Abstract

In addressing issues of plastic accumulation in the environment and negative impacts of plastic degradation, the development of biobased alternatives is crucial in solving these hazards. Single-use, disposable hygiene products, such as diapers and feminine hygiene, significantly contribute to plastic waste. These products often contain non-biodegradable, synthetic, and superabsorbent polymers. In this research, biobased superabsorbent polymers have been designed and synthesized, using biological crosslinker and backbone components to create a hydrogel system, which absorbs water into the polymeric matrix. The hydrogels are synthesized using chitosan and sodium alginate as the backbone foundation and genipin as the crosslinker, which are all commonly found in nature. Through chemical ratio alteration, including the crosslinker to backbone ratio, the superabsorbent polymers successfully absorb and retain water. The characterization of the hydrogels, including the absorbency capacity, absorbency retention, performance under a load, and performance with ion presence, has proven that fully biological superabsorbent polymers are possible.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

Plastic waste has been a highly discussed issue in public discourse, largely due to the urgency of this crisis. Approximately 300 million pounds of plastic are produced every year, half of which is single-use plastic [1]. Municipal landfills contain household waste products that contain large amounts of synthetic polymers in various forms such as packaging films, storage containers, carpet fibers, and absorbent hygienic products. Only a small variety of polymers found in consumer products are bio- or photo-degradable, but most public landfills are not properly equipped with facilities or technologies to biodegrade or photodegrade solid waste components. Nearly 25% of the anticipated 24 million tons of plastic products produced in the United States reach landfills every year [2].

The entire life cycle of current plastic, from production to disposal, is creating a significant environmental problem, due to carbon emissions upon production, how these plastics degrade in nature, and plastic waste accumulation. While high carbon emissions from production directly contribute to climate change, these plastics often will break down into smaller pieces that are ingested by animals, creating a significant impact on the environment and wildlife. Furthermore, as these plastics degrade, toxins are released into the water, leading to contamination [3]. While there are many solutions that show potential, a significant factor in reversing these issues will be creating biobased alternatives to current synthetic and petroleum-based plastics.

The differences between synthetic and biological polymers are important in addressing the problems of plastic accumulation and their effect on the environment. While there are various differences between the two types of polymers, biological polymers typically have many kinds of monomers. As opposed to biological polymers, there are only a few different monomers in synthetic polymers. Both synthetic and biological polymers are used in many applications. The purpose of this project is to analyze the effects of each type within single-use plastics [4]. A more comprehensive comparison of synthetic and biological polymers in single-use products can be seen in Table 1.

The general structures of synthetic and biological polymers are essentially the same. Polymers are made up of many monomers which are small chemical molecules that can build on each other to create a polymer. A large contributor to single-use plastic waste is superabsorbent polymers (SAPs). SAPs are a specific type of polymer known as a hydrogel, which are polymer networks able to retain water without compromising the structural integrity of the network. These features of the polymer matrix within hydrogel structures are necessary for the development of products whose primary function is the absorption of liquids [5]. This type of polymer is often able to absorb up to 300 times their weight in liquids, making them useful in various applications [6]. As the polymer network absorbs water, the structure begins to expand, often resulting in the swelling of the material. These polymers have various commercial applications, including personal care products such as diapers, feminine hygiene products, and incontinence products. There are also many other applications such as enzyme immobilization, preparative chromatography, agricultural mulches, and controlled release devices [6].

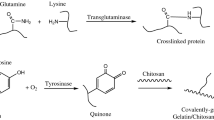

The backbone of the polymer can alter the properties of the hydrogel significantly, depending on the functional groups and the associated properties. The crosslinker provides resistance to the hydrogel structure when water is being absorbed. There are two types of crosslinking in polymer structures, chemical crosslinks, and physical crosslinks. Chemical crosslinks create permanent covalently bonded networks, while physical crosslinks typically involve crystalline domains. The polymerization and crosslinking process starts with thermal- or photo-initiation [5]. The purpose of this study is to examine the absorbency capacity of biological polymer materials that have the potential for use as superabsorbent polymers.

Superabsorbent Polymers

Materials and Methods

In both initial studies and the actual synthesis of the biological SAP, similar synthesis methods were followed. Each study and test required the use of a backbone monomer and a crosslinking monomer. Chitosan, sodium alginate, and genipin were used as received from Sigma Aldrich.

In order to create the biological SAP, the backbone of the polymeric structure was first synthesized. To begin the process, a mixture of chitosan and sodium alginate, or 100% of either compound, was synthesized through suspension. Using a beaker, the compound, or mixture of the compounds, was placed into isopropyl alcohol and stirred at room temperature, with a magnetic stir bar and stirring machine, until the powder completely dissolved. Sodium hydroxide was then added incrementally over a 25 min period and continuously stirred using the stir bar. After the mixture reacted, monochloroacetic acid was added while stirring and heating the solution to 60 °C for approximately three hours. The solution was monitored to ensure that it did not exceed 60 °C in order to prevent boiling. Using a filtering flask setup, the solid precipitate was filtered out of the solution and then dried at room temperature [7].

Once the solid completely dried, the solid was then added to deionized (DI) water and mixed with genipin. This mixture was left at room temperature and stirred, in order to remove air bubbles, for 15 h. After the designated time passed, the mixture was rinsed using DI water and dried at room temperature. This process created an interpenetrating polymer network where genipin is the crosslinker. The polymer is typically in a large polymeric slab, which can be broken down to proceed with absorbency testing and other characterization techniques [7].

Testing Methods

The synthesized SAP must meet various industrial standards in order to transition into industry-grade applications. Those standards include a high absorbency, performance under a load, various liquid retention, and have high absorbency capacity. Each of these requirements will be tested in the lab. The polymer composition can also be altered accordingly to best fulfill these standards.

Absorbency Testing

As the SAP will be used in applications where high amounts of liquid will be absorbed, the polymer must have a high absorbency capacity. In order to properly measure how much liquid is absorbed, two absorbency tests will be performed, using DI as a baseline. The two testing methods being used to measure the performance of the polymer are an oversaturation test and a simple water addition test. The oversaturation test places the synthesized polymer into a beaker containing an excess of water and left to saturate for a long period of time, typically overnight. The polymer is weighed using a basic scale both before and after the oversaturation process. Weighing the polymer at both of these instances will allow for the percent mass increase to be calculated. Similar to the oversaturation test, the simple water addition method will measure the mass of the polymer both before and after the addition of DI water. In the simple water addition method, the polymer will be placed on a dry surface, and using a pipette, DI water will be placed onto the polymer until the matrix no longer absorbs anything. The percent mass increase of both methods can be compared in order to determine a relative time of absorbency.

Since the applications of superabsorbent polymers vary greatly and often absorb various liquids, the effect of the presence of ions must be assessed. The absorbency tests use DI water as a baseline; however, to test the effect of ions, DI water can be replaced with ionized water in all methods. By comparing the results of DI water and ionized water, the effect of ion presence can be determined. Similarly, any liquid can be used in any method in order to observe the effect of that liquid.

Absorbency Under a Load

Being that many applications of superabsorbent polymers perform under a load, such as diapers, pet pads, and feminine hygiene products, the polymer must perform properly and still meet standards under these conditions. In order to test performance under a load, the polymer will be synthesized and saturated, using the previously described methods. After saturation of the SAP, various amounts of pressure will be applied to the polymer using a weight. The polymer mass will be measured before and after the load to determine the amount of liquid lost during performance. Weight versus mass loss graphs can be deducted from this process, which allows for an assessment of the polymer’s success.

Similarly to performance under a load, superabsorbent polymers need to retain the water during movement or use to prevent leaking of any liquid, which is important in many applications. The water retention capability of the synthesized SAP will be tested by saturating the polymer with DI water to maximum capacity, using one of the saturation methods, and then placing the sample in a centrifuge and spun. Using the centrifuge will remove any excess water that is not retained in the SAP structure and will thus indicate how much water is retained during use.

Results

Using similar testing and characterization techniques, the absorbency of synthetic and biological polymers was successfully assessed. It was found that synthetic, industry-grade SAPs absorb 300–700 g of water for every 1 g of SAP [8, 9]. In these tests, sodium polyacrylate was used, being the most common SAP. Fossil-fuel-based SAPs, such as sodium polyacrylate, were found to have a very negative impact on the environment. During production, sodium polyacrylate generates various toxins which lead to water and air pollution. Sodium polyacrylate was also found to be highly absorbed in landfill soils and wastewater, which poses a serious problem due to the high toxicity of the SAP. In addition to the harsh environmental impact, sodium polyacrylate and other synthetic SAPs were found to not be biodegradable, taking hundreds of years to degrade [8,9,10,9,].

Similar to that of synthetic SAPs, tests have also been performed using biological polymers. There is not a lot of research on fully biological polymer networks, which includes a biological backbone and crosslinker monomer; however, many studies have been performed using synthetic monomers in conjunction with biological monomers. While the ideal biological SAP would have a biological backbone monomer and biological crosslinker monomer, this research can provide a foundation in developing a fully biological SAP. As seen in Table 2, the absorbency was tested for these hydrogels.

In current research, completely biological backbone and crosslinker monomers are being used, specifically chitosan, sodium alginate, and genipin. Using the synthesis and absorbency techniques outlined, hydrogels have been synthesized with these biological components to serve as a baseline for future research. Five main hydrogel compositions have been synthesized, with various ratios of chitosan and sodium alginate: 100% chitosan, 100% sodium alginate, 25% sodium alginate with 75% chitosan, 50% sodium alginate with 50% chitosan, and 75% sodium alginate with 25% chitosan. After the synthesis of each hydrogel was complete, absorbency testing was performed, using both the oversaturation and simple water addition methods.

An absorbency of 8.1 g of water absorbed for every 1 g of polymer (g/g) was found for the sodium alginate hydrogel in both the oversaturation and simple water addition absorbency testing methods, while an absorbency of 11.4 g/g was found for the 100% chitosan hydrogel in both absorbency testing methods. Absorbency capacities were also measured for each of the ratios containing a mixture of sodium alginate and chitosan with absorbency capacities of 9.88 g/g for the 25% sodium alginate hydrogel, 7.38 g/g for the 50% sodium alginate hydrogel, and 1.64 g/g for the 75% sodium alginate hydrogel. In order to relate the hydrogels to industrial standards, the same testing was performed for sodium polyacrylate. An absorbency capacity of 59.6 g/g was found for the sodium polyacrylate sample. A comparison of each of these polymers and their associated absorbency capacity can be seen in Fig. 1.

The research previously conducted in various studies in relation to biological polymer potential is very promising. While these tests used synthetic components and were not aiming to develop a fully biodegradable hydrogel, the results show that the use of biological backbones is possible while maintaining a high level of absorbency. In some cases, the biological backbone, specifically chitosan, performed just as well as current industry-grade synthetic polymers. Chitosan performed extremely well when crosslinked with a synthetic crosslinker, with absorbency of up to 700 g/g, which is at the high end of current technology. While there were SAPs in this study that performed well, there were also SAPs that performed very poorly. While this is not ideal, the results are still important. Despite the performance of the SAP, this study proved that biological-based SAPs can be successfully synthesized.

With these initial studies establishing a foundation, five fully biological SAPs were synthesized, with ratios of 100% chitosan-based backbone, 100% sodium alginate-based backbone, a backbone of 25% sodium alginate, a backbone of 50% sodium alginate, and a backbone of 75% sodium alginate. Based on absorbency characterization, the chitosan hydrogel performed best of all the hydrogel compositions, with the absorbency capacity significantly decreasing as the ratio of sodium alginate increased. While each SAP was successful, an ideal SAP will have a better absorbency capacity than any of the baselines created in order to meet the industrial standards of sodium polyacrylate, which may be addressed by altering the polymer composition. The absorbency capacity test results remained consistent across all absorbency capacity testing, the oversaturation, and simple water addition test methods, for each composition. Because the simple water addition test is more time effective, provides consistent results with the oversaturation method, and is more accurate due to the ability to control the polymer, the simple water addition test will continue to be used in future testing.

Conclusions

With the urgency of the speed at which plastic accumulation is increasing, the need for biodegradable and biobased alternatives to plastic is at an all-time high. SAPs negatively impact the environment through the production and degradation processes and plastic accumulation. In order to address these issues, biobased polymers are being designed and developed.

Previous studies successfully created SAPs with biological backbone monomers. These studies used synthetic crosslinkers; however, the results were promising. This research proved that a biological SAP was possible and that there is potential to develop a fully biological SAP. Using these studies as a guide and using standard hydrogel synthesis techniques involving backbone and crosslinking components, five biological SAPs were designed and synthesized. Each SAP used a varying ratio of chitosan and sodium alginate as the backbone, all compositions using genipin as the crosslinking component. Each polymer network successfully absorbed water and further proved that biological SAPs are possible. The absorbency capacity of the hydrogels needs to be significantly increased in order to meet the industrial standard of sodium polyacrylate; however, the initial results are promising and will be explored in future testing.

In order to optimize and further develop these SAPs in order to maximize absorbency, more testing is needed. Water and liquid retention testing will be performed in order to determine how much liquid the hydrogel network can retain under a load, as well as measuring the amount of time it takes for the SAP to absorb a liquid. The ion concentration of the liquid absorbed into the matrix will also be tested. This will be done by absorbing liquids with varying pH in order to determine the effect of ion presence on the performance of the SAP. In order to optimize each of these hydrogel characteristics, alteration of the chemical composition will be performed, specifically alteration of the ratio of crosslinker to backbone. In addition to these future directions, optimization of the drying and synthesis techniques and processes will need to occur in order to better standardize and optimize the overall SAP synthesis, which will ideally aid in the performance of the hydrogel.

The construction of bioreactors, including the environments and microbes that samples will be placed in, is a challenge for measuring how degradable these materials are. The systems needed to achieve acceptable results largely depend on maintaining optimal conditions. Failure to do so may render inconclusive results. Characterization standards for these materials are dependent on constraints including the expected time frame of degradation, sample composition, and intended use. As polymers derived from natural, renewable resources become increasingly available for single-use consumer applications, and removal of these polymers via composting or repurposing through recycling is the next emerging trend. Non-biodegradable polymeric materials mostly accumulate in landfills and remain intact without any degradation for hundreds of years. Developing fully biodegradable plastics is a crucial step in alleviating environmental stresses induced by municipal waste products.

References

Lindwall C (2020) Single-use plastics 101, NRDC (2020)

Hamilton J, Reinert K, Hagan J, Lord W (1995) Polymers as solid waste in municipal landfills. J Air Waste Manag Assoc 45(4):247–251

Prata JC, Silva ALP, da Costa JP, Mouneyrac C, Walker TR, Duarte AC, Rocha-Santos T (2019) Solutions and integrated strategies for the control and mitigation of plastic and microplastic pollution. Int J Environ Res Public Health 453–500

Martin JE (1998) Environmental impact studies of the disposal of polyacrylate polymers used in consumer products. Sci Total Environ 191(3):225–226

Ahmed EM (2013) Hydrogel: preparation, characterization, and applications: a review. J Adv Res 6(2):105–121

Buchholtz FL, Peppas NA (1993) Superabsorbent polymers: science and technology. HathiTrust 573(7):88–99

Kijchavengkul T, Auras R, Rubino M, Ngouajio M, Fernandez R (2006) Development of an automatic laboratory-scale respirometric system to measure polymer biodegradability. Polym Test 25(8):1006–1016

Chen S-C, Wu Y-C, Lin Y-H, Yu L-C, Sung H-W (2017) A novel pH-sensitive Hydrogel Composed of N,O-carboxymethyl Chitosan and Alginate cross-linked by Genipin for protein drug delivery. J Controlled Release: Off J Controlled Release Soc 96(2):285–300

Geissdoerfer M, Savaget P, Bocken N, Hultink E (2017) The circular economy—a new sustainability paradigm? J Clean Prod 143:757–768

Essawy HA, Ghazy MBM, El-Hai FA, Mohamed MF (2016) Superabsorbent hydrogels via graft polymerization of acrylic acid from chitosan-cellulose hybrid and their potential in controlled release of soil nutrients. Int J Biol Macromol 89:144–151

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Draney, K., Bates, J. (2022). Biodegradable Superabsorbent Polymers. In: TMS 2022 151st Annual Meeting & Exhibition Supplemental Proceedings. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-92381-5_69

Download citation

DOI: https://doi.org/10.1007/978-3-030-92381-5_69

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-92380-8

Online ISBN: 978-3-030-92381-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)