Abstract

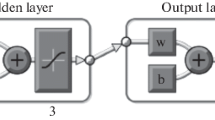

The study aims to examine the challenges and approaches to intelligent monitoring in diversified automated manufacturing in the context of its digitalization as well as to provide a quality monitoring case based on neural networks. Perspectives of artificial neural networks application to real-time monitoring the produced part quality are discussed. The analysis of network structures and a number of algorithms prove that a counter-propagation network can be used as the selected neural network. The work proposes a modification of the counter-propagation network topology for solving the problem of determining the quality parameters of a manufactured part, as well as a structure for intelligent machining quality monitoring. The paper analyzes the challenges of intelligent monitoring in digitalized diversified automated production. A system for intelligent quality monitoring based on neural networks (counter-propagation network) has been developed. Real time quality monitoring together with the control correction will ensure the improved quality and will make the manufacturing as a whole more efficient.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

LNCS Homepage: http://www.springer.com/lncs. Last accessed 2020/02/25

Chryssolouris, G., Mavrikios, D., Papakostas, N., Mourtzis, D., Michalos, G., Georgoulias, K.: Digital manufacturing: history, perspectives, and outlook. Proc. Inst. Mech. Eng. Part B CIRP Ann. 223(5), 451–462 (2009). https://doi.org/10.1243/09544054jem1241

Li, B., Hou, B.-C., Yu, W.-T., Lu, X.-B., Yang, C.-W.: Applications of artificial intelligence in intelligent manufacturing: a review. Front. Inf. Technol. Electron. Eng. 18(1), 86–96 (2017). https://doi.org/10.1631/fitee.1601885

Galar, D., Thaduri, A., Catelani, M., Ciani, L.: Context awareness for maintenance decision making: a diagnosis and prognosis approach. Measurement 67, 137–150 (2015). https://doi.org/10.1016/j.measurement.2015.01.015

Álvares, A.J., Ferreira, J.C.E.: WebTurning: teleoperation of a CNC turning center through the internet. J. Mater. Process. Technol. 179(1–3), 251–259 (2006). https://doi.org/10.1016/j.jmatprotec.2006.03.096

Choudhary, A.K., Harding, J.A., Tiwari, M.K.: Data mining in manufacturing: a review based on the kind of knowledge. CIRP Ann. 20(5), 501–521 (2008)

Ambhore, N., Kamble, D., Chinchanikar, S., Wayal, V.: Tool condition monitoring system: a review. Mater. Today Proc. 2(4–5), 3419–3428 (2015)

Liu, H.L., Dong, J.C., Wang, T.Y., Yu, Z.Q.: The digital manufacturing equipment and development of high speed and high precision with monitoring and intelligent maintenance. Key Eng. Mater. 693, 1948–1953 (2016)

Tao, F., Cheng, J., Qi, Q., Zhang, M., Zhang, H., Sui, F.: Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 94(4), 3563–3576 (2017)

Tao, F., Zhang, M.: Digital twin shop-floor: a new shop-floor paradigm towards smart manufacturing. IEEE Access 5, 20418–20427 (2017)

Brzhozovskii, B.M., Martynov, V.V., Yankin, I.N., Brovkova, M.B.: Dynamic Monitoring of Processing Equipment: Monograph, 312 p. Saratov State Technical University, Saratov (2008)

Liu, C., Vengayil, H., Zhong, R.Y., Xu, X.: A systematic development method for cyber-physical machine tools. J. Manuf. Syst. 48, 13–24 (2018)

Lee, J., Azamfar, M., Singh, J., Siahpour, S.: Integration of digital twin and deep learning in cyber-physical systems: towards smart manufacturing. IET Collaborative Intell. Manuf. 2(1), 34–36 (2020)

DEmilia, G., Gaspari, A., Hohwieler, E., Laghmouchi, A., Uhlmann, E.: Improvement of defect detectability in machine tools using sensor-based condition monitoring applications. Procedia CIRP 67, 325–331 (2018)

Teti, R., Jemielniak, K., O’Donnell, G., Dornfeld, D.: Advanced monitoring of machining operations. CIRP Ann. 59(2), 717–739 (2010)

Alsina, E.F., Chica, M., Trawiński, K., Regattieri, A.: On the use of machine learning methods to predict component reliability from data-driven industrial case studies. Int. J. Adv. Manuf. Technol. 94(5–8), 2419–2433 (2017). https://doi.org/10.1007/s00170-017-1039-x

Aggarwal, C.C.: Neural Networks and Deep Learning. A Textbook. Springer International Publishing AG, Cham (2018)

Hassoun, M.H.: Fundamentals of Artificial Neural Networks. MIT Press, Cambridge, Massachusetts (1995)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Brovkova, M., Martynov, V. (2023). Intelligent Monitoring System Formation in Modern Production in the Context of Manufacturing Digitalization. In: Silhavy, R., Silhavy, P., Prokopova, Z. (eds) Data Science and Algorithms in Systems. CoMeSySo 2022. Lecture Notes in Networks and Systems, vol 597. Springer, Cham. https://doi.org/10.1007/978-3-031-21438-7_49

Download citation

DOI: https://doi.org/10.1007/978-3-031-21438-7_49

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-21437-0

Online ISBN: 978-3-031-21438-7

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)