Abstract

Along with the rapid development of flexible and wearable electronics, there has been a strong need for flexible energy storage devices to power these devices. Flexible supercapacitors (FSCs), having the unique characteristics of high-power density, long lifetime, wide operating temperature range, and remarkable safety in a flexible fashion, have been extensively studied for this emerging technology. An ideal FSC would have both superior electrochemical performances and excellent mechanical deformabilities, which require thorough research on the electrode materials and device configurations of FSCs. This chapter reviews the recent progress on these aspects of FSCs. Electrode materials, specifically pseudocapacitive materials (including metal oxides, conducting polymers, and Mxenes) and their composites, of FSCs are firstly elucidated. This is followed by the discussion about the device configurations of pseudocapacitive material-incorporated FSCs, ranging from one-dimensional fiber-shaped to two-dimensional film-shaped and three-dimensional structural. Finally, the practical applications of pseudocapacitive material incorporated FSCs are summarized. In conclusion, the current challenges and future prospects for pseudocapacitive material-incorporated FSCs are discussed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Flexible supercapacitors

- Electrochemical performances

- Mechanical deformabilities

- Electrode materials

- Pseudocapacitive materials

- Device configurations

1 Introduction

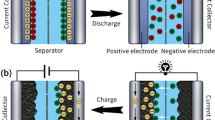

In recent years, the rapid applications of flexible and wearable electronic devices, such as flexible touch screens, artificial electronic skins, wearable electronic suits and smart sensors, miniature biomedical devices, and health monitoring and management, have dramatically influenced our daily lives [1, 2]. This has triggered the extensive research and development of flexible power sources [3], mainly including flexible batteries (FBs) and flexible supercapacitors (FSCs) [4,5,6]. Compared to FBs, FSCs possess the advantages of higher power density, wider operating temperature range, longer cycle life, and better safety but a distinct disadvantage of lower energy density. In this regard, owing to their higher capacitances than those of traditional electric-double-layer-capacitor (EDLC) materials, pseudocapacitive materials have been studied to enhance the energy density for FSCs, resulting in a family of pseudocapacitive material-incorporated FSCs [7,8,9] in the community of flexible power sources.

An ideal FSC would have not only superior electrochemical performances (including high energy/power densities, long lifetime, and high safety) but also the excellent mechanical deformabilities (such as flexibility, stretchability, bendability, foldability, and twistability) [5, 6], with the former largely determined by the properties of the electrode materials [10] and the latter by the configuration designs of the devices [3]. Herein, this chapter systematically discusses the recent progress in the research of pseudocapacitive electrode materials (including metal oxides (MOs), conducting polymers (CPs), and Mxenes (MXs) as well as their composites) for FSCs and the device configurations (from one-dimensional (1D) fiber-shaped to two-dimensional (2D) film-shaped and three-dimensional (3D) structural) of the resultant FSCs. This is followed by a discussion about the practical applications of pseudocapacitive material incorporated FSCs. Towards the conclusion, the current challenges and future prospects of pseudocapacitive material incorporated FSCs are spotlighted.

2 Pseudocapacitive Materials for FSCs

Different from the energy storage mechanism of a so-called electric double layer for an EDLC material, that of a pseudocapacitive material is characterized by its fast and reversible redox reactions at or near the electrode surface [11, 12]. This results in higher capacitances for pseudocapacitive materials and thus higher energy densities for pseudocapacitors over those of their EDLC counterparts [7, 8]. In the past decades, considerable efforts have been made to utilize a large variety of pseudocapacitive materials including, for example, MOs [3, 8], CPs [7, 13, 14], and MXs [9, 11], for developing FSCs. It is straightforward to directly fabricate pseudocapacitive materials into electrodes for FSCs. By doing so, however, some shortcomings exist in, for example, capacitance, rate capability, mechanical deformability, and cycling stability (especially under repeated deformation conditions), for the resultant electrodes [3, 9, 11]. In this regard, processing pseudocapacitive materials into composite electrodes has been demonstrated to be efficient to address these limitations towards high-performance FSCs [14].

On the one hand, multiple pseudocapacitive materials can be incorporated to fabricate composite electrodes. By integrating the superiorities from different types of pseudocapacitive materials (such as high theoretical capacitances of MOs, excellent intrinsic flexibility of CPs, and high density and metallic-like conductivity of MXs), the resultant multi-component-pseudocapacitive-material composite electrodes can achieve enhanced properties over their original individual ingredients [3, 7,8,9, 14].

On the other hand, compositing pseudocapacitive materials with carbon nanomaterials has attracted considerable research efforts to develop flexible composite electrodes for FSCs. It is known that carbon nanomaterials (e.g., graphene, carbon nanotube (CNT), and carbon nanofiber (CNF)) possess the excellent properties of large specific surface area (SSA), high electrical and thermal conductivities, outstanding flexibility, light weight, high Young’s modulus, and high tensile strength [1, 5, 15]. By combing these unique advantages of carbon nanomaterials with the high capacitance of pseudocapacitive materials, the resultant composite electrodes exhibit significantly enhanced properties over their original pseudocapacitive-material counterparts [3, 7,8,9, 14].

2.1 Metal Oxides and Their Composites for FSCs

Owing to their high theoretical capacitances [5], MOs are an attractive group of pseudocapacitive materials for FSCs [3, 8]. However, the inherent brittleness and stiffness, low electrical conductivity, and poor stability and durability of MOs [10] inevitably limit their practical FSC applications. To address these issues, MOs have been composited with carbon nanomaterials and/or other pseudocapacitive materials.

The integration of MOs with carbon nanomaterials can not only reinforce the mechanical properties but also enhance the conductivity and capacitance for the resultant composites. Among various MOs, MnO2 has been investigated the most intensively mainly because of its high theoretical capacitance (~1370 F g−1), environmental friendliness, low cost, and abundant resources [8]. For example, Lv et al. [16] developed a stirring hydrothermal method to synthesize a ultralong MnO2 nanowire/CNT (MNWs/CNT) composite, followed by sandwiching the resultant composite between two thin layers of nanocellulose fibers (NCFs) to achieve a mechanically strengthened MNW-NCF electrode (Fig. 1a). With a polyvinyl alcohol (PVA) gel electrolyte, this composite electrode was assembled into a honeycomb-like symmetric FSC, showing a high capacitance of 227.2 mF cm−2. Mechanically, the FSC thus constructed presented excellent stretchability (Fig. 1b) and superior cycling stability upon varied deformations (Fig. 1c). Moreover, this FSC retained nearly 98% of its initial capacitance even subjected to stretch-release cycling under a 400% tensile strain for 10,000 cycles (Fig. 1d). Compared with a MnO2 nanoflowers (MNFs)/CNT-NCF electrode (Figs. 1b, c), these achievements can be understood by the interconnected fabric-like microstructure of the MNWs/CNT enabled by the intact contact between the ultralong MnO2 nanowire and CNT. Therefore, the enhanced electrochemical and mechanical performances of such carbon-MO composites indicate a good strategy for introducing carbon nanomaterials to process MOs into realistically useful electrodes for FSCs.

a Schematic illustration of the construction of a MNWs/CNT-NCF based FSC (side view). b Normalized specific capacitances of different FSCs tested at 1.6 mA cm−2 under different strains. c Electrochemical performance comparison between different FSCs upon cycling at 1.6 mA cm−2 under various mechanical deformations. Insets are the photographs of FSCs under various mechanical deformations. d Capacitance retention ratio of the FSC at 1.6 mA cm−2 under a recycling tensile strain of 400%. Adapted with permission [16], Copyright (2018), Wiley–VCH. e Schematic illustration of the synthesis of a SnO2@PPy/CC composite. f (a) photograph of a stainless steel autoclave hanged by the SnO2@PPy/CC composite; (b–f) photographs of a SnO2@PPy/CC based symmetric FSC under different bending angles and twisting state; g. cyclic voltammetry (CV) curves of the FSC at 50 mV s−1 under various bending and twisting conditions (inset is CV curves of the FSC before and after 200 bending cycles). Adapted with permission [17], Copyright (2022), Elsevier

Alternatively, another strategy to overcome the shortcomings of MOs is to composite them with inherently conductive and flexible pseudocapacitive materials, i.e., CPs. This way, the simultaneous utilization of the high capacitance of MOs and the intrinsic conductivity and flexibility of CPs makes the resultant composites superior over not only their MO but also the CP components. With this concept, for example, Zhuang et al. [17] developed a carbon cloth (CC) flexible scaffold supported SnO2@polypyrrole (PPy) composite electrode (SnO2@PPy/CC). The SnO2 nanosheets were in-situ grown on CC fibers by a simple solvothermal method, followed by polymerizing PPy on the SnO2 nanosheets thus prepared (Fig. 1e). Benefiting from the combination of SnO2 and PPy, the as-obtained SnO2@PPy/CC composite electrode showed significant improvements in both electrochemical and mechanical performances compared to its single-component counterpart without PPy. In particular, the conductivity and flexibility of PPy made the SnO2-incorporated composite electrode conductive and flexible (inset (a) in Fig. 1f), while its electroactivity provided SnO2 with additional pseudocapacitance. Consequently, a symmetric FSC constructed from this composite electrode with a PVA-KOH gel electrolyte realized a high capacitance of 265.9 mF cm−2, a maximum energy and power densities of 0.7 mWh cm−3 and 94.7 mW cm−3, respectively, and a superior cycling stability. Moreover, this FSC exhibited excellent mechanical deformabilities without an apparent capacity decay under various bending and twisting conditions (Fig. 1f, g). The above results reveal the effectiveness of incorporating other pseudocapacitive materials to make MOs more suitable for practically useful FSCs.

2.2 Conducting Polymers and Their Composites for FSCs

CPs, mainly represented by polyaniline (PANi), PPy, polythiophene (PTh), and their derivatives, are another type of pseudocapacitive materials for FSCs, thanks to their high theoretical capacitance (e.g., 750 F g−1 for PANi and 620 F g−1 for PPy). Compared to MOs, CPs possess the distinctive advantages of ease of production, environmental friendliness, and especially inherently high flexibility. However, CPs usually encounter with an inferior rate capability determined by their relatively low conductivity [10] and poor cycling stability by their volume change during the doping-dedoping process [7, 14]. Compositing CPs with carbon nanomaterials and/or other pseudocapacitive materials has been demonstrated to be simple yet effective to address such shortcomings.

The integration of the high capacitance from CPs and the excellent conductivity and stability from carbon nanomaterials endows the resultant carbon-CP composite electrodes with enhanced capacitance, rate capability, and cycling stability over their original CP and carbon counterparts. Among various CPs, PPy is a frequently studied candidate [7, 13]. For example, Li et al. [18] firstly painted reduced graphene oxides (rGO) layers on the surface of SnCl2 modified polyester fibers (M-PEF) via a repeated “dyeing and drying” strategy, followed by in-situ polymerization of PPy onto the resultant rGO/M-PEF substrate to fabricate a PPy/rGO/M-PEF composite electrode (Fig. 2a). While the highly flexible and conductive rGO/M-PEF scaffolds served as a continuous conductive skeleton, the hierarchical PPy/rGO/M-PEF textile structures permitted a large loading of PPy, synergistically enabling excellent mechanical deformabilities with a high capacitance and rate capability for the resultant composite. When combined with a PVA/H2SO4 gel electrolyte, the PPy/rGO/M-PEF based symmetric FSC thus assembled showed an excellent rate capability with a high capacitance of 350 mF cm−2 at 50 mA cm−2 versus that of 474 mF cm−2 at 1 mA cm−2, corresponding to a high energy and power densities of 0.0658 mWh cm−2 and 0.5 mW cm−2, respectively. This FSC exhibited a remarkable cycling stability with its 100% capacitance retention after being charged/discharged for 10,000 cycles. Furthermore, it showed an outstanding bendability, maintaining its initial capacitance at 97.6% and 99.2% after being bend-cycled for 1000 cycles (Fig. 2b) and bent to an angle up to 180° (Fig. 2c), respectively.

a Schematic illustration of the synthesis route toward (a) a textile electrode (PPy/RGO/M-PEFT) and (b) a yarn electrode (PPy/RGO/M-PEFY). b. Capacitance retention and CV curves of the device after repeated bending. c Capacitance retention and CV curves of the device at different bending states. Adapted with permission [18], Copyright (2018), Wiley–VCH. d (i–ii) schematic illustration of the preparation of a PEDOT:PSS/CNP; (iii) digital photos of the PEDOT:PSS/CNP lifting an 2 kg autoclave; (iv) illustration of a PEDOT:PSS/CNP based FSC device; (v) digital photo of a green-light LED powered by three FSC devices in series. Adapted with permission [19], Copyright (2022), Elsevier. e Schematic illustration of the fabrication of an ACPM composite. f–g Capacitance retention, digital photographs, and CV curves of a solid-state ACPM//ACFC asymmetric SC under different bending angles and after bending for various cycles. Adapted with permission [20], Copyright (2018), American Chemical Society

As an important derivative of PTh, poly (3,4-ethylenedioxythiphoenes) (PEDOT) is attractive for FSCs, due to its easier processability, higher conductivity, and better stability than other CPs such as PANi and PPy [19]. For example, Du et al. [19] developed a facile strategy to fabricate mechanically strong and conductive PEDOT: poly(styrenesulfonate) (PSS) bulk films (Fig. 2d). By using CNFs as building blocks to reinforce the mechanical strength, PEDOT:PSS/CNF suspension was firstly prepared via a simple in-situ polymerization process. Afterwards, a flexible and conductive PEDOT:PSS/CNF nanopaper (PEDOT:PSS/CNP) was obtained through vacuum filtration and dimethyl sulfoxide (DMSO) post-treatment (inset i-ii in Fig. 2d). The as-prepared PEDOT:PSS/CNP exhibited outstanding flexibility, electrical conductivity, and tensile strength and can lift up a heavy autoclave (inset iii in Fig. 2d). With a 1 M H2SO4 electrolyte, the PEDOT:PSS/CNP-based symmetric FSC (inset iv in Fig. 2d) delivered a capacitance of as high as 854.4 mF cm−2 (~122.1 F cm−3) and realized a high energy density of 30.86 μWh cm−2 and power density of 28.27 mW cm−2. It presented a high capacitance retention of 95.8% after being charged/discharged for 10,000 cycles and maintained its original capacitance even under severe deformations.

Moreover, another pseudocapacitive material can be introduced into the carbon-CP binary system as elaborated above, resulting in multi-component pseudocapacitive material-carbon nanomaterial composites with further enhanced properties [17, 20, 21]. For instance, Wang et al. [20] reported a layer-by-layer method to develop 3D activated carbon fiber cloth/CNT/PANi/MnO2 (ACFC/CNT/PANi/MnO2) (denoted as ACPM) composite textile electrodes. Specifically, PANi was firstly deposited on ACFC via an electropolymerization process, followed by the deposition of CNT and MnO2 through a dipping-drying procedure and an in-situ chemical reaction, respectively (Fig. 2e). In the resultant multi-component composite electrode, the ACFC/CNT hybrid framework served as a porous and conductive 3D network to facilitate the transport of electrons and electrolyte ions, while PANi and MnO2 synergistically ensured a high capacitance. As a consequence, the ACPM electrode thus prepared realized an ultra-high capacitance up to 4615 mF cm−2. Coupling the ACPM electrode (as anode) with an ACFC cathode and a PVA/H2SO4 gel electrolyte, the as-assembled ACPM//ACFC asymmetric FSC presented excellent electrochemical and mechanical performances, delivering an energy and power densities of 413 µWh cm−2 and 16,120 µW cm−2, respectively, and retaining its capacitance under different bending conditions (Fig. 2f, g). This work demonstrates the significance of incorporating multiple pseudocapacitive materials with carbon nanomaterials to fabricate composite electrodes with further enhanced properties for FSCs.

2.3 Mxenes and Their Composites for FSCs

With respect to MOs and CPs, MXs, i.e., the 2D transition metal carbides and nitrides, are a relatively new member in the pseudocapacitive materials community. MXs have been intensively investigated for electrochemical energy storage due to their remarkable physical and chemical characteristics, including unique 2D layered structure, good processability, metallic conductivity, large SSA, excellent mechanical strength, hydrophilic nature, and ability to accommodate intercalants [9, 22]. These superior properties of MXs, along with their high theoretical capacity of 615 C g−1 [23], make them especially suitable for FSCs.

However, MXs may suffer from a undesirable capacitance because of their restacking of 2D nanosheets caused by the strong interplanar van der Waals interactions (leading to reduced ion-accessible SSA and blocked electrolyte ion diffusion) and an inferior rate capability because of their anisotropic behavior (leading to poor interlayer and interparticle conductivity) [24,25,26]. In order to address these shortcomings, MXs have been composited with carbon nanomaterials and/or other pseudocapacitive materials (e.g., MOs or CPs), resulting in various composites, such as carbon-MX [24, 25, 27,28,29], MX/CP [30], and carbon-MX/MO [26]. In the resultant composites, carbon nanomaterials, MOs, and CPs can not only serve as special spacers to mitigate the restacking of MX nanosheets but also further boost the overall electrochemical and mechanical properties of the composites (owing to the synergistic effects from all constituents of these composites) [26, 31].

In the carbon-MX system, for example, Chen et al. [29] utilized vacuum filtration to incorporate CNF, porous carbon (PC), and Ti3C2TX to fabricate a free-standing Ti3C2TX/CNF/PC composite electrode, in which CNF and PC formed a flexible scaffold (Fig. 3a). In addition to constructing the flexible scaffold, CNF and PC can also serve as spacers to suppress the self-restacking of the Ti3C2TX nanosheets, thereby increasing the interlayer distance and creating open gaps for facilitating ion transport. Synergistically, owing to the porous structure of PC, abundant porosity and good mechanical properties of CNF, excellent conductivity of Ti3C2TX, and the well-established 3D interconnected hierarchical structure of the composite, the Ti3C2TX/CNF/PC electrode possessed a high SSA of 574.5 m2 g−1 and a high conductivity up to 83.1 S cm−1. Coupling this composite electrode with a PVA/KOH gel electrolyte, the resultant symmetrical FSC displayed a high capacitance of 143 mF cm−2, an excellent rate capability (a capacitance retention of 50.9% at 10 mA cm−2), a high energy and power densities of 2.4 uWh cm−2 and 2000 uW cm−2, respectively, and especially superior mechanical deformabilities under various bending angles. These results highlight the significance of compositing MXs with multiple carbons (including carbon nanomaterials) in constructing a 3D conductive scaffold to enhance both the electrochemical and mechanical properties for the resultant carbon-MX composite electrodes.

a Schematic illustration of the preparation of a Ti3C2TX/CNF/PC hybrid film and a quasi-solid-state SC: (a) mixing of a dispersion containing Ti3C2TX, CNF, and PC; (b) vacuum assisted filtration of the dispersion into a Ti3C2TX/CNF/PC hybrid film; (c) fabrication of a SC using two hybrid films as free-standing electrodes with a PVA/KOH gel electrolyte. Adapted with permission [29], Copyright (2020), Elsevier. b Schematic illustration of the preparation of a MXene/CNT@MnO2 film and its corresponding all-in-one FSC device. c Digital photographs of the FSC under different bending conditions and its corresponding galvanostatic charge/discharge (GCD) curves at 0.5 A g−1. Adapted with permission [26], Copyright (2021), The Royal Society of Chemistry

Into the carbon-MX system as discussed above, moreover, the introduction of another pseudocapacitive material has been demonstrated to be efficient to further enhance the properties of the resultant multi-component composite electrodes. For example, Huang et al. [26] developed a vacuum-filtration assisted layer-by-layer strategy to synthesize a carbon-MX/MO-based multi-component composite for FSCs. Specifically, a CNT@MnO2 composite was firstly prepared via a hydrothermal process, followed by embedding the as-synthesized CNT@MnO2 into the MX nanosheet interlayers to obtain the MX/CNT@MnO2 composite film electrode (Fig. 3b). In this electrode, while the CNT@MnO2 composites can suppress the restacking of MX nanosheets, the MX nanosheets and CNTs can form a 3D conductive network for MnO2 loading, jointly facilitating the electron transport and electrolyte ion diffusion for the entire system. As a result of these unique features, the MX/CNT@MnO2 composite electrode showed a high capacitance of 221 F g−1. Incorporating this composite electrode with a PVA/Na2SO4 gel electrolyte, the resultant all-in-one FSC exhibited a high energy and power densities of 24.5 mWh cm−3 and 2.5 W cm−3, respectively, as well as a good cycling stability (no apparent capacitance decay after 1800 cycles) and bendability (negligible change in capacitive behavior upon mechanical bending) (Fig. 3c). These promising results spotlight the excellence of combining multiple pseudocapacitive materials with carbon nanomaterials to fabricate superior multi-component composites for high-performance FSCs.

As discussed above, due to the shortcomings of their direct use, pseudocapacitive materials are usually processed into composites to fulfill their FSC applications. Specifically, pseudocapacitive materials can be incorporated each other or combined with carbon nanomaterials to fabricate composites with superior electrochemical and mechanical properties for FSCs. Therefore, with appropriate electrode and device design, these composites can be fabricated into FSCs in varied configurations to satisfy the application requirements for various wearable and flexible electronic devices, to be discussed as follows.

3 Device Configurations of Pseudocapacitive Material-Incorporated FSCs

Apart from the electrode properties, the device design is also essential in determining the performances of FSCs [32]. Pseudocapacitive material-incorporated FSCs have been fabricated in 1D fiber-shaped, 2D film-shaped, and 3D structural configurations to meet the application demands for varied mechanical deformation conditions [32, 33].

3.1 One-Dimensional Fiber-Shaped FSCs

1D FSCs are characterized by a fiber-shaped (or wire-like, cable-type) configuration possessing the advantages of lightweight and good stretchability and knittability [32, 33]. 1D fiber-shaped FSCs have been fabricated in three configurations, i.e., parallel, twisted, and coaxial (or core–shell) [4, 32], with various pseudocapacitive materials [25, 34,35,36,37,38,39,40,41].

A parallel 1D fiber-shaped FSC consists of two fiber electrodes in parallel that are separated by an electrolyte. For instance, Li et al. [35] designed a prestraining-then-buckling method to develop a stretchable fiber-shaped FSC composed of two MnO2/oxidized CNT fiber electrodes and a LiCl-PVA gel electrolyte on a poly(dimethylsiloxane) (PDMS) film in a continuously buckled pattern (Fig. 4a). The FSC thus fabricated displayed a remarkable capacitance of 409.4 F cm−3, a superior energy and power densities of 14.2 mWh cm−3 and 6250 mW cm−3, respectively, and an excellent cycling stability (98% of capacitance retention after 5000 cycles). Moreover, it showed negligible change in electrochemical properties under various stretching and folding conditions (Fig. 4b).

a Schematic illustration of the fabrication process of a stretchable FSC. b CV curves of the FSC obtained at a scan rate of 50 mV s−1 under stretching and folding, respectively. Adapted with permission [35], Copyright (2017), Wiley–VCH. c Schematic illustration of the fabrication processes of an all-solid-state AFSC with an ionic liquid incorporated gel-polymer electrolyte. d GCD curves of the AFSC measured at 0.5 A cm−3 under different bending angles. e Normalized capacitance of the AFSC after bending at 90° for 1000 cycles. Adapted with permission [41], Copyright (2019), Wiley–VCH. f Schematic demonstration of a FSS with a core-sheath structure. g–h CV and GCD curves of the FSS under different bending angles. Adapted with permission [39], Copyright (2021), American Chemical Society

In a parallel 1D fiber-shaped FSC, the electric field formed in the radial direction (across the diameters) of its two parallel electrodes is not uniform, limiting its electrochemical performances [4]. This drawback can be addressed by arranging the two fiber electrodes in a more efficient configuration, such as with a twisted or coaxial structure.

Constructed by twisting two fiber electrodes together along with an electrolyte in between, a twisted 1D fiber-shaped FSC can form a uniform electric field between its two electrodes. With this design, Pan et al. [41] twisted a MnOx@Titanium Nitride nanowires/CNT (MnOx@TiN NWs@CNT) fiber cathode and a carbon@TiN NWs/CNT (C@TiN NWs@CNT) fiber anode with an ionic liquid (IL) gel polymer electrolyte to assemble an asymmetric fiber-shaped SC (AFSC) (Fig. 4c). The resultant AFSC achieved a high working voltage up to 3.5 V and thus an ultrahigh energy density of 61.2 mWh cm−3, comparable to those of commercially available planar lead-acid batteries (50 ~ 90 mWh cm−3), and a high-power density of 10.1 W cm−3. Furthermore, the well-maintained shape of the GCD curves under different bending angles (Fig. 4d) and the high capacitance retention of 92.7% after 1000 bending cycles (Fig. 4e) of this AFSC strongly indicate its exceptional flexibility.

The two fiber electrodes of a coaxial (or core–shell) 1D fiber-shaped FSC are well-arranged in a coaxial configuration, i.e., an external electrode wrapping around an internal electrode with an electrolyte in between, making the electric field between the two electrodes uniform in both the axial and radial directions, maximizing the effective area for the electrodes, and lowering the internal resistance for the device [32]. This configuration is especially useful for fabricating stretchable FSCs. For example, Xu et al. [39] fabricated a fiber-shaped SC (FSS) by wrapping a MnO2 deposited CNT film (MnO2@CNT) electrode (as cathode) on a PPy deposited carbon fiber (PPy@CF) electrode (as anode) (Fig. 4f). The as-assembled FSS delivered a high capacitance of 66.27 mF cm−2 at 5 mV s−1 with a good rate performance retaining 67% of initial capacitance at 100 mV s−1. Meanwhile, it displayed a high energy and power densities of 23.56 uWh cm−2 and 3.3 mW cm−2, respectively, and exhibited a remarkable flexibility with a negligible change in capacitance under different bending angles (Fig. 4g, h) and a high capacitance retention of 90% after 200 bending cycles.

The active material loading of a 1D fiber-shaped FSC is relatively low (because of its use of small-sized fiber electrodes) and its internal resistance would increase upon the increase in length of its fiber electrodes [5]. Use of film electrodes would be capable of addressing these issues, resulting in two-dimensional film-shaped FSCs, to be discussed below.

3.2 Two-Dimensional Film-Shaped FSCs

2D FSCs have a film-shaped (or paper-like) appearance, in which two thin-film flexible electrodes sandwich an electrolyte [32]. In recent years, the substantial achievements in the research of pseudocapacitive materials have accelerated the development of 2D film-shaped FSCs with either a symmetric or asymmetric configuration [28, 42, 43].

In the symmetric configuration, for example, Li et al. [43] reported a bendable FSC by sandwiching two identical MX (Ti3AlC2)/α-Fe2O3-C-MoS2-PEDOT:PSS/MX (Ti3AlC2) (M/FMP/M) film electrodes with a PVA/H2SO4 gel electrolyte in a CC framework (Fig. 5a, b). In the electrode design, while PEDOT:PSS can provide active sites and lower resistance for α-Fe2O3 and C-MoS2 to efficiently utilize their capacitances, the resultant FMP composite can suppress the restacking of the Ti3AlC2 sheets. At the device level, the CC framework can provide flexibility for the FSC. As a result, the as-assembled symmetric FSC delivered a high energy and power densities of 371 uWh cm−2 and 50 mW cm−2, respectively, and showed a superior bendability retaining its capacitance up to 98.6% under a bending angle of 180° (Fig. 5c).

a Illustration of the preparation of a M/FMP/M film on a carbon cloth. b Structure of a device assembled from two M/FMP/M-20% film electrodes. c Capacitance retention of the device tested at 20 mV s−1 in different bending states. Adapted with permission [43], Copyright (2022), American Chemical Society. d Schematic representation of the designing of a FHSC device by employing CoPO-CMO238 as the positive electrode and CNT–Ti3C2TX/CC as the negative electrode with a PVA–KOH gel electrolyte. e Photos of the device in its initial position and at various bending angles of 90°, 120°, and 180°, and the corresponding CV curves at 100 mV s −1. Adapted with permission [44], Copyright (2021), The Royal Society of Chemistry. f Schematic of an internal asymmetric tandem all-in-one FSC. g GCD curves of the FSC measured at 4 mA cm−2 under different bending angles. h Normalized capacitance of the FSC upon cycling with a bending angle of 90° for 6000 cycles. i Two blue-light LEDs powered by the FSC (bending angle from 0 to 135°). Adapted with permission [45], Copyright (2020), Elsevier

Constructed from two different electrodes, an asymmetric (hybrid) FSC has an enlarged operating voltage and hence an enhanced energy output. In an example by Patil et al. [44], a CC supported porous Co3(PO4)2 transparent stacked micropetals (TSMs) decorated with Co2Mo3O8 nanosheets (Co3(PO4)2@Co2Mo3O8) composite and a CC supported 2D CNT/MX (CNT-Ti3C2TX) composite were employed as the positive electrode and negative electrode, respectively, to sandwich a PVA/KOH gel electrolyte (Fig. 5d). The resultant flexible hybrid solid-state SC (FHSC) realized an enlarged working voltage up to 1.5 V and thus delivered an exceptional energy and power as high as 2.47 mWh cm−3 and 225 mW cm−3, respectively, along with an outstanding cycling stability retaining its capacitance at 93.2% after charging/discharging for 5000 cycles. Under various bending angles (Fig. 5e), this FHSC was able to maintain its initial capacitance with negligible decay.

Moreover, by integrating multiple asymmetric cells into a tandem structure, the working voltage and hence energy density of the resultant FSCs can be further boosted. In this regard, Zhou et al. [45] built an asymmetric FSC by incorporating a CNT film supported MnO2@N-doped carbon skeleton (CNTF/MnO2@N–C) cathode, a CNTF/N–C@vanadium nitrogen (CTF/N–C@VN) anode, and a LiCl/PVA gel electrolyte in a tandem configuration (Fig. 5f). This tandem design enabled the as-assembled FSC to have a maximum working voltage up to 6.6 V (versus that of 2.2 V for a single cell), thereby a high energy and power of 118.2 mWh cm−3 and 3821.9 mW cm−3, respectively. Furthermore, it retained 95.1% of its initial capacitance after charging/discharging for 15,000 cycles. More importantly, this FSC exhibited impressive mechanical deformabilities, maintaining its GCD curves almost unchanged upon the increase of bending angle from 0° to 180° (Fig. 5g), presenting a high capacitance retention of 97.2% after 6000 bending cycles (Fig. 5h), and holding a stable energy output under various bending angles (Fig. 5i). The above results clearly demonstrate the effectiveness of the asymmetric configuration and the tandem structure design in boosting the energy output for 2D film-shaped FSCs.

As can be seen, fruitful progress has been achieved for pseudocapacitive material-incorporated 1D fiber- and 2D film-shaped FSCs. For practical applications, moreover, the active material loading of these devices needs to be efficiently increased (without a decay in specific capacitance [46]) and their deformabilities need to be significantly improved. These have, in fact, triggered the efforts on the research of higher-dimensional, i.e., 3D structural, FSCs [33].

3.3 Three-Dimensional Structural FSCs

A 3D structural FSC is constructed in a 3D configuration by integrating low-dimensional (1D or 2D) FSCs as the building units. Compared to their low-dimensional counterparts, 3D structural FSCs incorporate more active materials into the device and can omni-directionally accommodate mechanical deformations [32], more suitable for practical applications.

In this context, for example, Lv et al. [47] utilized a 2D film-shaped SC as the building unit to develop a 3D stretchable FSC in a configuration mimicking a honeycomb lantern. With a honeycomb lantern structure (Fig. 6a), the proposed 3D stretchable FSC was constructed by incorporating a symmetric capacitor composed of a PPy/black-phosphorous oxide electrodeposited on CNT film (PPy/BPO/CNT) composite electrode and a PVA/H2SO4 gel electrolyte as the building unit. Consequently, the unique expandable architecture of the honeycomb lantern enabled the FSC with device-thickness-independent ion-transport path and stretchability that allowed the fabrication of FSCs into customizable device thickness for enhancing the energy output and adjusting the integrability for fitting with various wearable devices. Remarkably, a 1.0 cm-thick FSC thus fabricated displayed a boosted capacitance of 7.34 F cm−2, 60 times that of its original 2D SC unit (120 mF cm−2). Mechanically, this 3D FSC could be stretched up to 2400% (Fig. 6b) and exhibited a device-thickness/shape-independent stretchability (Fig. 6c). It maintained its electrochemical performance unchanged under 2400% stretching (Fig. 6d) and retained its capacitance at 95% even upon stretch-release cycling under 2000% strain for 10,000 cycles (Fig. 6e). These results clearly demonstrate the practical application superiorities of 3D structural FSCs over their low-dimensional counterparts.

a Schematic representation showing the fabrication procedure of a 3D rectangular-shaped stretchable FSC. b Digital images of the FSC under varied strains. Inset is a scheme presenting the expandable honeycomb structure and hexagonal unit cells of the FSC before and after stretching. c Effect of device thickness on the rupture strain of the FSC. d Normalized capacitances of FSCs from different PPy-based electrodes tested at 7.8 mA cm−2 with varied strains. e Capacitance retention of the FSC from PPy/BPO/CNT electrodes tested at 7.8 mA cm−2 under stretch cycling with a tensile strain of 2000%. Adapted with permission [47], Copyright (2018), Wiley–VCH

To this end, remarkable progress has been achieved in the research of pseudocapacitive materials and the development of their FSCs. This has facilitated the practical application exploration of FSCs for flexible and wearable electronics as briefly elaborated as follows.

4 Practical Applications of Pseudocapacitive Material Incorporated FSCs

Pseudocapacitive material incorporated FSCs have shown great potentials for practical applications because of their excellent safety, electrochemical performances, and mechanical deformabilities [1, 48]. While 1D FSCs are promising for wearable applications, 2D and 3D FSCs have better suitability for large-scale flexible electronics, and 3D FSCs are especially useful for multi-direction-deformation applications. Pseudocapacitive material-incorporated FSCs have been incorporated into many application concepts and even prototypes, such as flexible and transparent electronics [49], healthcare monitoring systems [16, 42, 50], skin-attachable wearables and sensors [51], wearable digital electronics [38], and self-powered wearable devices [52]. In some specific scenarios, furthermore, the special functionalities, such as transparency or self-power, are needed, resulting in multifunctional FSCs.

For the emerging electronics of flexible and transparent devices [53], for instance, many attempts have been made to fabricate FSCs that are flexible and also transparent. In this regard, a multifunctional wearable electrochromic patch device powered by an all-transparent stretchable electrochromic SC (all-TSES) was developed (Fig. 7a) [54]. Attributed to the pseudocapacitive/coloration dual characteristics of the PEDOT:PSS/WO3 electrodes, this patch device delivered a maximum energy and power densities of 52.6 Wh kg−1 and 19.1 kW kg−1, respectively, and showed reversible coloration at –1.5 V and bleaching at –0.1 V (Fig. 7b, c). It demonstrated stable electrochromic and electrochemical properties by holding 95.0% and 97.6% of its normalized transmittance change and normalized specific capacitance, respectively, even after being exposed to the ambient conditions for 2 weeks (Fig. 7d). Mechanically, it was stable upon stretch-bend cycling and exhibited a high capacitance retention of 98.6% even under a tensile strain up to 20% (Fig. 7e, f). These results highlight the importance of fabricating FSCs with unique features such as transparency in providing power for emerging flexible electronics such as skin-attachable wearables and bioelectronics.

a Schematic illustration of an all-TSES wearable patch device. b Real images of the bleached and colored states of the patch device. c Demonstration of the patch device. d Normalized transmittance change and capacitance change of the patch device after exposure in ambient conditions for 14 days. e CV results of the patch device under different stretching conditions. f Normalized capacitance change of the patch device under a tensile strain to 20%. Adapted with permission [54], Copyright (2019), American Chemical Society. g Illustration of the composition of a MnO2–CNT/CNT/PEDOT:PSS composite. h–j Schematic illustration of a self-powered textile composed of a BFC and a FSC. The energy generated by the BFC from the lactate in sweat charges the FSC. k–m Photographs of the textile under different deformations of bending, twisting, and 20% stretching, respectively. Adapted with permission [52], Copyright (2018), The Royal Society of Chemistry

For self-powered wearable devices, on the other hand, a FSC is used to store the energy harvested from sunlight, body motion or even human biofluids rather than provided by conventional external power supplies. For example, Lv et al. [52] developed a screen-printed textile-based hybrid SC-biofuel cell (SC-BFC) system for on-body testing (Fig. 7g–m). In this self-powered system, an epidermal BFC (Fig. 7j) was used to harvest the biochemical energy generated from the wearer’s sweat and a CNT/MnO2/PEDOT:PSS composite based FSC (Fig. 7g, i) to store the energy thus harvested. Owing to the remarkable electrochemical stability and high energy density (17.5 mWh cm−2) of the FSC, this self-powered hybrid system can deliver a stable energy output over long charging periods, boost the voltage output of the BFC, and exhibit excellent stability under a variety of mechanical deformations (Fig. 7k–m). These results clearly reveal the great potential of such unique FSC-based hybrid power systems as next-generation self-powered flexible power supplies for wearable electronics and smart textiles.

5 Summary and Outlooks

The research and development of FSCs as a group of flexible power sources for flexible and wearable electronic devices have gained significant progresses. In order for FSCs to be practically useful, they should have both superior electrochemical performances and excellent mechanical deformabilities. This has triggered substantial research on the electrode materials of FSCs and the development of their device configurations.

Largely owing to their high capacitances, pseudocapacitive materials (including MOs, CPs, and MXs) are promising electrode materials for FSCs. While the direct processing of pseudocapacitive materials into electrodes possesses shortcomings, the incorporation of varied pseudocapacitive materials together and the compositing of pseudocapacitive materials with carbon nanomaterials are efficient to fabricate flexible composite electrodes with both well-defined electrochemical and mechanical properties for FSCs. This also indicates a future direction to continue the research on synthesis method, composition optimization, and morphology design of such pseudocapacitive material-based composite electrodes for practically useful FSCs.

Pseudocapacitive material-incorporated FSCs have been realized in a range of configurations from 1D fiber-shaped to 2D film-shaped and 3D structural, providing them with tremendous opportunities for varied mechanical deformation scenarios. Specifically, they have been integrated into prototype products with 1D FSCs promising for wearable, 2D and 3D FSCs for large-scale flexible, and 3D FSCs for multi-direction-deformation applications. Furthermore, with the incorporation of special features (such as transparency or self-power), the FSCs become multifunctional, significantly enhancing their practical application capabilities.

Therefore, with the remarkable progresses accomplished in the past and the extensive research in the future on pseudocapacitive materials and their FSCs, practically useful flexible power sources with both superior electrochemical performances and excellent mechanical deformabilities would be anticipated into the market for flexible and wearable electronic devices.

References

C. Wang, K. Xia, H. Wang, X. Liang, Z. Yin, Y. Zhang, Advanced carbon for flexible and wearable electronics. Adv. Mater. 31, e1801072 (2019)

Y. Liu, M. Pharr, G.A. Salvatore, Lab-on-skin: a review of flexible and stretchable electronics for wearable health monitoring. ACS Nano 11, 9614–9635 (2017)

L. Lyu, W. Hooch Antink, Y. S. Kim, C. W. Kim, T. Hyeon, Y. Piao, Recent development of flexible and stretchable supercapacitors using transition metal compounds as electrode materials. Small 17, e2101974 (2021)

Y. Zhou, C.H. Wang, W. Lu, L. Dai, Recent advances in fiber-shaped supercapacitors and lithium-ion batteries. Adv. Mater. 32, e1902779 (2020)

P. Xie, W. Yuan, X. Liu, Y. Peng, Y. Yin, Y. Li, Z. Wu, Advanced carbon nanomaterials for state-of-the-art flexible supercapacitors. Ene. Stor. Mater 36, 56–76 (2021)

G. Shao, R. Yu, N. Chen, M. Ye, X.Y. Liu, Stretchable supercapacitors: From materials and structures to devices. Small Methods 5, 2000853 (2021)

Y. Han, L. Dai, Conducting polymers for flexible supercapacitors. Macromol. Chem. Phys. 220, 1800355 (2019)

S. A. Delbari, L. S. Ghadimi, R. Hadi, S. Farhoudian, M. Nedaei, A. Babapoor, A. Sabahi Namini, Q. V. Le, M. Shokouhimehr, M. Shahedi Asl, M. Mohammadi, Transition metal oxide-based electrode materials for flexible supercapacitors: a review. J. Alloys Compd. 857, 158281 (2021)

S. Nam, J.-N. Kim, S. Oh, J. Kim, C.W. Ahn, I.-K. Oh, Ti3C2Tx MXene for wearable energy devices: supercapacitors and triboelectric nanogenerators. APL Mater. 8, 110701 (2020)

T. An, W. Cheng, Recent progress in stretchable supercapacitors. J. Mater. Chem. A 6, 15478–15494 (2018)

S. Sahoo, R. Kumar, E. Joanni, R.K. Singh, J.-J. Shim, Advances in pseudocapacitive and battery-like electrode materials for high performance supercapacitors. J. Mater. Chem. A 10, 13190–13240 (2022)

Y. Shao, M.F. El-Kady, J. Sun, Y. Li, Q. Zhang, M. Zhu, H. Wang, B. Dunn, R.B. Kaner, Design and mechanisms of asymmetric supercapacitors. Chem. Rev. 118, 9233–9280 (2018)

Y. Wang, Y. Ding, X. Guo, G. Yu, Conductive polymers for stretchable supercapacitors. Nano Res. 12, 1978–1987 (2019)

C. Zhao, X. Jia, K. Shu, C. Yu, G.G. Wallace, C. Wang, Conducting polymer composites for unconventional solid-state supercapacitors. J Mater Chem A 8, 4677–4699 (2020)

L. Huang, D. Santiago, P. Loyselle, L. Dai, Graphene-based nanomaterials for flexible and wearable supercapacitors. Small 14, e1800879 (2018)

Z. Lv, Y. Luo, Y. Tang, J. Wei, Z. Zhu, X. Zhou, W. Li, Y. Zeng, W. Zhang, Y. Zhang, D. Qi, S. Pan, X.J. Loh, X. Chen, Editable supercapacitors with customizable stretchability based on mechanically strengthened ultralong MnO2 nanowire composite. Adv. Mater. 30, 1704531 (2018)

Q. Zhuang, W. Li, Z. Zhu, H. Yu, W. Chen, J. Yang, M. Fu, Facile growth of hierarchical SnO2@PPy composites on carbon cloth as all-solid-state flexible supercapacitors. J. Alloy. Compd. 906, 164275 (2022)

X. Li, R. Liu, C. Xu, Y. Bai, X. Zhou, Y. Wang, G. Yuan, High-performance Polypyrrole/Graphene/SnCl2 modified polyester textile electrodes and yarn electrodes for wearable energy storage. Adv. Funct. Mater. 28, 1800064 (2018)

H. Du, M. Zhang, K. Liu, M. Parit, Z. Jiang, X. Zhang, B. Li, C. Si, Conductive PEDOT:PSS/cellulose nanofibril paper electrodes for flexible supercapacitors with superior areal capacitance and cycling stability. Chem. Eng. J. 428, 131994 (2022)

J. Wang, L. Dong, C. Xu, D. Ren, X. Ma, F. Kang, Polymorphous supercapacitors constructed from flexible three-dimensional carbon network/polyaniline/MnO2 composite textiles. ACS Appl. Mater. Inter. 10, 10851–10859 (2018)

H.U. Lee, C. Park, J.-H. Jin, S.W. Kim, A stretchable vertically stacked microsupercapacitor with kirigami-bridged island structure: MnO2/graphene/Poly(3,4-ethylenedioxythiophene) nanocomposite electrode through pen lithography. J. Power. Sources 453, 227898 (2020)

C. Zhang, Y. Ma, X. Zhang, S. Abdolhosseinzadeh, H. Sheng, W. Lan, A. Pakdel, J. Heier, F. Nüesch, Two dimensional transition metal carbides and nitrides (MXenes): synthesis properties, and electrochemical energy storage applications. Energ. Environ. Mater 3, 29–55 (2020)

M.R. Lukatskaya, S. Kota, Z. Lin, M.-Q. Zhao, N. Shpigel, M.D. Levi, J. Halim, P.-L. Taberna, M.W. Barsoum, P. Simon, Y. Gogotsi, Ultra-high-rate pseudocapacitive energy storage in two-dimensional transition metal carbides. Nat. Energy 2, 17105 (2017)

H. Li, R. Chen, M. Ali, H. Lee, M.J. Ko, In Situ grown MWCNTs/MXenes nanocomposites on carbon cloth for high-performance flexible supercapacitors. Adv. Funct. Mater. 30, 2002739 (2020)

C. Yu, Y. Gong, R. Chen, M. Zhang, J. Zhou, J. An, F. Lv, S. Guo, G. Sun, A solid-state fibriform supercapacitor boosted by host-guest hybridization between the carbon nanotube scaffold and MXene nanosheets. Small, e1801203 (2018)

Y.-L. Huang, S.-W. Bian, Vacuum-filtration assisted layer-by-layer strategy to design MXene/carbon nanotube@MnO2 all-in-one supercapacitors. J. Mater. Chem. A. 9, 21347–21356 (2021)

A. Salman, S. Padmajan Sasikala, I. H. Kim, J. T. Kim, G. S. Lee, J. G. Kim, S. O. Kim, Tungsten nitride-coated graphene fibers for high-performance wearable supercapacitors. Nanoscale, 12, 20239–20249 (2020)

Y. Zhou, K. Maleski, B. Anasori, J.O. Thostenson, Y. Pang, Y. Feng, K. Zeng, C.B. Parker, S. Zauscher, Y. Gogotsi, J.T. Glass, C. Cao, Ti3C2Tx MXene-reduced graphene oxide composite electrodes for stretchable supercapacitors. ACS Nano 14, 3576–3586 (2020)

W. Chen, D. Zhang, K. Yang, M. Luo, P. Yang, X. Zhou, Mxene (Ti3C2Tx)/cellulose nanofiber/porous carbon film as free-standing electrode for ultrathin and flexible supercapacitors. Chem. Eng. J. 413, 127524 (2020)

M. Zhu, Y. Huang, Q. Deng, J. Zhou, Z. Pei, Q. Xue, Y. Huang, Z. Wang, H. Li, Q. Huang, C. Zhi, Highly flexible freestanding supercapacitor electrode with enhanced performance obtained by hybridizing Polypyrrole chains with MXene. Adv. Energy Mater. 6, 1600969 (2016)

Q. Zhu, J. Li, P. Simon, B. Xu, Two-dimensional MXenes for electrochemical capacitor applications: progress, challenges and perspectives. Energy Stor. Mater 35, 630–660 (2021)

X. Chen, N.S. Villa, Y. Zhuang, L. Chen, T. Wang, Z. Li, T. Kong, Stretchable supercapacitors as emergent energy storage units for health monitoring bioelectronics. Adv. Energy Mater. 10, 1902769 (2019)

J. Liang, C. Jiang, W. Wu, Toward fiber-, paper-, and foam-based flexible solid-state supercapacitors: electrode materials and device designs. Nanoscale 11, 7041–7061 (2019)

Q. Zhou, X. Chen, F. Su, X. Lyu, M. Miao, Sandwich-structured transition metal oxide/graphene/carbon nanotube composite Yarn electrodes for flexible two-ply yarn supercapacitors. Ind. Eng. Chem. Res. 59, 5752–5759 (2020)

M. Li, M. Zu, J. Yu, H. Cheng, Q. Li, Stretchable fiber supercapacitors with high volumetric performance based on buckled MnO2/oxidized carbon nanotube fiber electrodes. Small 13, 1602994 (2017)

S. Wang, N. Liu, J. Su, L. Li, F. Long, Z. Zou, X. Jiang, Y. Gao, Highly stretchable and self-healable supercapacitor with reduced graphene oxide based fiber springs. ACS Nano 11, 2066–2074 (2017)

J. Sun, Y. Huang, C. Fu, Z. Wang, Y. Huang, M. Zhu, C. Zhi, H. Hu, High-performance stretchable yarn supercapacitor based on PPy@CNTs@urethane elastic fiber core spun yarn. Nano Energy 27, 230–237 (2016)

Z. Wang, S. Qin, S. Seyedin, J. Zhang, J. Wang, A. Levitt, N. Li, C. Haines, R. Ovalle-Robles, W. Lei, Y. Gogotsi, R.H. Baughman, J.M. Razal, High-performance Biscrolled MXene/carbon nanotube Yarn supercapacitors. Small 14, e1802225 (2018)

Y. Xu, Y. Yan, W. Lu, S. Yarlagadda, G. Xu, High-performance flexible asymmetric fiber-shaped supercapacitor based on CF/PPy and CNT/MnO2 composite electrodes. ACS Appl. Energy Mater 4, 10639–10645 (2021)

Z. Pan, J. Yang, L. Li, X. Gao, L. Kang, Y. Zhang, Q. Zhang, Z. Kou, T. Zhang, L. Wei, Y. Yao, J. Wang, All-in-one stretchable coaxial-fiber strain sensor integrated with high-performing supercapacitor. Ene. Stor. Mater 25, 124–130 (2020)

Z. Pan, J. Yang, Q. Zhang, M. Liu, Y. Hu, Z. Kou, N. Liu, X. Yang, X. Ding, H. Chen, J. Li, K. Zhang, Y. Qiu, Q. Li, J. Wang, Y. Zhang, All-solid-state fiber supercapacitors with ultrahigh volumetric energy density and outstanding flexibility. Adv. Energy Mater. 9, 1802753 (2019)

G. Lee, J.W. Kim, H. Park, J.Y. Lee, H. Lee, C. Song, S.W. Jin, K. Keum, C.H. Lee, J.S. Ha, Skin-Like, dynamically stretchable, planar supercapacitors with buckled carbon nanotube/Mn-Mo mixed oxide electrodes and air-stable organic electrolyte. ACS Nano 13, 855–866 (2019)

C. Li, S. Wang, Y. Cui, X. Wang, Z. Yong, D. Liang, Y. Chi, Z. Wang, Sandwich-like MXene/alpha-Fe2O3-C-MoS2-PEDOT:PSS/MXene Film electrodes with ultrahigh area capacitance for flexible supercapacitors. ACS Appl Mater Inter 14, 9172–9182 (2022)

A.M. Patil, N.R. Chodankar, E. Jung, S. Roy, D.P. Dubal, G. Guan, Y.-K. Han, S.C. Jun, 2D-on-2D core-shell Co3(PO4)2 stacked micropetals@Co2Mo3O8 nanosheets and binder-free 2D CNT-Ti3C2TX-MXene electrodes for high-energy solid-state flexible supercapacitors. J Mater Chem A 9, 26135–26148 (2021)

Z. Zhou, Q. Li, L. Yuan, L. Tang, X. Wang, B. He, P. Man, C. Li, L. Xie, W. Lu, L. Wei, Q. Zhang, Y. Yao, Achieving ultrahigh-energy-density in flexible and lightweight all-solid-state internal asymmetric tandem 6.6 V all-in-one supercapacitors. Ener. Stor. Mater, 25, 893–902 (2020)

N. Swain, A. Tripathy, A. Thirumurugan, B. Saravanakumar, L. Schmidt-Mende, A. Ramadoss, A brief review on stretchable, compressible, and deformable supercapacitor for smart devices. Chem. Eng. J. 446, 136876 (2022)

Z. Lv, Y. Tang, Z. Zhu, J. Wei, W. Li, H. Xia, Y. Jiang, Z. Liu, Y. Luo, X. Ge, Y. Zhang, R. Wang, W. Zhang, X.J. Loh, X. Chen, Honeycomb-lantern-inspired 3D stretchable supercapacitors with enhanced specific areal capacitance. Adv. Mater. 30, 1805468 (2018)

J. Wen, B. Xu, Y. Gao, M. Li, H. Fu, Wearable technologies enable high-performance textile supercapacitors with flexible, breathable and wearable characteristics for future energy storage. Energy Stor. Mater 37, 94–122 (2021)

J. Yun, H. Lee, C. Song, Y.R. Jeong, J.W. Park, J.H. Lee, D.S. Kim, K. Keum, M.S. Kim, S.W. Jin, Y.H. Lee, J.W. Kim, G. Zi, J.S. Ha, A Fractal-designed stretchable and transparent microsupercapacitor as a Skin-attachable energy storage device. Chem. Eng. J. 387, 124076 (2020)

H. Park, J.W. Kim, S.Y. Hong, G. Lee, H. Lee, C. Song, K. Keum, Y.R. Jeong, S.W. Jin, D.S. Kim, J.S. Ha, Dynamically stretchable supercapacitor for powering an integrated biosensor in an all-in-one textile system. ACS Nano 13, 10469–10480 (2019)

H. Park, J. W. Kim, S. Y. Hong, G. Lee, D. S. Kim, J. H. Oh, S. W. Jin, Y. R. Jeong, S. Y. Oh, J. Y. Yun, J. S. Ha, Microporous polypyrrole-coated graphene foam for high-performance multifunctional sensors and flexible supercapacitors. Adv. Funct. Mater, 28 1707013 (2018)

J. Lv, I. Jeerapan, F. Tehrani, L. Yin, C.A. Silva-Lopez, J.-H. Jang, D. Joshuia, R. Shah, Y. Liang, L. Xie, F. Soto, C. Chen, E. Karshalev, C. Kong, Z. Yang, J. Wang, Sweat-based wearable energy harvesting-storage hybrid textile devices. Energ. Environ. Sci. 11, 3431–3442 (2018)

C. Zhang, V. Nicolosi, Graphene and MXene-based transparent conductive electrodes and supercapacitors. Energy Stor. Mater 16, 102–125 (2019)

T.G. Yun, M. Park, D.H. Kim, D. Kim, J.Y. Cheong, J.G. Bae, S.M. Han, I.D. Kim, All-transparent stretchable electrochromic supercapacitor wearable patch device. ACS Nano 13, 3141–3150 (2019)

Acknowledgements

This work was supported by The Special Significant Science and Technology Program of Yunnan Province (grant number: 2016HE001-2016HE002).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Cheng, F., Yang, X., Lu, W. (2024). Pseudocapacitive Materials for Flexible Supercapacitors. In: Gupta, R.K. (eds) Pseudocapacitors. Engineering Materials. Springer, Cham. https://doi.org/10.1007/978-3-031-45430-1_14

Download citation

DOI: https://doi.org/10.1007/978-3-031-45430-1_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-45429-5

Online ISBN: 978-3-031-45430-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)