Abstract

The presence of fault in a structure may lead to catastrophic failure if it remains undetected. So the damage diagnosis is an essential part in health monitoring of structures. Damage in a structure leads to change in the dynamic response which will be helpful for diagnosis of the structure. The relation between modal response and damage vector is in such a way that there exist unique change in response for unique damage. So damage detection is an inverse problem where it is required to relate the modal response to the damage state.

Problems of damage detection are too intricate and the distinct boundary between crisp values cannot be identified for expressing the damage level and measurement deltas. Thus, mapping technique like Fuzzy Logic Inference System (FLIS) can be used for such problems. A fuzzy logic will operate on linguistic variables and associate the data (structural response) with the damage conditions and provide output as level of damage and damage location.

In this study, the change of modal response due to damage in a cantilever beam is investigated and a FLIS is designed for the structural health monitoring purpose. The change in natural frequency is the measurement delta. FLIS is designed using data pool obtained from Finite Element (FE) analysis of different damaged scenarios of the specimen. The FLIS is tested with noise up to 20% and it is found to be robust against small contamination in measurement deltas.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Damage detection is an essential part of structural health monitoring. Damage can be defined as “a deficiency or deterioration in the strength of a structure caused by external loads, environmental conditions, or human errors” [1]. Detection of fault characteristics are necessary that too in non-destructive way so that the down time can be minimized resulting in low cost structural health monitoring [2]. The Damage detection methodologies based on their nature has been classified into classical method, Finite element method, AI method and other miscellaneous methods [3]. The fuzzy inference system is an AI based scheme useful in predicting damages. The fuzzy logic is an inference system which works on predefined rules on fuzzy sets. The fuzzy sets include members of set with continuously graded membership ranging from 0 to 1. [4].

Presence of fault in a structure consequently results in changes of its performance. This changes can be quantified by studying the changes in frequency, mode shapes and maximum extent of free vibration and so on [5]. There exist substantial changes in natural frequency when there is increase in flexibility due to fault. In beams maximum changes are observed at location of higher bending moment [6], also the magnified view of mode shapes are useful in identification of crack location [5]. Sazonov et. al. [7] detected damage by mode shapes and curvature of mode shape by forming fuzzy logic to mimic human like decision making process. The inverse problem of damage detection was studied by Vestroni and Capecchi [8], they related the amount and quality of data required for damage detection and showed the process of finding the optimum number of natural frequency required to locate and quantify the damage uniquely. The use of natural frequency is popular because it is simple to determine [1]. Das and Pahri [9] formulated fuzzy logic based crack detection system and compared its performance with experimental results, the fuzzy logic system show quick response within nanoseconds. Pawar and Ganguli [1] have given detail procedure to use genetic fuzzy logic inference system for fault diagnosis in various type of structures like beam, composite tube etc. Ashigbi et. al. [10] provided crack in beam like structure by saw cut and fuzzy logic was designed by comparing the modal frequency in damaged and undamaged condition measured from experiment as well as with the analytical method. The study concluded that more clustered data pairs will be helpful in better prediction by fuzzy rule base.

The present study include the design of fuzzy logic for a steel cantilever beam on the basis of the change in modal responses, calculated numerically by FE analysis of beam in undamaged and damaged condition, there after forming the fuzzy logic. Fuzzy logic with artificial neural network based supervised learning was used for automatic forming of membership function and rule by Wenning Yu et. al. [11]. To determine the health status of a structure or machine Swayer et al. [12] used the principle of continuum damage mechanics to identify the location and extent of the damage, fuzzy logic was formulated by monitoring the static, eigenvalue, and dynamic responses. Angelov and Filev [13] designed fuzzy logic first with limited information and then modifying the existing rule base, this evolving approach provided summarized rule base and compact fuzzy logic. Pawar and Ganguli [14] related the damage, in composite tube, in the form of matrix cracking with the changes in natural frequency and a robust genetic fuzzy inference system was designed by incorporating the effect of noise in measurement deltas. Chandrasekhar and Ganguli [15] provided details of probabilistic variation of measurement deltas due to various uncertainty and discussed its implication on fuzzy logic damage detection scheme and fuzzy logic architecture was created and tested for contaminated measurements due to the uncertainties involved. Ganguli [1] developed fuzzy logic system for structural health monitoring of helicopter rotor blade, fuzzy logic system showed 100% correct prediction of four damage cases for noise level up to 15%. The present study utilizes C++ codes for reading the measurement deltas and writing command for forming fuzzy logic system using the fuzzy logic tool box in MATLAB.

Vimal et. al. [16] provide the damage as decrease in mass and detection of crack was done by first four natural frequencies. Ganguli [15] provided the damage by changing the Young’s modulus of elasticity of the elements in finite element model. Das and Parhi [17] provide the damage as a cut of various relative depth. In the present study damage parameter is defined as various cut depth as percentage of overall depth of 2 mm wide cut at five different locations along the longitudinal direction of the cantilever beam. The dynamic response of the cantilever beam is evaluated by finite element analysis in ABAQUS. Fuzzy logic deals with partial truth. Fuzzy logic is a logic which maps the given numerical input to a linguistic output (a word or a group of words). This property is useful in classifications of the data in such a manner that output is not affected by the uncertainty of data. Thus, in present study the output has been tested with contaminated measurement deltas.

2 Theoretical Background

A FLIS is an inference scheme which maps the input and output of a problem. In other words it is an inference engine which evaluates and executes a set of predefined rules connecting the input and output of a problem. Fuzzy means vague. It is different from Boolean logic which understand only true and false. Fuzzy logic deals with partial truth.

In FLIS, the system reads measured structural responses (numerical or crisp values) and then convert them into the fuzzy sets (linguistic variables). The inference scheme processes the damage implication through reading and implementing the related rules in the knowledge base and the supplied fuzzy states. The output of this implication procedure is a fuzzy vector, which can also be defuzzified with different methods to get numerical value, describing possible damage levels of predefined regions in the structure.

2.1 Terminologies

Input and Output.

For damage detection problems change in any structural response which is occurred as the consequence of the change in the stiffness of the structure or part of the structure because of prevailing damage, can be used. Natural frequencies are the input and the output are damage location and severity.

Fuzzy Set.

A set in which every member has a degree of membership. A fuzzy set is a set in the form of ordered pairs.

Fuzzy Rules.

The fuzzy rules are usually of the form of “if–then” statements. The ‘If’ part is the antecedent part and then part is known as the consequent part. The two fuzzy parts are connected with words like AND, OR, NOT, etc.

For example,

“If X is A1 and Y is B1, then Z is C1”

Fuzzifier.

It performs the fuzzification and maps numbers into fuzzy sets. This number-to-word transformation is very important in fuzzy logic, as all further operations such as rules are performed on the words. If the input is relative change in first natural frequency, it can be fuzzified as linguistic measures ‘F1R1’, ‘F1R2’ for two different measurements of first frequency. The appropriate choices of linguistic variable and associated range of measurement deltas depend on the problem and can be different for different problems.

Defuzzifier.

In some case if the output is required as numerical value, then defuzzifier is used. Defuzzifier maps the linguistic term (output) into a numerical or crisp value. For our problem we can either get the output as a linguistic variable indicating a portion (or range of length) of structure where fault is present or as a crisp value indicating the location of fault. The former has more significance as the latter one is subjected to accuracy of defuzzification methods.

There are several methods of defuzzification presented by Ross T.J. [18] in the present study centroid method is used. In this method the centroid of the output area is calculated and the crisp value corresponding to the same is called the output of the fuzzy logic. This method is more appealing because it takes into consideration of whole area. It doesn’t give higher weightage to the part of output area with relatively higher membership value.

It can be expressed as given in Eq. (1),

where, \({y}^{*}\) is the defuzzified value and ∫ signifies the algebraic integration.

3 Problem Formulation

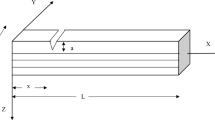

A steel cantilever beam is taken for forming FLIS based SHM scheme for detection of presence of fault along the span. The problem is solved by earlier researchers also. The basic problem of cantilever beam for genetic fuzzy logic formation was done by Pawar et.al [1]. The geometric and material properties of the beam has been taken from Chandrupatla and Belegundu [19]. The cantilever beam is as shown in the Fig. 1.

The beam has been indicated with the distance from the fixed end as the fraction of the span length (L). The SHM scheme is designed to provide the damage parameter and the location of the fault. In the present study the damage is provided in five different locations marked in Fig. 1. The information about the beam’s material and geometric properties is as shown in the Table 1 (Chandrupatla and Belegundu [19]).

For damage detection, the reference baseline can be formed with numerically obtaining the first eight natural frequencies of cantilever beam in bending. For numerical simulation the beam behavior can be depicted as an Euler–Bernoulli beam. In Fig. 1 reference coordinate system can be assumed x as 0 at the fixed end and x equals to L at the tip. The natural frequencies of the beam can be numerically calculated by solving the partial differential equation given in Eq. (2),

Here, E is the Young’s modulus of elasticity, and I is the moment of inertia. The above equation has no exact solution, it can be solved by using finite element method. The problem can be expressed as an eigenvalue problem involving Global Stiffness Matrix [K] and Global Mass Matrix [M] stated as in Eq. (3),

In the above equation, ϕ and ω are the eigenvector (mode shape) and eigenvalue (natural frequency).

The cantilever beam is modelled in ABAQUS, was meshed for a size of 1.75 mm for both undamaged and damaged beam. Based on the computing limitations, the mesh size as well as the cut width (2 mm) is decided, the cut width is chosen slightly greater than the mesh size. The element used in the finite element analysis is a 10- nodded quadratic Tetrahedron element designated as C3D10. The eight different damage cases were introduced at five location namely, 0.1L, 0.3L, 0.5L, 0.7L & 0.9L from the fixed end of cantilever beam as shown in the Fig. 2. Thus, forty finite element models were created and modal analysis was performed. The values of first eight natural frequency was found for all the models.

The steel beam has to be damaged at various location, since a crack or a cut will better represent the damage. So in the present study, cut of various depth dcut was made in the beam for inducing damage. The cut was provided on the top side of the cantilever beam throughout the width of the beam. The depth of cut varies in the proportion of the actual depth of beam, dundamaged as its percentage like 10%, 20%, up to 80%. For example, if the damage parameter is D3 then the depth of cut is 3 mm. The damage parameter used in the present study, is mathematically shown in Eq. (4),

The damage D is discretized into eight different linguistic variables shown in Fig. 3. It can be expressed by the following representation,

For fuzzification of measurement deltas, the whole universe discourse was classified into different sets in the form of F(N)R(n), where linguistic terms F and R indicate the frequency and range, N and n are the indices representing Nth frequency and nth range respectively. Gaussian membership function with a standard deviation (σ) of 15% of the measurement delta is used for fuzzification.

The membership function (μ) used here is as follows in Eq. (5),

where ω and Δω are frequency and change in frequency, m is the mid-point of fuzzy sets.

The membership function plots for measurement delta corresponding to the first and eighth mode focused in the range 0 to 200 is shown in Fig. 4. Table 2 gives the midpoint of the fuzzy sets used for fuzzification of measurement deltas.

The above plot shows only a part of the universe discourse for better visualization of the membership plot; for example, the actual plot of the eighth measurement delta is in the universe discourse of 0 to 982.143. The first and eighth measurement deltas can be expressed in 25 discretized linguistic variables as follows,

The C++ codes are made in such a way that the overlapping ΔZ ranges within ± 2σ are discarded and unique ΔZ ranges have been retained. It automatically provides the standard deviation of the plot as the absolute value of 15% of the ΔZ. Thus the specified linguistic variable will easily cover variation of measurement deltas. The above Gaussian variation of memberships of measurement deltas are chosen so that the small changes in measurement deltas can be incorporated and the results obtained are robust against the contamination. The effect of noise in the form of random deviation in the measurement deltas was introduced in the data pool. The effect can be mathematically expressed as,

where, ΔZnoisy is the changed measurement delta, α is the noise level say 10%, 15% etc. and ε is the random number between 0 to 1.

4 Numerical Results

4.1 Frequencies in Undamaged Condition

The first eight natural frequencies for the beam is as shown in Table 3,

Using the above reference frequencies, the percentage change in frequencies due to various damages was calculated, and the same was scaled up by multiplying a constant 100 so that small damage cases are also identified uniquely. This constitutes eight measurement deltas. The changes in the dynamic response are obtained as expected. The first measurement delta is plotted against the changing damage parameter for damage at different locations in Fig. 5.

The plot shows that the value of measurement delta is higher corresponding to the presence of fault near the fixed end and negligible when fault is near to the free end.

4.2 Fuzzy Logic Rule Base

The measurement deltas were fuzzified into linguistic form, thus written as fuzzy rules. There are a total of unique forty rules, from which six rules for damage at location 0.1L are shown in Table 4 as follows,

On the basis of the above rules, fuzzy logic inference system will be able to predict the damage cases. For example, the fuzzy logic inference system will interpret rule no. 1 as,

-

If

-

ΔZ1 is F1R14 and ΔZ2 is F2R7 and ΔZ3 is F3R6 and ΔZ4 is F4R2 and ΔZ5 is F5R12 and ΔZ6 is F6R1 and ΔZ7 is F7R7 and ΔZ8 is F8R8

-

Then,

-

Damage is D1 at location 0.1L

4.3 Test with Noisy Data

The presence of noise in the data may lead to the failure of the damage detection scheme. The FLIS is robust to these noises because of its spread of inputs in the form of Gaussian membership function. 40 rules stated above were tested with two different level of noises. The noises were introduced in the measurement deltas as stated in Eq. (6). The values of some results showing the prediction by FLIS are mentioned in Table 5. It shows the damage prediction by the Rule no. 1 and 13 with random noises for α = 15%.

The noises are made in a random fashion and for each level of noises 320 trial have been performed. The success rate (SR) can be defined as the ratio of number of trial in which a rule is giving correct results to the total number of trials. The Table 6 shows the success rate FLIS for two values of α.

5 Conclusion

A fuzzy logic rule base has been formulated for the prediction of location of damage, which is very useful for SHM. The procedure has been demonstrated by its application in a steel cantilever beam. It is observed that the fuzzy rules were capable of detection damages cases which were provided as the rules.

To check the reliability of the prediction, random noises within 20% was introduced in the measurement deltas and the working of fuzzy logic was checked. It is noted that the success rate of the prediction is as high as 99.68%. It shows the robustness of the fuzzy logic against uncertainty dues to material properties and modeling. More robustness can be achieved with more data and more number of damage location.

C++ codes prepared are capable of handling large data, thus by creating FE model of the other structures with choosing appropriate damage parameter and measurement deltas, FLIS can be used for other structures also.

References

Pawar, P., Ganguli, R.: Structural Heath Monitoring using Genetic Fuzzy System, 1st edn. Springer, London (2011)

Nayak, B.B., Sahu, S., Roy, S.: Damage detection in structural elements: using optimization of fuzzified rules. Mater. Today Proc. 44, 797–800 (2021)

Parhi, D.R.K., Kumar, D.A.: Analysis of methodologies applied for diagnosis of fault in vibrating structures. Int. J. Veh. Noise Vib. 5(4), 271–286 (2009)

Zadeh, L.A.: Information and control. Fuzzy sets 8(3), 338–353 (1965)

Agarwalla, D.K., Parhi, D.R.: Effect of crack on modal parameters of a cantilever beam subjected to vibration. Procedia Eng. 51, 665–669 (2013)

Quila, M., Mondal, S.C., Sarkar, S.: Free vibration analysis of an un-cracked & cracked fixed beam. J. Mech. Civil Eng. 11(3), 76–83 (2014)

Sazonov, E.S., Klinkhachorn, P., Gangarao, H.V., Halabe, U.B.: Fuzzy logic expert system for automated damage detection from changes in strain energy mode shapes. Nondestruct. Test. Eval. 18(1), 1–20 (2002)

Vestroni, F., Capecchi, D.: Damage detection in beam structures based on frequency measurements. J. Eng. Mech. 126(7), 761–768 (2000)

Das, H.C., Parhi, D.R.: Online fuzzy logic crack detection of a cantilever beam. Int. J. Knowl.-Based Intell. Eng. Syst. 12(2), 157–171 (2008)

Ashigbi, D.M., Sackey, M.N., Fiagbe, Y.A., Quaye-Ballard, J.: Vibration response based crack diagnosis in beam-like structures using fuzzy inference system. Sci. Afr. 14, e01051 (2021)

Yu, W., Wang, Y., Gui, W., Yang, C.: A vibration fault diagnosis system of HGS based on FNN. IFAC Proc. Vol. 39(13), 252–257 (2006)

Sawyer, J.P., Rao, S.S.: Structural damage detection and identification using fuzzy logic. AIAA J. 38(12), 2328–2335 (2000)

Angelov, P.P., Filev, D.P.: An approach to online identification of Takagi-Sugeno fuzzy models. IEEE Trans. Syst. Man Cybern. Part B (Cybern.) 34(1), 484–498 (2004)

Pawar, P.M., Ganguli, R.: Matrix crack detection in thin-walled composite beam using genetic fuzzy system. J. Intell. Mater. Syst. Struct. 16(5), 395–409 (2005)

Chandrashekhar, M., Ganguli, R.: Uncertainty handling in structural damage detection using fuzzy logic and probabilistic simulation. Mech. Syst. Signal Process. 23(2), 384–404 (2009)

Mohan, V., Parivallal, S., Kesavan, K., Arunsundaram, B., Ahmed, A.F., Ravisankar, K.: Studies on damage detection using frequency change correlation approach for health assessment. Procedia Eng. 86, 503–510 (2014)

Das, H.C., Parhi, D.R.: Detection of the crack in cantilever structures using fuzzy Gaussian inference technique. AIAA J. 47(1), 105–115 (2009)

Ross, T.J.: Fuzzy Logic With Engineering Applications, 3rd edn. John Wiley & Sons, United Kingdom (2005)

Chandrupatla, T.R., Belegundu, A.D.: Introduction to Finite Elements in Engineering. Prentice Hall, Englewood Cliffs (2001)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Sharma, A., Thankachan, P., Pillai, T.M.M. (2023). Fuzzy Logic-Based Inference System for Structural Health Monitoring of a Cantilever Beam. In: Marano, G.C., Rahul, A.V., Antony, J., Unni Kartha, G., Kavitha, P.E., Preethi, M. (eds) Proceedings of SECON'22. SECON 2022. Lecture Notes in Civil Engineering, vol 284. Springer, Cham. https://doi.org/10.1007/978-3-031-12011-4_69

Download citation

DOI: https://doi.org/10.1007/978-3-031-12011-4_69

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-12010-7

Online ISBN: 978-3-031-12011-4

eBook Packages: EngineeringEngineering (R0)