Abstract

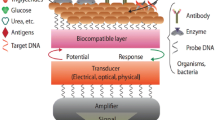

A biosensor is a measuring system that contains a biological receptor unit that is highly selective for target analytes (DNA/RNA, proteins, or simple chemicals like glucose or hydrogen peroxide). Carbon nanomaterials (CNMs) are appealing possibilities for enhancing biosensor sensitivity while maintaining low detection limits due to their ability to immobilize a high number of bioreceptor units in a small space while also acting as a transducer. Furthermore, CNMs can be functionalized and conjugated with organic compounds or metallic nanoparticles; the generation of surface functional groups leads to the formation of nanomaterials with novel capabilities (electrical, physical, chemical, optical, and mechanical). CNMs have been frequently used in biosensor applications due to their fascinating features. Carbon nanotubes (CNTs) and carbon fibers (CFs) are used as scaffolds for biomolecule immobilization at their surfaces, as well as transducers for signal conversion involved in biological analyte recognition. This chapter provides an in-depth examination of the synthesis and functionalization of CNMs, as well as their potential applications in electrochemical devices (based primarily on the detection of current, potential, impedance, or other electrical property).

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keyword

1 Overview

Carbon atoms have a narrow band gap between their 2s and 2p electronic shells can undergo sp, sp2, and sp3 hybridizations. The two most well-known allotropic forms of carbon are diamond (sp3 hybridization) and graphite (sp2 hybridization) [1]. Graphite is the most widely used natural material option, with applications in a wide range of large-scale industrial technical problems. Because of the high demand for synthetic graphite in the market, its use has increased significantly in recent years. Widespread scientific in-depth investigation into graphite has shown that its exclusive integration of physical and chemical features of stacked layers of hexagonal sp2 carbon arrays. Over the last two decades, graphite has been used as a precursor material to generate a wide range of carbon nanomaterials using enhanced manufacturing processes and nanostructured materials, most notably fullerenes, single- and multi-walled nanotubes, and grapheme [2]. The geometrical structure of nanomaterial particles is the primary criterion for their classification, since nanomaterials have size-dependent physical, chemical, and biological properties. These particles may take the form of tubes, horns, spheres, or ellipsoids. CNTs and carbon nanohorns (CNHs) are tube or horn-shaped particles, respectively; fullerenes contain spherical or ellipsoidal nanoparticles [3]. Due to low toxicity and large-scale demand, CNMs have numerous technical uses in micro and nanoelectronics, gas storage, the fabrication of conductive polymers, composites, paints, textiles, batteries with extended lives, and biosensors [4].

According to their structural dimensions, NMs are divided into four classes (Fig. 1). Zero-dimensional nanomaterials (0D-NMs, i.e., fullerenes, particulate diamonds, and carbon dots) are nanoscale materials in all dimensions. One-dimensional nanoscale materials (1D-NMs, i.e., CNTs, CNFs, and diamond nanorods) have one dimension larger than nanoscale. Thin-sheet materials with nanoscale thickness are commonly referred to as two-dimensional NMs (2D-NMs, i.e., graphene, graphite sheets). Fibrous, powdery, polycrystalline, and multilayer materials are all examples of three-dimensional NMs (3D-NMs), which are made up of various building blocks, such as 0D-, 1D-, and 2D-NMs [5]. 2D hexagonal carbon lattices make up the majority of carbon nanostructures. However, in fact, employing a carbon lattice as a starting material hinders the creation of carbon nanostructures. Graphitic nanostructures are typically made by reorganizing carbon atoms from sources such as graphite, organic gases, or volatile organic compounds, as opposed to graphene nanoplatelets and multilayer carbon nanosheets that can be isolated from naturally occurring graphite, using instrumental techniques. Carbon vapor deposition (CVD), laser ablation, and arc discharge are the most popular methods [6, 7].

Carbon nanoallotropes: Carbon dots, nanodiamond, fullerenes, carbon nanotubes, carbon nanohorns, graphene, carbon nanoribbons, and combined superstructures. Reprinted from [5] with permission

Because of their large surface area, CNMs have been widely used in electrochemical biosensors because many detection events can occur simultaneously on their surface and biomolecule attachment is easy. These materials have electrical, photonic, physical, and mechanical qualities that allow them to be used in biosensors [8]. These materials are inexpensive, have a wide voltage range over which the CNM electrode can perform, and have good electrocatalytic activity for a variety of redox systems (chemical and biological). Biosensors’ electrochemical performance can be enhanced by altering their structure to modify their electrical, chemical, and structural properties for a given application [9]. CNMs-based surfaces can be easily tailored through various covalent and non-covalent functionalization methods, which improve their electrochemical sensing capabilities. Furthermore, these materials are highly biocompatible. Electrochemical sensors based on CNTs have higher sensitivity, selectivity, fast electron transfer rate, and low detection limits [10, 11].

Doping can have a significant impact on the electronic, mechanical, and conducting properties of CNTs [12]. Furthermore, the different types of CNMs have different densities of states. The density of states of the CNMs-based electrode determines the electron transfer capabilities with target molecules. For a faster electron transfer process, the energy of electrons in the electrode should be equivalent to the energy of electrons in the redox reaction. The chance of electrons having enough high energy to transfer to the redox system grows as the density of states increases. The density of states in CNMs varies with structure and can be altered by modulating their atomic bonding patterns. It is also determined by the tube diameter in the case of CNTS. By carefully peeling off CNTs, the density of states can be enhanced. By altering the electronic structure of multi-walled CNTS, controlled oxidation can improve their electrochemical performance [5, 13]. Inorganic particles can be effectively chemically linked to CNMs to modify the electronic structure of each component, resulting in hybrid structures with synergistic electrocatalytic activity [9].

2 Carbon Nanomaterials

Fullerenes, C60 molecules of varying sizes (30–3000 carbon atoms), were found in the early 1980s. Fullerenes are closed hollow cages composed of sp2-hybridized carbon atoms organized in 12 pentagons and a calculable number of hexagons based on the total amount of carbon atoms. A fullerene containing 20 + 2n carbon atoms will include n hexagons [5]. The closed shapes of the fullerenes dictate the number of pentagons, which is always 12 in those with perfect structures known as truncated icosahedral (stable carbon nanostructures). As a result, C60 and other fullerenes (C70, C76, C82, and C84) can be thought of as a carbon nanoallotrope with hybridization between sp2 and sp3 [8]. The carbon atom arrangement is pyramidalized rather than planar, and thus, a “pseudo”-sp3-bonding component must be present in the essentially sp2 carbons. C60 is succinctly a spherical molecule with an exterior diameter of 0.71 nm and chemical characteristics that are extremely comparable to organic molecules. It is, nonetheless, the smallest carbon nanostructure and a representative 0D carbon nanoallotrope [7]. Because of its ability to avoid the formation of double bonds in the pentagonal rings, the C60 molecule is commonly stated to be not superaromatic. There are two types of bond lengths discovered using an X-ray diffraction pattern, one with a length of 1.38 Å connecting C-atoms common to a couple of neighboring hexagons and the other with a length of 1.45 Å connecting C-atoms common to the pentagon-hexagon pair. Nowadays, vaporization of graphite by pyrolysis, radio-frequency-plasma, or arc discharge-plasma processes is widely used for commercial-scale production of fullerenes [14, 15].

Among the many investigations on fullerene, one of the most admirable discoveries is the ability of the C60 molecule to acquire from one to six electrons, even though it is already rich in electrons, forming equivalent anions. This is only feasible because the C60 molecule’s non-binding LUMO molecular orbitals have an extremely low energy level [5]. Fullerenes also have good chemical stability, huge surface area, high mechanical resistance, and the ability to create a superconductor when mixed with alkali metals and can be easily modified with a wide range of functionalized chemicals via structural flaws or the intermediary production of epoxy rings [7]. Furthermore, fullerenes can interact hydrophobically with CNTs and graphene materials. Nevertheless, fullerenes have a high electron exchange capacity and can mediate electron transfer in the construction of various electrochemical sensors and biosensors with electrocatalytic response [15].

Carbon nanotubes (CNTs) are one of the allotropic modifications of carbon that were discovered in 1991 by Japanese scientist Iijima [16]. Using sp2 hybridization, each carbon atom with three electrons forms trigonally coordinated bonds to three other carbon atoms in CNTs. CNT is made up of one layer of graphene that has been seamlessly rolled into the shape of a hollow tube. Carbon nanotubes are distinguished by rolled graphene sheets stacked in cylindrical/tubular structures with diameters of several nanometers. CNTs can vary in length, diameter, number of layers, and chirality vectors (symmetry of the nulled graphite sheet) [7].

CNTs are classified into two types based on their structures: single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs). SWCNTs are made by rolling a single layer of graphite (referred to as a graphene layer) into a seamless cylinder (long wrapped graphene sheets). SWCNTs have a length-to-diameter ratio of 1000 or larger, allowing them to be called a nearly one-dimensional structure, as previously stated. The majority of SWCNTs have a diameter of approximately 1–3 nm, (whereas MWCNTs have a diameter of 5–25 nm and a length of approximately 10 nm) [6]. Two separate areas with diverse physical and chemical properties form a SWCNT. The tube’s sidewall is the first, and the tube's end cap is the second. The terminating cap is made up of pentagons and hexagons. The well-known C60 hemisphere appears to be the smallest cap that fits on to the cylinder of the carbon tube. This cap is well supported by the smallest experimental value of CNT diameter of 0.7 nm [17].

MWCNTs are a cluster of concentric SWCNTs of varied diameters (made of many layers of graphite rolled in on themselves to produce a tube shape). The length and diameter of these structures, as well as their characteristics, differ greatly from those of SWCNTs. MWCNTs have an interlayer distance of about 3.3 Å, which is comparable to the gap between graphene layers in graphite [6]. MWCNTs (double-walled carbon nanotubes, or DWCNTs) are a unique case that must be noted due to their morphology and features that are extremely similar to SWCNTs [18]. The gram-scale synthesis of DWCNTs was first proposed in 2003 by the chemical vapor deposition (CVD) technique, which involves the selective reduction of oxide solid solutions in methane and hydrogen [19].

The single layer of graphene in CNTs can be rolled in a variety of ways. The CNTs are classified as zigzag, armchair, or chiral based on the number of unit vectors in the graphene crystal lattice along two directions in the honeycomb structure, as can be seen in Fig. 2a. The chirality of carbon nanotubes has a significant impact on their properties. SWCNTs' electrical properties are determined by their chirality or hexagon orientation with respect to the tube axis [20]. The chirality of a CNT determines whether it is metallic or semiconducting in nature. The electrochemical properties of SWCNTs are determined by their roll-up vectors (n, m). The SWCNTs are metallic if the roll-up vectors n − m = 3q, where q can be any integer/zero. If n − m = 3q, the SWCNTs are semi-conductive. If n = m, the nanotubes are referred to as armchair. If m = 0, they are referred to as zigzag; otherwise, they are referred to as chiral [21]. Furthermore, depending on the diameter of the tubes, SWCNTs can exhibit electrical conductivity or semi-conductive properties. Armchair SWCNTs have higher electrical conductivity than copper, whereas zigzag and chiral SWCNTs have semi-conductive properties that allow them to be used in sensor fabrication [20,21,22,23].

Structure and models of carbon nanotubes in function of their number of walls. a Single-wall carbon nanotubes (SWCNTs) structures in function of their chirality (zigzag, armchair, and chiral); b double-walled carbon nanotubes (DWCNTs); and c multi-walled carbon nanotubes (MWCNTs) made up of several concentric sheets. Reprinted from [24] with permission

When compared to other fibrous materials, CNTs have superior physical properties such as rigidity, strength, and elasticity. They have a higher aspect ratio (length-to-diameter ratio) than other materials. CNTs’ high aspect ratios can range from 102 to 107 [23]. Because of their smaller diameter, SWCNTs have a higher aspect ratio than MWCNTs. In addition, they have high thermal and electrical conductivities when compared to other conductive materials. CNTs have a strength that is 10–100 times that of strong steel at a fraction of the weight [25]. These nanomaterials do have such distinguishing characteristics that make them potential candidates for use in technological fields. Because of their high electron transfer capabilities, carbon nanotubes have been used as an electrode in electrochemical reactions [7, 26]. They can be used in electrochemical sensors because they allow electron transfer in chemical reactions at the electrode interface. CNTs have numerous applications in nano-electro-mechanical systems [4, 27, 28].

3 Synthesis

As aforementioned, carbon nanotubes were discovered in the carbon soot of graphite electrodes during an arc discharge experiment in 1991, using a current of 100 amps to produce fullerenes [16]. However, two researchers at NEC’s Fundamental Research Laboratory produced the first macroscopic CNTs in 1992 [29]. The same method was used as in 1991. Because of the high temperatures caused by the discharge, the carbon contained in the negative electrode sublimates during this process. Because carbon nanotubes were discovered using this method, it has become the most widely used method of CNT synthesis.

First, a carbon arc discharge with a suitable catalyst was used to synthesize SWCNTs or MWCNTs with a high yield and greater control over the size of the synthesized nanotubes [6]. The CVD method has resulted in CNTs with smaller diameters, lower yield, but higher quality. The laser ablation method produces a lower yield and a much smaller diameter, but it produces much finer quality. Metallic and semi-conductive carbon nanotubes can be synthesized via selective functionalization, selective destruction via electrical heating, or separation via density gradient ultra-centrifugation [23].

Using transition metal nanoparticle catalysts, CVD was used to produce high-quality SWCNTs and MWCNTs in vertically aligned arrays. They were synthesized on a massive scale using arc discharge and CVD methods (Co-Mo catalysts). The CVD method, which requires simple equipment and mild temperature and pressure conditions, is better suited for large-scale CNT production than the other two methods. Vertically aligned arrays of CNTs were created using metallic and quasi-crystalline substrates. CNTs have been reported to be synthesized by pyrolyzing metal carbonyls in the presence of other hydrocarbons. The presence of transition metals in graphite electrodes has resulted in CNTs with higher product output and reproducibility [5]. Transition metal catalysts and the CVD method have been investigated to obtain high-quality CNTs in vertically aligned arrays. Catalysts are used in the CVD synthesis to grow nanotubes on substrates. Metallic nanoparticles are used as catalysts, and their size is determined by the diameter of the nanotubes to be synthesized (0.5–5 nm for SWCNTs, 8–10 nm for MWCNTs) [7]. Ni, Co, and Fe nanoparticles have been used as nano catalysts in the synthesis of CNTs. The CVD reactors use inert gas methane to produce SWCNTs and ethylene to produce MWCNTs. The substrate is heated to 850–1000 °C for SWCNTs and 550–700 °C for MWCNTs synthesis [6, 23]. Carbon is produced during the thermal decomposition of hydrocarbons and is dissolved in the metal nanocatalyst. When a certain concentration of carbon is reached, a semi-fullerene cap forms, which serves as the fundamental unit for the growth of the nanotube. Carbon is continuously flowed from the hydrocarbon source to the catalyst particle. Finally, CNTs are obtained following a purification process and the removal of catalysts from the tips and surfaces of nanotubes [30]. The final step is being researched so that high-quality synthesized material can be obtained.

When different carbon nanomaterials are purified, often with acid(s) at elevated temperatures and for extended periods of time, changes in the amount of metallic catalyst nanoparticles, surface functionalization of carbon, and overall morphology occur. Spectroscopic studies revealed that changes in the morphology of CNF, for example, were significant depending on their original morphology [31]. Although arc discharge and laser ablation methods produce a large amount of SWCNTs, they have drawbacks as well, such as the need to evaporate C-atoms from solid state sources at very high temperatures (>3000 °C), and the nanotubes bundle together during formation, which limits their applications [32]. The length of a CNT is determined by the time it takes for it to grow. The diameter of synthesized SWCNTs ranges from 0.7 to 3 nm, while MWCNTs range from 10 to 200 nm. Because of their large surface area, CNTs can effectively load various types of drugs on their internal and external surfaces [27].

Graphene nanoribbons (GNR): Thin ribbons of graphene monolayers are a new type of graphene that is gaining a lot of attention in the scientific community. The majority of research on these materials has concentrated on the thin elongated graphene monolayer strips that can be created by “unzipping” CNTs [9, 33]. Graphene nanoribbons are frequently described as a one-dimensional sp2-hybridized carbon strip of finite dimension with defined edges, with carbon atoms that are not three-coordinated. Graphene nanoribbons are classified into three types based on their edge termination: (i) armchair, (ii) zigzag, (iii), and chiral nanoribbons [34]. Edge reconstruction is possible because the edge carbon atoms are not bound saturated. While the edge pattern of the armchair graphene nanoribbon is stable due to the presence of strong dangling bonds, edge reconstructions are expected at high temperatures for zigzag graphene nanoribbons. Hydrogen saturation is commonly used to stabilize the edge structure [35]. Other edge profiles involving pentagonal and heptagonal carbon rings have been observed; however, such edge reconstructions are extremely rare. Graphene nanoribbons, like graphene, can have bilayered or few-layered configurations; the design is designated a graphitic nanoribbon when more layers of finite graphene strips are placed together [36, 37].

Carbon nanodiamonds (CNDs) are a structural family of nanocarbons that includes fullerens, tubes, onions, and horns. The first nanoscale diamond particles were created in the 1960s by detonating carbon-containing explosives. However, it took nearly three decades after the initial discovery for these nanodiamonds to become more well-known in the scientific world. Only in the late 1990s did nanodiamonds begin to be studied more thoroughly, and they gradually began to find their way into various applications [31]. CNDs are diamondoid-like sp3 carbon nanoparticles with sizes more than 1–2 nm but less than 20 nm. They are not dispersible, and thus, top-down processes like jet milling or microdiamond abrasion are used to make them. With diameters greater than 20 nm, this form of nanostructure acts as bulk diamonds [9]. Diamondoids, on the other hand, are naturally occurring sp3 carbon nanostructures with diameters less than 1 nm found in petroleum deposits. The sp3-hybridized surface-bound carbon atoms of these diamondoids are generally attached to hydrogen or other non-carbon atoms. As a result, they have properties that are more akin to organic molecules than bulk diamonds [31]. As the diameter of the sp3 carbon cluster increases, the percentage of carbon atoms at the surface drops, and the diamond feature of the nanoparticles becomes more prominent [38].

Nanodiamonds’ size, shape, and quality are determined by the procedures employed to make them. Detonating an explosive mixture of carbon-containing substances such as trinitrotoluene and hexogen is the most well-known method for mass-producing nanodiamonds. Up to 75% of the resulting soot is made up of nanodiamonds with diameters of 4–5 nm and a limited size distribution. Because of their small size and narrow size distribution, they are a popular research topic. They tend to aggregate with each other if not thoroughly cleaned. Furthermore, they are relatively chemically inert while remaining reactive enough to allow functionalization. Another benefit is their large relative surface area, which can be used to effectively attach various compounds. They have high hardness, thermal conductivity, refractive index, coefficient of friction, insulation properties, and high biocompatibility [31, 39].

Carbon nanohorns. Iijima discovered SWNHs in 1999 while researching CNT formation [40]. Nanohorns are tubular/conical structures made of a single graphenic layer. They are typically found in large spherical aggregates with diameters ranging from 80 to 100 nm and resembling dahlia flowers. Individual nanohorns have diameters of 1–2 nm at the tips and 45 nm at the base of the cone. The wall-to-wall distance between SWNHs is approximately 0.4 nm [9]. Other types of SWNH aggregations were observed that resembled the characteristics of buds and seeds. Cones are formed by cutting a wedge from a single graphenic layer and connecting the exposed edges in a seamless manner. They are more easily synthesized than CNTs, on a larger scale, at room temperature without the use of metal catalysts. They can be created through the use of carbon rod arc discharge, laser ablation of pure graphite, and Joule heating. CNHs have a high surface area and good porosity, which can be used to their advantage in the field of biosensing [8].

Carbon dots (CDs) are quasi-spherical carbon nanoparticles with diameters of 2–10 nm that have a high oxygen content and composed of various volumetric ratios of graphitic and turbostratic carbon. CDs are typically amorphous and contain mostly sp3-hybridized carbon [9]. Carbon nanodot, carbon quantum dot, and graphene quantum dot classes are mentioned in addition to CD classes. As a result, graphene quantum dots are frequently used in electrochemical sensors. They have a lateral dimension of about 100 nm and are made up of up to ten single atom layers with a visible graphene lattice [14]. CDs have been proved to be non-toxic in vitro experiments. They were also a promising candidate for biosensor components because of their capacity to operate as an electron donor and receiver. As a result, CDs are the CNM with the most biosensor publications, trailing only graphene and carbon nanotubes. Carbon nanodots are relatively smaller (spherical particles of about 10 nm in diameter). They are typically used in electrochemical sensor assemblies after being functionalized with redox labels or receptors [15].

Carbon nanodots are created utilizing a variety of processes, and there has been a surge of interest in carbon nanomaterials in recent years. Carbon nanodots are typically manufactured utilizing a top-down process based on a laser ablation strategy and treated mixes of graphite powder and cement. This process creates the main structure of the carbon dots, which will then be treated with oxidative to enrich the surfaces of the carbon dots with reactive oxygen groups [14, 15]. Surface passivation occurs with a range of organic compounds and oligomers that are often incorporated on carbon dots. Because of the multiple advantages of the electrochemical etching strategy, such as abundant conductive carbonaceous substrates (graphite rod), abundant natural resources, and low cost, the electrochemical etching method, a top-down approach, is a viable method to create carbon nanodots [2]. Carbon nanodots’ dimensions and chemical compositions can be easily adjusted by adjusting a variety of synthetic parameters such as pH, concentration, electrolyte composition, and electrochemical mode of electrolysis (potentiostatic, galvanostatic, and potential varying techniques, etc.). However, long-term stability, which is one of the most crucial features in a biosensor, is hardly obtained [5].

Carbon black (CB) belongs to the amorphous nanocarbon family, with average diameters ranging from 3 to 100 nm, and has lately been used in biosensing applications, compared to nanocarbons that are notable in biosensor applications [9]. It is a potential nanocarbon for biosensing applications because of its low cost, high analytical sensitivity, experimental simplicity, mobility, and good selectivity. CB has also been claimed to be a feasible alternative to other members of the family, such as graphene and graphene-like structures, fullerenes, and CNTs, and to boost the activity in enzyme biosensors, due to its high conductivity [5, 41]. Particle size, porosity, surface chemical characteristics, aggregate morphology, and surface area define the physical properties of CB, which is made up of sp2 and sp3 hybridized carbon atoms. CB is also frequently seen as a loosely bound agglomerates piled on top of one another [15]. This makes it difficult to collect consistent and rigorous data in the production operations of biomolecular applications of CB, such as obtained with graphene and graphene-like structures [7]. In addition, characterization methods for these structures, which are each a few unit cell size, are required.

4 Functionalization of CNMs

CNMs are regarded to be excellent building blocks for manufacturing nanoscale functionalized materials due to their huge surface area and outstanding electrical and mechanical capabilities. In order to develop diverse functionalized CNMs, a wide range of organic and inorganic NMs have been investigated to date. Based on the difference in bonding between CNMs and their functionalized derivatives, these techniques are categorized into two categories: covalent and non-covalent functionalization [2, 42].

Covalent functionalization in CNMs depends on reactions with oxygen-containing groups bonded to the CNMs'-conjugated skeleton. Non-covalent functionalization involves the use of various functional molecules or active species as assembly mediators to functionalize the surface of CNMs through non-covalent interactions [43]. The most straightforward method for chemical functionalization of CNMs is to insert carboxylic acid (–COOH) groups on the surface via an oxidation process that uses concentrated acids such as H2SO4, HNO3, HCl, or H2O2, or acid mixture [2, 44]. Furthermore, the structure of these carboxylic acids can be used for covalent attachment of organic or inorganic groups, resulting in highly dispersible carbon materials [12]. Carbodiimide compounds (Fig. 3), which can activate carboxyl groups on CNTs for direct reactivity with primary amines in biomolecules, can be used to react carboxylated CNTs with biomolecules. N-ethyl-N'-(3-dimethylaminopropyl) carbodiimide hydrochloride is a common water-soluble carbodiimide (EDC). When EDC combines with carboxyl groups, it forms an intermediate o-acylisourea ester that can be easily displaced by primary amine in the biomolecule [45].

Reaction scheme for EDC and EDC-NHS-based covalent crosslinking of biomolecule with carbon nanotube. Reprinted from [43] with permission

Surface modification of CNMs is critical for biomedical applications. Firstly, most CNMs are insoluble in aqueous solutions. Nonetheless, several biomedical applications of these materials could be understood on the basis of their water solubility and ease of use in a biological system [27]. These materials' solubility can be increased with the right surface modification. Second, the surface treatment can imbue the CNMs with properties that can be used in various applications. The surface treatment is also effective in reducing the toxicity of CNMs [46,47,48].

The modification of CNMs with metal and metal oxide NPs, with strict control over the size, shape, and crystalline structure, has become critical for nanotechnology applications in many fields such as medicine, catalysis, and electronics [8]. Surface deposition of metals and metal oxides onto CNMs has traditionally been accomplished through a bottom-up approach. Many wet chemistry methods, such as hydrothermal, microwave synthesis, and sol–gel processing, have been developed to date for the synthesis of metal and metal oxide NPs [48]. The role of hydrothermal synthesis is performed in an autoclave using an aqueous solution reaction. The inner temperature of the autoclave can be raised above the boiling point of water, reaching the pressure of vapor saturation. Hydrothermal synthesis is commonly used for depositing metal and metal oxide NPs on CNMs such as graphene and CNTs, which can be easily obtained by hydrothermally treating peptized precipitates of a metal precursor with water. By controlling the solution composition, reaction temperature, pressure, solvent properties, additives, and aging time, the hydrothermal method can be used to monitor particle size, morphology, crystalline phase, and surface chemistry [8].

5 Application of CNMs in Biosensing

The sensors and biosensors developed are usually evaluated for some parameters that determine their analytical performance, such as sensitivity, selectivity, limit of detection (LOD) and quantification (LOQ), repeatability, and reproducibility, in order to guarantee the quality of the results obtained and to validate the analytical method. Different modifications to the same base electrode can result in sensors with varying specificities for a given analyte. Numerous studies involving electrochemical sensors and biosensors based on graphene, carbon nanotubes, and fullerene have been described in recent literature for the detection of drugs and compounds of clinical interest.

Arvand and Hemmati developed a nanocomposite of graphene quantum dots (GQDs), Fe3O4 nanoparticles, and functionalized MWCNT (Fe3O4@GQD/f–MWCNT) for sensitive detection of progesterone (P4). The estimated LOD and sensitivity were 2.18 nmol L−1 and 16.84 µA L µmol−1, respectively. This sensor demonstrated outstanding stability, selectivity, sensitivity, and repeatability, and it could be successfully used to determine P4 in human serum samples and pharmaceutical items with high recoveries and without interference from interfering substances [49].

Sutradhar and Patnaik using thiol-capped gold nanoparticle-based nanocomposite with 3-amino-5-mercapto-1,2,4-triazole as the ligand created a gold nanoparticle-functionalized fullerene (C60)-modified vitreous carbon electrode for glucose detection (Fig. 4). The electrocatalytic behavior of the AuNPs@C60/GCE sensor was investigated using cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS). The highly stable and low onset potential non-enzymatic sensor exhibited high electrocatalytic activity and effective electron transfer from the electro-catalyst to the substrate electrode in a linear concentration range of 0.025–0.8 mmol L−1 and a higher sensitivity response of 1.2 µAµmol−1 L cm−2 with good reproducibility, long-term stability, free of interference from chlorine and oxygen, and detection limit of 22.0 μmol L−1 [50].

Schematic representation for synthetic route of AuNPs@C60 nanocomposite. Reprinted from [50] with permission

By covering and attaching SWNT with conductive polymer, Jin et al. create stretchable and transparent electrochemical sensors based on single-walled carbon nanotubes (SWNTs). Poly-(3,4-ethylenedioxythiophene), PEDOT, was chosen as a binder for its high conductivity, strong electrochemical activity, and biocompatibility. Additionally, as an excellent conductive coating and binder, it minimizes contact resistance and considerably improves the electrochemical performance of SWNTs films. Furthermore, the optoelectronic and electrochemical sensing performance is exceptionally stable during the stretching and bending processes. Proof-of-concept tests were carried out, which involved recording NO release from mechanically sensitive endothelial cells cultivated on the stretchable sensor, revealing its promising potential in real-time monitoring of mechanically induced biochemical signals from living cells and tissues [51].

The determination of L-Dopa is critical because it is the immediate precursor of dopamine (DA) and is used to treat Parkinson’s disease. Because DA does not cross the blood–brain barrier, it cannot be administered orally. Thus, L-Dopa is administered and converted into dopamine by the enzyme dopa-decarboxylase, stimulating dopamine production in the body. Sooraj and colleagues developed a sensor for L-Dopa determination in human urine and pharmaceutical samples by grafting copper nanoparticles with molecular imprinted polymer on MWCNTs (CuNPs/MWCNT-MIPs). The non-covalent interaction between L-Dopa and the functional groups present in the polymer composite sorbent's selective binding sites is primarily responsible for the recognition capacity toward L-Dopa with a detection limit of 7.23 nmol L−1. The electrochemical investigation reveals that the imprinted (CuNPs/MWCNT-MIP) material has adequate selectivity, distinguishing between L-Dopa and structurally related compounds like DA, uric acid (UA), 3,4-dihydroxyphenylacetic acid, and homovanillic acid [52].

Anojčić et al. [53] developed carbonaceous nanomaterial-modified carbon paste electrodes (CPEs) with MWCNTs in their native and functionalized (ox-MWCNT) forms to determine DA. The method demonstrated a linear concentration range of 16.15–192.70 ng mL−1, low detection limit of 4.89 ng mL−1, and a relative standard deviation (RSD) of less than 1.3%, under optimized conditions. Interferences from ascorbic acid were also insignificant. The developed method was successfully applied for DA determination in injection/selected infusion matrix solutions, with the obtained results being in good agreement with the DA content declared by the producer and the method’s RSD being less than 1.0% [53].

Upadhyay and Srivastava [54] describe an enantioselective electrochemical sensor that distinguishes atorvastatin isomers for the first time (ATS). The sensor was created using a glassy carbon electrode (GCE) that had been modified with a functionalized MWCNT containing hydroxypropyl-β-cyclodextrin (HBC). The developed method demonstrated the outstanding benefits of chiral nanocomposite-modified electrodes, such as excellent enantioselectivity, high stereospecificity, and good reproducibility [54].

Zhang and Li [55] used a glassy carbon electrode modified with non-covalent self-assembly of porphyrin-diazocine-porphyrin (PDP) and fullerene (C60), PDP-C60/GCE for DA detection. This process, widely employed for the production of novel functional optoelectronic materials, involves the combination of electron-rich and electron-withdrawing chemical moieties inside a donor–acceptor (D-A) systems. DA electrochemical activity was measured using cyclic voltammetry (CV) and differential pulse voltammetry (DPV). The anodic peak current rose linearly with increasing DA concentration in the 0–200 µmol L−1 range, and the detection limit was determined to be 0.015 µmol L−1. Thus, the suggested sensor demonstrated good sensitivity, acceptable selectivity, outstanding repeatability, and stability, indicating that PDP–C60/GCE is a viable electrode material for dopamine analysis in real samples [55].

The examples listed above illustrate some characteristics of biodevices built from modifications and/or combinations of CNMs, such as CNTs, C60 and CDs. Next, carbon fibers (CFs), another type of CNM, will be discussed.

6 Carbon Fibers

The electrochemistry of carbon materials has been prominent recently in the scientific community due to properties such as reproducibility, low cost, high sensitivity, and easy handling [56]. Among these materials, carbon fibers (CFs) have drawn attention in 1950s when Bacon produced the first CFs [57]. CFs are long filaments that have 90% by weight of carbon in their composition and exhibit these properties high modulus, compressive and tensile strength, flexibility, and adjustable electrochemical performance that candidates these materials for a range of applications. Aerospace, automobiles, chemicals, transportation, construction, sewage treatment, and other areas are examples [58, 59]. Furthermore, chemical and electrochemical techniques are used to functionalize CFs to promote the production of reactive groups for attaching electrochemically active molecules such as noble metals, metal oxides, polymers, and proteins [60,61,62]. CFs are used to make electrochemical sensors with high sensitivity and adaptability, as well as energy equipment (supercapacitors and batteries) with high energy/power density, because of this change [63]. Thus, this topic will discuss the characteristics, fabrication methods of fibers, and their applications, focusing on the current progress on biosensors based on CFs. Figure 5 describes the interest and focus of this topic.

6.1 Structure of Carbon Fibers

CFs can have a crystalline, amorphous, or partially crystalline structure and can be short, long, or continuous. Carbon fiber has an atomic structure comparable to graphite, with a spacing of 3.35 (d, d (002) in the c direction between the planes of the layers. It is composed of layers of carbon atoms arranged in a pattern [64]. Shaped hexagonal (Fig. 6.) It has a high modulus of 0.18–0.35 GPa; however, in a wet environment, its shear strength along the axis is poor [65].

In graphitic microdomains, the fiber structure is made up of sp2 hybridized carbon atoms organized in a two-dimensional hexagonal structure stacked parallel to each other in a regular pattern bonded by van der Waals forces [65, 66]. The carbon atoms in the graphite layer are covalently linked to this structural configuration due to the superposition of the sp2 orbitals and the delocalization of electrons. This structural configuration is responsible for graphite's high electrical and thermal conductivity [67]. The primary structural unit of most fibers is stacked turbostratic layers [68]. The spacing between the turbostratic layers is greater than the graphitic layers (Fig. 6).

The basic structural unit can split, fold, twist, and connect the other basic structural units in an irregular or random pattern to form microdomains. Carbon fibers have a non-uniform structure as a result [64]. The d spacing was raised to 3.44 because of sp3 binding and uneven stacking. The fiber production process, which includes precursors and processing conditions, determines the structural unit. Carbon fibers with alternative precursors, such as polyacrylonitrile (PAN), have a turbostratic structure, whereas mesophase pitch and steam-grown carbon fibers have a well-stacked graphitic crystal structure [69]. During graphitization of stabilized PAN-based fibers, the crystalline domain is produced by amalgamation with nearby crystallites or integration of the surrounding disordered carbons. In addition, by rotation and displacement, the layer planes inside the crystalline domain were repositioned. Graphite fibers, on the other hand, nevertheless have enormous turbostratic domains since these configurations occur only locally [70].

6.2 Fabrication of Carbon Fibers

The discovery of CFs took place over a century ago. The most frequent precursors utilized in the manufacture of CFs are PAN, pitch, and rayon. In these cases, 90% of CFs made of PAN, and the remaining 10% are made of pitch, rayon, or other materials. Because PAN-based CFs have higher strength, modulus, and voltage, as well as higher throughput [59, 71, 72].

Most of the time, the fiber production process combines chemical and mechanical stages. Three fundamental processes are typical in the case of polymeric precursors, as they are in the case of PAN: spinning, thermostabilization, and carbonization. The graphitization phase is a follow-up to the carbonization process, in which the heat treatment temperature is increased to about 3000 °C [57]. Figure 7 depicts a simple PAN fiber fabrication process.

The initial step is spinning, which can be accomplished in three ways: melt spinning, wet spinning, or dry spinning. The precursor is melted and extruded in the first step. After the filaments emerge, they cool and solidify into the desired shape [73, 74]. It is the favored approach since it does not require any resources other than the melting of basic materials. In the second scenario, a concentrated precursor solution is extruded through the pores in a coagulation bath. Because the solvent is more soluble in the coagulation fluid than the precursor, the precursor precipitates as a fiber as the solution emerges through the perforations. A concentrated precursor solution is used in the dry spinning process. In a drying chamber, extrude the yarn such that the solvent evaporates, and the precursor crystallizes as a fiber. Dry or wet centrifugation is indicated if the raw material degrades at melting temperature [73, 75].

The extruded material in the spinning process must be heat-treated to improve its glass transition temperature. During the carbonization process, which converts the PAN from thermoplastic to thermoset, this phase is necessary to ensure the material's infusibility. Because it is one of the priciest aspects of the process, optimization studies have been used to reduce the time it takes to stabilize while maintaining the required characteristics [76]. If a thermostabilization procedure is not completed, fiber quality suffers. The procedure must be heated at an acceptable rate such that Tg rises faster than the thermostabilization temperature and the supplied groups oxidize [59].

For organic materials, carbonization and graphitization are similar processes, which differ only in the degree of orientation and crystallization obtained based on temperature. The proposal to carbonize the fiber is to produce flat sheets of graphene, graphene, or hybrid, with high carbon content [57, 65]. During this stage, the majority of the non-carbon components in the fiber are volatilized as methane, hydrogen, cyanide, water, carbon monoxide, carbon dioxide, ammonia, and a range of other gases, enriching the carbon bonds and enhancing the fiber’s mechanical, electrical, and thermal characteristics [57, 69].

Precursors with many heteroatoms lose more carbon during gasification, resulting in a fiber with a lot of pores and poor mechanical characteristics. The amount of mass lost at this step differs depending on the precursor. PAN has a density of 55–60%, whereas isotropic pitches have a density of 20–45%, with substantial dimensional contraction [77]. The carbonization stage increases the carbon content, but the graphitization step transforms carbon into graphite, which has a unique structure [70, 78]. At 1500 °C, the maximum tensile strength is achieved. There is a rise in modulus and a decrease in strength above this temperature. A fast carbonization rate causes fiber defects, while slow rates cause a very large loss of heteroatoms [64]. An optimization of the process is recommended.

6.3 Classification of Carbon Fibers

CFs have been classified in three different ways, namely performance, precursor, and commercial availability. Based on performance as CFs, they can be classified into the following groups: ultra-high modulus (UHM), high modulus (HM), intermediate modulus (IM), standard modulus type (HT), and low modulus type (LM). The UHM and HM CFs are highly graphitized between 2000 and 3000 °C, characterized by a high modulus (>450 GPa) and (>350 GPa), respectively. As type IM CFs have carbon fiber tensile strength greater than (>200 GPa). The HT type is isotropic carbon fibers, which show a random orientation of the crystals and have a modulus less than (<100 GPa). As LM-type CFs have lower tensile strength (>4.5 GPA) [57, 65].

Carbon fibers are created by heating and stretching synthetic fibers (precursor fibers). Processing carbon fibers from diverse precursors needs a variety of circumstances to generate acceptable end products. The fundamental features are the same in both cases. The processing routes for many precursors are comparable on a macro level. Furthermore, carbon fiber precursor materials are crucial because the first precursor materials have a significant impact on the combination of diverse mechanical, physical, and chemical properties and behaviors in carbon fibers [57, 65]. PAN, pitch, Rayan, and cellulose are among the precursors that may be used to classify fibers.

They are categorized as high-performance carbon fibers (HPCF), general-purpose carbon fibers (GPCF), and activated carbon fibers based (ACF) on their commercial availability as fibers. HPFCs are distinguished by their high graphitic carbon content, which gives them mechanical strength. They are primarily utilized in carbon fiber reinforced polymer composites (CFRPs) for the aerospace sector [79]. They have low tensile strength and modulus as type GPCF, but they are inexpensive, thanks to isotropic carbon fibers, which are mostly utilized in the textile sector. Because of their unusual characteristics, including as adsorptive capabilities, ACF-type fibers have recently attracted interest in materials. Because of their nanopore architectures and particular CO2 affinity of ACF surface, ACFs absorb more CO2 than well-known adsorbent materials such as MOF-5, zeolite, and active carbon [80]. Figure 8 shows the classification of carbon fibers according to performance, precursor, and commercial availability.

6.4 Application of Carbon Fibers in Biosensing

Because of its superior mechanical properties, high-performance carbon fibers are utilized in aerospace, aeronautics, transportation, sports, compressed gas storage, and civil engineering. Carbon fibers have recently acquired popularity as a foundation material for biodevice manufacturing [65]. Because of the remarkable characteristics of CFs, including as low relative density, high mechanical strength, high conductivity, high temperature resistance, and flexibility, fiber-based electrochemical biosensors have stood out in this context. Thus, the next paragraphs describe the application of carbon fibers in the most diverse electrochemical biodevices.

Although the first analytical application of carbon fibers was made in 1975 by Jennings et al., their interest in electrochemical devices only grew after work carried out in 1979 by Armstrong-James, Ponchon and collaborators [81, 82]. The results found by these researchers showed a remarkable improvement in the quality of voltammetric results due to the unique characteristics of carbon fibers. From these works, the interest in the use of this material in the construction of sensors and biosensors has grown, and it is currently possible to observe a growing increase in the number of publications on the use of carbon fibers in electrochemical measurements. Carbon fiber-based electrochemical biosensors are widely used for the detection of physiological and cancer biomarkers and for wearable electrochemical sensor applications.

The work by Liu Deng and associates, which describes a carbon fiber biosensor modified with Au@Pt nanoparticles for microbial detection, is an example of carbon fiber-based electrochemical biosensors. In this study, the relative suppression of E. coli activity is linear and has a LOD of 0.09 mg L−1. The use of carbon fiber modified with NPs Au@Pt and its high conductivity, biocompatibility, and electrocatalytic activity, according to the scientists, improved the microbial biosensor. The microbial biosensor of this material has the potential to be used in environmental monitoring [83].

Human physiological indices and cellular activity components are also monitored using CF-based biosensors. One of the most significant indicators is glucose, and keeping track of it is critical for avoiding health concerns including hypertension, heart disease, and neurological issues. Salazar and colleagues describe the development of a glucose biosensor using a Prussian Blue modified carbon fiber electrode. Carbon fibers and PB film have electrocatalytic characteristics that allow for enzymatic by-product (H2O2) identification. Against a variety of physiologically interfering substances, the biosensor showed good glucose selectivity. Furthermore, the biosensor's sensitivity and stability are adequate to monitor multiphase and reversible changes in brain ECF glucose levels throughout physiological tests, demonstrating the biosensor’s good characteristics and use in neuroscience [84].

With the 0.132 μmol L−1 LOD and rapid reaction time for an AU detection in GE/CFE, Jiao and colleagues developed a simple and cost-effective graphene-modified carbon fiber (GE/CFE) biosensor for uric acid (UA) determination. With a relative standard deviation of 2.8%, the UA with GE/CFE determination is extremely selective and repeatable [85].

Iost and colleagues also describe the development of a carbon fiber-based biosensor for glucose detection. An electrochemical mediator and glucose oxidase enzyme are used to modify biosensors like carbon fibers. The sensor was shown to detect 30 mg dL−1 in a normal and 200 mg dL−1 in a diabetic state in vivo. The biosensor has shown promise in terms of potential implanted bioelectronic device applications [86]. The research presented in this issue demonstrates the rising need for electrochemical biodevices made of carbon fibers, as well as their relevance in the scientific community for medical applications.

Yan Zhang and colleagues created a flexible carbon fiber-based biosensor enclosed by gold nanoparticles and adorned with nitrogen-doped carbon nanotube arrays, CF@NCNTAs–AuNPs (Fig. 9), and investigated its practical use in electrochemical detection in situ H2O2 produced by live cancer cells. With a LOD of 50 nmol L−1, this biosensor has outstanding electrocatalytic capabilities [87]. An electrochemical H2O2 biosensor was also published by Yuan et al. To construct a two-dimensional core–shell structure, carbon sheets doped with VS2@VC@N and decorated with ultra-fine Pd nanoparticles grown vertically in CFs are used. With the 50 nmol L−1 LOD, this biosensor exhibited strong electron transfer capability, electrocatalytic activity, stability, and biocompatibility to detect H2O2 in live cancer cells and cancer tissue in real time, although the unique rosette-like matrix structure [88].

Manufacturing of the CF@NCNTAs–GNPs nanocomposite is depicted schematically. a Digital microscope pictures of the CF@NCNTAs–AuNPs microelectrode, which was placed near the cells using a micromanipulator. b Current responses of the CF@NCNTAs–GNPs microelectrode in amperometric mode. Reproduced with the author's permission [87]

In addition to traditional carbon fiber-based biosensors, flexible electronic and wearable smart devices have evolved substantially recently. Rather of lowering sensitivity and accuracy, they make the device smaller, more portable, and more intelligent. As a result, these devices have stood out. Vomero and colleagues, for example, describe the development of a flexible biosensor made of carbon fibers that may be implanted in mouse brain tissue. The micromachining technique is used to insert flexible CFS in this study. The whole electrocorticography (ECoG) electrode set is made entirely of single carbon fiber, with no joints or metal linkages. In vitro, the produced super flexible neural biodevice exhibited high electrochemical stability and outstanding mechanical characteristics, and after in vivo implantation, it displays good recording performance [89].

In carbon fiber microelectrodes, Asrat and colleagues demonstrated direct detection of DNA and RNA. And they show that this detection is effective even in complex serum samples, and according to the author, this measurement is not masked due to the properties of the combination of the FSCV technique and CFs. This is the first paper to show that FSCV can co-detect nucleobases when polymerized into DNA or RNA when employed with CFMEs, and it might open the way for future therapeutic, diagnostic, and research applications [90].

7 Concluding Remarks

Carbon nanomaterials (CNMs) pose as a versatile group of nanomaterials that can be used to fabricate or modify biodevices. Such versatility comes from the possibility of creating different functional groups that act as binding sites for different biomolecules or tissues. Carbon nanostructures, which have unique electrical, optical, physical, and chemical properties, have gotten a lot of attention. In recent decades, the number of published works reporting the use of these nanomaterials draws attention due to their range of applications, covering fields of research as varied as energy storage and supercapacitors to nanomedicine. In addition, the compatibility shown by carbon nanomaterials allows the creation of composites that have additional advantages to the original materials, such as higher biocompatibility and dispersibility.

The incorporation of different nanomaterials into the design of electrochemical biosensors has substantially enhanced their detection sensitivity. Alternatively, flexible and wearable point-of-care (POC) electrochemical sensor can be developed to quantify sweat metabolites and secretions in real time. It is thought to be a promising approach for real-time monitoring of mechanically produced biochemical signals in sensitive cells and tissues during mechano-transduction.

Further Reading

JARIWALA, Deep, et al. Carbon nanomaterials for electronics, optoelectronics, photovoltaics, and sensing. Chemical Society Reviews, v. 42, n. 7, p. 2824–2860, 2013.

ALKIRE, Richard C.; BARTLETT, Philip N.; LIPKOWSKI, Jacek (Ed.). Electrochemistry of Carbon Electrodes. John Wiley & Sons, 2015.

GEORGAKILAS, Vasilios et al. Broad family of carbon nanoallotropes: classification, chemistry, and applications of fullerenes, carbon dots, nanotubes, graphene, nanodiamonds, and combined superstructures. Chemical reviews, v. 115, n. 11, p. 4744–4822, 2015.

SATTLER, Klaus D. (Ed.). Carbon Nanomaterials Sourcebook: Graphene, Fullerenes, Nanotubes, and Nanodiamonds, Volume I. CRC Press, 2016.

YANG, Nianjun. Nanocarbons for electroanalysis. John Wiley & Sons, 2017.

HUI, Yuen Y. et al. (Ed.). Carbon nanomaterials for bioimaging, bioanalysis, and therapy. John Wiley & Sons, 2019.

YANG, Nianjun; ZHAO, Guohua; FOORD, John S. (Ed.). Nanocarbon Electrochemistry. John Wiley & Sons, 2020.

Abbreviations

- ACF :

-

Activated Carbon Fibers

- AuNPS :

-

Gold Nanoparticles

- CB :

-

Carbon Black

- CDs :

-

Carbon Dots

- CFRPs :

-

Carbon Fiber Reinforced Polymer Composites

- CFs :

-

Carbon Fibers

- CND :

-

Carbon Nanodiamonds

- CNH :

-

Carbon Nanohorns

- CNM :

-

Carbon Nanomaterials

- CNT :

-

Carbon Nanotubes

- CPEs :

-

Carbon Paste Electrodes

- CuNPs :

-

Cooper Nanoparticles

- CVD :

-

Chemical Vapor Deposition

- DA :

-

Dopamine

- DNA :

-

Deoxyribonucleic Acid

- DWCNTs :

-

Double-Walled Carbon Nanotubes

- ECoG :

-

Electrocorticography

- EIS :

-

Electrochemical Impedance Spectroscopy

- FSCV :

-

Fast-Scan Cyclic Voltammetry

- GCE :

-

Glassy Carbon Electrode

- GNR :

-

Graphene Nanoribbons

- GPCF :

-

General-Purpose Carbon Fibers

- GQDs :

-

Graphene Quantum Dots

- HBC :

-

Hydroxypropyl-B-Cyclodextrin

- HM :

-

High Modulus

- HPCF :

-

High-Performance Carbon Fibers

- HT :

-

Standard Modulus

- IM :

-

Intermediate Modulus

- LM :

-

Low Modulus

- LOD :

-

Limit Of Detection

- LUMO :

-

Lowest Unoccupied Molecular Orbital

- MIP :

-

Molecular Imprinted Polymer

- MWCNT :

-

Multi-Walled Carbon Nanotubes

- NCNTAs :

-

Nitrogen-Doped Carbon Nanotube Arrays

- PAN :

-

Polyacrylonitrile

- PB :

-

Prussian Blue Fe4[Fe(CN)6]3

- POC :

-

Point-of-care

- RNA :

-

Ribonucleic Acid

- RSD :

-

Relative Standard Deviation

- SWCNT :

-

Single-Walled Carbon Nanotubes

- UA :

-

Uric Acid

- UHM :

-

Ultra-High Modulus

References

Putz MV (2011) Carbon bonding and structures, 1st edn. Springer Netherlands, Dordrecht

Maduraiveeran G, Jin W (2021) Carbon nanomaterials: synthesis, properties and applications in electrochemical sensors and energy conversion systems. Mater Sci Eng B 272:115341. https://doi.org/10.1016/j.mseb.2021.115341

Jiang X, Kang Z, Guo X, Zhuang H (2019) Novel carbon materials and composites—synthesis, properties and applications, 1st edn. Wiley

Hazra A, Goswami R (2021) Carbon nanomaterial electronics: devices and applications. Springer Singapore, Singapore

Georgakilas V, Perman JA, Tucek J, Zboril R (2015) Broad family of carbon nanoallotropes: classification, chemistry, and applications of fullerenes, carbon dots, nanotubes, graphene, nanodiamonds, and combined superstructures. Chem Rev 115:4744–4822. https://doi.org/10.1021/cr500304f

Kingston CT, Simard B (2003) Fabrication of carbon nanotubes. Anal Lett 36:3119–3145. https://doi.org/10.1081/AL-120026564

Porto LS, Silva DN, de Oliveira AEF, Pereira AC, Borges KB (2020) Carbon nanomaterials: synthesis and applications to development of electrochemical sensors in determination of drugs and compounds of clinical interest. Rev Anal Chem 38:1–16. https://doi.org/10.1515/revac-2019-0017

Barhoum A, Shalan AE, El-Hout SI, Ali GAM, Abdelbasir SM, Abu Serea ES, Ibrahim AH, Pal K (2019) A Broad family of carbon nanomaterials: classification, properties, synthesis, and emerging applications. Handbook of nanofibers. Springer International Publishing, Cham, pp 1–40

Kour R, Arya S, Young S, Gupta V, Bandhoria P, Khosla A (2020) Review—recent advances in carbon nanomaterials as electrochemical biosensors. J Electrochem Soc 167:037555. https://doi.org/10.1149/1945-7111/ab6bc4

Si Y, Lee HJ (2020) Carbon nanomaterials and metallic nanoparticles- incorporated electrochemical sensors for small metabolites: Detection methodologies and applications. Curr Opin Electrochem 22:234–243. https://doi.org/10.1016/j.coelec.2020.08.007

Ehtesabi H (2020) Carbon nanomaterials for salivary-based biosensors: a review. Mater Today Chem 17:100342. https://doi.org/10.1016/j.mtchem.2020.100342

Power AC, Gorey B, Chandra S, Chapman J (2018) Carbon nanomaterials and their application to electrochemical sensors: a review. Nanotechnol Rev 7:19–41. https://doi.org/10.1515/ntrev-2017-0160

Wong H-SP, Akinwande D (2010) Carbon nanotube and graphene device physics, 1st edn. Cambridge University Press, Cambridge

Arnault J-C, Eder D (2021) Synthesis and applications of nanocarbons, 1st edn. Wiley

Evtugyn G, Porfireva A, Shamagsumova R, Hianik T (2020) Advances in electrochemical aptasensors based on carbon nanomaterials. Chemosensors 8. https://doi.org/10.3390/chemosensors8040096

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56–58. https://doi.org/10.1038/354056a0

Wildgoose GG, Banks CE, Leventis HC, Compton RG (2006) Review chemically modified carbon nanotubes for use in electroanalysis. Microchim Acta 214:187–214. https://doi.org/10.1007/s00604-005-0449-x

Saito Y, Nakahira T, Uemura S (2003) Growth conditions of double-walled carbon nanotubes in arc discharge. J Phys Chem B 107:931–934. https://doi.org/10.1021/jp021367o

Cui H, Eres G, Howe JY, Puretkzy A, Varela M, Geohegan DB, Lowndes DH (2003) Growth behavior of carbon nanotubes on multilayered metal catalyst film in chemical vapor deposition. Chem Phys Lett 374:222–228. https://doi.org/10.1016/S0009-2614(03)00701-2

Artyukhov VI, Penev ES, Yakobson BI (2014) Why nanotubes grow chiral. Nat Commun 5.https://doi.org/10.1038/ncomms5892

Doi Y, Nakatani A (2016) Structure and stability of discrete breather in zigzag and armchair carbon nanotubes. Lett Mater 6:49–53. https://doi.org/10.22226/2410-3535-2016-1-49-53

Wang Q (2004) Effective in-plane stiffness and bending rigidity of armchair and zigzag carbon nanotubes. Int J Solids Struct 41:5451–5461. https://doi.org/10.1016/j.ijsolstr.2004.05.002

Endo M, Hayashi T, Ahm Kim Y, Terrones M, Dresselhaus MS (2004) Applications of carbon nanotubes in the twenty-first century. Philos Trans R Soc London Ser A Math Phys Eng Sci 362:2223–2238. https://doi.org/10.1098/rsta.2004.1437

Tîlmaciu CM, Morris MC (2015) Carbon nanotube biosensors. Front Chem 3:1–21. https://doi.org/10.3389/fchem.2015.00059

Salvetat J-P, Bonard J-M, Thomson NH, Kulik AJ, Forró L, Benoit W, Zuppiroli L (1999) Mechanical properties of carbon nanotubes. Appl Phys A Mater Sci Process 69:255–260. https://doi.org/10.1007/s003390050999

Zanin H, May PW, Fermin DJ, Plana D, Vieira SMC, Milne WI, Corat EJ (2014) Porous boron-doped diamond/carbon nanotube electrodes. ACS Appl Mater Interfaces 6:990–995. https://doi.org/10.1021/am4044344

Sireesha M, Jagadeesh Babu V, Kranthi Kiran AS, Ramakrishna S (2018) A review on carbon nanotubes in biosensor devices and their applications in medicine. Nanocomposites 4:36–57. https://doi.org/10.1080/20550324.2018.1478765

Gergeroglu H, Yildirim S, Ebeoglugil MF (2020) Nano-carbons in biosensor applications: an overview of carbon nanotubes (CNTs) and fullerenes—(C60). SN Appl Sci 2:1–22. https://doi.org/10.1007/s42452-020-2404-1

Ebbesen TW, Ajayan PM (1992) Large-scale synthesis of carbon nanotubes. Nature 358:220–222. https://doi.org/10.1038/358220a0

Sudha PN, Sangeetha K, Vijayalakshmi K, Barhoum A (2018) Chapter 12—Nanomaterials history, classification, unique properties, production and market. Elsevier

Laurila T, Sainio S, Caro MA (2017) Hybrid carbon based nanomaterials for electrochemical detection of biomolecules. Prog Mater Sci 88:499–594. https://doi.org/10.1016/j.pmatsci.2017.04.012

Li Y, Maruyama S (2019) Single-walled carbon nanotubes: preparations, properties and applications, 1st edn. Springer Nature Switzerland, Cham, Switzerland

Santos H, Chico L, Brey L (2009) Carbon nanoelectronics: unzipping tubes into graphene ribbons. Phys Rev Lett 086801:24–27. https://doi.org/10.1103/PhysRevLett.103.086801

Terrones M (2009) Nanotubes unzipped. Nature 458:845–846. https://doi.org/10.1038/458845a

Li Y, Liao J, Wang S, Chiang W (2016) Intercalation-assisted longitudinal unzipping of carbon nanotubes for green and scalable synthesis of graphene nanoribbons. Nat Publ Gr 1–12.https://doi.org/10.1038/srep22755

Pillai VK (2011) Electrochemical unzipping of multi-walled carbon nanotubes for facile synthesis of high-quality graphene nanoribbons. J Am Chem Soc, 4168–4171. https://doi.org/10.1021/ja1101739

Kosynkin DV, Higginbotham AL, Sinitskii A, Lomeda JR, Dimiev A, Price BK, Tour JM (2009) Longitudinal unzipping of carbon nanotubes to form graphene nanoribbons. Nature 458:872–877. https://doi.org/10.1038/nature07872

Zhang Y, Rhee KY, Hui D, Park SJ (2018) A critical review of nanodiamond based nanocomposites: synthesis, properties and applications. Compos Part B Eng 143:19–27. https://doi.org/10.1016/j.compositesb.2018.01.028

Kazi S (2014) A review article on nanodiamonds discussing their properties and applications. Int J Pharm Sci Invent 3:40–45

Iijima S, Yudasaka M, Yamada R, Bandow S, Suenaga K, Kokai F, Takahashi K (1999) Nano-aggregates of single-walled graphitic carbon nano-horns. Chem Phys Lett 309:165–170. https://doi.org/10.1016/S0009-2614(99)00642-9

Nelis JLD, Migliorelli D, Jafari S, Generelli S, Lou-Franco J, Salvador JP, Marco MP, Cao C, Elliott CT, Campbell K (2020) The benefits of carbon black, gold and magnetic nanomaterials for point-of-harvest electrochemical quantification of domoic acid. Microchim Acta 187. https://doi.org/10.1007/s00604-020-4150-x

Wang J, Lin Y (2008) Functionalized carbon nanotubes and nanofibers for biosensing applications. TrAC 27:619–626. https://doi.org/10.1016/j.trac.2008.05.009

Zhou Y, Fang Y, Ramasamy RP (2019) Non-covalent functionalization of carbon nanotubes for electrochemical biosensor development. Sensors (Switzerland) 19.https://doi.org/10.3390/s19020392

Georgakilas V, Otyepka M, Bourlinos AB, Chandra V, Kim N, Kemp KC, Hobza P, Zboril R, Kim KS (2012) Functionalization of graphene: covalent and non-covalent approaches. Deriv Appl. https://doi.org/10.1021/cr3000412

Liu S (2019) Functionalization of carbon nanomaterials for biomedical applications. C—J Carbon Res 5:72. https://doi.org/10.3390/c5040072

Shin SW, Song IH, Um SH (2015) Role of physicochemical properties in nanoparticle toxicity. Nanomaterials, 1351–1365. https://doi.org/10.3390/nano5031351

Buzea C, Pacheco II, Robbie K, Buzea C (2016) Nanomaterials and nanoparticles: sources and toxicity. Biointerphases 17. https://doi.org/10.1116/1.2815690

Hwang HS, Jeong JW, Kim YA, Chang M (2020) Carbon nanomaterials as versatile platforms for biosensing applications. Micromachines 11:814. https://doi.org/10.3390/mi11090814

Arvand M, Hemmati S (2017) Magnetic nanoparticles embedded with graphene quantum dots and multiwalled carbon nanotubes as a sensing platform for electrochemical detection of progesterone. Sens Actuators, B Chem 238:346–356. https://doi.org/10.1016/j.snb.2016.07.066

Sutradhar S, Patnaik A (2017) A new fullerene-C60—nanogold composite for non-enzymatic glucose sensing. Sens Actuators B Chem 241:681–689. https://doi.org/10.1016/j.snb.2016.10.111

Jin ZH, Liu YL, Chen JJ, Cai SL, Xu JQ, Huang WH (2017) Conductive polymer-coated carbon nanotubes to construct stretchable and transparent electrochemical sensors. Anal Chem 89:2032–2038. https://doi.org/10.1021/acs.analchem.6b04616

Sooraj MP, Nair AS, Pillai SC, Hinder SJ, Mathew B (2020) CuNPs decorated molecular imprinted polymer on MWCNT for the electrochemical detection of l-DOPA. Arab J Chem 13:2483–2495. https://doi.org/10.1016/j.arabjc.2018.06.002

Anojčić J, Guzsvány V, Kónya Z, Mikov M (2019) Rapid, trace-level direct cathodic voltammetric determination of dopamine by oxidized multiwalled carbon nanotube-modified carbon paste electrode in selected samples of pharmaceutical importance. Ionics (Kiel) 25:6093–6106. https://doi.org/10.1007/s11581-019-03156-5

Upadhyay SS, Srivastava AK (2019) Hydroxypropyl β-cyclodextrin cross-linked multiwalled carbon nanotube-based chiral nanocomposite electrochemical sensors for the discrimination of multichiral drug atorvastatin isomers. New J Chem 43:11178–11188. https://doi.org/10.1039/C9NJ02508A

Zhang M, Li J (2020) Preparation of porphyrin derivatives and C60 supramolecular assemblies as a sensor for detection of dopamine. Dye Pigment 173:107966. https://doi.org/10.1016/j.dyepig.2019.107966

McCreery RL (2008) Advanced carbon electrode materials for molecular electrochemistry. Chem Rev 108:2646–2687. https://doi.org/10.1021/cr068076m

Frank E, Steudle LM, Ingildeev D, Spörl JM, Buchmeiser MR (2014) Carbon fibers: precursor systems, processing, structure, and properties. Angew Chemie Int Ed 53:5262–5298. https://doi.org/10.1002/anie.201306129

Hiremath N, Mays J, Bhat G (2017) Recent developments in carbon fibers and carbon nanotube-based fibers: a review. Polym Rev 57:339–368. https://doi.org/10.1080/15583724.2016.1169546

Choi D, Kil H-S, Lee S (2019) Fabrication of low-cost carbon fibers using economical precursors and advanced processing technologies. Carbon N Y 142:610–649. https://doi.org/10.1016/j.carbon.2018.10.028

Szczurek A, Barcikowski M, Leluk K, Babiarczuk B, Kaleta J, Krzak J (2017) Improvement of interaction in a composite structure by using a sol-gel functional coating on carbon fibers. Materials (Basel) 10:990. https://doi.org/10.3390/ma10090990

García-Ruíz J, Díaz Lantada A (2017) 3D printed structures filled with carbon fibers and functionalized with mesenchymal stem cell conditioned media as in vitro cell niches for promoting chondrogenesis. Materials (Basel) 11:23. https://doi.org/10.3390/ma11010023

Wenrui Z, Fanxing M, Yanan Q, Fei C, Haitao Y, Minwei Z (2020) Fabrication and Specific functionalisation of carbon fibers for advanced flexible biosensors. Front Chem 8.https://doi.org/10.3389/fchem.2020.582490

Wang C, Xia K, Wang H, Liang X, Yin Z, Zhang Y (2019) Advanced carbon for flexible and wearable electronics. Adv Mater 31:1801072. https://doi.org/10.1002/adma.201801072

Huang X (2009) Fabrication and properties of carbon fibers. Materials (Basel) 2:2369–2403. https://doi.org/10.3390/ma2042369

Park S (2018) Carbon fibers, 2nd edn. Springer Singapore, Singapore

Joshi K, Arefev MI, Zhigilei LV (2019) Generation and characterization of carbon fiber microstructures by atomistic simulations. Carbon N Y 152:396–408. https://doi.org/10.1016/j.carbon.2019.06.014

Conard J (2002) Electronic structure of various forms of solid state carbons. Graphite intercalation compounds. In: New trends in intercalation compounds for energy storage. Springer Netherlands, Dordrecht, pp 39–62

Kim M-A, Jang D, Tejima S, Cruz-Silva R, Joh H-I, Kim HC, Lee S, Endo M (2016) Strengthened PAN-based carbon fibers obtained by slow heating rate carbonization. Sci Rep 6:22988. https://doi.org/10.1038/srep22988

Newcomb BA (2016) Processing, structure, and properties of carbon fibers. Compos Part A Appl Sci Manuf 91:262–282. https://doi.org/10.1016/j.compositesa.2016.10.018

Rahaman MSA, Ismail AF, Mustafa A (2007) A review of heat treatment on polyacrylonitrile fiber. Polym Degrad Stab 92:1421–1432. https://doi.org/10.1016/j.polymdegradstab.2007.03.023

Al Aiti M, Jehnichen D, Fischer D, Brünig H, Heinrich G (2018) On the morphology and structure formation of carbon fibers from polymer precursor systems. Prog Mater Sci 98:477–551. https://doi.org/10.1016/j.pmatsci.2018.07.004

Saritas O, Sokolov A, Vishnevskiy K (2019) New materials: the case of carbon fibres. In: Meissner D, Gokhberg L, Saritas O (eds) Emerging technologies for economic development, 1 st edn. Springer Nature Switzerland AG 2019, Cham, Switzerland, pp 13–47

Nakajima T, Kajiwara K, McIntyre JE (1994) Advanced fiber spinning technology, 1st edn. Elsevier

Chen JY (2017) Activated carbon fiber and textiles, 1st edn. Elsevier

Beckman I, Lozano C, Freeman E, Riveros G (2021) Fiber selection for reinforced additive manufacturing. Polymers (Basel) 13:2231. https://doi.org/10.3390/polym13142231

Baker DA, Rials TG (2013) Recent advances in low-cost carbon fiber manufacture from lignin. J Appl Polym Sci 130:713–728. https://doi.org/10.1002/app.39273

Chung DDL (1994) Carbon fiber composites, 1st edn. Elsevier

Chen H, Wang S, Zhang X, Zhao Y, Zhang H (2021) A study of chemical structural evolution of thermally altered coal and its effect on graphitization. Fuel 283:119295. https://doi.org/10.1016/j.fuel.2020.119295

Altin Karataş M, Gökkaya H (2018) A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials. Def Technol 14:318–326. https://doi.org/10.1016/j.dt.2018.02.001

Chiang Y-C, Juang R-S (2017) Surface modifications of carbonaceous materials for carbon dioxide adsorption: a review. J Taiwan Inst Chem Eng 71:214–234. https://doi.org/10.1016/j.jtice.2016.12.014

Ponchon JL, Cespuglio R, Gonon F, Jouvet M, Pujol JF (1979) Normal pulse polarography with carbon fiber electrodes for in vitro and in vivo determination of catecholamines. Anal Chem 51:1483–1486. https://doi.org/10.1021/ac50045a030

Armstrong-James M, Millar J (1979) Carbon fibre microelectrodes. J Neurosci Methods 1:279–287. https://doi.org/10.1016/0165-0270(79)90039-6

Deng L, Guo S, Zhou M, Liu L, Liu C, Dong S (2010) A silk derived carbon fiber mat modified with Au@Pt urchilike nanoparticles: a new platform as electrochemical microbial biosensor. Biosens Bioelectron 25:2189–2193. https://doi.org/10.1016/j.bios.2010.02.005

Salazar P, O’Neill RD, Martín M, Roche R, González-Mora JL (2011) Amperometric glucose microbiosensor based on a Prussian Blue modified carbon fiber electrode for physiological applications. Sensors Actuators B Chem 152:137–143. https://doi.org/10.1016/j.snb.2010.11.056

Du J, Yue R, Yao Z, Jiang F, Du Y, Yang P, Wang C (2013) Nonenzymatic uric acid electrochemical sensor based on graphene-modified carbon fiber electrode. Colloids Surf A Physicochem Eng Asp 419:94–99. https://doi.org/10.1016/j.colsurfa.2012.11.060

Iost RM, Sales FCPF, Martins MVA, Almeida MC, Crespilho FN (2015) Glucose biochip based on flexible carbon fiber electrodes. In vivo diabetes evaluation in rats. ChemElectroChem 2:518–521. https://doi.org/10.1002/celc.201402339

Zhang Y, Xiao J, Sun Y, Wang L, Dong X, Ren J, He W, Xiao F (2018) Flexible nanohybrid microelectrode based on carbon fiber wrapped by gold nanoparticles decorated nitrogen doped carbon nanotube arrays: in situ electrochemical detection in live cancer cells. Biosens Bioelectron 100:453–461. https://doi.org/10.1016/j.bios.2017.09.038

Yuan H, Zhao J, Wang Q, Manoj D, Zhao A, Chi K, Ren J, He W, Zhang Y, Sun Y, Xiao F, Wang S (2020) Hierarchical core-shell structure of 2D VS 2 @VC@N-doped carbon sheets decorated by ultrafine Pd nanoparticles: assembled in a 3D rosette-like array on carbon fiber microelectrode for electrochemical sensing. ACS Appl Mater Interfaces 12:15507–15516. https://doi.org/10.1021/acsami.9b21436

Vomero M, Gueli C, Zucchini E, Fadiga L, Erhardt JB, Sharma S, Stieglitz T (2020) Flexible bioelectronic devices based on micropatterned monolithic carbon fiber mats. Adv Mater Technol 5:1900713. https://doi.org/10.1002/admt.201900713

Asrat TM, Cho W, Liu FA, Shapiro SM, Bracht JR, Zestos AG (2021) Direct detection of DNA and RNA on carbon fiber microelectrodes using fast-scan cyclic voltammetry. ACS Omega 6:6571–6581. https://doi.org/10.1021/acsomega.0c04845

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

da Costa Oliveira, T., Nascimento, S.Q. (2023). Carbon Nanomaterials in Electrochemical Biodevices. In: Crespilho, F.N. (eds) Advances in Bioelectrochemistry Volume 5. Springer, Cham. https://doi.org/10.1007/978-3-031-10832-7_3

Download citation

DOI: https://doi.org/10.1007/978-3-031-10832-7_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-10831-0

Online ISBN: 978-3-031-10832-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)