Abstract

This work has been realized within the framework of Action No. 4 of the SAVASCO collaborative project (EFA353/19/SAVASCO) co-funded by INTERREG POCTEFA (INTERREG V-A Spain - France - Andorra 2014–2020). This action was carried out between June 2020 and May 2022, and is devoted to the development and characterization of a constructive solution based on corn and sunflower stalks as raw material.

At the end of Action No. 3 of the project, different fractions of plant aggregates from corn and sunflower stalks were produced. The objective of Action 4 is to formulate different construction materials and products from these raw materials. The present paper will focus on the mechanical and thermal behavior of samples made of lightweight earth and concrete implemented by vibrocompaction at laboratory scale, as a model for prefabricated construction products assembled in a dry state on site.

The influence of the nature of the aggregate on the properties of the composites was studied by working on the entire crushed stalks of corn, but also on sunflower pith and bark fractions produced from the separation process developed in the project. Finally, the influence of the particle size distribution of the sunflower bark particles was also evaluated. In the entire experimental campaign, hemp shives were used as the reference aggregate.

Considering the binders, a commercial formulated lime binder was selected as well as two alternative clay binders produced locally in the regions of Tarbes, France and Barcelona, Spain.

The first part of the paper summarises the main physical characteristics of the different aggregate fractions studied: bulk and particle densities, particle size distribution, water absorption, mechanical behavior and thermal conductivity. Some of these characteristics are used as formulation parameters for composites, others could be indicators to correlate with the performance of composites.

The second part aims to evaluate the thermal and mechanical performance of composites formulated from these fractions. The highly anisotropic character of these composites and the significant influence of the nature of the particles and binders is highlighted. Several fractions, in particular from sunflower stalks, show a definite potential as an alternative plant aggregate to hemp shiv, in regions where the availability of the latter is limited.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Due to its negative environmental impacts, the building industry should reconsider its activities. Indeed, buildings are responsible for approximately 40% of energy consumption and 36% of greenhouse gas emissions in the European Union [1]. On the trans-Pyrenean territory, the construction sector is responsible for the production of more than 4 million tons of waste in Midi-Pyrénées [2] and 5,7 million tons in Catalonia [3], which exceeds the production of domestic waste. In 2018, the residential/tertiary sector was leading energy consumption item (45%) in the Occitanie region and accounts for 29% of the region’s greenhouse gas emissions [4]. The reduction of the environmental impact is therefore a major challenge for this territory that possesses high level of activity in the construction/renovation sector. In 2020, with 9 billion euros, Occitanie ranked as the fifth region in France in terms of turnover related to construction activities [5]. Like Andalusia, Catalonia stands out as the region in Spain that have hosted most works (>5 000) in 2021 [6]. To meet these challenges, one needs to assess and reduce the environmental impacts generated by all building-related activities. To do so, circular economy and resource efficiency principles should be applied to buildings.

Bio-aggregate based building materials offer promising prospects to achieve these objectives thanks to the use of agricultural by-products, which have considerable environmental benefits. First, bio-aggregates are derived from an abundant, renewable vegetal resource, which is also a carbon sequestration material as agricultural products have the property of capturing carbon dioxide from the atmosphere during their growth and storing it in their organisms. Besides, the use of plant particles in building materials helps to economize valuable natural resources thanks to agricultural waste recovery [7].

Hemp concrete has been the most commonly investigated bio-aggregate based material in recent years. However, hemp is not widely produced in France nor in Spain and little is available in the trans-Pyrenean territory. To minimize transport distances and thus carbon emissions, the raw material has to be locally available. It is the case for corn and sunflower stems, two agricultural by-products produced in greater quantities in this region.

The Spanish POCTEFA areas account for more than a third of corn production in Spain [8]. According to France AgriMer figures [9], assuming that 52% of the stalks are returned to the soil to maintain its fertility, the potential deposit corn stalks in Occitanie would be of 154 560 t/year. In France, about one third of the national cultivated surface area of sunflower is located in Occitanie (207 505 ha in 2017) [10].

Moreover, corn and sunflower stalks exhibit strong potential for the development of insulating materials for construction. Indeed, previous works conducted by the project’s partner laboratories demonstrated the feasibility of separating the two main stalks fractions (pith and bark) on an industrial scale. Those studies also highlighted the interest and potential of using by-product of corn or sunflower cultivation in order to develop insulating panels [11,12,13,14] or bio-based concretes [15,16,17].

The INTERREG V-A (POCTEFA 2014–2020) project entitled ‘StructurAtion of a cross-border Value chAin for corn and Sunflower stems for COnstructions’ (SAVASCO) helps to meet these challenges by substituting non-renewable resources of mineral or petroleum origin with renewable agricultural waste. SAVASCO aims to structure an innovative and eco-efficient trans-Pyrenean construction sector based on corn and sunflowers stalks. It relies on innovative technologies for the use of currently non-valued agricultural by-products to develop a low-cost process for collecting and processing stalks into aggregates with controlled characteristics.

This article focuses on the insulating construction products developed using those aggregates in association with a mineral binder. The first part of the paper summarises the basic physical characteristics of the different aggregate fractions studied: bulk and particle densities, particle size distribution and water absorption, mechanical. Some of these characteristics are used as formulation parameters for composites, others could be indicators to correlate with the performance of composites. The second part aims to evaluate the thermal and mechanical performance of composites formulated from these fractions.

2 Materials and Methods

2.1 Materials

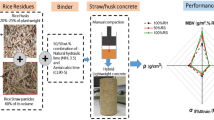

Plant Particles. A multi-stage process for the collection, fractionation and separation of corn and sunflower stalks was previously develop in the frame of the SAVASCO project [18] to obtain bio-aggregates (Fig. 1).

Field collection was carried out in collaboration with the Federació de Cooperatives Agràries de Catalunya (FCAC) (a federation of agricultural cooperatives), and plant aggregates were obtained thanks to the use of industrial tools available in LCA laboratory. The combination of grinding, dedusting, sieving, separating and screening steps allowed obtaining different fractions of plant particles compatible with a use as plant aggregates for construction. The applied process is summarized in Fig. 1.

The 7 fractions written in grey frame in Fig. 1 were characterized and used as aggregates for the development of lime or clay concretes during the project. Among them, we will present, in the present article, the results concerning 4 SAVASCO aggregates (ground corn stem, sunflower pith and sunflower barks larger and smaller than 4 mm) as well as those obtained with hemp shiv also studied as a reference plant aggregate.

The physical characterization of aggregates was conducted according to the methodology proposed by Ratsimbazafy [16] for the determination of the densities and intra and interparticle porosities, the dry density of aggregates compacted in wet state and the real water absorption after compaction which have been proven to be good formulation parameters for composites. Those characteristics are presented in Sect. 3.1.

Mineral Binders.

Among the 5 distinct mineral binders studied in SAVASCO, the results obtained with 2 of them will be presented and analysed in the present paper. The first one is a preformulated commercial lime-based binder BATICHANVRE® produced by the company ‘Chaux & Enduits de Saint-Astier’. This type of binder is highly recommended for the manufacture of hemp concrete [19]. According to the technical data from the manufacturer, BATICHANVRE® is composed of 70% natural lime and 30% hydraulic and pozzolanic binder plus specific additives. With the aim of reducing the environmental impact of composites and benefiting from the high hygroscopicity of the clay minerals, the second studied binder was a clayish binder composed of fines from the aggregate washing process of a quarry in south-west France.

2.2 Methods

Plant Particles Characterization

Bulk Density, Particles Size Distribution and Water Absorption.

Measurements were carried out according to the recommendations of the RILEM TC 236-BBM [20].

Dry Density of Aggregates Compacted in Wet State, and real Water Absorption After Compaction.

Measurements were carried out according to the methods detailed in [21].

Particle Density, Solid Density and Porosities.

The method applied for particle density measurement is a pycnometric method using fine sand adapted by Ratsimbazafy [16] and previously mentioned by Monreal et al. [22] and Karaky et al. [23]. It consists in determining the real volume (particle volume) of a representative quantity of plant aggregates of known mass by “embedding” them in very fine sand capable of filling all inter-particle voids, without saturating the intra-particle porosity.

Solid density is deduced from the determination of:

-

the parietal constituents (cellulose, hemicelluloses and lignins) via the gravimetric method known as ADF-NDF (ADF for Acid Detergent Fiber, NDF for Neutral Detergent Fiber) of Van Soest and Wine [24, 25]

-

the total mineral content, determined by mineralization in an ash furnace according to ISO 749:1977 [26].

-

the water solubles content by measuring the mass loss in aqueous solutions at pH 7.

-

the mean densities of these elementary chemical components deducted from a literature review and reported in Table 1.

Assuming that the dry solid part of the aggregates is formed only by cellulose, hemicelluloses, lignins, minerals and water-solubles extracted at pH 7, the density of the solid (ρs) is calculated from the Eq. 1.

With:

wi: the mass content of component i in proportion to the sum of the contents of these 5 components

ρi: the density of the component i.

The inter- and intra-particle porosities (ninter and nintra) can then be determined from the Eq. 2 and Eq. 3 respectively.

With:

\({\rho }_{b}\): the bulk density (kg/m3)

\({\rho }_{p}\): the particle density (kg/m3)

\({\rho }_{s}\): the solid density (kg/m3).

Composite Characterization

Mechanical Behaviour. The compressive strength tests on the cubical specimens (15 × 15 × 15 cm3) were performed after one year of curing, using a 100kN capacity hydraulic press. Three to four samples were tested for each formulation. The load was applied at a constant deflection rate of 3 mm/min while the unloading was carried out at 6 mm/min. The following 4-step loading cycle was applied to samples:

-

loading up to 1% of strain - unloading back to 0%;

-

loading up to 2% - unloading to 0%;

-

loading up to 3% - unloading to 0%;

-

loading up to 10% - unloading to 0%.

Thermal Conductivity.

Cubical samples of 15 × 15 × 15 cm3 were dried in an oven at a temperature of 60 °C until the sample mass change was less than 0.1% between three weighings at least 24 h apart. Thus, tests were conducted with a Neotim-FP2C hot wire apparatus that consists in placing a shock probe between two pieces of material so that a power supply can be broadcast and the rise of temperature within the material may be measured. The heat flow and heating time were chosen so that a temperature rise higher than 5 °C and a correlation coefficient between experimental data and theoretical behaviour higher than 0.999 could be reached. This transient method only allows local measurements. To overcome the question of accuracy and representativeness for heterogeneous materials, thermal conductivity is defined as the average of at least five measurements. For each formulation, the device was placed at several locations on different samples.

3 Results and Discussion

3.1 Plant Particles Properties

Particle Size Distribution. The particle size distributions of the 5 aggregates studied are shown in Fig. 2.

Two groups of aggregates can be identified in terms of size. The first group includes hemp particles, sunflower pith and the sunflower bark fraction passing the 4 mm sieve. The second is composed of the ground corn stalk and sunflower bark particles retained on the 4 mm sieve. Among the smaller aggregates (D50 between 4 and 4.5 mm), hemp shiv has the narrowest particle size, probably due to its calibration in the processing plant. In the pith and bark fractions, on the contrary, larger elements are identified.

As far as particle morphology is concerned, clear differences can also be observed in Fig. 3.

It can be seen that size reduction by grinding also tends to limit the elongation of the particles. The larger particles (ground corn stalk and sunflower bark particles constituting the 4 mm retain) are also those with the lowest circularity. The arrangement of ground corn stalk particles in particular contains a large proportion of very elongated particles (more than 45% of particles with a circularity of less than 0.05). Amongst the smaller particles, sunflower pith is characterized by the presence of very rounded particles (more than 18% of the particles with a circularity higher than 0.5). The hemp shiv and sunflower bark of small size present varied morphologies.

Densities and Porosities.

In order to understand and predict the properties of composites including plant particles, it is necessary to characterize their porosity. The measurement of the bulk density of the particles gives a first indication but it is not sufficient. It does not provide information on the distribution between interparticle porosity (which will be reduced by rearrangement and partially filled by the binder at the time of mixing of the composite) and intraparticle porosity, which will remain in the composite or be reduced by compression of the particles. In order to access this data, a measurement of the density of the particles is carried out, the results obtained for the 5 aggregates considered are presented in Table 2 as well as the values of bulk density and solid density. From these measurements, it is then possible to calculate the different volume proportions of solid, interparticle voids and intraparticle voids in each arrangement. The results are shown in the graphs in Fig. 4.

Whatever the nature of the particles considered, the total porosity of the arrangements is very important, it varies between 90% for the small sunflower bark and 97% for the ground corn stalk.

The distribution of voids is close for hemp shiv and sunflower bark aggregates. On the contrary, sunflower pith has a much higher intraparticle porosity than the other particles, while the ground corn stalk arrangement has the highest interparticle porosity, caused by the interlocking of the large, elongated particles that mainly constitute this arrangement, as evidenced by the particle size analysis.

Water Absorption.

The capacity of the particles to absorb water is an important parameter especially for the formulation of composites. In Fig. 5, different behaviours can be seen. Sunflower pith, due to its high particle porosity, absorbs the most water (almost 500% by mass after only 30 s of immersion). The three other aggregates from sunflower and maize stalks have lower absorption capacities than the reference aggregate, which seems rather favourable.

Design Parameters.

Based on the methodology proposed by Ratsimbazafy [16], the characterization of the aggregates was completed by the determination of the properties of the aggregates compacted in the wet state, which is considered to be representative of the state of the aggregates in a vibrocompacted plant concrete or lightened earth. The dry density of aggregates compacted in wet state and the real water absorption of the aggregates during this process are presented in Table 3.

Regarding water absorption, the water absorption determined after compaction exceeds the absorption after one minute of immersion for all aggregates except the small sunflower bark aggregate. This parameter will be retained for the formulation of composites. A relative difference between the bulk density and the dry density of aggregates compacted in wet state is observed, which differs from one aggregate to another. Indeed, depending on their morphology and stiffness, the behavior of the arrangement of aggregates subjected to compaction is distinct. The phenomena of rearrangement and then compression of the different particles will tend to increase the density of the arrangement but, at the same time, the absorption of water by the aggregates will lead to a swelling and bulking of the particles after demolding which can compensate for this phenomenon as shown in Fig. 6.

In the case of hemp shiv and sunflower bark, wet compaction leads to a delayed swelling of the particles and a decrease in the bulk density. In the case of sunflower pith, the two densities are equivalent. On the contrary, in the particle arrangement of ground corn stalks, the one with the highest interparticle porosity, compaction significantly reduces these voids and results in an increase in density.

3.2 Composites Design and Fabrication

Based on the formulation method developed by Ratsimbazafy et al. [16], plant-based concrete or lightweight earth were produced with a constant binder dosage in order to enable evaluation of the influence of the properties of the aggregates on the composites performances. The designation of the studied mixes is reported in Table 4. The proportions of the other components were determined from a reference formulation listed in the first row of Table 5. Based on this wall type hemp-lime mix design, the water requirement and the mass of plant aggregates to be introduced were adjusted according to the dry density of aggregates compacted in wet state ρc and to the real water absorption capacity after compaction, in order to take into account the specificities of each aggregate. The composition of each mix as well as their fresh and dry densities are presented in Table 5.

3.3 Use Properties

Mechanical Behaviour. Typical stress-strain curves obtained from the cyclic compression tests performed on the composites are shown in Fig. 7.

In the direction parallel to compaction, a maximum stress is reached before failure for some aggregates (BP Para), while progressive compression of the particles is observed for others (BC Para).

The comparison of the compressive behaviour of the plant concrete in the two directions of solicitation (parallel (BP Para) and perpendicular (BP Per) to the direction of compaction) highlights their mechanical anisotropy linked to the structural anisotropy induced during compaction, which generates a preferential orientation of the elongated aggregates in the plane perpendicular to the compaction. In order to compare the mechanical performance of the different composites, the characteristic mechanical parameter chosen is the stress reached at a strain of 1.5%. The results are shown in Fig. 8.

Whatever the aggregate considered, the stress reached in the perpendicular direction exceeds that reached in the parallel direction (the ratio between the two stresses at 1.5% deformation is respectively 2.1, 2.3, 2.7 and 4.6 for the BB < 4, BP BH and BC mixtures). Indeed, during a stress perpendicular to the direction of compaction, i.e. parallel to the plane of preferential orientation of the plant particles, it is the stiffest element of the composite that controls its deformation.

Whatever the direction of loading or the type of binder, the best mechanical performance is achieved with the reference aggregate, hemp shiv. Sunflower pith comes next, followed by sunflower bark and then ground corn stalks. Considering the results obtained for parallel loading with lime binder, the increase in particle size of sunflower bark seems to have a beneficial effect on the mechanical performance. This result is in agreement with the majority of the few studies dealing with the subject in the literature [37,38,39] even if other authors observe an opposite tendency with a clay matrix [40].

The mixes formulated with a clay binder have significantly lower compressive stresses than those based on formulated lime. It is nevertheless important to underline that despite low mechanical compressive performances, these mixes could be used in the prototype built within the framework of action 5 of the SAVASCO project, either by spraying or by onsite casting for the construction of walls between 14.5 and 29 cm thick. This raises the question of the relevance of studying the behavior in compression of this type of composite, which is not very representative of its mechanical solicitation in the structure.

Figure 9 shows a more detailed comparison of the mechanical behavior of composite including the reference aggregate i.e. hemp shiv with the one including sunflower pith particles. For the hemp shiv and sunflower pith aggregates, whatever the nature of the binder and the direction of loading, the stress-strain curve reaches a maximum value before the sample fails. Three characteristic mechanical parameters were therefore retained: the stress reached at a strain of 1.5%, the maximum stress and the strain at this maximum stress.

The difference in performance between hemp shiv and sunflower pith aggregates is particularly marked for composites with a formulated lime matrix, loaded perpendicular to the direction of compaction. On the contrary, if we consider as a performance indicator the stress reached for a strain of 1.5%, the impact of the nature of the aggregates is not significant for clay-based mixes or lime-based mixes loaded parallel to the compaction direction. Finally, the nature of the aggregate has no influence on the deformation reached for the maximum stress.

Thermal Conductivity.

The formulated composites will primarily function as thermal insulation in buildings. Figure 10 shows the results of dry thermal conductivity measurements.

The composites have low thermal conductivities (between 0.063 and 0.091 W/(m.K)), consistent with their dry densities (348 to 441 kg/m3) which place them in the range of the lightest mixtures for this type of material [41]. The results do not show any significant impact of the nature of the binder on the thermal performance. Regarding the nature of the plant particles, the mixes incorporating hemp shiv have slightly higher thermal conductivities at equivalent density. In contrast, mixtures based on sunflower pith and ground corn stalk particles achieve the lowest conductivities. These are the two aggregates with the highest intra- and inter-particle porosities respectively.

4 Conclusion and Perspectives

In the framework of the INTERREG POCTEFA SAVASCO project, different plant aggregates were produced from sunflower and corn stalks. 4 aggregates are studied in this paper and compared to hemp shiv, selected as reference aggregate.

The determination of the bulk, particle and solid densities shows a variable pore distribution within the different particle arrangements. Larger particles generally have lower circularity and higher inter-particle porosity. Sunflower pith is distinguished from other aggregates by high circularity and high intraparticle porosity.

Additional characterization parameters are proposed to assess the wet compaction ability of the aggregates and to serve as formulation parameters.

The different particles are combined with a commercial formulated lime binder and a clay binder to form composites with the same binder content. The mechanical and thermal characterization of these composites shows the high potential of sunflower pith aggregates which achieve the best mechanical performance among alternative aggregates and surpass the hemp shiv-based reference mix in terms of thermal conductivity.

Predicting the mechanical and thermal performance of composites from aggregate properties is a complex problem. Indeed, the size, the shape but also the stiffness of the aggregates condition their behavior during compaction and consequently the structuring of the pore network and of the binding matrix in the composites in the hardened state. Complementary modelling approaches using homogenization methods should be used to complete this experimental study. The morphology and size of the particles can then be optimized by additional steps of grinding, sieving, dedusting etc.

References

European Commission, ‘Buildings - Energy’, Energy (2018). /energy/en/topics/energy-efficiency/buildings. Accessed 30 May 2018

CRC Midi-Pyrénées. https://www.cercoccitanie.fr/IMG/pdf/midi-pyrenees_-_septembre_2015.pdf. Accessed 08 Aug 2022

Generalitat de Catalunya Departament d’Acció Climàtica, Alimentació i Agenda Rural and Agència de Residus de Catalunya. https://residus.gencat.cat/web/.content/home/lagencia/publicacions/estadistiques/estadistiques_2020.pdf. Accessed 08 Aug 2022

Fedene. https://www.fedene.fr/wp-content/uploads/sites/2/2022/06/FEDENE_Fiche-Region-2022-OCCITANIE.pdf. Accessed 08 Aug 2022

GIE Réseau des CERC. https://www.cercoccitanie.fr/IMG/pdf/cp_octobre_2021.pdf. Accessed 10 Aug 2022

Construnario.com. https://www.construnario.com/notiweb/55896/el-sector-de-la-construccion-crece-un-22-en-espana/. Accessed 10 Aug 2022

Peñaloza, D., Erlandsson, M., Falk, A.: Exploring the climate impact effects of increased use of bio-based materials in buildings. Constr. Build. Mater. 125, 219–226 (2016). https://doi.org/10.1016/j.conbuildmat.2016.08.041

Encuesta sobre Superficies y Rendimientos Cultivos (ESYRCE). Encuesta de Marco de Áreas de España. https://www.mapa.gob.es/es/estadistica/temas/estadisticas-agrarias/agricultura/esyrce/default.aspx. Accessed 10 Aug 2022

FranceAgriMer: L’Observatoire National des Ressources en Biomasse Évaluation des ressources agricoles et agroalimentaires disponibles en France – édition 2020. FranceAgriMer (2020). https://www.franceagrimer.fr/content/download/66147/document/DON-ONRB-VF4.pdf. Accessed 08 Aug 2022

Agreste: Pratiques culturales en grandes cultures en 2017 – Occitanie. Agreste (2019). https://draaf.occitanie.agriculture.gouv.fr/IMG/pdf/premiers_resultats_pkgc_2017_cle8ff4e6.pdf. Accessed 08 Aug 2022

Laborel-Préneron, A., Ampe, C., Labonne, L., Magniont, C., Evon, P.: Thermal insulation blocks made of sunflower pith particles and polysaccharide-based binders: influence of binder type and content on their characteristics, pp. 43–50 (2022). https://doi.org/10.4028/www.scientific.net/CTA.1.43

Palumbo, M., Lacasta, A.M., Holcroft, N., Shea, A., Walker, P.: Determination of hygrothermal parameters of experimental and commercial bio-based insulation materials. Constr. Build. Mater. 124, 269–275 (2016). https://doi.org/10.1016/j.conbuildmat.2016.07.106

Sabathier, V., Maaloum, A.A., Magniont, C., Evon, P., Labonne, L.: Développement d’un panneau isolant 100% biosourcé à base de moelle de tournesol. Auxerre, France (2017)

Verdier, T., Balthazard, L., Montibus, M., Magniont, C., Evon, P., Bertron, A.: Development of sunflower-based insulation materials coated with glycerol esters to prevent microbial growth. Acad. J. Civ. Eng. 37(2), Art. no. 2, (2019). https://doi.org/10.26168/icbbm2019.7

Lagouin, M., Magniont, C., Sénéchal, P., Moonen, P., Aubert, J.-E., Laborel-préneron, A.: Influence of types of binder and plant aggregates on hygrothermal and mechanical properties of vegetal concretes. Constr. Build. Mater. 222, 852–871 (2019). https://doi.org/10.1016/j.conbuildmat.2019.06.004

Ratsimbazafy, H.H.: Evaluation du potentiel de co-produits agricoles locaux valorisables dans le domaine des matériaux de construction. Université Toulouse III - Paul Sabatier, Tarbes (2022)

Magniont, C., Escadeillas, G., Coutand, M., Oms-Multon, C.: Use of plant aggregates in building ecomaterials. Eur. J. Environ. Civ. Eng. 16(sup1), s17–s33 (2012). https://doi.org/10.1080/19648189.2012.682452

Evon, P., et al.: Development of a multi-stage process for the collection, fractionation and separation of corn and sunflower stalks to obtain bio-based construction materials. In: 4th International Conference on Bio-Based Building Materials, Barcelona, Spain, p. 1 (2021)

Pichon, Q., Naumovic, J.-M.: Guide des bonnes pratiques - Construire en chanvre (2016). https://www.construire-en-chanvre.fr/documents/pdf/documentation/CenC_Bonnes_Pratiques_Tome_2.pdf. Accessed 23 Nov 2020

Amziane, S., Collet, F., Lawrence, M., Magniont, C., Picandet, V., Sonebi, M.: Recommendation of the RILEM TC 236-BBM: characterisation testing of hemp shiv to determine the initial water content, water absorption, dry density, particle size distribution and thermal conductivity. Mater. Struct. 50(3), 1–11 (2017). https://doi.org/10.1617/s11527-017-1029-3

Ratsimbazafy, H.H., Laborel-Préneron, A., Magniont, C., Evon, P.: Comprehensive characterization of agricultural by-products for bio-aggregate based concretes formulation. In: 4th International Conference on Bio-based Building Materials, Barcelona, Spain (2021)

Monreal, P., Mboumba-Mamboundou, L.B., Dheilly, R.M., Quéneudec, M.: Effects of aggregate coating on the hygral properties of lignocellulosic composites. Cem Concr Compos. 33, 301–308 (2011)

Karaky, H., Maalouf, C., Bliard, C., Polidori, G.: Elaboration and physical characterization of an agro-material based on sugar beet pulp and potato starch. Acad. J. Civ. Eng. 35(2), 606–612 (2017). https://doi.org/10.26168/icbbm2017.91

Van Soest, P.J., Wine, R.H.: Use of detergents in the analysis of fibrous feeds. Part IV. Determination of plant cell-wall constituents. J. Assoc. Off. Agric. Chem. 50, 50–55 (1967)

Van Soest, P.J., Wine, R.H.: Determination of lignin and cellulose in acid-detergent fiber with permanganate. J. Assoc. Off. Agric. Chem. 51, 780–785 (1968)

ISO. ISO 749:1977, Oilseed Residues - Determination of Total Ash; International Organization for Standardization: Geneva, Switzerland (1977)

Barnett, J., Jeronimidis, G.: Wood Quality and its Biological Basis. Wiley, Hoboken (2009)

Bouasker, M., Belayachi, N., Hoxha, D., Al-Mukhtar, M.: Physical characterization of natural straw fibers as aggregates for construction materials applications. Materials 7, 3034–3048 (2014). https://doi.org/10.3390/ma7043034

Chabannes, M.: Formulation et étude des propriétés mécaniques d’agrobétons légers isolants à base de balles de riz et de chènevotte pour l’éco-construction (phdthesis). Université Montpellier (2015)

Ehrnrooth, E.M.L.: Change in pulp fibre density with acid-chlorite delignification. J. Wood Chem. Technol. 4, 91–109 (1984). https://doi.org/10.1080/0277381840806228531

Nozahic, V., Amziane, S., Torrent, G., Saïdi, K., De Baynast, H.: Design of green concrete made of plant-derived aggregates and a pumice-lime binder. Cem Concr Compos. 34, 231–241 (2012)

Qi, C., Hou, S., Lu, J., Xue, W., Sun, K.: Thermal characteristics of birch and its cellulose and hemicelluloses isolated by alkaline solution. Holzforschung 74, 1099–1112 (2020). https://doi.org/10.1515/hf-2019-0285

Rowell, R.M.: Handbook of Wood Chemistry and Wood Composites. CRC Press (2012). https://doi.org/10.1201/b1248734

Salas, J., Alvarez, M., Veras, J.: Lightweight insulating concretes with rice husk. Int. J. Cem. Compos. Lightweight Concret. 8, 171–180 (1986)

Sun, C.: True density of microcrystalline cellulose. J. Pharm. Sci. 94, 2132–2134 (2005). https://doi.org/10.1002/jps.20459

Terashima, N., Kitano, K., Kojima, M., Yoshida, M., Yamamoto, H., Westermark, U.: Nanostructural assembly of cellulose, hemicellulose, and lignin in the middle layer of secondary wall of ginkgo tracheid. J. Wood Sci. 55(6), 409–416 (2009). https://doi.org/10.1007/s10086-009-1049-x

Niyigena, C., Amziane, S., Chateauneuf, A.: Multicriteria analysis demonstrating the impact of shiv on the properties of hemp concrete. Constr. Build. Mater. 160, 211–222 (2018)

Chabannes, M., Bénézet, J.C., Clerc, L., Garcia-Diaz, E.: Use of raw rice husk as natural aggregate in a lightweight insulating concrete: an innovative application. Constr. Build. Mater. 70, 428–438 (2014)

Niyigena, C., et al.: Variability of the mechanical properties of hemp concrete. Mater Today Commun. 7, 122–133 (2016)

Laborel-Préneron, A., Aubert, J.E., Magniont, C., Maillard, P., Poirier, C.: Effect of plant aggregates on mechanical properties of earth bricks. J Mater Civ Eng. 29, 04017244 (2017)

Ratsimbazafy, H.H., Laborel-Préneron, A., Magniont, C., Evon, P.: A review of the multi-physical characteristics of plant aggregates and their effects on the properties of plant-based concrete. Recent Progr. Mater. 3(2), 68 (2021). https://doi.org/10.21926/rpm.2102026

Acknowledgements

This research was co-funded by the European Regional Development Fund as part of the POCTEFA (Interreg V A Espagne/France/Andorre 2012–2020) program (project number EFA353/19/SAVASCO).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Avellaneda, A. et al. (2023). Evaluation of the Potential of Plant Aggregates from Corn and Sunflower Stalks for the Design of Building Materials. In: Amziane, S., Merta, I., Page, J. (eds) Bio-Based Building Materials. ICBBM 2023. RILEM Bookseries, vol 45. Springer, Cham. https://doi.org/10.1007/978-3-031-33465-8_7

Download citation

DOI: https://doi.org/10.1007/978-3-031-33465-8_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-33464-1

Online ISBN: 978-3-031-33465-8

eBook Packages: EngineeringEngineering (R0)