Abstract

This chapter provides a brief overview of SF6 use in medium- and high-voltage gas-insulated electrical equipment and the outsized environmental impact of SF6 which has prompted a decades-long search for alternative gases and gas mixtures. Section 2 summarizes the key gas properties required for gas insulators, the early SF6 gas mixture alternatives that were considered, and the recent successes in the development and testing of gas mixtures based on 3 M’s Novec™ 4710 and Novec™ 5110 gas. Section 3 briefly summarizes the life cycle challenges associated with the use of SF6, including leak detection and end-of-life disposal. Section 4 describes the hardware development of new electrical equipment when near drop-in SF6 replacements are not possible or desirable.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Today, the electric grid in the United States is responsible for distributing over 4 trillion kWh per year of electricity from generators to consumers. It forms an integrated network that has become an indispensable asset to the nation’s economy, infrastructure, and security. The physical infrastructure of this network depends on a combination of specialized equipment including transformers, power converters, power factor correctors, and switchgear. A critical component for the safety and reliability of the electric grid is a man-made gas, sulfur hexafluoride (SF6). In 1937, General Electric (GE) introduced SF6 as an insulation gas to the electric industry; since then, SF6 has become ubiquitous in medium-voltage (MV) and high-voltage (HV) equipment. Among its many key attributes are its intrinsic nontoxic, noncorrosive, and nonflammable nature, in addition to its superior stability over a wide operating window, good thermal conductivity, high dielectric strength, and excellent arc-quenching capabilities. These properties make it particularly amenable as an insulating and arc-quenching gas in electrical equipment [1]. As a result, over 90% of gas-insulated switchgear globally uses SF6 as the insulating gas [2]. However, SF6 emissions from the electric transmission and distribution sector pose a significant climate risk as a potent and long-lived greenhouse gas (GHG) source. One ton of SF6 emitted to the atmosphere has an equivalent 100-year global warming potential (GWP) of 22,800–26,700 tons of carbon dioxide and has an estimated atmospheric lifetime of 3200 years [3]. As a result of its strong radiative forcing and long atmospheric lifetime, SF6 was designated as one of the six main greenhouse gases in the 1997 Kyoto Protocol.

As countries set increasingly ambitious emission targets in accordance with the Paris Agreement, emissions of all GHGs, particularly from the electric grid, will be scrutinized. Furthermore, regulations being considered in places like California and the European Union (EU) aim to completely phase out SF6 from electrical equipment, necessarily setting a timeline to develop alternative solutions to SF6-insulated equipment. Alternative solutions developed today could define the market for decades to come, both in the United States and globally.

Equipment leaks are a major source of SF6 emissions from the electrical transmission and distribution sector. This fact is particularly true for aging equipment which, due to natural deterioration, is more prone to gas leaks [4]. A study presented at the 2000 International Conference on SF6 and the Environment suggests that 10% of circuit breakers in the United States leak; of that 10%, 15% were identified as minor leaks and 85% were identified as major leaks or leaks that required operations to schedule repairs [5, 6]. The National Electrical Manufacturers Association (NEMA) estimates leak rates of 0.1% per year, while the International Electrotechnical Commission (IEC) standard 62271-1 (2004) sets the standard for equipment leakage at 0.5% [7]. Across the entire life cycle of the equipment, however, SF6 emissions may be as high as 15% and potentially underreported by at least a factor of two [8, 9]. In addition to the emissions associated with equipment service life, losses due to poor gas handling practices are to blame. The operation and maintenance of SF6 gas carts are considered a major source of handling-related losses [4], and some in industry say the eventuality that all created SF6 will ultimately end up being released into the atmosphere should be considered [10].

Today, significant effort is dedicated toward supplanting fossil fuel-derived electricity generation with wind and solar power, with the concomitant effect of the grid becoming increasingly decentralized. The electrification of transport, heating, and cooling will also require grid expansions [11]. Barring any disruptive technological advances or policy-driven trends, more gas-insulated equipment (GIE) employing SF6 will be added to the grid, increasing the emission risks and, ironically, potential climate impacts. Between 1994 and 2022, the measured SF6 in the atmosphere has increased 3.5-fold [12], and as more clean energy is integrated onto the grid, SF6 emissions from the transmission and distribution (T&D) sector (0.25% of combined emissions from SF6 and power generation, 0.07% of total GHG emissions from the United States in 2019) will likely continue to rise and constitute a larger proportion of emissions from the electric grid [13] (Fig. 18.1).

Projected SF6 emissions as a percentage of the emissions from power generation and T&D and in real terms, expressed as MMT CO2e. Calculations based on emissions from power generation decreasing linearly to zero by 2035 and SF6 nameplate capacity increasing by 4% per year (consistent with the average historical increase between 1999 and 2013) and SF6 emission rates of 1.5% consistent with EPA reported values (recent SF6 emission rates have plateaued since 2015) [14, 15]. Note: SF6 emission rates may be underreported by a factor of two, as one study suggested, based on atmospheric concentrations [9]

In addition, a large portion of the US grid was built in the 1960s and 1970s, implying that the equipment currently in use is approaching or exceeding its useful life span [11]. The aging infrastructure has two important implications. First, older equipment tends to leak more SF6 or require more volumes of SF6 which pose a significant climate risk [4]. Second, within the next few decades, much of this equipment will be replaced and will require large investments. Precluding any market-ready alternatives, this equipment will be replaced with new equipment that still uses SF6, potentially locking in this potent greenhouse gas in the grid for the next 20–50 years and increasing the risk of future SF6 emissions. Because of the environmental challenges associated with using SF6 in the electric grid, a few states, including California and Massachusetts, are updating their legislation to address SF6 emission reporting and to set new, more stringent, emission limits. Given the age of the equipment, the investment needed to update and expand the grid, and the stricter policy measures, new technologies and/or alternative gases that minimize or eliminate SF6 and SF6 emissions from gas-insulated equipment (GIE) will be required.

2 The Search for SF6 Substitutes

SF6 is used extensively as the insulating and arc-quenching medium in MV and HV (12–720 kV) electrical power systems due to its high dielectric strength, nontoxicity, nonflammability, chemical inertness, excellent thermal interruption and heat transfer properties, high vapor pressure at low temperatures, and “self-healing” or fast recovery properties when exposed to an electrical arc. It is an excellent and reliable gas for gas-insulated equipment, were it not for its outsized impact on global warming.

The search for SF6 alternative gases with a lower environmental impact has been an area of focus for decades [16]. The most critical property for alternative insulating gases is a high dielectric strength, implying that the gas molecules are strongly electronegative. Practically speaking, the dielectric strength of the gas is an indication of its ability to reduce the number of free electrons in an electrically stressed dielectric gas. An appropriate substitute, therefore, must be able to scavenge free electrons with a wide range of energies and over a range of temperatures, have favorable electron slowing down properties which reduce additional electron generation from electron impact ionization, and be characterized by a low ionization cross-section/high ionization onset [17].

If the only concern for an SF6 alternative was the dielectric strength, several alternatives would have been identified decades ago. As can be seen from Table 18.1, which has been reproduced from a 1997 NIST report, there are several gasses with higher dielectric strengths than SF6.

However, the many gases with high dielectric strengths were ruled out because they did not meet other performance requirements [17]. In addition to dielectric strength, gas insulators must have a high vapor pressure to ensure they stay in the gas phase, even at low temperatures. They must have high thermal conductivity, high specific heat, and long-term thermal stability (i.e., no significant degradation when exposed to elevated temperatures over long periods of time) which is essential for managing the significant thermal loading during an arcing event. They must also feature high breakdown voltages under uniform and nonuniform electric fields, be robust to factors like surface roughness or moisture content, and be compatible with the materials of construction used for gas-insulated equipment. For safety reasons, gas insulators must be nonflammable and nonexplosive and must have low toxicity to minimize adverse impacts during gas handling or in the event of a gas leak. The chemical compatibility and toxicity levels of the breakdown products after a gas insulator is exposed to an arc must be considered, as these will impact performance and safety over the lifetime of the gas-insulated equipment. These stringent performance and property requirements, on top of environmental considerations like a low GWP and zero ozone depletion potential (ODP), have challenged the search for a suitable gas insulator alternative to SF6 for decades.

Early candidates considered as possible SF6 substitutes included carbon dioxide, nitrogen, and mixtures of carbon dioxide and/or nitrogen with SF6 [17]. A key driver in selecting mixtures based on SF6 was to find a “universal” drop-in replacement that could be used across all types of gas-insulated equipment with only minor equipment modifications. For some applications, like gas-insulated transmission lines, comparable performance with modest increases in gas pressures relative to pure SF6 were observed for 50/50 and 40/60 SF6-N2 mixtures with the added benefit of slightly lower GWP and lower cost [18,19,20,21]. Under some conditions like nonuniform fields or in some interrupter applications, mixtures of SF6-N2 were even found to confer superior performance over pure SF6 due to factors like nitrogen’s better insulating properties at high pressures or because nitrogen has complimentary thermal properties at temperatures below 3000 K relative to SF6 which is better at temperatures higher than 3000 K [22, 23]. However, SF6 mixtures or pure N2/CO2/dry air were found to not be compatible as drop-in replacements for gas-insulated substation circuit breakers and switchgear without a significant thermal derating or redesign [24]. Additional concerns were raised regarding safety issues associated with the rate of pressure rise during an internal failure arc and additional costs associated with gas mixture recycling. It is perhaps because of these and other drawbacks that rollout of these early SF6 alternatives was limited to MV (12 kV/24 kV) in the case of N2 and dry air and HV gas circuit breakers up to 72.5 kV for CO2 [25].

Later research sought to identify alternatives beyond gases like nitrogen and carbon dioxide. One study by Rabie and Franck compared the dielectric strength of SF6 to 2611 carbonyl compounds as a preselection process to identify potential SF6 alternatives [26, 27]. They focused their search on groups of hydrofluoro-ketones and hydrofluoro-aldehydes, acyl fluorides, and perfluoro-ketones and perfluoro-aldehydes. Figure 18.2 shows the 2611 molecules grouped into three classes of C3-, C4-, and C5-carbonyl compounds and their predicted dielectric strength (Er) relative to SF6 and TB, the molecules’ boiling point. The most promising candidate molecules, due to their relatively high values of Er and low values of TB, are captured in the black box. Fluorinated compounds have been of particular interest, in terms of their favorable dielectric strengths, but most had key drawbacks like high GWPs (5000–12,000 for perfluorocarbons) and/or high toxicity (CF3I) which excluded them from further consideration. Two of the most promising fluorinated compounds are a fluoronitrile (C4F7N or (CF3)2-CF-CN) and a fluoroketone (C5F10O or CF3C(O)CF(CF3)2) which have acceptable GWPs and low toxicities [25, 28]. Both are currently marketed under 3 M’s Novec™ dielectric gases, Novec™ 4710 and Novec™ 5110, as SF6 gas alternatives for power utility applications.

Predicted dielectric strength Er vs predicted boiling point TB for 2611 carboxyl compounds. The complete list of molecules is split into carbonyl compounds containing three (triangles), four (circles), and five carbon atoms (dots) [27]

Original equipment manufacturers (OEMs) are currently testing mixtures based on the Novec™ dielectric fluids in high-voltage electrical equipment. For example, GE developed green gas for grid (g3) using CO2 and O2 mixed with Novec™ 4710 for gas-insulated substation (GIS) and gas-insulated line (GIL) applications [29]. Testing to assess the performance of g3 gas in 60 bays of 145 kV gas-insulated substations, over 2000 meters of 420 kV gas-insulated lines, and in 6 AIS 245 kV current transformers has produced promising results. ABB has also developed AirPlus™, which combines dry air with Novec™ 5110, for GIL and GIS applications.

Zhang et al. recently reviewed studies that have modeled and experimentally characterized the arc plasma and decomposition products of the Novec™ gas mixtures [25, 30]. The basic properties of the arc plasma produced from mixtures of C4F7N and C5F10O are critical for understanding arc plasma behavior and evaluating arc-quenching capability. The main takeaway from a comparison of the composition of the arc plasmas calculated assuming local thermodynamic equilibrium conditions (LTE), non-LTE but local chemical equilibrium condition (LCE), and using chemical kinetics models with no equilibrium assumptions reveals a discrepancy at low temperatures. Chemical kinetics are more critical for low-temperature conditions where the impact of energy barriers for each decomposition pathway is expected to dominate; LTE assumptions ignore the influence of energy barriers. Regarding the decomposition products, the recognition that, unlike SF6, the decomposition by-products of the proposed gas mixture alternatives do not recombine to form the original structure has necessitated studies that characterize the decomposition products under thermal degradation, spark discharges, corona discharges, and arcing. To this end, researchers have conducted experimental studies to characterize the decomposition products directly and developed computational models to understand the chemical kinetics and decomposition mechanisms [29,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46]. Erroneous or incongruous results are still prevalent, however, due to the limitations of the chosen methods. The detection methods most often used in experimental studies that characterize the gas composition are Fourier transform infrared spectroscopy (FTIR) and gas chromatography-mass spectroscopy (GC/MS). FTIR enables in-line gas composition analysis but is limited by a relatively high detection threshold. Conversely, GC/MS is excellent for detecting trace gasses but introduces a significant time delay, so the decomposition products are detected when they are no longer under their formation conditions. In the case of computational methods, the accuracy will necessarily depend on the input assumptions which should be documented carefully and provided with adequate rationale.

A few studies from the last decade focus on the materials compatibility of C4F7N and C5F10O and their decomposition products with metals, metal oxides, common elastomers, and lubricating greases. Early computational results indicate, for example, that C4F7N may be more compatible with aluminum than copper, while experimental results from Pohlink et al. found no serious compatibility issues among the most common metals used in HV equipment over a period of several months at 120 °C [32]. The most prevalent compatibility issues for both C4F7N and C5F10O were associated with polymers, particularly ethylene propylene diene monomer (EPDM) which is used as a gasket/sealing material. C4F7N can also have an effect on the degradation of other common materials found in circuit breakers such as nitrile O-rings and synthetic zeolite molecular sieves used to remove decomposition by-products [47]. In addition to material incompatibilities, the different decomposition pathways of these gases are important in order to design molecular sieves to capture by-products and to preserve the integrity of the dielectric and cooling properties of the gas in the chamber. In summary, research regarding arc plasma behavior, decomposition products, and materials compatibility are still at the early stages for both C4F7N and C5F10O but are critical to understand before moving entirely away from SF6.

Although potential gas alternatives like those previously mentioned are promising, several challenges exist in accomplishing full replacement of SF6. Though some of the proposed alternatives can reduce the GWP by over 98% relative to SF6, a 98% reduction still leaves many alternatives with a GWP >300 [48]. What’s more, alternative gas and gas mixtures are not necessarily drop-in solutions for SF6 under all conditions; some gas mixtures pose a potential performance risk in colder climate zones due to their higher boiling points, while some gas mixtures require modest increases in pressure to achieve equivalent performance to SF6 [49]. Alternative gases and gas mixtures may require new or modified equipment specially designed to use these gases, new leak detection and monitoring equipment, and new practices to address end-of-life disposal or recycling. Like the work described earlier related to arc plasma characterization and decomposition products, toxicological studies are also at the beginning stages and reflect conflicting results, though some initial results are promising [28]. Finally, there is still a degree of uncertainty around the potential of future regulations which may impact adoption. Even if these points are addressed, market adoption will require overcoming challenges associated with workforce training and spacing constraints, in addition to the need to assess the connection compatibility with existing equipment/infrastructure.

A final comment regarding vacuum dry air or vacuum solid dielectric circuit breakers as another route to SF6-free electrical equipment will be made, which is the route that OEMs like Siemens and Mitsubishi are currently pursuing [50]. A vacuum is used as the arc-quenching medium and insulator between the contacts as part of a vacuum interrupter (VI) and either dry air or a solid dielectric as the insulator around the VI and in the bushings, eliminating the need for SF6 or related gases entirely. Several manufacturers already have vacuum technologies for 38 and 72.5 kV, while technologies at 145 kV are expected to become available within the next year. Although these vacuum or near-vacuum technologies have a higher dielectric strength compared to SF6 circuit breakers, OEMs consider scaling to higher voltages (i.e., 245 kV) a difficult technical challenge.

3 SF6 Life Cycle Considerations

There are other considerations in the life cycle of the equipment beyond developing alternatives for SF6-insulated GIE. One of the most effective strategies for mitigating SF6 emissions in existing equipment is to detect leaks early and to fix these quickly. The International Electrotechnical Commission sets the maximum allowable leakage rate of SF6 at 0.5% per year [51]. Most new equipment achieves leakage rates far below this limit, but as the equipment (which has a useful lifetime of several decades) ages, the leakage rates may exceed 0.5% per year. To achieve this stringent requirement, it is necessary to continuously monitor for leaks; IEEE Guide for the Selection of Monitoring for Circuit Breakers also recommends monitoring SF6 density which can fluctuate in response to thermal fluctuations. Several technologies are currently available on the market including portable point source nondispersive infrared (NDIR) detectors, NDIR room sensors which detect ppb and ppm SF6 concentration levels in enclosed GIE substations, and pressure gauges interfaced with alarm systems that monitor changes in pressure in GIE [52,53,54,55,56,57]. While these technologies are mature and widely available, further improvements in continuous, sensitive, early-warning detection systems are merited. Developing sensors that combine lower cost, higher sensitivity, and continuous monitoring for all equipment settings could lead to advances in early detection technologies that reduce SF6 emissions in the short and medium term as the electric grid transitions to non-SF6 alternatives as well as lead to more accurate accounting of emission rates. Of particular interest are cost-effective detection technologies with remote notification systems or systems sensitive enough to detect slow leaks in small-capacity gas-insulated equipment which pose unique challenges that demand low detection limits and high accuracy under a variety of environmental conditions. Today’s continuous sensors primarily rely on pressure gauges that are not sensitive enough to detect slow leaks or leaks in small-capacity equipment. As a result, even with the technology that is on the market today, several small-capacity GIE owners responded to the proposed policy changes in the California legislation by noting that achieving 1% emission rates on a consistent basis is challenging [58]. One percent emission rate still corresponds to the equivalent of at least 1 megaton of CO2 released per year in the United States; these emissions could potentially increase fivefold by the year 2035 if SF6 nameplate capacity continues to increase at an average of 4% per year and the emission rate stay the same.Footnote 1 NDIR-based sensors offer higher sensitivity than pressure gauges, but they currently have several drawbacks. NDIR point source sensors are more sensitive and can detect ppm or ppb SF6 concentrations but are not continuous, are cost-prohibitive, and require a technician to manually check all equipment for leaks. NDIR room sensors can continuously monitor dilute SF6 concentrations but are still costly and are only applicable for equipment housed in an enclosure. Density and pressure sensors carefully located at optimal locations on the equipment and potentially supplemented with CFD models may enable NDIR-level accuracy at a similar cost and robustness of pressure gauges, thereby leading to more accurate leak rate monitoring [51]. Looking longer-term, cost-effective sensors for proposed gas and gas mixture alternatives will be required because the alternative gases on the market today have a GWP potential that is lower than SF6 but still significant when compared with other greenhouse gases [59, 60]. Of note, alternatives based on gas mixtures may demand higher accuracy or bespoke sensors to monitor the conditions of the gas-insulated equipment where risks of changes in mixture composition will have major implications on the equipment operation. The gas composition must be always known to ensure the dielectric gas is within a safe operational window.

In addition to leak detection, there are other items to consider when using SF6 alternatives. The characteristics of SF6 replacements dictate changes to the mechanical structure of the breaker to accommodate variations in pressure and dielectric withstand. Because of this, several studies have been published regarding the life cycle impact of the manufacture, use, and disposal of the new GIE hardware. For example, hardware changes required for Novec 4710™ mixtures for a 145-kV, 40-kA breaker were found to have minimal impact relative to the equivalent SF6-based switchgear when accounting for the emissions and waste generation from production of material, manufacturing, distribution, construction, operation and maintenance, and end-of-life destruction [61]. In contrast, while vacuum-based breakers will not have any deleterious emissions during use, compared to a Novec 4710™ -based circuit breaker, researchers in [62] conclude that the need for larger equipment (a direct result from the vacuum’s lower dielectric strength), the GWP, among other negative factors, is higher for vacuum-based breakers at 72.5 kV.

Finally, novel end-of-life processes for SF6 must be considered as SF6-insulated equipment is retired and replaced with non-SF6 alternatives. While SF6 is available, it poses a significant environmental risk. This represents an opportunity to develop novel SF6 destruction pathways which are less energy-intensive and do not produce toxic and/or corrosive products [63,64,65]. Alternative pathways for efficient and complete destruction of SF6 use strong reducing agents [66,67,68], low-valent transition metal complexes [69,70,71,72,73,74,75,76], strong nucleophiles [77], monovalent aluminum reagents [78], and catalytically enhanced dielectric barrier discharge processes [79]. A more recent approach has been to use SF6 as a safe fluorinating agent in organic synthesis, opening new valorization routes for stranded SF6 supplies when it is no longer needed in electrical equipment [70, 80,81,82,83,84,85,86]. For alternative gas and gas mixtures, end-of-life considerations are in their nascent stage.

4 SF6-Free Circuit Breaker Hardware

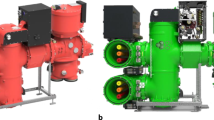

Alternative dielectric mediums in HVAC switchgear and near drop-in replacements for SF6 require changes to the system hardware that can involve significant research, development, design, and testing. While allowing for more significant hardware redesigns offers more options for dielectric mediums, trade-offs in size and life cycle impacts must still be taken into account. Ensuring safety aspects are considered and that the dielectric withstand capability of the circuit breakers can still pass power frequency, lightning impulse, and chopped wave dielectric tests according to IEEE C37-04 or other standards is also critically important when any changes to dielectric medium or hardware are made. Dynamic tests such as those in IEEE C37-04 serve to verify fundamental performance parameters critical for any new design such as how to extinguish the arc quickly and safely and ensure a speedy and full dielectric recovery. For reference, an example of a high-voltage SF6-based dead tank AC breaker and a corresponding bushing and tank cutaway is shown in Fig. 18.3.

Example of three-phase HVAC dead tank breaker (left) and cutaway drawing of example chamber, bushings, and contacts for a single phase (right) [87]

One of the initially more attractive options for SF6-free switchgear is vacuum-based circuit breakers due to their ease of maintenance and zero GWP [88]. While vacuum interrupters (VI) perform well at lower voltages, at voltages above 72.5 kV, as a result of practical design limitations, there can be diminishing returns for increased gap lengths [89, 90]. As a result, multibreak VI designs are often proposed as a solution though this is still an active area of research and considerations for voltage balancing between the sets of electrodes, such as grading capacitors, must be considered [91]. Other active areas of research for increasing a single VI’s interruption capabilities particularly beyond 72.5 kV are similar to those for other mediums such as new contact materials and geometries, improved speed and control of operating mechanisms, new solid insulator material, and improved designs for electric field control [92,93,94,95]. For dead tank breakers, an insulating medium must also be used in the tank that contains the VI as well as the bushings. While technical air is a common choice, VIs with technical air insulators could have weights and footprints 132% higher and 160% larger, respectively, than an SF6 breaker of similar performance [62, 96]. Recent work has also looked at dielectric mediums primarily for the tank and bushings such as CF3I-CO2 to improve the footprint of VI-based breakers with technical air while maintaining lower GWP [97].

In [24], researchers demonstrated how non-vacuum dielectric mediums combined with circuit breaker redesigns can achieve design goals while maintaining a low GWP. Using a 72.5-kV breaker redesigned to use a 0.8-MPa CO2, the researchers reduced the GWP of the circuit breaker significantly while still meeting the key fault and capacitive switching requirements of IEC 62271-100. The redesign included accounting for the lower heat capacity of 0.8 MPa CO2 which causes a more rapid pressure rise and fall than SF6 at similar starting temperatures and pressures. As a result, the CO2 puffer pressure may not be adequately maintained for long-duration arcs, necessitating a larger puffer cylinder volume. The authors conclude that higher pressures of CO2 as well as blends with O2, which has better arc-quenching capability than CO2, could possibly overcome some of these issues as well as further improve the GWP. Another option for higher-pressure CO2, as demonstrated in [98], is to use it in its supercritical state. Supercritical carbon dioxide (scCO2) at around 8 MPa has a dielectric strength of around three times that of SF6 in addition to high heat transfer capability and low viscosity. scCO2-based breakers have already been proposed for a compact, low-arcing, medium-voltage breaker [99]; however, scCO2 breakers have their own challenges as they require the chamber, bushings, and all external seals to manage the 8-MPa pressure and a well-controlled temperature to maintain the CO2 at supercritical levels. Additionally, during an AC fault, the great amounts of heat energy released from the arc over the course of several milliseconds or partial cycles could cause more overpressure in the switchgear enclosure and bushings, resulting in rupture. While this phenomenon has been studied at lower starting pressures for SF6, CO2, and N2 [100], further analysis on the higher operating pressure effects over time and in operation during arcing faults in scCO2 are needed.

In addition to looking to CO2 at higher pressures, in [101], researchers demonstrated that N2, with a combination of higher pressures and/or increased sparking distance, can achieve a dielectric insulation equivalent to SF6 at 0.7 MPa. In [102], researchers further evaluated gaseous nitrogen at pressures up 2.6 MPa and with various mixtures of SF6 and showed that, for example, with a working pressure of 1 MPa and only 5% SF6 and 95% N2, a similar insulation performance could be achieved to SF6 at its typical working pressure of 0.7 MPa. As has been discussed, for application to circuit breakers, a suitable dielectric medium is dependent on many other variables besides dielectric strength, such as gas flow characteristics and various thermal properties, that should be considered to definitively evaluate the equivalency of the insulating medium as a replacement for SF6 in switchgear.

Other work has also looked at nongaseous forms of nitrogen. If future substations have available liquid nitrogen (LN2), then concepts proposed in [103] such as a 126-kV LN2-cooled superconducting fault current limiter (SCFCL), which reduces the fault current energy, could enable a smaller, cryogenically cooled vacuum interrupter in series which would have the added benefit of an “on” resistance of less than a third of a traditional AC breaker. Alternatively, since LN2 can have a higher breakdown voltage than SF6 at its standard operating pressure, LN2 has been proposed as the dielectric medium in the interrupter itself where it can both serve to greatly reduce steady-state losses due to reduced resistivity of the cryo-cooled contacts and extinguish the arc. In [104], the arc-extinguishing capability of LN2 was tested up to nearly 3-kA peak with 50-mm-diameter contacts, opening at 1 m/s to reach a 25-mm gap. The LN2 was shown to help successfully extinguish the arc at the zero crossing without reignition for root mean square currents of less than 2085 A. The two concepts of SCFCL and dielectric medium are combined in [105] where researchers have also proposed and tested at lower voltages with LN2 as the dielectric medium in the interrupting mechanism combined with a SCFCL. The results indicate the system is fast-acting and results in lower current and therefore lower-energy faults, though many other items, including the hardware redesign, the logistics of cooling the LN2, and how to deal with any GN2 that is generated, must be considered. For those that envision liquid nitrogen and cryo-cooled elements as part of the solution for the future grid, demonstrating the value of fault current limiters and liquid nitrogen in switchgear could play a part but may require rethinking of traditional fault coordination systems.

Another area of research as it relates to SF6 alternatives is in the materials, speed, and movement of the mechanisms that separate the contacts, determine the movement of the arc, and control gas flow. In [106], researchers demonstrate in a low-voltage circuit breaker the use of permanent magnets to help guide the arc toward a splitter stack that elongates and cools it. However, physical prototypes to prove the efficacy of these approaches on high-voltage equipment are costly, and theoretically evaluating the range of possible solutions also proves challenging. The simulation of such systems are complex due the multi-physics phenomena related to flow, pressure, contaminants, electrical operating points, mechanical structures, the shape and movement of contacts, and dielectric medium management mechanisms. Much research has been done to make the simulation problem more accurate and manageable such as defining the ignition of discharges and their lifetime transitions from corona to streamer or to Townsend avalanches by evaluating the discharge’s stability mathematically as an eigenvalue problem [107] or defining an iterative calculation of streamer propagation with a dependence on pressure into an algorithm that helps simplify finite element simulation. A similar effort to simplify simulations in [108] uses computational fluid dynamics and detailed enthalpy flow simulations to determine the discharge coefficients of various geometries of gas valves during the circuit breaker operation that can then be plugged into enthalpy flow models of the full circuit breaker system. The need for high accuracy simulations and the multidisciplinary nature of the problem is apparent even in research related to existing high-voltage switchgear. For example, some 550-kV HVAC SF6-based breakers must now manage higher short-circuit ratings than ever, such as 80 kA versus a previous maximum of 63 kA, as a result of new grid conditions. This increase in peak fault current is compelling researchers to explore electromagnetic- and mechanical-based solutions that can reduce contact travel time and guide the arc so that it extinguishes more effectively so as to not cause significant changes to equipment size and operation as a result of the increased fault current rating [109, 110].

5 Concluding Remarks

The risks of using SF6 as the insulating medium on the grid due to its outsized GWP have long been recognized by researchers and regulators. The search for suitable alternatives to SF6-insulated GIE has spanned decades and only recently has it achieved gains in the form of unique fluorinated gas mixtures, vacuum dielectrics pushing higher voltages, and cryo-insulators. Though early results are promising, there remain many open questions related to the life cycle impacts of new GIE or vacuum-based equipment, the performance of the dielectric medium when exposed to an arc, the safety and monitoring aspects that will be required, and the end-of-life handling practices. With much of the current grid infrastructure approaching end of useful life, the introduction of new renewable energy generation to the grid, and upcoming policy mandates, the need for alternatives to SF6-insulated GIE has never been greater. Addressing these questions, analyzing the findings from ongoing pilot studies, and anticipating future needs for SF6 alternative technologies are sure to be a top priority for stakeholders in this space and will be critical for achieving a zero-emission grid.

Notes

- 1.

The emissions are estimated by using a 1% emission rate on the reported and projected SF6 nameplate capacities (see Fig. 18.1). Of note, the EPA does not require SF6 emission reporting for utility operators with a combined total of 17,820 lbs. SF6 nameplate capacity, and therefore, the numbers available for nameplate capacity may not be complete.

References

Y. Wang, D. Huang, J. Liu, Y. Zhang, L. Zeng, Alternative environmentally friendly insulating gases for SF6. Processes 7(4), 216 (2019). https://doi.org/10.3390/pr7040216

Gas-insulated switchgear market worth $26.5 billion by 2025 – Report by MarketsandMarkets™. https://www.marketsandmarkets.com/PressReleases/gas-insulated-switchgear.asp. Accessed 23 June 2022

O. US EPA, Inventory of U.S. greenhouse gas emissions and sinks: 1990–2015, Apr. 24, 2016. https://www.epa.gov/ghgemissions/inventory-us-greenhouse-gas-emissions-and-sinks-1990-2015. Accessed 23 June 2022

J. Blackman, M. Averyt, SF6 leak rates from high voltage circuit breakers – U.S. EPA investigates potential greenhouse gas emissions source, p. 4

J.D. McCreary, AEP: A Case Study (San Diego, 2000)

D. Keith, J. Fisher, T. McRae, Experience with Infrared Leak Detection on FPL Switchgear (San Diego, 2000)

Management on SF6 gas for use in electrical power equipment, in Ad-Hoc Task Group on SF6, Switchgear Section (8-SG), Feb. 1998

M. McGrath, Climate change: Electrical industry’s ‘dirty secret’ boosts warming, BBC, Sept. 13, 2019. https://www.bbc.com/news/science-environment-49567197. Accessed 28 June 2022

R.F. Weiss, R.G. Prinn, Quantifying greenhouse-gas emissions from atmospheric measurements: A critical reality check for climate legislation. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 369(1943), 1925–1942 (2011). https://doi.org/10.1098/rsta.2011.0006

Industry Leader, Presented at the DOE ARPA-E grid hardware annual review, Pittsburgh, PA, Nov. 25, 2022

Power grid long-term outlook 2021, BloombergNEF, Feb. 2021

E. S. R. L. NOAA, NOAA global monitoring laboratory – Sulfur hexafluoride. https://gml.noaa.gov/hats/combined/SF6.html. Accessed 26 Nov 2022

Inventory of U.S. Greenhouse gas emissions and sinks 1990–2019, EPA, EPA 430-R-21-005, Apr. 2021. [Online]. Available: https://www.epa.gov/ghgemissions/inventory-us-greenhouse-gas-emissions-and-sinks

V. Roshchanka, SF6 gas storage inventories: Strategies for tracking, EPA, May 08, 2019. [Online]. Available: https://www.epa.gov/sites/default/files/2019-07/documents/sf6storageinventories_webinar_050819.pdf

SF6 emission reduction partnership for electric power systems, EPA, 2014 annual report, Mar. 2015. [Online]. Available: www.epa.gov/electricpower-sf6

L. Niemeyer, A systematic search for insulation gases and their environmental evaluation, in Gaseous Dielectrics VIII, ed. by L.G. Christophorou, J.K. Olthoff, (Springer US, Boston, 1998), pp. 459–464. https://doi.org/10.1007/978-1-4615-4899-7_61

L.G. Christophorou, J.K. Olthoff, D.S. Green, Gases for Electrical Insulation and Arc Interruption: Possible Present and Future Alternatives to Pure SF6 (NIST, Gaithersburg, 1997), Technical Note

Gases superior to SF6 for insulation and interruption, Electric Power Research Institute, EPRI EL-2620, Sept. 1982

D.W. Bouldin, D.R. James, M.O. Pace, L.G. Christophorou, Current assessment of the potential of dielectric gas mixtures for industrial applications, in 4th Intern. Symp. on Gaseous Dielec, Knoxville, Tennessee, Apr. 1984. Accessed 28 June 2022. [Online]. Available: https://ui.adsabs.harvard.edu/abs/1984gadi.symp.....B

D.R. James, M.O. Pace, D.W. Bouldin, L.G. Christophorou, Current assessment of research on insulating gas mixtures and their potential for industrial applications (Oak Ridge National Lab., TN (USA), ORNL/TM-9017, 1984). Accessed 28 June 2022. [Online]. Available: https://www.osti.gov/biblio/5282616

N.H. Malik, A.H. Qureshi, A review of electrical breakdown in mixtures of SF6 and other gases. IEEE Trans. Electr. Insul. EI-14(1), 1–13 (1979). https://doi.org/10.1109/TEI.1979.298198

L.G. Chrisophorou, D.R. James, I. Sauers, M.O. Pace, R.Y. Pai, A. Fatheddin, Ternary Gas Dielectrics. New York, 151–165 (1982). Accessed 28 June 2022. [Online]. Available: https://www.osti.gov/biblio/5279201

K. Nakanishi, New Gaseous insulation. IEEE Trans. Electr. Insul. EI-21(6), 933–937 (1986). https://doi.org/10.1109/TEI.1986.349005

T. Uchii, Y. Hoshina, H. Kawano, K. Suzuki, T. Nakamoto, M. Toyoda, Fundamental research on SF6-free gas insulated switchgear adopting CO2 gas and its mixtures. Proc. Int. Symp. EcoTopia Sci. ISETS07, 5 (2007)

B. Zhang, J. Xiong, L. Chen, X. Li, A.B. Murphy, Fundamental physicochemical properties of SF6 -alternative gasses: A review of recent progress. J. Phys. Appl. Phys. 53(17), 173001 (2020). https://doi.org/10.1088/1361-6463/ab6ea1

M. Rabie, D.A. Dahl, S.M.A. Donald, M. Reiher, C.M. Franck, Predictors for gases of high electrical strength. IEEE Trans. Dielectr. Electr. Insul. 20(3), 856–863 (2013). https://doi.org/10.1109/TDEI.2013.6518955

M. Rabie, C. Franck, Predicting the electric strength of proposed SF6 replacement gases by means of density functional theory, in ISH – 18th Int. Symp. High Volt. Eng, (2013)

J. Owens, A. Xiao, J. Bonk, M. DeLorme, A. Zhang, Recent development of two alternative gases to SF6 for high voltage electrical power applications. Energies 14, 5051 (2021). https://doi.org/10.3390/en14165051

Y. Kieffel, A. Ficheux, R. Luescher, E. Laruelle, L. Maksoud, SF6 alternative – What to learn from the high voltage experience. AIM (2019). https://doi.org/10.34890/891

L. Chen, X. Li, J. Xiong, A.B. Murphy, M. Fu, R. Zhuo, Chemical kinetics analysis of two C5-perfluorinated ketone (C5 PFK) thermal decomposition products: C4F7O and C3F4O. J. Phys. Appl. Phys. 51(43), 435202 (2018). https://doi.org/10.1088/1361-6463/aade62

X. Li, H. Zhao, A.B. Murphy, SF6-alternative gases for application in gas-insulated switchgear. J. Phys. Appl. Phys. 51(15), 153001 (2018). https://doi.org/10.1088/1361-6463/aab314

K. Pohlink, F. Meyer, J. Owens, Characteritics of Fluoronitrile/CO2 Mixture (Paris, 2016), p. D1-204

P. Simaka, C.B. Doiron, S. Scheel, A. Di-Gianni, Decomposition of Alternative Gaseous Insulation Under Partial Discharge (Buenos Aires, 2017)

B. Zhang et al., Thermal and electrical decomposition products of C5F10O and their compatibility with Cu(111) and Al(111) surfaces. Appl. Surf. Sci. 513, 145882 (2020). https://doi.org/10.1016/j.apsusc.2020.145882

B. Zhang, C. Li, J. Xiong, Z. Zhang, X. Li, Y. Deng, Decomposition characteristics of C4F7N/CO2 mixture under AC discharge breakdown. AIP Adv. 9(11), 115212 (2019). https://doi.org/10.1063/1.5115588

B. Radisavljevic, P.C. Stoller, C.B. Doiron, D. Over, A. Di-Gianni, S. Scheel, Switching Performance of Alternative Gaseous Mixtures in High-Voltage Circuit Breakers (Bueno, 2017)

J. Mantilla, M. Claessens, M. Kriegel, Environmentally friendly perfluoroketones-based mixture as switching medium in high voltage circuit breakers, in CIGRE, (Paris, France, 2016), p. A3-348

P.C. Stoller, J. Hengstler, C.B. Doiron, S. Scheel, P. Simaka, P. Muller, Environmental aspects of high voltage gas-insulated switchgear that uses alternatives to SF6 and monitoring and long-term performance of a pilot installation, in CIGRE, (Paris, France, 2018), p. D1-202

Y.K. Bousoltane Kieffel, L. Maksoud, D. Vigouroux, D. Vancell, P. Teulet, P. Robin-Jouan, Investigation on the influence of the O2 content in fluoronitrile/CO2/O2 (g3) mixtures on the breaking in high voltage circuit breakers, in 22nd International Conference on Gas Discharges and Their Applications, (Novi Sad, Serbia, 2018)

X. Yu, H. Hou, B. Wang, Mechanistic and kinetic investigations on the thermal unimolecular reaction of heptafluoroisobutyronitrile. J. Phys. Chem. A 122(38), 7704–7715 (2018). https://doi.org/10.1021/acs.jpca.8b07189

L. Chen, B. Zhang, J. Xiong, X. Li, A.B. Murphy, Decomposition mechanism and kinetics of iso-C4 perfluoronitrile (C4F7N) plasmas. J. Appl. Phys. 126(16), 163303 (2019). https://doi.org/10.1063/1.5109131

S. Xiao, Y. Li, X. Zhang, S. Tian, Z. Deng, J. Tang, Effects of micro-water on decomposition of the environment-friendly insulating medium C5F10O. AIP Adv. 7(6), 065017 (2017). https://doi.org/10.1063/1.4990512

X. Zhang, Y. Li, S. Xiao, S. Tian, Z. Deng, J. Tang, Theoretical study of the decomposition mechanism of environmentally friendly insulating medium C3F7CN in the presence of H2O in a discharge. J. Phys. Appl. Phys. 50(32), 325201 (2017). https://doi.org/10.1088/1361-6463/aa783a

L. Chen, B. Zhang, T. Yang, Y. Deng, X. Li, A.B. Murphy, Thermal decomposition characteristics and kinetic analysis of C4F7N/CO2 gas mixture. J. Phys. Appl. Phys. 53(5), 055502 (2020). https://doi.org/10.1088/1361-6463/ab56a0

Y. Li et al., Decomposition properties of C4F7N/N2 gas mixture: An environmentally friendly gas to replace SF6. Ind. Eng. Chem. Res. 57(14), 5173–5182 (2018). https://doi.org/10.1021/acs.iecr.8b00010

X. Zhang et al., Decomposition mechanism of the C5-PFK/CO2 gas mixture as an alternative gas for SF6. Chem. Eng. J. 336, 38–46 (2018). https://doi.org/10.1016/j.cej.2017.11.051

W. Gao et al., Materials compatibility study of C4F7N/CO2 gas mixture for medium-voltage switchgear. IEEE Trans. Dielectr. Electr. Insul. 29(1), 270–278 (2022). https://doi.org/10.1109/TDEI.2022.3146460

Y. Kieffel, T. Irwin, P. Ponchon, J. Owens, Green gas to replace SF6 in electrical grids. IEEE Power Energy Mag. 14(2), 32–39 (2016). https://doi.org/10.1109/MPE.2016.2542645

H.E. Nechmi, A. Beroual, A. Girodet, P. Vinson, Fluoronitriles/CO2 gas mixture as promising substitute to SF6 for insulation in high voltage applications. IEEE Trans. Dielectr. Electr. Insul. 23(5), 2587–2593 (2016). https://doi.org/10.1109/TDEI.2016.7736816

Siemens energy and Mitsubishi electric to develop high-voltage switching solutions with zero GWP, Energy Industry Review, June 08, 2021. https://energyindustryreview.com/environment/siemens-energy-and-mitsubishi-electric-to-develop-high-voltage-switching-solutions-with-zero-gwp/. Accessed 07 July 2022

L. Graber, Improving the accuracy of SF6 leakage detection for high voltage switchgear. IEEE Trans. Dielectr. Electr. Insul. 18(6), 1835–1846 (2011). https://doi.org/10.1109/TDEI.2011.6118621

V. Hermosillo, M. Kelly, M. Broglio, Advances in leak detection in the manufacturing process, May 28, 2014. [Online]. Available: https://www.epa.gov/sites/default/files/2016-02/documents/hermosillo-kelly-broglio-alstom-grid-presentation-2014-wkshp.pdf

SF6 Gas Leak Detector (3-033-R501) | DILO Company, Inc. https://dilo.com/sf6-gas/products/measuring-devices/leak-detection-and-monitoring/portable-leak-detector. Accessed 28 June 2022

SF6 transmitter high voltage technology. Draeger, 2019. [Online]. Available: https://www.draeger.com/Products/Content/sf6-transmitter-pi-9107808-en-gb.pdf

T. Heckler, Mitigating potential SF6 leaks through early leak detection, Atlanta, GA, 2012. [Online]. Available: https://www.epa.gov/sites/default/files/2016-02/documents/conf12_heckler.pdf

NDIR Infrared (IR) gas sensor for CO2, methane, SF6, refrigerants, Nano Environmental Technology S.r.l. https://www.nenvitech.com/products/ndir-sensors/. Accessed 28 June 2022

Gas detector – GIR-10 – WIKA. https://www.wika.com/en-us/gir_10.WIKA? Accessed 28 June 2022

Public hearing to consider the proposed amendments to the regulation for reducing sulfur hexafluoride emissions from gas insulated switchgear. California, 2020. [Online]. Available: https://ww2.arb.ca.gov/sites/default/files/barcu/regact/2020/sf6/isor.pdf

S. Blázquez, M. Antiñolo, O.J. Nielsen, J. Albaladejo, E. Jiménez, Reaction kinetics of (CF3)2CFCN with OH radicals as a function of temperature (278–358K): A good replacement for greenhouse SF6? Chem. Phys. Lett. 687, 297–302 (2017). https://doi.org/10.1016/j.cplett.2017.09.039

M.P. Sulbaek Andersen, M. Kyte, S.T. Andersen, C.J. Nielsen, O.J. Nielsen, Atmospheric chemistry of (CF3)2CF–C≡N: A replacement compound for the most potent industrial greenhouse gas, SF6. Environ. Sci. Technol. 51(3), 1321–1329 (2017). https://doi.org/10.1021/acs.est.6b03758

D. Gautschi, R. Luescher, Comparative life cycle assessment of an environmentally friendly 145 kV gas insulated substation, p. 11

V. Hermosillo, E. Laruelle, L. Darles, C. Gregoire, Y. Kieffel, Environmental performance of dead-tank circuit breakers with SF6 and alternative gases, Aug. 2020

R. Kurte, H.M. Heise, D. Klockow, Analysis of spark decomposition products of SF6 using multivariate mid-infrared spectrum evaluation. J. Mol. Struct. 480–481, 211–217 (1999). https://doi.org/10.1016/S0022-2860(98)00642-5

C.-H. Tsai, J.-M. Shao, Formation of fluorine for abating sulfur hexafluoride in an atmospheric-pressure plasma environment. J. Hazard. Mater. 157(1), 201–206 (2008). https://doi.org/10.1016/j.jhazmat.2008.01.010

W.-T. Tsai, The decomposition products of sulfur hexafluoride (SF6): Reviews of environmental and health risk analysis. J. Fluor. Chem. 128(11), 1345–1352 (2007). https://doi.org/10.1016/j.jfluchem.2007.06.008

H.C. Cowen et al., The reaction of sulphur hexafluoride with sodium. J. Chem. Soc., 4168–4188 (1953). https://doi.org/10.1039/JR9530004168

G.C. Demitras, A.G. MacDiarmid, The low temperature reaction of sulfur hexafluoride with solutions of sodium. Inorg. Chem. 3(8), 1198–1199 (1964). https://doi.org/10.1021/ic50018a033

H.L. Deubner, F. Kraus, The decomposition products of sulfur hexafluoride (SF6) with metals dissolved in liquid ammonia. Inorganics 5(4), 68 (2017). https://doi.org/10.3390/inorganics5040068

S. Bouvet et al., Controlled decomposition of SF6 by electrochemical reduction. Beilstein J. Org. Chem. 16, 2948–2953 (2020). https://doi.org/10.3762/bjoc.16.244

C. Berg, T. Braun, M. Ahrens, P. Wittwer, R. Herrmann, Activation of SF6 at platinum complexes: Formation of SF3 derivatives and their application in deoxyfluorination reactions. Angew. Chem. Int. Ed. 56(15), 4300–4304 (2017). https://doi.org/10.1002/anie.201612417

P. Holze, B. Horn, C. Limberg, C. Matlachowski, S. Mebs, The activation of sulfur hexafluoride at highly reduced low-coordinate nickel dinitrogen complexes. Angew. Chem. Int. Ed. 53(10), 2750–2753 (2014). https://doi.org/10.1002/anie.201308270

L. Zámostná, T. Braun, B. Braun, SÀF and SÀC activation of SF6 and SF5 derivatives at rhodium: Conversion of SF6 into H2S. Angew. Chem. Int. Ed. 53(10), 2745–2749 (2014). https://doi.org/10.1002/anie.201308254

B.G. Harvey, A.M. Arif, A. Glöckner, R.D. Ernst, SF6 as a selective and reactive fluorinating agent for low-valent transition metal complexes. Organometallics 26(11), 2872–2879 (2007). https://doi.org/10.1021/om070175i

R. Basta, B.G. Harvey, A.M. Arif, R.D. Ernst, Reactions of SF6 with organotitanium and organozirconium complexes: The ‘inert’ SF6 as a reactive fluorinating agent. J. Am. Chem. Soc. 127(34), 11924–11925 (2005). https://doi.org/10.1021/ja052214s

M. Wozniak et al., Activation of SF6 at a Xantphos-type rhodium complex. Organometallics 37(5), 821–828 (2018). https://doi.org/10.1021/acs.organomet.7b00858

D. Dirican, N. Pfister, M. Wozniak, T. Braun, Reactivity of binary and ternary sulfur halides towards transition-metal compounds. Chem. Eur. J. 26(31), 6945–6963 (2020). https://doi.org/10.1002/chem.201904493

F. Buß, C. Mück-Lichtenfeld, P. Mehlmann, F. Dielmann, Nucleophilic activation of sulfur hexafluoride: Metal-free, selective degradation by phosphines. Angew. Chem. Int. Ed. 57(18), 4951–4955 (2018). https://doi.org/10.1002/anie.201713206

D.J. Sheldon, M.R. Crimmin, Complete deconstruction of SF 6 by an aluminium(i) compound. Chem. Commun. 57(58), 7096–7099 (2021). https://doi.org/10.1039/D1CC02838C

X. Zhang, G. Zhang, Y. Wu, S. Song, Synergistic treatment of SF 6 by dielectric barrier discharge/γ-Al2O3 catalysis. AIP Adv. 8(12), 125109 (2018). https://doi.org/10.1063/1.5054729

M. Rueping, P. Nikolaienko, Y. Lebedev, A. Adams, Metal-free reduction of the greenhouse gas sulfur hexafluoride, formation of SF5 containing ion pairs and the application in fluorinations. Green Chem. 19(11), 2571–2575 (2017). https://doi.org/10.1039/C7GC00877E

T.A. McTeague, T.F. Jamison, Photoredox activation of SF6 for fluorination. Angew. Chem. Int. Ed. 55(48), 15072–15075 (2016). https://doi.org/10.1002/anie.201608792

D. Rombach, H.-A. Wagenknecht, Photoredox catalytic α-alkoxypentafluorosulfanylation of α-methyl- and α-phenylstyrene using SF6. Angew. Chem. Int. Ed. 59(1), 300–303 (2020). https://doi.org/10.1002/anie.201910830

P. Tomar, T. Braun, E. Kemnitz, Photochemical activation of SF6 by N-heterocyclic carbenes to provide a deoxyfluorinating reagent. Chem. Commun. 54(70), 9753–9756 (2018). https://doi.org/10.1039/C8CC05494K

P. Tomar, T. Braun, E. Kemnitz, Preparation of NHC stabilized Al(III)fluorides: Fluorination of [(SIMes)AlMe3] with SF4 or Me3SnF. Eur. J. Inorg. Chem. 2019(44), 4735–4739 (2019). https://doi.org/10.1002/ejic.201900921

S. Kim, Y. Khomutnyk, A. Bannykh, P. Nagorny, Synthesis of glycosyl fluorides by photochemical fluorination with sulfur(VI) hexafluoride. Org. Lett. 23(1), 190–194 (2021). https://doi.org/10.1021/acs.orglett.0c03915

D. Rombach, H.-A. Wagenknecht, Photoredox catalytic activation of sulfur hexafluoride for pentafluorosulfanylation of α-methyl- and α-phenyl styrene. ChemCatChem 10(14), 2955–2961 (2018). https://doi.org/10.1002/cctc.201800501

H. Wilson, D. Dufournet, H. Mercure, R. Yeckley, History of circuit breakers, in Switching Equipment, ed. by H. Ito, (Springer International Publishing, Cham, 2019), pp. 157–198. https://doi.org/10.1007/978-3-319-72538-3_5

L.T. Falkingham, The strengths and weaknesses of vacuum circuit breaker technology, in 2011 1st International Conference on Electric Power Equipment – Switching Technology, (Xi’an, China, Oct. 2011), pp. 701–703. https://doi.org/10.1109/ICEPE-ST.2011.6122975

M. Godbole, A.M. Jain, Double break vacuum circuit breaker — A brief overview, in 2016 10th International Conference on Intelligent Systems and Control (ISCO), (Coimbatore, India, Jan. 2016), pp. 1–4. https://doi.org/10.1109/ISCO.2016.7727112

H.C. Miller, Surface flashover of insulators. IEEE Trans. Electr. Insul. 24(5), 765–786 (1989). https://doi.org/10.1109/14.42158

D. Huang, W. Gaobo, J. Ruan, Study on static and dynamic voltage distribution characteristics and voltage sharing design of a 126-kV modular triple-break vacuum circuit breaker. IEEE Trans. Plasma Sci. 43(8), 2694–2702 (2015). https://doi.org/10.1109/TPS.2015.2449075

G. Ge et al., Experimental investigation into the synergy of vacuum circuit breaker with double-break. IEEE Trans. Plasma Sci. 44(1), 79–84 (2016). https://doi.org/10.1109/TPS.2015.2502241

H. Kojima, T. Takahashi, N. Hayakawa, K. Hasegawa, H. Saito, M. Sakaki, Dependence of spark conditioning on breakdown charge and electrode material under a non-uniform electric field in vacuum. IEEE Trans. Dielectr. Electr. Insul. 23(5), 3224–3230 (2016). https://doi.org/10.1109/TDEI.2016.7736889

C.-H. Lee, B.H. Shin, Y.-B. Bang, Designing a permanent-magnetic actuator for vacuum circuit breakers using the Taguchi method and dynamic characteristic analysis. IEEE Trans. Ind. Electron. 63(3), 1655–1664 (2016). https://doi.org/10.1109/TIE.2015.2494006

B. Zhang et al., A relationship between minimum arcing interrupting capability and opening velocity of vacuum interrupters in short-circuit current interruption. IEEE Trans. Power Delivery 33(6), 2822–2828 (2018). https://doi.org/10.1109/TPWRD.2018.2838344

ABB, Circuit Breaker Basics (Orlando, 2019)

P. Widger, A. Haddad, H. Griffiths, Breakdown performance of vacuum circuit breakers using alternative CF 3 I-CO 2 insulation gas mixture. IEEE Trans. Dielectr. Electr. Insul. 23(1), 14–21 (2016). https://doi.org/10.1109/TDEI.2015.005254

J. Wei, A. Cruz, A. West, F. Haque, C. Park, L. Graber, Theoretical modeling and experimental testing on the electrical breakdown in supercritical fluids, in 2021 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), (Vancouver, BC, Canada, Dec. 2021), pp. 179–182. https://doi.org/10.1109/CEIDP50766.2021.9705453

C. Xu, J. Wei, L. Graber, Compatibility analysis of piezoelectric actuators in supercritical carbon dioxide, in 2020 IEEE Electrical Insulation Conference (EIC), (Knoxville, TN, USA, June 2020), pp. 171–174. https://doi.org/10.1109/EIC47619.2020.9158670

M. Li, P. Gong, H. Yang, P. Guo, Investigation on the pressure rise and energy balance due to fault arcs in a closed container filled with different insulating gases. IEEE Trans. Plasma Sci. 47(12), 5226–5233 (2019). https://doi.org/10.1109/TPS.2019.2950331

A. Hopf, M. Rossner, F. Berger, U. Prucker, Dielectric strength of alternative insulation gases at high pressure in the homogeneous electric field, in 2015 IEEE Electrical Insulation Conference (EIC), (Seattle, WA, USA, Aug. 2015), pp. 131–136. https://doi.org/10.1109/ICACACT.2014.7223575

A. Hopf, M. Rossner, F. Berger, U. Prucker, Dielectric strength of alternative insulation gases at high pressure in the inhomogeneous electric field, in 2015 IEEE Electrical Insulation Conference (EIC), (Seattle, WA, USA, Aug. 2015), pp. 369–374. https://doi.org/10.1109/ICACACT.2014.7223618

J. Wang, Y. Tan, L. Zhang, Y. Geng, Z. Liu, S. Wang, Conceptual design of a liquid-nitrogen-insulated metal-enclosed switchgear. IEEE Trans. Appl. Supercond. 26(7), 1 (2016). https://doi.org/10.1109/TASC.2016.2587480

B. Xiang et al., AC current interruption by liquid nitrogen in a superconducting fault current limiting switchgear, in 2020 IEEE International Conference on Applied Superconductivity and Electromagnetic Devices (ASEMD), (Tianjin, China, Oct. 2020), pp. 1–2. https://doi.org/10.1109/ASEMD49065.2020.9276340

M. Junaid, B. Xiang, J. Wang, Z. Liu, Y. Geng, Experimental test of superconductor fault-current switchgear using liquid nitrogen as the insulation and arc-quenching medium. IEEE Trans. Appl. Supercond. 29(5), 1 (2019). https://doi.org/10.1109/TASC.2019.2898523

H. Hofmann, C. Weindl, M.I. Al-Amayreh, O. Nilsson, Arc movement inside an AC/DC circuit breaker working with a novel method of arc guiding: Part I—Experiments, examination, and analysis. IEEE Trans. Plasma Sci. 40(8), 2028–2034 (2012). https://doi.org/10.1109/TPS.2012.2200697

M.S. Benilov, P.G.C. Almeida, N.G.C. Ferreira, R.M.S. Almeida, G.V. Naidis, A practical guide to modeling low-current quasi-stationary gas discharges: Eigenvalue, stationary, and time-dependent solvers. J. Appl. Phys. 130(12), 121101 (2021). https://doi.org/10.1063/5.0057856

A. Smajkic, B.B. Hadzovic, M. Muratovic, M.H. Kim, M. Kapetanovic, Determination of discharge coefficients for valves of high voltage circuit breakers. IEEE Trans. Power Delivery 35(3), 1278–1284 (2020). https://doi.org/10.1109/TPWRD.2019.2939746

H. Zhang, Z. Wang, M. Li, Y. Yao, J. Li, J. Zhao, Simulation analysis of the breaking process of 550kV 80kA SF6 circuit breaker, in 2022 4th Asia Energy and Electrical Engineering Symposium (AEEES), (Chengdu, China, Mar. 2022), pp. 1–5. https://doi.org/10.1109/AEEES54426.2022.9759699

S. Tan, H. Zhang, M. Li, X. Duan, Z. Wang, B. Zhang, Simulation research on breaking performance of 550 kV 80 kA SF6 circuit breaker under different opening characteristics, in 2021 11th International Conference on Power and Energy Systems (ICPES), (Shanghai, China, Dec. 2021), pp. 47–51. https://doi.org/10.1109/ICPES53652.2021.9683917

L.G. Christophorou, P.G. Datskos, Effect of temperature on the formation and autodestruction of parent anions. Int. J. Mass Spectrom. Ion Processes 149(150), 59–77 (1995)

Acknowledgments

The writing of this chapter was funded in part by the Advanced Research Projects Agency-Energy (ARPA-E), U.S. Department of Energy. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof. Special thanks to Dr. Sade Ruffin for her contributions.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 This is a U.S. government work and not under copyright protection in the U.S.; foreign copyright protection may apply

About this chapter

Cite this chapter

Yedinak, E., Lentijo, K., Kizilyalli, I.C. (2023). Eliminating SF6 from Switchgear. In: Kizilyalli, I.C., Shen, Z.J., Cunningham, D.W. (eds) Direct Current Fault Protection. Power Systems. Springer, Cham. https://doi.org/10.1007/978-3-031-26572-3_18

Download citation

DOI: https://doi.org/10.1007/978-3-031-26572-3_18

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-26571-6

Online ISBN: 978-3-031-26572-3

eBook Packages: EnergyEnergy (R0)