Abstract

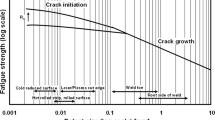

The article deals with the issue of increasing the efficiency of the machining operation of hard-to-treat steels with a heat-strengthened surface and contact fatigue failures on the case study of restoring the rolling surface of mounted wheels. The paper analyzes the statistical data and shows that the weakest point of the repair process and quality assurance is machining of wheel tread. A new machining flow chart based on the softening of the surface layer by a powerful local laser-based heating source is proposed. When the material was machined, the effect of hardness loss in the cutting zone during heating was used. The article analyzes the temperatures in hard-face plates when the latter are machined.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Arrazola PJ, Özel T, Umbrello D, Davies M, Jawahir IS (2013) Recent advances in modelling of metal machining processes. CIRP Ann Manuf Technol 62(2):695–718. https://doi.org/10.1016/j.cirp.2013.05.006

Gutiérrez I, Altuna MA (2008) Work-hardening of ferrite and microstructure-based modelling of its mechanical behaviour under tension. J Mater 56(17):4682–4690. https://doi.org/10.1016/j.actamat.2008.05.023

Abouridouanea M et al (2019) Microstructure-based approach to predict the machinability of the ferritic-pearlitic steel C60 by cutting operations. Procedia CIRP 82:107–112. https://doi.org/10.1016/j.procir.2019.04.013

Abouridouane M, Klocke F, Lung D, Veselovac D (2015) The mechanics of cutting: in-situ measurement and modelling. Procedia CIRP 31:246–251. https://doi.org/10.1016/j.procir.2015.03.048

Puls H, Klocke F, Lung D (2014) Experimental investigation on friction under metal cutting conditions. Wear 63–71. https://doi.org/10.1016/j.wear.2013.12.020

Neishi Y, Makino T, Matsui N, Matsumoto H, Higashida M, Ambai H (2013) Influence of the inclusion shape on the rolling contact fatigue life of carburized steels metall. Phys Metall Materials Sci 44(5):2131–2140. https://doi.org/10.1007/s11661-012-1344-9

Alley ES, Neu RW (2010) Microstructure-sensitive modeling of rolling contact fatigue. Int J Fatigue 32(5):841–850. https://doi.org/10.1016/j.ijfatigue.2009.07.012

Kabo E (2002) Material defects in rolling contact fatigue–influence of overloads and defect clusters. Int J Fatigue 24(8):887–894. https://doi.org/10.1016/S0142-1123(01)00193-1

Nigon GN, Isgor OB, Pasebani S (2021) The effect of annealing on the selective laser melting of 2205 duplex stainless steel: microstructure, grain orientation, and manufacturing challenges. Opt Laser Technol 134. https://doi.org/10.1016/j.optlastec.2020.106643

Sarkar S, Mukherjee S, Kumar CS, Kumar Nath A (2020) Effects of heat treatment on microstructure, mechanical and corrosion properties of 15–5 PH stainless steel parts built by selective laser melting process. J Manuf Process 50:279–294. https://doi.org/10.1016/j.jmapro.2019.12.048

Oh WJ, Son Y, Cho SY, Yang SW, Shin GY, Shim DS (2020) Solution annealing and precipitation hardening effect on the mechanical properties of 630 stainless steel fabricated via laser melting deposition. Mater Sci Eng 794. https://doi.org/10.1016/j.msea.2020.139999

Wang C, Shen XJ, An ZB, Zhou LC, Chai Y (2016) Effects of laser shock processing on microstructure and mechanical properties of K403 nickel-alloy. Mater Des 89:582–588. https://doi.org/10.1016/j.matdes.2015.10.022

Kokawa H (2011) Potential of grain boundary engineering to suppress welding degradations of austenitic stainless steels. Sci Technol Weld Join 16(4):357–362. https://doi.org/10.1179/1362171811Y.0000000021

Zhang QK, Wang XM, Song ZL (2021) Effects of thin cladding layer and annealing treatments on mechanical properties of AISI4340 steel. Eng Fract Mech 256.https://doi.org/10.1016/j.engfracmech.2021.107997

Sun SD, Liu QC, Brandt M, Luzin V, Cottam R, Janardhana M et al (2014) Effect of laser clad repair on the fatigue behavior of ultra-high strength AISI4340 steel. Mater Sci Eng A 606:46–57. https://doi.org/10.1016/j.msea.2014.03.077

Wen SF, Li S, Wei QS, Yan CZ, Zhang S, Shi YS (2014) Effect of molten pool boundaries on the mechanical properties of selective laser melting parts. J Mater Process Tech 214:2660–2667. https://doi.org/10.1016/j.jmatprotec.2014.06.002

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Biserikan, M., Kashbulina, A. (2023). Improvement of Edge Cutting Machining of Materials with Fatigue and Thermomechanical Failures. In: Guda, A. (eds) Networked Control Systems for Connected and Automated Vehicles. NN 2022. Lecture Notes in Networks and Systems, vol 510. Springer, Cham. https://doi.org/10.1007/978-3-031-11051-1_30

Download citation

DOI: https://doi.org/10.1007/978-3-031-11051-1_30

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-11050-4

Online ISBN: 978-3-031-11051-1

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)