Abstract

The paper aims to compare NX Mechatronic Concept Designer (MCD) and Tecnomatix Process Simulate (TPS) and their suitability for simulating mechatronic machines in digital twinning. A Digital Twin (DT) is a virtual model that serves as a real-time digital counterpart of a physical object or process. Compared to a conventional simulation, it differs in its ability to model the behavior of the actual counterpart from many points of view and with much greater complexity. Digital Twins have a crucial role in the Fourth Industrial Revolution but are also used in different areas like meteorology, traffic simulation in smart cities, and civil engineering. Digital Twins in industrial engineering help maintain the optimal pace of assembly lines, flexibly adapt production, increase manufacturing process efficiency, and generate cost-effective products. Increasing usage of IoT solutions drives the Digital Twin market, which is growing exponentially. The paper discusses the two software packages’ possibilities, advantages, and disadvantages and proposes the methodology and philosophy of making DT. The contribution of this work is to compare the possibilities of making mechatronic devices for educational and research purposes from scratch through to their final implementation.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The development of Industry 4.0 ideas supports the growth of Digital Twin technology, particularly in the manufacturing sector. It can be characterized as a two-way data integration between a physical and a virtual machine [1]. Intelligent manufacturing solutions use information from production processes to enhance individual and overall industrial production. Most of the time, the most expensive part of production is the human workforce.

A Digital Twin is a virtual model of a physical object. It models the object’s whole lifecycle and uses real-time data sent from sensors on the object to simulate the behavior and monitor operations [2]. This method combines traditional mechanical engineering, mechatronics, computer science, and artificial intelligence. Engineers can evaluate the functionality of industrial concepts without creating a prototype due to the advanced simulation of the machine. Early correction of mistakes greatly minimizes the costs needed for any modifications during a machine’s operational time. Manufacturing processes are complicated and involve significant data generation, conversion, storage, and processing. In these circumstances, simulations have become crucial and extremely useful. Digital Twin technology can be utilized to create cost-effective products for customers, maintain optimal production processes, and increase manufacturing efficiency.

Efficient and correct Product Lifecycle Management (PLM) plays a significant manufacturing role. It allows the use of data from all life stages of the product supply chain, from design and manufacturing, sales, and usage to decommissioning, to improve the next product iteration [3, 4] (Fig. 1).

Influence on Design and Cost in the Product Design and Process Planning [4].

Digital Twins and PLM software can also predict the product’s lifecycle before manufacturing. Siemens is one of the producers of PLM software and offers a whole PLM solution. However, smaller companies typically cannot afford the entire portfolio and are limited to only essential SW (software) [5].

This paper compares SW, which could be used for simulations of the main part of the manufacturing process. The study compares the simulation of educational and research models of assembly lines that can serve as a benchmark because they are in the fuzzy area between design and commissioning.

2 Literature Review

During the design of mechatronic devices, it is necessary to consider the increasing complexity of the manufacturing machines. Since a mechatronic device comprises mechanical, electrical, and software parts, the number of potential failures is increased [6].

One of the most widely used development models is the “V-Model” (Fig. 2). It shows a product’s lifecycle from the requirements analysis to the final commissioning. Figure 2 shows the full version of the V-Model for designing mechatronic devices. For purely mechanical devices, the V-Model is simplified [7].

The left part of the diagram shows the problem specification, analyses, and design phase. The bottom part shows prototype testing and problem-solving (DTs are most beneficial in this part). The right part shows integration tests, Hardware in the Loop (HIL) testing, debugging, and preparation for commissioning [7].

One of the main advantages is avoiding errors in the control code. Testing a code on a physical mechatronic system is complicated because every mistake can lead to a crash. This is significant, especially for manufacturing machines, because they must move various components simultaneously, making crashes sometimes hard to predict [10]. However, the DT is not just that. Another essential part is physics simulation and line layout optimization by a real-time two-way flow of the data between the physical and digital models of the studied system. Correction of errors [11] during the operational phase of the lifetime [12] is also costly [1, 4, 13].

3 Research Methodology

The educational assembly lines were chosen as practical examples because all the features of the programs could be easily demonstrated. The machine was designed in sections. Simulation SW (Process Simulate or Mechatronic Concept Designer) that allows users to define 3D models and all their movements, sensors, physical attributes, and input/output signals was used for the mechatronics design [4].

This paper compares DT creation of the assembly lines for education and research purposes, described in the following sections. Digital Twins are especially suitable for education not only to understand the concept and the methodology of making DTs but also for co-simulation purposes in Totally Integrated Automation (TIA) Portal programming. So each student has access to the device. Even though it is just a digital model, it suits the purpose well enough. Then we establish a connection with the TIA Portal, where DT can be used as a surrogate model of the real Hardware to create robotic manipulators.

The work aims to make a functional DT and compare the possibilities of different software not just from a functionality point of view but also with the stress on educational purposes, user-friendliness, and the possibility of simulating real-life machine parts, similar to the solution presented in [13]. Another study goal is to discuss areas in the V-Model covered by combining the MCD and TPS with TIA Portal. It is also necessary to define which areas are covered by mentioned SW and deserve increased attention. A further aim is also to compare both programs and provide recommendations for the further development of the system engineering process.

3.1 Mechatronic Concept Designer

An assembly line MecLab (Fig. 3) prepared by the company FESTO was used for NX Mechatronic Concept Designer. It consists of three separate stations that can be combined and/or used separately. The first one consists of a pneumatic gripper that can manipulate the part from one position to the second. The second part is the conveyor with a separating actuator that can push the part from the conveyor to the slide. The third part is the press that connects two manipulated parts. MecLab’s goal is to teach students automation technology through realistic, practical examples that are also simple to understand. Students can grasp new concepts or enhance their knowledge by comparing the digital simulation and the actual machine and understand the fundamentals of electrical and control design [14].

3.2 Process Simulate

A manipulation line shown in Fig. 4 was used for the Tecnomatix Process Simulate. It was designed at the Department of Machine Design for education in automation and fluid mechanism control using PLC. The device contains all the basic automation elements: a conveyor, linear and angular pneumatic drive, both bistatic and monostatic valves, two infrared position sensors and end position sensors, and two gravity conveyors. When the part is at the end of the conveyor, it is pushed by the pneumatic drive and slides to the position gripped by a magnetic actuator attached to the linear drive. Then it is manipulated above the second slide and slides back on the conveyor.

Model of the manipulation line [contains parts from 15].

3.3 TIA Portal

Defining the physical and mechanical properties of the various machine parts is the first step in creating a Digital Twin of a machine. It models the dynamic behavior and interactions of several components. TIA Portal enables a control program to be programmed. DT can be combined with the PLC SimAdvanced for the code function assessment. Finally, it can be connected to a PLC and used in a program control [16].

4 Results and Discussion

In this part, the main areas of the SW comparison are covered. They can be divided into the following categories:

-

Physics and reality reflection

-

Kinematics settings

-

Sensors

-

Others

The thing not discussed in the results chapter is the connection of the Digital Twin to the TIA Portal. This issue is beyond the scope of this paper because it relies a lot on the quality of the Digital Twin and will be discussed in the following papers in the future. Generally speaking, both SW packages allow a TIA Portal connection.

4.1 Model and Reality Reflection

The objective of the Digital Twin is to reflect reality closely. However, because of the problematic physics involved, it is evident that some aspects are challenging to mimic. Co-Simulation using an actual physical model of pneumatic pistons is partly present in MCD but not in TPS.

A similar issue is gripping. It usually combines two challenging steps – exact positioning and friction estimation during contact. The type of collision body selected has a significant influence on MCD. In TPS’s case, the gripping tool cannot be limited, e.g., by a maximum payload. It only considers the contact with the manipulated part. Also, the gripper can “pierce” the part, and nothing happens in the simulation. On the other hand, this can be used when simulating magnetic gripping. Magnetic grippers cannot be specified, but the magnetic force can be partially mimicked using an elongated “core” of the coil that “pierces” the manipulated object.

Another necessary thing is the definition of forces. MCD allows gravity to be used and interaction between the objects for force transitions. TPS does not allow it. It can only change the position of the objects based on their kinematics or if they are “gripped” by another kinematic entity.

In our version of TPS (16.0.2), there is a beta version of the physical module that allows parts to be “distributed” into the bin for “pick and place” simulations and bin picking. Although this function should allow gravitational conveyors, how it works is unclear.

4.2 Kinematics Analysis and Collisions

MCD is suitable for simulating the general movements of machines. However, it is not made for precise prediction of gripping, collisions, sliding, or connecting of different parts. In MCD, when a rigid body is squeezed between two others, MCD often responds inadequately. Gripping is generally a problematic aspect to simulate. Due to the simplification of the parts, incorrect meshing, and assumption of perfect rigidity, MCD is not the best software for it. The selection of an appropriate collision shape significantly influences the “result” of a simulation.

Choosing the correct mesh type is necessary because it affects how the bodies collide. For example, during a simulation involving the pressing of a puck, if the meshes of collided parts are not perfect, parts are not gripped correctly. Furthermore, stiffness and friction cannot be simulated. Therefore, the DT cannot validate this technological aspect of the line.

TPS allows calculating the trajectory volume of the moving parts and collision states, even though physics is not generally allowed in the TPS. The user can define that the simulation stops when the moving parts interfere so they can investigate the problem and choose better operation timing. However, as with MCD, it cannot co-simulate deformations. Therefore, it cannot validate pressing and forging operations.

4.3 Sensor Simulation

MCD does not simulate sensor functions. Their functionality is just mimicked. As mentioned, they are typically simulated as a collision of two parts. This, however, goes against the DT principle. Real sensors have flaws in particular environments and situations (due to magnetism, fast movements, etc.) All of this cannot be included in the simulation.

Process Simulate allows the use of various sensors that are used in industrial robotics (like lidar or photoelectric sensors). Sensors in TPS cannot simulate advanced physics (e.g., electromagnetic compatibility), but they are customizable and behave relatively close to real ones. Although a camera tool is present, image processing is not available. This function can be mimicked by the “property sensor”, which can be “taught” to recognize defined properties like the color of an object.

4.4 Other Functionalities and Additional Notes

Mechatronic Concept Designer is part of the Siemens NX CAD SW. Therefore, it is an excellent tool for making fast changes in a model or modeling new parts. Tecnomatix Process Simulate has limited modeling capability. An MCD user can also rapidly transition to other computational environments and make proper design evaluations using, e.g., the FEM solver.

Process Simulate has a lot of additional tools for observing material flows and making Gant diagrams, etc. Human – Machine Interaction and ergonomics can be simulated with limitations as well. Another good thing is the ability to design a control panel directly inside Process Simulate.

4.5 Contribution

The work compares SW for DT creation from the system engineering point of view. Features in design and simulation are compared and shown in Table 1. Attributes were scored as “Good” (allows to perform given task almost perfectly or on the professional level), average (allows only limited feature usage), or poor (doesn’t allow specified feature or is very limited).

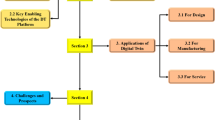

Based on this information, we can determine which areas of the V-Model are covered by the software tools (shown in Fig. 5).

Siemens NX and its extension Mechatronics Concept Designer is more suitable for hardware development and testing and can be used for most parts during the product’s lifecycle.

5 Conclusions

The paper aimed to compare MCD and TPS and their suitability for digital twinning. Both software were found to be helpful tools for research and industrial practice. However, each one is focused on a Digital Twin from a different point of view. MCD is better in general modeling and physics simulation. In those areas, TPS performs relatively poorly. SW is equally good in kinematics definition and collision detection. TPS is a little bit better prepared for gripping operations and has a significant advantage in logistic functions and simulation of different types of sensors. SW is performing poorly in advanced sensor modeling.

Tecnomatix Process Simulate can be mainly used for testing from the signal and operational point of view. Necessary operation times and sensor placement evaluation can be done using this SW. Process Simulate has a lot of additional tools for observing material flows and making Gant diagrams, etc. Human – Machine Interaction and ergonomics can be simulated with limitations as well. Another good thing is the ability to design a control panel directly inside Process Simulate.

Siemens NX and its extension Mechatronics Concept Designer is more suitable for developing and testing a new product. MCD is part of the Siemens NX CAD SW. Therefore, it is a great tool for making fast changes in a model or modeling new parts.

TIA Portal is used mainly as a PLC programming tool but can be used with Digital Twin and co-simulation for software testing and evaluation. Even though this is not the DT’s primary purpose, it is a helpful feature that can decrease the possibility of damaging the machine. The machine’s error states can also be tested without an actual error state.

Further work in this project is to design the optimal portfolio of SWs that can fulfill the whole V-Model and be presented to our students as guidelines and tools for the complete product development portfolio, which is essential knowledge of the engineer in the 21st century.

References

Karabegović, I., Turmanidze, R., Dašić, P.: Robotics and automation as a foundation of the fourth industrial revolution - industry 4.0. In: Tonkonogyi, V., et al. (eds.) InterPartner 2019. LNME, pp. 128–136. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-40724-7_13

Aws: What is Digital Twin Technology. Amazon https://aws.amazon.com/what-is/digital-twin/. last accessed 2022/12/06

Ashaolu, B.A.: What is Product Lifecycle Management (PLM)? (2020). Converged https://converged.propelsoftware.com/blogs/what-is-product-lifecycle-management. last accessed 2023/01/06

Lenord, M.: Mechatronics Concept Designer, Quickstart and User Manual (2010). http://www2.me.rochester.edu/courses/ME204/nx_help/en_US/graphics/fileLibrary/nx/mechtronics/. last accessed 2023/01/06

Siemens software. Siemens Digital Industries Software (2022). https://www.plm.automation.siemens.com/global/en/#top. last accessed 2023/01/09

Ulf, S., Törngren, M., Malvius, D., Biehl, M.: PLM for mechatronics integration. In: Proceedings of the International Conference on Product Lifecycle Management. Inderscience Publishers (2009)

System lifecycle process models: VEE. Guide to the System Engineering Body of Knowledge (SEBoK) (2022). https://www.sebokwiki.org/wiki/System_Lifecycle_Process_Models:_Vee. last accessed 2023/01/06

Salehi, V.: Development of an agile concept for MBSE for future digital products through the entire life cycle management called munich agile MBSE concept (MAGIC). Comput. Aided Des. Appl. 17, 147–166 (2019). https://doi.org/10.14733/cadaps.2020.147-166

Bender, K.: Embedded Systems - qualitätsorientierte Entwicklung. Springer-Verlag, Berlin, Heidelberg (2005). https://doi.org/10.1007/b138984. (in Germany)

Fait, D., Mašek, V., Čermák, R.: Using digital twins in mechatronics and manufacturing. In: 2022 International Symposium on Multidisciplinary Studies and Innovative Technologies (ISMSIT), pp. 434−438 (2022). https://doi.org/10.1109/ISMSIT56059.2022.9932840

MarketsandMarkets. Opportunities in the digital twin market. News details,. https://www.industrysourcing.com/mobile/article/details.html?id=320133. last accessed 2023/01/06

Siemens Česká republika, Digitální dvojče Siemens a jeho výhody v praxi (2022). https://www.vseoprumyslu.cz/inspirace/nazory-a-komentare/siemens-digitalni-dvojce-a-jeho-vyhody-v-praxi.html. last accessed 2023/01/06

Husar, J., Knapcikova, L., Balog, M.: Implementation of material flow simulation as a learning tool. In: Ivanov, V., et al. (eds.) DSMIE 2018. LNME, pp. 33–41. Springer, Cham (2019). https://doi.org/10.1007/978-3-319-93587-4_4

Hüttner, A., et al.: Teaching with MecLab. Festo Didactic GmbH & Co. KG, Denkendorf, Germany (2008)

2D/3D CAD Library. SMC (2022). https://www.smcworld.com/cadlib/en-jp/. last accessed 2023/01/06

Tia Portal. siemens.com Global Website. https://new.siemens.com/global/en/products/automation/industry-software/automation-software/tia-portal.html. last accessed 2023/01/06

Acknowledgment

This contribution is supported by project SGS-2022–009.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Fait, D., Mašek, V. (2023). Digital Twins for Industrial Robotics: A Comparative Study. In: Ivanov, V., Trojanowska, J., Pavlenko, I., Rauch, E., Piteľ, J. (eds) Advances in Design, Simulation and Manufacturing VI. DSMIE 2023. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-32767-4_3

Download citation

DOI: https://doi.org/10.1007/978-3-031-32767-4_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-32766-7

Online ISBN: 978-3-031-32767-4

eBook Packages: EngineeringEngineering (R0)