Abstract

Tin oxide nanoparticles were synthesized using the sol–gel technique, where metallic tin, ammonia hydroxide, nitric acid, ascorbic acid, ethanol, and deionized water were used. A white powder characteristic of tin oxide was obtained. X-ray diffraction was performed on the synthesis product and identified as cassiterite (SnO2), with a tetragonal unit cell, which lattice parameters are at a = 4.74 Å and c = 3.19 Å, the ICDD-PDF letter is 96-210-4755. Scanning electron microscopy characterization showed that nanoparticles have a spherical morphology and sizes ranging from 23 to 67.6 nm. Analysis performed by infrared spectroscopy show that it has the tin bond oxygen 667 cm−1 region.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

Nanotechnology has had a huge impact on science, because the small size can allow the automation of tasks that were previously inaccessible due to physical constraints. The main benefits of nanotechnology include improved manufacturing methods, water purification systems, energy systems, physical improvement, nanomedicine, better food production methods, nutrition and large-scale self-manufacturing infrastructure. So nanotechnology is the study of the synthesis, characterization and application of matter at the nanometric scale, which in recent years has seen a great interest in nanoparticles, especially metal nanoparticles, such as zinc oxide (ZnO), silver (Ag), gold (Au), copper (Cu) titanium dioxide (TiO2) and tin oxide (SnO), although the latter have not been very studied because they show some limitations to obtain them because it is complex. Tin oxide is a wide band, n-type semiconductor (about 3.5 eV) and, in the form of thin sheets, is a transparent conductive material, characterized by a high optical transmission (80–90%). Tin oxide has two crystalline phases, romarchite (SnO) and cassiterite (SnO2), the latter being the most stable due to the tetragonal arrangement of atoms [1,2,3,4]. The heat of formation of cassiterite structure is ΔH = 1.9 × 103 J mol−1 and the heat capacity of the material is Cp = 52.59 J mol−1 K−1; its density at 25 °C is 6.95 g cm−3 and the melting point of the material is 1630 °C. This crystalline structure contains metal atoms in octahedral coordination and oxygen in planar coordination; the lattice parameters are a = 4.737 Å and c = 3.186 Å [1,2,3]. The physical and chemical properties of crystalline tin oxide are often different from crystalline or amorphous. These properties depend on the crystalline structure and morphology, as well as on the grain size. The synthesis of tin oxide nanostructures with the desired structure and morphology is of great scientific and technological interest, due to their superior physical and chemical properties and their wide range of applications, such as gas sensors, photocatalysts, nanofiltration membranes, thermal mirrors and glass coatings. Therefore, it is very important to develop ways to control its dimensions, structure, surface and interface properties.

Tin oxide nanoparticles (SnO2 NP’s) can be synthesized by different methods, generally classified as chemical, physical and biosynthesis methods. Chemical methods are effective, because the process and equipment required are simple, and they also offer the advantage of being easy and economical to perform. These can be synthesized by sol–gel [1], mechanochemical [2], co-precipitation [3], hydrolysis [4], microwave [5] and precipitation [6].

Applications reported by various authors of tin oxide nanoparticles have been reflected as optoelectronic devices [7], catalysis [8], dye-based solar cells [9], medicine [10], photosensors and antistatic coatings [11].

Therefore, in this work the synthesis of tin oxide nanoparticles (SnO2 NP’s) was performed using a methodology of Zhang et al. [12] but with a novel reagent: ascorbic acid, in which nanoparticles of SnO2 in the form of cassiterite with a diameter size of 23–67.6 nm were favorably obtained with a spherical morphology. By X-ray diffraction it was possible to determine that there is a crystalline phase of tin oxide, which has been confirmed as cassiterite and by FTIR-ATR was confirmed the presence of metal oxides.

Materials and Methods

For the synthesis of tin oxide nanoparticles, 8 M of HNO3 was added to a mixture of 3 g of metallic tin shot and 10 g of ascorbic acid in a flask, stirred at 300 rpm. The solution was filtered to remove lead in solid form, because tin was a Sn–Pb alloy. Ammonium hydroxide (25%) was added drop by drop to the solution with agitation until a pH of 8 was reached, the solution slowly developed into a turbid colloidal solution. The solution was centrifuged at 300 rpm for 20 min to recover the precipitate, and washed several times with 50/50 ethanol and water solution. It dried at 100 °C for 5 h in a muffle. The powder obtained was ground in a mortar, and finally roasted in an oven at 400 °C for 2 h. This whole process is shown in Fig. 1.

To identify the synthesized compound, X-ray diffraction was performed, and equipment used is a Bruker D8 powder diffractometer, with Ni filtered radiation from a Cu anode, kα1 = 1.5406 Å; 40 kV and 35 mA. Diffraction patterns were recorded in the angular range 2θ of 10–80°, with a step size = 0.01° and a step time = 3 s. Scanning electron microscopy (SEM) was used to determine the morphology and size of nanoparticles, the equipment is a Field Emission Scanning Electron Microscopy‐Energy Dispersive X‐Ray Spectrometry (FESEM‐EDS a JEOL JSM‐670 IF, JEOL, Tokyo, Japan). The metal oxide was confirmed by FTIR-ATR y in a PerkinElmer Spectrum Two with Universal ATR (PerkinElmer Inc. Waltham, MA, USA) 2500‐450 cm−1.

Results and Discussion

The presence of tin dioxide was confirmed by X-ray diffraction, as the peaks match with the crystallographic chart of the International Centre for Diffraction Data- Powder Diffraction File (ICDD-PDF) 00-041-1445, which belongs to the cassiterite (SnO2). The crystalline structure of a cassiterite is tetragonal, with lattice parameters of a = 4. 7382 Å and c = 3.1871 Å. Figure 2 shows the diffractogram where it is observed that the crystallographic planes match with those of the cassiterite, however, noise is shown, which is attributed to the organic acid that was used.

To determine particle size and morphology, scanning electron microscopy was used (Fig. 3), where particles with spherical morphology and size of approximately 23–67.6 nm are observed. Figure 4 shows the spectrum of energy dispersive x-ray spectroscopy, where tin, chlorine, carbon and oxygen are observed; tin and oxygen check the presence of nanoparticles of SnO2, the chlorine is due to the washing that was given to the sample and the presence of carbon is due to the ascorbic acid that remains even after the washing of the nanoparticles.

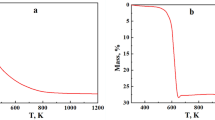

Figure 5 shows the spectrum of FTIR-ATR made to the nanoparticles of SnO2, which shows the presence of organic compounds even after washing the sample, these organic compounds belong to ascorbic acid and ammonium hydroxide. However, the absorption bands at 856 and 667 cm−1 belong to the Sn = O bond with which the presence of metal oxide is confirmed and suggests that it should be washed with some solvent to remove the excess of organic material.

Conclusions

The tin oxide nanoparticles were synthesized using the sol–gel method and ascorbic acid was added. The sample was characterized by DRX showing that there is tin oxide in the form of cassiterite, its unit cell parameters are a = 4.7382 Å and c = 3.1871 Å. Samples were characterized by SEM and nanoparticles of SnO2 in size were obtained between 23 and 67.6 nm. The samples were characterized by FTIR-ATR to confirm the presence of the tin oxide bond. It is required to wash the material to remove the most amount of organic material that have since the synthesis, however, the proposed method has effectiveness, since particles of nanometric sizes are obtained and the morphology is spherical.

References

Subramaniam MP, Arunachalam G, Kandasamy R, Veluswamy P, Hiroya I (2017) Effect of pH and annealing temperature on the properties of tin oxide nanoparticles prepared by sol–gel method. J Mater Sci Mater Electron 29(1):658–666. https://doi.org/10.1007/S10854-017-7959-2

Yang H, Hu Y, Tang A, Jin S, Qiu G (2004) Synthesis of tin oxide nanoparticles by mechanochemical reaction. J Alloy Compd 363(1–2):276–279. https://doi.org/10.1016/S0925-8388(03)00473-0

Tazikeh S, Akbari A, Talebi A, Talebi E (2014) Synthesis and characterization of tin oxide nanoparticles via the Co-precipitation method. Mater Sci Poland 32(1):98–101. https://doi.org/10.2478/S13536-013-0164-Y

Guo X, Kang Y, Wang L, Liu X, Zhang J, Yang T, Wu S, Wang S (2011) Mesoporous tin dioxide nanopowders based sensors to selectively detect ethanol vapor. Mater Sci Eng, C 31(7):1369–1373. https://doi.org/10.1016/J.MSEC.2011.05.002

Parthibavarman M, Sathishkumar S, Prabhakaran S (2017) Enhanced visible light photocatalytic activity of tin oxide nanoparticles synthesized by different microwave optimum conditions. J Mater Sci Mater Electron 29(3):2341–2350. https://doi.org/10.1007/S10854-017-8152-3

Nejati-Moghadam L, Esmaeili Bafghi-Karimabad A, Salavati-Niasari HS (2015) Synthesis and characterization of SnO2 nanostructures prepared by a facile precipitation method. Nanostructures 9–25

He JH, Wu TH, Hsin CL, Li KM, Chen LJ, Chueh YL, Chou LJ, Wang ZL (2006) Beaklike SnO2 nanorods with strong photoluminescent and field-emission properties. Small 2(1):116–120. https://doi.org/10.1002/smll.200500210

Carreño NLV, Fajardo HV, Maciel AP, Valentini A, Pontes FM, Probst LFD, Leite ER, Longo E (2004) Selective synthesis of vinyl ketone over SnO2 nanoparticle catalysts doped with rare earths. J Mol Catal A Chem 207(2):91–96. https://doi.org/10.1016/S1381-1169(03)00496-5

Snaith HJ, Ducati C (2010) SnO2-Based dye-sensitized hybrid solar cells exhibiting near unity absorbed photon-to-electron conversion efficiency. Nano Lett 10(4):1259–1265. https://doi.org/10.1021/nl903809r

Sudhaparimala S (2014) Green synthesis of tin based nano medicine: assessment of microstructure and surface property. Am J Nanosci Nanotechnol 2(4):75. https://doi.org/10.11648/j.nano.20140204.13

Zhao Q, Ma L, Zhang Q, Wang C, Xu X (2015) SnO2-based nanomaterials: synthesis and application in lithium-ion batteries and supercapacitors. J Nanomater 2015(1). https://doi.org/10.1155/2015/850147

Zhang J, Gao L (2004) Synthesis and characterization of nanocrystalline tin oxide by sol-gel method. J Solid State Chem 177(4–5):1425–1430

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Yañez, F.S. et al. (2023). Synthesis and Characterization of SnO2 Nanoparticles Obtained by Sol–Gel Method. In: Zhang, M., et al. Characterization of Minerals, Metals, and Materials 2023. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22576-5_61

Download citation

DOI: https://doi.org/10.1007/978-3-031-22576-5_61

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22575-8

Online ISBN: 978-3-031-22576-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)