.e., for (PC-CCS) the GWP is reduced by 68–87%, (IGCC-CCS), and the reduction is by 47–80% for (NGCC-CCS), and in (Oxyfuel) the GWP is reduced by 76–97%. However, the deployment of CCS technology in PC, IGCC, and NGCC leads to relative increases in eutrophication and acidification compared to power plants without CCS. The assessments of power plants with CCS should consider upstream emissions from coal mining, coal transport, and MEA production and downstream emissions from CO2 transport and CO2 storage for the accurate assessment of environmental performance of power plants with CCS [2, 10].

In the study by [31], post-combustion CO2 capture combined with CO2-enhanced oil recovery was investigated using lignite coal as the fuel and post-combustion CCS based on monoethanolamide (MEA). The results showed a significant reduction in global warming and air impact categories. Although some categories associated with soil and water increased, the broad distribution associated with atmospheric release was significantly reduced [32, 33].

Life cycle greenhouse gas emission evaluation of power plants with carbon capture and storage (CCS) is a critical factor in energy and policy analysis. Studies show that 90% carbon dioxide (CO2) capture efficiency can be achieved with overall reduction in life cycle greenhouse gas emissions by 75–84% based on technology applied. IGCC technology is the most favorable compared to NGCC with CCS and can achieve GHG emissions of less than 170 g/kWh. IGCC technology is found to be favorable too. Through sensitivity analysis, it is established that coal power plants have varying CO2 capture efficiency while the coal transport distance has a pronounced effect on life cycle GHG emissions compared to changing the length of carbon dioxide (CO2) transport pipeline. Although the global warming potential is reduced when MEA-based CO2 capture is applied, other pollutants like NOx and NH3 increase leading to higher impact in firm of eutrophication and acidification potentials [28, 34].

8 Results and Discussion

Life cycle assessments have identified hydropower, particularly the run-of-river and with reservoir, nuclear energy, and wind power, as most sustainable options for power generation. Although hydropower with storage or reservoir has high land requirements, the sustainability is enhanced by high-capacity factors and efficiency as well as multiple secondary applications like irrigation, domestic water supply, flood control and energy security, and high reliability as well as operational flexibility [5, 35].

Analyses show very attractive performance for nuclear energy in many parameters. However nuclear energy faces resistance in any many parts of the world due to radioactive waste and concerns about catastrophic accidents. However, it remains difficult for LCAs to adequately address such concerns [5, 36].

Natural gas is the cleanest fossil fuel for power generation compared to coal and oil-fired generation. However, natural gas has high emissions, compared to renewable sources of energy. Long distance delivery and exploitation of natural gas is however characterized by high upfront emissions which may be hard to account through LCA [5, 37,38,39,40].

Coal clearly emerges as the worst option in most criteria, i.e., emissions of greenhouse gases, emissions of SO2, emissions of NOx, volatile organic compounds, particulates emissions, toxicity, and land requirements. However, coal has a better energy payback ratio only if there is no scrubbing and the process has minimal transportation [5].

The study shows that LCA has numerous analysis tools and data challenges, hence the need to consider the development of spatial and temporal methods. Substantial gaps remain in LCA analysis that considers spatial and temporal factors. It is important for stakeholders, decision-makers, policy makers, and practitioners to have greater understanding of how broadly applicable LCA results are or whether they are just specific to a particular region or a snapshot in time. Life cycle assessments (LCAs) should be a strong basis for decision-making in power generation. Specifications that consider spatial and temporal dimensions would be valuable in making sustainable decisions and create an environmentally sound supply chain and with minimum risks [1, 5].

Life cycle cost (LCC) is not a financial accounting method, but instead a cost management tool meant to estimate and analyze all the costs associated with a product’s existence. The life cycle cost (LCC) methodology has been in use since the 1960s for the assessment of economic issues related to products and systems. Today, interest has grown in combining economic and environmental elements in sustainability analysis through integrating LCC and life cycle assessment (LCA) meant to estimate the environmental impacts of the life cycle of a product or service [5, 41]. The coupling of LCA and LCC can be achieved by means of Environmental LCC (eLCC), which is an expansion of conventional LCC considering all direct costs incurred during the life cycle of the product to incorporate externalities having well-defined market price and are likely to be internalized soon. These externalities include greenhouse gas emissions. The study is known as Full Environmental Life Cycle Cost if other environmental externalities are also monetized and incorporated into the analysis [41].

Although hydropower with reservoir has high land requirements, considering that it has secondary benefits and applications like provision of water for irrigation, industrial and domestic use, flood control, and above water solar power, it is possible to conclude hydro with reservoir has the highest performance.

Evaluation of life cycle greenhouse gas emissions for power plants with carbon capture and storage (CCS) is important for energy and policy analysis. Analysis shows that if 90% CO2 is captured, life cycle greenhouse gas emissions (GHG) can be reduced by 75–84% depending on the type of technology applied. Life cycle greenhouse gas emissions for coal power plants can also be significantly changed by reducing the coal transport distance as well as the length of CO2 transport pipeline. The global warming potential is also reduced when CO2 capture is employed although this may increase other air pollutants such as NOx and NH3, leading to higher eutrophication and acidification potentials [28]. Investment in CO2 removal is partially offset by an increase in greenhouse gas emissions in the up- and downstream processes caused by the CCS infrastructure. The most notable environmental trade-offs caused by CCS are the increase in human toxicity, ozone layer depletion, and fresh water ecotoxicity potential. Power plants without CCS are better in eutrophication, acidification, and photochemical oxidation potential although they are outperformed in Sox and NOx by CCS power plants although the reductions can be offset by increased emissions in the life cycle, leading to energy penalty and a factor five increase in NH3 emissions [29].

For power plants without CCS, the contribution to the global warming potential (GWP), acidification, and eutrophication comes from direct emissions, while for power plants with CCS, the main contribution to GWP, acidification, and human toxicity potential comes from indirect emissions. It is therefore important to consider emissions from upstream operations like coal mining, coal transport, and MEA production and downstream operations like transport of captured CO2 and CO2 storage for accurate assessment of the environmental performance of power plants [30].

9 Conclusion

The use of life cycle analysis (LCA) for power generation technologies has a promising future as the world seeks solutions for the growing global electricity demand while attaining emission and climate targets and sustainable development. Although use of LCAs have some limitations, the LCAs of power generation technologies can shed light on the life cycle energy, greenhouse gas emissions, air pollutant emissions, water consumption, and other environmental and sustainability concerns. The electricity grid consists of highly diverse conversion technologies from fossil fuels, nuclear, wind, and solar, leading to differences in mixes for different regions. Life cycle assessments for power generation need to better characterize spatial and temporal characteristics for accuracy.

The application of LCAs shows that renewable power technology options compare favorably with conventional and fossil fuel–based generation technologies. Most renewable generation technologies outperform conventional technologies with respect to both life cycle primary energy use and air pollutant emissions. Conventional or traditional environmental analyses are often limited to operational impacts like power plant stack emissions and effluent discharge to the environment, but the LCA perspective considers both upstream and downstream issues in addition to operation- and maintenance-level impacts. Therefore, the LCA approach naturally increases the understanding of the potential environmental trade-offs between technologies and identify their competitive advantage. Carbon sequestration and scrubbing of CO2 emissions from flue gas are complex and expensive. For sulfur, the benefits of scrubbing technologies are justifiable by the fact that the waste generated by these technologies are manageable, but for CO2 emissions, it is complex because carbon is responsible for about 50% CO2 emissions of the coal, while sulfur is 1% or 2% in coal, making capturing all this carbon and pumping it in deep underground reservoirs is energy intensive, polluting, and expensive, hence fewer relative benefits. Therefore, the next few decades may not see major technologies to solve the climate change challenges. Therefore, energy efficiency measures and renewable energy technologies will remain the best options to reduce greenhouse gas emissions in the power generation.

The global warming potential reduced by over 70% when CCS was applied but notable environmental trade-offs encountered are increased: ozone layer depletion, human toxicity, and fresh water ecotoxicity potential. State-of-the-art power plant having no CCS performs better in eutrophication, acidification, and photochemical oxidation potential although we have deeper reduction in emissions in the form of Sox and NOx in the CCS power plant. It is therefore important to consider emissions from upstream operations like coal mining, coal transport, and MEA production and downstream operations like transport of captured CO2 and CO2 storage for the accurate assessment of the environmental performance of power plants.

Abbreviations

- CAL:

-

Ca-looping

- CCS:

-

Carbon capture and sequestration

- eLCC:

-

Electricity levelized cost

- (ExLCA):

-

Exergetic life cycle assessment

- GWP:

-

Global Warming Potential

- LCA:

-

Life cycle assessment

- LCC:

-

Life cycle cost

- MEA:

-

Monoethanolamine

- NMVOC:

-

Non-methane volatile organic compounds

- TWh:

-

Terawatt hour

References

Jordaan, S.M., Combs, C., Guenther, E.: Life cycle assessment of electricity generation: a systematic review of spatiotemporal methods. Adv. Appl. Energy. 3, 100058 (2021). https://doi.org/10.1016/j.adapen.2021.100058

Petrescu, L., Bonalumi, D., Valenti, G., Cormos, A.-M., Cormos, C.-C.: Life cycle assessment for supercritical pulverized coal power plants with post-combustion carbon capture and storage. J. Clean. Prod. 157, 10–21 (2017). https://doi.org/10.1016/j.jclepro.2017.03.225

Edenhofer, O., Seyboth, K., Creutzig, F., Schlömer, S.: On the sustainability of renewable energy sources. Annu. Rev. Environ. Resour. 38(1), 169–200 (2013). https://doi.org/10.1146/annurev-environ-051012-145344

Paredes, M.G., Padilla-Rivera, A., Güereca, L.P.: Life cycle assessment of ocean energy technologies: a systematic review. J. Marine Sci. Eng. 7(9). https://doi.org/10.3390/jmse7090322

Gagnon, L., Bélanger, C., Uchiyama, Y.: Life-cycle assessment of electricity generation options: the status of research in year 2001. Energy Policy. 30(14), 1267–1278 (2002). https://doi.org/10.1016/S0301-4215(02)00088-5

Turconi, R., Tonini, D., Nielsen, C.F.B., Simonsen, C.G., Astrup, T.: Environmental impacts of future low-carbon electricity systems: detailed life cycle assessment of a Danish case study. Appl. Energy. 132, 66–73 (2014). https://doi.org/10.1016/j.apenergy.2014.06.078

Kabeyi, M.J.B., Olanrewaju, O.A.: Bagasse electricity potential of conventional sugarcane factories. J. Energy. 2023, 5749122 (2023). https://doi.org/10.1155/2023/5749122

Rentizelas, A., Georgakellos, D.: Incorporating life cycle external cost in optimization of the electricity generation mix. Energy Policy. 65, 134–149 (2014). https://doi.org/10.1016/j.enpol.2013.10.023

Kabeyi, M.J.B., Oludolapo, A.O.: Characteristics and applications of geothermal wellhead powerplants in electricity generation. In: 31ST Annual Southern African Institution for Industrial Engineering Conference, South Africa, H. Teresa, Ed., 5th – 7th October 2020 2020, vol. 2020, No. 31, South Africa: South African Journal of Industrial Engineering, pp. 222–235 (2020). Available: https://www.saiie.co.za/system/files/2021-11/SAIIE31%20Conference%20Proceedings.pdf

Kabeyi, M.J.B.: Potential and challenges of bagasse cogeneration in the Kenyan sugar industry. Int. J. Creat. Res. Thoughts. 10(4), 379–526 (2022). https://doi.org/10.1729/Journal.30042

Ciacci, L., Passarini, F.: Life Cycle Assessment (LCA) of environmental and energy systems. Energies. 13(22). https://doi.org/10.3390/en13225892

Kabeyi, M.J.B., Olanrewaju, A.O.: Managing sustainability in electricity generation. In: 2020 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), 14–17 December 2020, pp. 530–536 (2020). https://doi.org/10.1109/IEEM45057.2020.9309994. Available: https://ieeexplore.ieee.org/abstract/document/9309994

Kabeyi, M.J.B., Olanweraju, O.A.: Sustainability assessment for non-combustible renewable power generation. In: Presented at the 12th Annual Istanbul International Conference on Industrial Engineering and Operations Management, Istanbul, Turkey, March 7–10, 2022, Paper 429 (2022). Available: https://ieomsociety.org/proceedings/2022istanbul/429.pdf

Kabeyi, M.J.B., Olanrewaju, O.A.: Review and design overview of plastic waste-to-pyrolysis oil conversion with implications on the energy transition. J. Energy. 2023, 1821129 (2023). https://doi.org/10.1155/2023/1821129

Nieuwlaar, E.: Life cycle assessment and energy systems☆. In: Reference Module in Earth Systems and Environmental. Elsevier, Sciences (2013)

Angoy, A., et al.: Chapter 17: Microwave technology for food applications. In: Chemat, F., Vorobiev, E. (eds.) Green Food Processing Techniques, pp. 455–498. Academic (2019)

Curran, M.A.: Life-cycle assessment. In: Jørgensen, S.E., Fath, B.D. (eds.) Encyclopedia of Ecology, pp. 2168–2174. Academic, Oxford (2008)

Zhu, X., Wang, S., Wang, L.: Life cycle analysis of greenhouse gas emissions of China’s power generation on spatial and temporal scale. Energy Sci. Eng. 10(4), 1083–1095 (2022). https://doi.org/10.1002/ese3.1100

UNECE: Carbon Neutrality in the UNECE Region: Integrated Life-Cycle Assessment of Electricity Sources, vol. 2022. United Nations Economic Commission For Europe, Uni, 2021 (2022). Available: https://unece.org/sites/default/files/2022-04/LCA_3_FINAL%20March%202022.pdf

Dincer, I., Bicer, Y.: Chapter 7: Enhanced dimensions of integrated energy systems for environment and sustainability. In: Dincer, I., Bicer, Y. (eds.) Integrated Energy Systems for Multigeneration, pp. 403–440. Elsevier (2020)

Hertwich, E.G., et al.: Integrated life-cycle assessment of electricity-supply scenarios confirms global environmental benefit of low-carbon technologies. Proc. Natl. Acad. Sci. 112(20), 6277–6282 (2015). https://doi.org/10.1073/pnas.1312753111

Burchart-Korol, D., Pustejovska, P., Blaut, A., Jursova, S., Korol, J.: Comparative life cycle assessment of current and future electricity generation systems in The Czech Republic and Poland. Int. J. Life Cycle Assess. 23(11), 2165–2177 (2018). https://doi.org/10.1007/s11367-018-1450-z

Turconi, R., Boldrin, A., Astrup, T.: Life cycle assessment (LCA) of electricity generation technologies: overview, comparability and limitations. Renew. Sust. Energ. Rev. 28, 555–565 (2013). https://doi.org/10.1016/j.rser.2013.08.013

Kabeyi, M.J.B., Olanrewaju, O.A.: The role of electrification of transport in the energy transition. In: Presented at the Fifth European Conference on Industrial Engineering and Operations Management, Rome, Italy, July 26–28, 2022, 426 (2022). Available: https://ieomsociety.org/proceedings/2022rome/426.pdf

Kabeyi, M., Olanrewaju, O.: Diesel powerplants: design and operation and performance enhancements. In: Presented at the Fifth European Conference on Industrial Engineering and Operations Management, Rome, Italy, July 26–28, 2022, 425 (2022). Available: https://ieomsociety.org/proceedings/2022rome/425.pdf

Toporov, D.D.: Chapter 2: coal combustion technologies. In: Toporov, D.D. (ed.) Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue Gas, pp. 5–22. Elsevier, Boston (2014)

Cormos, C.C.: Economic evaluations of coal-based combustion and gasification power plants with post-combustion CO2 capture using calcium looping cycle. Energy. 78, 665–673 (2014). https://doi.org/10.1016/j.energy.2014.10.054

Odeh, N.A., Cockerill, T.T.: Life cycle GHG assessment of fossil fuel power plants with carbon capture and storage. Energy Policy. 36(1), 367–380 (2008). https://doi.org/10.1016/j.enpol.2007.09.026

Koornneef, J., van Keulen, T., Faaij, A., Turkenburg, W.: Life cycle assessment of a pulverized coal power plant with post-combustion capture, transport and storage of CO2. Int. J. Greenh. Gas Control. 2(4), 448–467 (2008). https://doi.org/10.1016/j.ijggc.2008.06.008

Corsten, M., Ramírez, A., Shen, L., Koornneef, J., Faaij, A.: Environmental impact assessment of CCS chains – lessons learned and limitations from LCA literature. Int. J. Greenh. Gas Control. 13, 59–71 (2013). https://doi.org/10.1016/j.ijggc.2012.12.003

Manuilova, A., Koiwanit, J., Piewkhaow, L., Wilson, M., Chan, C.W., Tontiwachwuthikul, P.: Life cycle assessment of post-combustion CO2 capture and CO2- enhanced oil recovery based on the boundary dam integrated carbon capture and storage demonstration project in Saskatchewan. Energy Procedia. 63, 7398–7407 (2014). https://doi.org/10.1016/j.egypro.2014.11.776. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84922896333&doi=10.1016%2fj.egypro.2014.11.776&partnerID=40&md5=30f8914abdf69e738457c978d001ccff

Restrepo, Á., Bazzo, E., Miyake, R.: A life cycle assessment of the Brazilian coal used for electric power generation. J. Clean. Prod. 92, 179–186 (2015)

Tang, L., Yokoyama, T., Kubota, H., Shimota, A.: Life cycle assessment of a pulverized coal-fired power plant with CCS technology in Japan. Energy Procedia. 63, 7437–7443 (2014). https://doi.org/10.1016/j.egypro.2014.11.780. Available: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84922931962&doi=10.1016%2fj.egypro.2014.11.780&partnerID=40&md5=b3a15523815688296028ebb817b08e3e

Kabeyi, M.J.B., Oludolapo, A.O.: Development of a biogas plant with electricity generation, heating and fertilizer recovery systems. In: Presented at the 2nd African International Conference on Industrial Engineering and Operations Management, Harare, Zimbabwe, 5–7 December 2020, 082 (2020). Available: http://ieomsociety.org/harare2020/papers/82.pdf

M. J. B. Kabeyi, "Challenges of implementing thermal powerplant projects in Kenya,the case of Kipevu III 120MW power station,Mombasa Kenya," Masters, Department of Education Management, University of Nairobi, Nairobi, 2012. Available: http://erepository.uonbi.ac.ke:8080/xmlui/handle/123456789/11023

Kabeyi, M.J.B., Olanrewaju, O.A.: Energy and environment: oportunities and challenges for the energy transition. In: Presented at the Fifth European Conference on Industrial Engineering and Operations Management, Rome, Italy, July 26–28, 2022, 427 (2022). Available: https://ieomsociety.org/proceedings/2022rome/427.pdf

Kabeyi, M., Olanrewaju, O.: Diesel to gas engine power plant conversion: a review and preliminary design for an operating power plant. J. Energy Manag. Technol. (2022). https://doi.org/10.22109/jemt.2022.292982.1312

Kabeyi, M.J.B., Olanrewaju, O.A.: Conversion of diesel and petrol engines to biogas engines as an energy transition strategy. In: Presented at the 4th African International Conference on Industrial Engineering and Operations Management, Nsukka, Nigeria, April 5–7, 2022, 448 (2022). Available: https://ieomsociety.org/proceedings/2022nigeria/448.pdf

Kabeyi, M.J.B., Olanrewaju, O.A.: Performance analysis and evaluation of ethanol potential of Nzoia Sugar Company Ltd. Energy Rep. 8(16), 787–799 (2022). https://doi.org/10.1016/j.egyr.2022.11.006

Kabeyi, M.J.B., Olanrewaju, O.A.: A techno-economic assessment of diesel to gas power plant conversion. In: Presented at the 12th Annual Istanbul International Conference on Industrial Engineering and Operations Management, Istanbul, Turkey, March 7–10, 2022, 406 (2022). Available: https://ieomsociety.org/proceedings/2022istanbul/406.pdf

Corona, B., Cerrajero, E., López, D., San Miguel, G.: Full environmental life cycle cost analysis of concentrating solar power technology: contribution of externalities to overall energy costs. Sol. Energy. 135, 758–768 (2016). https://doi.org/10.1016/j.solener.2016.06.059

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Kabeyi, M.J.B., Olanrewaju, O.A. (2024). Environmental Impacts of Power Plants and Energy Conversion Systems. In: Chen, L. (eds) Advances in Clean Energy Systems and Technologies. Green Energy and Technology. Springer, Cham. https://doi.org/10.1007/978-3-031-49787-2_40

Download citation

DOI: https://doi.org/10.1007/978-3-031-49787-2_40

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-49786-5

Online ISBN: 978-3-031-49787-2

eBook Packages: EnergyEnergy (R0)