Abstract

The issues of resource conservation are relevant in our time as never before. The study suggests a way to modify wood by vacuum infusion methods using a polymer composition. This method is relevant in the manufacture of new types of wooden structures, reinforcement of nodes and interfaces. Of the greatest interest are structural elements and manufacturing technologies of wooden structures using modern composite polymer materials with the inclusion of carbon nano-tubes (CNTs) in their composition, which leads to increased strength and rigidity, reduced mate-rial consumption and mounting weight of structures, reduces the effect of anisotropy of proper-ties and defects of wood on the bearing capacity.

The wood was impregnated with a polymer composition based on dimethacrylic polyester with a nanostructured filler. At the stage of destruction of samples, during bending tests, the stress level in wood is equal to 25–26% of the temporary bending strength for wood modified with compo-site, and 36–37% - with the addition of carbon nanotube filler to the composite. Experiments on samples have shown the prospects of using a polymer composition to modify wood in order to increase its strength properties.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Wood is an environmentally friendly material, it resists static and dynamic loads well, it is very light and at the same time durable. Wood, as a product of plant origin, is a layered-fibrous porous material in its structure and consists of numerous fused elementary cells, diverse in shape, size, and elongated mainly along the trunk. All of them are strongly connected with each other. The cell cavities can be filled with res-ins, gums (resinous secretions), tiles, and water. Vessels, core rays, and wood pulp are formed from the cells. Each cell has its own shell (wall). The cell walls are 99% com-posed of organic compounds: carbohydrates (70–80%) and lignin (about 30%). The carbohydrate part of wood includes cellulose, glucose, sugar, hemicellulose. Carbo-hydrates and lignin are natural high-molecular compounds (polymers).

The location of wood fibers along the axis of the tree causes a sharp difference in the mechanical properties of wood along and across the trunk. The elastic modulus of pine for the direction along the fibers is almost 40 times greater than across, and the compressive strength is 10 times, and the tensile strength is 20–30 times [1,2,3,4,5,6,7].

One of the ways to improve the physical and mechanical properties of wood is its modification. Modification of wood should be considered as a process of directed change of physico-mechanical, thermophysical, tribotechnical, biochemical proper-ties of wood in relation to the operating conditions of products made of it [8,9,10].

Thermochemical modification is based on the impregnation of wood with syn-thetic monomers and oligomers, followed by polymerization and curing by a thermo-catalytic method [11,12,13]. The technological process of impregnating wood with a modifier based on monomers, oligomers or polycondensation resins is carried out according to the vacuum-pressure or vacuum-pressure-vacuum method at a temper-ature of 20–30 °C. The amount of absorbed impregnation composition is assumed to be equal to 30–80% of the mass of the original wood. Phenol alcohols, furan-, ace-tate, methyl methacrylate, styrene methylmethacrylate, styrene vinyl acetate, polyes-ter resins, styrene polyester resins, phenol-formaldehyde, epoxy, furan, urea-formaldehyde, etc. are used as modifiers, the conditional viscosity of which accord-ing to the VZ-4 viscometer should be 11–14 c at a temperature of 20 °C [14,15,16,17]. The viability of the modifier should ensure a complete technological cycle of wood impregnation. The composition can be cured by radiation and thermocatalytic meth-od [18,19,20].

The study is carried out in order to study the strength properties of wood impreg-nated with a polymer composition when working on bending standard samples.

2 Methods

The impregnation composition for wood modification is a polymer composition based on dimethacrylic polyester with a nanostructured filler. The main components that make up the polymer composition are: liquid resin, dry hardener (0.25 mass parts), surfactant (OP–10) in an amount (0.5 mass parts), carbon nanotubes (CNTs of the Taunit-M series) (0.5 mass parts). Mixing of the components was carried out using a PE-8300 top-drive agitator equipped with a built-in control unit [20,21,22,23].

The modification was carried out in the following order:

-

1.

Drying of workpieces to a humidity of 5–7% for 2 h at (110 + 5) °C in a standard drying cabinet (SHS-100–01) at atmospheric pressure.

-

2.

Checking the moisture content of each workpiece with a wood moisture meter (Testo-616). If the tests are not breaded immediately after drying, then they should be stored for no more than 3 days in a tightly closed container, for example, in a desiccator) at a temperature of (18–25) °C and humidity control.

-

3.

The blanks are placed in a container for impregnation, fixed with a plate from floating the blanks and filled with an impregnating compound 5 cm above the plate. The container is transferred to a mobile unit for vacuum infusion MVS-20 (−01). Slowly, preventing rapid foaming of the impregnating composition from the air available in the blanks, the air is pumped out to a residual pressure of minus (0.8–0.9) atm. The blanks are kept under vacuum until there is no visible release of even the smallest air bubbles in the layer of the impregnation composition above the blanks, then the vacuum is discharged (see Fig. 1a).

-

4.

To achieve the effect of modification for full volume impregnation, it is recommended to carry out additional exposure (soaking) already impregnated billets in the impregnating composition for up to 15 days.

-

5.

Visually control the degree of filling with the composition of the workpiece. At the end of impregnation, the workpiece should sink in the impregnating composition, and not float. The completeness of the impregnation of the workpiece is controlled visually by a cross-section.

-

6.

The samples are wrapped in aluminum foil and placed at atmospheric pressure in a drying cabinet with forced internal ventilation. The curing temperature is (95–105) °C. The holding time is determined by the type of wood, it is selected for the dimensions of the workpiece and is usually at least 1 h (see Fig. 1b).

The research was carried out on a RM-50 M bursting machine. The bursting ma-chine with a pulsator is equipped with an electrohydraulic automated control system for the loading process based on a computer, which provides static and dynamic tensile tests of metal and alloy samples, concrete samples, wood and polymer mate-rials in manual and semi-automatic modes. Loading of standard samples was carried out uniformly with a constant speed of movement of the loading head of the ma-chine - 4 mm/min [24,24,25,26,27,28,29,30,31].

15 samples were subjected to the radial cleavage test - 3 series of samples of 5 pieces each. 1 series - samples without modification, 2 series - images with modification by polymer composite and 3 series with modification by polymer composition with nanostructured filler. According to the test results, statistical processing of experimental data was carried out.

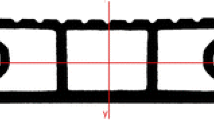

Cleavage tests were performed on standard samples (Fig. 2).

3 Results and Discussions

Figure 3a shows the results of mechanical bending tests of standard wood samples without polymerization, Fig. 3b – wood samples with a modified polymer composition, Fig. 3b - wood samples with a modified polymer composition with a nanostructured filler.

The bending strength of the samples was determined by the formula:

where Pmax - is the maximum load, kN; a,b - the cross-sectional dimensions of the working part of the sample, mm.

According to the test results, statistical processing of experimental data was carried out.

The lowest strength value was determined by the formula:

where σ - is the average strength value; x – is the standard deviation.

The accuracy index of the obtained average value is determined by the formula:

where σx – is the average error of the average value.

To summarize the test results obtained, Table 1 has been compiled.

4 Conclusions

Based on the conducted studies of prismatic bending wood samples modified with a polymer composition with a carbon nanotube filler, the following conclusions can be drawn:

-

1.

Modification of wood by means of its impregnation with polymer compositions has prospects and is relevant for further use. This solution makes it possible to significantly increase the efficiency of the use of various structures and compositions made of wood.

-

2.

At the stage of destruction of samples, during bending tests, the stress level in wood is equal to 25–26% of the temporary bending strength for wood modified with composite, and 36–37% - with the addition of carbon nanotube filler to the compo-site. The limiting state occurs at the moment of rupture of the stretched fibers or by weakening in the form of various defects of the stretched zone.

-

3.

As a modifier, in the above series of tests, a polymer composition based on di-methacrylic polyester with a nanostructured filler was used. The main components that make up the polymer composition are: liquid resin, dry hardener (0.25 mass parts), surfactant (OP–10) in an amount (0.5 mass parts), carbon nanotubes (CNTs of the Taunit-M series) (0.5 mass parts).

-

4.

The conducted research contributes to the knowledge base on the use of polymer composites with CNTs for thermochemical modification of wood, which will give development to composite building structures.

References

Lisyatnikov, M.S., Shishov, I.I., Sergeev, M.S., Hisham, E.: Precast monolithic coating of an industrial building based on variable-height beam-slabs. In: IOP Conference Series: Materials Science and Engineering (2020). https://doi.org/10.1088/1757-899X/896/1/012064

Sergeev, M., Rimshin, V., Lukin, M., Zdralovic, N.: Multi-span composite beam. In: IOP Conference Series: Materials Science and Engineering (2020). https://doi.org/10.1088/1757-899X/896/1/012058

Roshchina, S., Lukin, M., Lisyatnikov, M.: Compressed-bent reinforced wooden elements with long-term load. In: Lecture Notes in Civil Engineering (2020). https://doi.org/10.1007/978-3-030-42351-3_7

Lukin, M., Prusov, E., Roshchina, S., Karelina, M., Vatin, N.: Multi-span composite timber beams with rational steel reinforcements.Buildings (2021). https://doi.org/10.3390/buildings11020046

Koshcheev, A.A., Roshchina, S.I., Lukin, M.V., Lisyatnikov, M.S.: Wooden beams with reinforcement along a curvilinear trajectory. Mag. Civ. Eng. (2018). https://doi.org/10.18720/MCE.81.19

Roshchina, S., Sergeev, M., Lukin, M., Strekalkin, A.: Reconstruction of fixed fertilizer folders in the Vladimir region. In: IOP Conference Series: Materials Science and Engineering (2018). https://doi.org/10.1088/1757-899X/463/4/042011

Wang, H., Zhao, Y.: Studies on pre-treatment by compression for wood impregnation III: effects of the solid content of low-molecular-weight phenol formaldehyde resin on the impregnation. J. Wood Sci. 68 (2022). https://doi.org/10.1186/s10086-022-02034-5

Feng, X., Chen, J., Yu, S., Wu, Z., Huang, Q.: Mild hydrothermal modification of beech wood (Zelkova schneideriana Hand-Mzt): its physical, structural, and mechanical properties. Eur. J. Wood Wood Prod. (2022). https://doi.org/10.1007/s00107-022-01805-7

Gao, Y., Li, Y., Ren, R., Li, L., Gao, J., Chen, Y.: Enhancing the mechanical properties and hydrophobicity of heat-treated wood by migrating and relocating sulfonated lignin.Holzforschung. (2022). https://doi.org/10.1515/hf-2021-0207

Wu, Y., Cai, Y., Yang, F., Gan, J., Zhang, J.: Chemical modification of poplar wood featuring compressible rebound 3D structure as water treatment absorbents. J. Clean. Prod. 331 (2022). https://doi.org/10.1016/j.jclepro.2021.129952

Ermeydan, M.A., Cambazoğlu, M., D. Tomak, E.: A methodological approach to ε-caprolactone modification of wood. J. Wood Chem. Technol. (2022). https://doi.org/10.1080/02773813.2022.2085747

Lisyatnikov, M.S., Glebova, T.O., Ageev, S.P., Ivaniuk, A.M.: Strength of wood reinforced with a polymer composite for crumpling across the fibers. In: IOP Conference Series: Materials Science and Engineering (2020). https://doi.org/10.1088/1757-899X/896/1/012062

Repin, V., Grinyov, V.: The experience in automating scientific research to identify dangerous zones in the near-support sections of wooden beams, pp. 1230–1238 (2022). https://doi.org/10.1007/978-3-030-96383-5_137

Lukin, M., Popova, M., Reva, D., Abdikarimov, R.: Reinforced concrete shallow shell of negative double Gaussian curvature built on the basis of a four-lobed hyperbolic paraboloid. Lect. Notes Civ. Eng. 182, 563–576 (2022). https://doi.org/10.1007/978-3-030-85236-8_49

Gonshakov, A., Gonshakov, N., Popova, M., Medvedev, E., Popova, O.: Lightweight construction formed on the basis of a typical reinforced concrete lattice beam, pp. 1450–1458 (2022). https://doi.org/10.1007/978-3-030-96383-5_162

Romanovich, A., Lisyatnikov, M., Vlasov, A., Aleksiievets, V.: Geodesic domes with installing floor using a cable stay system, pp. 1459–1466 (2022). https://doi.org/10.1007/978-3-030-96383-5_163

Lisyatnikov, M., Glebova, T., Rusak, K., Ivaniuk, A.: Strength and deformability of reinforced wooden beams of variable stiffness. Lect. Notes Civ. Eng. 182, 549–561 (2022). https://doi.org/10.1007/978-3-030-85236-8_48

Lisyatnikov, M.S., Chukhlanov, V.Y., Korshakov, A.V.: Composition based on one-component polyurethane modified with tetrapropoxysilane. J. Phys. Conf. Ser. 2131 (2021). https://doi.org/10.1088/1742-6596/2131/4/042038

Modin, A., Lukin, M., Vlasov, A., Hisham, E.: Energy-efficient indicators of panel housing mass construction in the climatic conditions of central Russia. In: IOP Conference Series: Materials Science and Engineering (2020). https://doi.org/10.1088/1757-899X/896/1/012063

Gribanov, A.S., Strekalkin, A.A., Kudryatseva, A.A., Zdralovic, N.: CFRP composites for strengthening wooden structures. In: IOP Conference Series: Materials Science and Engineering (2020). https://doi.org/10.1088/1757-899X/896/1/012114

Julian, T.C., Fukuda, H., Novianto, D.: The Influence of high-temperature and -pressure treatment on physical properties of Albizia falcataria board. Forests. 13 (2022). https://doi.org/10.3390/f13020239

Sargent, R.: Evaluating dimensional stability in modified wood: an experimental comparison of test methods. Forests. 13 (2022). https://doi.org/10.3390/f13040613

Younesi-Kordkheili, H., Pizzi, A.: Preparation and properties of a modified corn flour-lignin-glyoxal as a Green wood adhesive. Int. Wood Prod. J. 13, 119–126 (2022). https://doi.org/10.1080/20426445.2022.2048338

Wang, X., Wang, M., Cao, J.: Dimensional stability of Scots pine modified by in-situ polymerization esterification | 原位聚合酯化改性欧洲赤松的尺寸稳定性. Beijing Linye Daxue Xuebao/J. Beijing Univ. 44, 129–139 (2022). https://doi.org/10.12171/j.1000-1522.20210271

Yang, H., Wang, D., Han, Y., Tian, P., Gao, C., Yang, X., Mu, H., Zhang, M.: Preparation and properties of modified poplar impregnated with PVA-nano silica sol composite dispersion system. J. Wood Chem. Technol. (2022). https://doi.org/10.1080/02773813.2022.2064875

Yasniy, P., Homon, S., Iasnii, V., Gomon, S.S., Gomon, P., Savitskiy, V.: Strength properties of chemically modified solid woods. In: Procedia Structural Integrity, pp. 211–216 (2022). https://doi.org/10.1016/j.prostr.2022.01.026

De Angelis, M., Humar, M., Kržišnik, D., Tamantini, S., Romagnoli, M.: Influence of thermal modification and impregnation with biocides on physical properties of Italian stone pine wood (Pinus pinea L.). Appl. Sci. 12 (2022). https://doi.org/10.3390/app12083801

De Ligne, L., et al.: Studying the spatio-temporal dynamics of wood decay with X-ray CT scanning.Holzforschung. 76, 408–420 (2022). https://doi.org/10.1515/hf-2021-0167

He, Z., et al.: Mechanical properties and dimensional stability of poplar wood modified by pre-compression and post-vacuum-thermo treatments. Polymers (Basel). 14 (2022). https://doi.org/10.3390/polym14081571

Thang, N.H., Huyen, N.T.B.: Fabrication of transparent composites from pinaceae wood packaging residues. Period. Polytech. Chem. Eng. 66, 135–146 (2022). https://doi.org/10.3311/PPch.18011

Xu, Y., et al.: Constructing SiO2 nanohybrid to develop a strong soy protein adhesive with excellent flame-retardant and coating ability. Chem. Eng. J. 446 (2022). https://doi.org/10.1016/j.cej.2022.137065

Acknowledgements

The research was carried out at the expense of the grant of the Russian Science Foundation No. 22-29-01637, https://rscf.ru/project/22-29-01637/.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Roschina, S., Sergeev, M., Chibrikin, D. (2024). Investigation of the Bending Bearing Capacity for Wood Modified with Polymers with Nanoparticle Filler. In: Vatin, N., Roshchina, S., Serdjuks, D. (eds) Proceedings of MPCPE 2022. MPCPE 2022. Lecture Notes in Civil Engineering, vol 335. Springer, Cham. https://doi.org/10.1007/978-3-031-30570-2_24

Download citation

DOI: https://doi.org/10.1007/978-3-031-30570-2_24

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-30569-6

Online ISBN: 978-3-031-30570-2

eBook Packages: EngineeringEngineering (R0)