Abstract

Due to the variety and interaction of volatile influencing factors as well as the increasing requirements resulting from individualization, the prediction of future demand development is becoming increasingly difficult and complex. In manufacturing companies, this leads to a need for shorter and faster production planning cycles. In addition, the production network must be secured against uncertainty. This is possible by scenario analysis integrated into automated planning. In this paper, an automated scenario analysis in combination with deterministic modeling for integrated product allocation and global network configuration is developed to tackle demand uncertainty in a medium-term planning horizon. When creating scenarios, a trade-off arises concerning the completeness of possible developments and the manageability of the set. The objective is to achieve a representative coverage of possible future states by a small number of reasonable scenarios. Therefore, change drivers are defined that can lead to modifications of customer orders. This is followed by an automated simulation of the occurrence of the change drivers using a Monte Carlo simulation with a high number of samples for statistical validation. A cluster analysis with upstream principal component analysis is used to reduce the number of scenarios while maintaining representativeness. Finally, the scenarios are optimized in a production planning tool. The approach is applied to a real use case. The results are used to validate the representativeness of the scenarios, as well as to conclude robust decisions.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Scenario analysis

- Uncertainty in production

- Changeability

- Global production systems

- Production system planning

1 Introduction

The ability to plan production and predict future developments has become steadily more difficult over the past 30 years due to growing uncertainty. This uncertainty results from increasingly fast-changing framework conditions, growing individualization and a high diversity of variants [1], which particularly affects demand and capacity in terms of quantity and flexibility. For global production networks, this represents a major challenge for their production strategy [2]. In the manufacturing environment, it also means that matching production resources and customer orders is becoming increasingly complex in the context of order allocation [3].

This leads to the need to be able to react quickly and in a robust manner to changing environmental conditions. In addition, the timely recognition and consideration of possible changes are of decisive importance for economic success [4]. One conceivable option is to automate global network configuration planning and job allocation for a single scenario, which leads to acceleration of planning but does not create a robust solution. If, on the other hand, several scenarios are considered, the time required for compilation increases in the case of classical scenario analysis methods, and the representativeness or required quantity is limited. With stochastic methods for the creation of a large number of scenarios, the future can be covered representatively, but due to the high amount of scenarios the manageability decreases. Based on the later validation, an Input is representative, if it covers all defined change drivers, such that the result based on this input can been seen as robust against these change drivers.

Section 2 summarizes the current state of the art referring these research problems.

The answer to this dilemma is a combination of a stochastic scenario building, an automated method to reduce the scenarios to a manageable number as well as the use of a deterministic automated planning tool to calculate an optimal network configuration and product allocation for each scenario which enables robust decisions based on these solutions (Sect. 3). Section 4 applies this approach to an industrial use case of an automotive supplier leading to the conclusion in Sect. 5.

2 State of the Art

The complexity of planning decisions as allocations and network configurations considering various restrictions leads to the fact that mathematical and optimization models are often used as a support. These optimization models are used to automatically find an optimal solution concerning quantitative goals [5]. Thus, various approaches can already be found in the literature that use optimization approaches for the configuration and product allocation in global production networks [6].

When designing the manufacturing network structure and defining an allocation strategy, the uncertainty of influencing factors has to be considered [3]. The ability to make early and proactive adjustments at all levels of the production system in order to respond economically to influencing factors, their uncertainty and the resulting challenges, is referred to as changeability. A distinction can be made between flexibility and reconfigurability. While flexibility is the ability of a system to react to changes without additional investments, reconfigurability describes the possibility to adapt the production system with little effort. Uncertain influencing factors that trigger such changes are called change drivers [1]. One option to consider them is the usage of specific scenarios, which are optimized individually.

While classic scenario analysis techniques were developed for strategic business management, similar methods are also used in strategic production planning. Due to the time consumption and limited manageability of many scenarios, few mostly qualitative scenarios are built based on possible developments of change drivers [7].

Other approaches use stochastic models, such as a Monte Carlo simulation, to create a variety of quantitative scenarios and representatively map the scenario funnel. [8] use this approach to generate scenarios for their design and planning model for manufacturing systems. Therefore they apply an accelerated Benders’ decomposition to solve a high number of scenarios. [9] use the Monte Carlo analysis to simulate scenario-based possible change drivers and developments, which were identified by experts. [18] combine possible customer order configurations into scenarios through Monte Carlo simulation. To be applicable for robust cost-minimal optimization of the medium-term order allocation, [10] reduce the number of scenarios by clustering.

Besides production, there are further approaches in literature that address similar problems and also identify ways to reduce a high number of scenarios. [11] simulate a “closed-loop” network with a scenario-based stochastic optimization model. To reduce the number of scenarios a k-means cluster algorithm is used. [12] build scenarios for investment decisions. Therefore, two approaches are applied. The first approach combines intervals of two uncertain parameters. The second approach clusters historic combinations of the uncertain parameters by using a k-means algorithm. [13] develop a stochastic model of the supply chain. For this purpose, scenarios are created using the Monte Carlo simulation and the number of scenarios is reduced by the application of a sample average approximation approach. All in all none of these approaches solves the problem of enabling robust decision making under uncertainty in global production networks. The aim of this paper is to combine production needs with state of the art scenario techniques to only plan for relevant demand scenarios.

3 Approach

The present approach combines and advances the existing methods to secure a global production network against uncertainty and ensures short-cycle production planning. Therefore, the methodology shown in Fig. 1 was developed which combines scenario analysis and automated planning for network configuration and product allocation.

The first step of the scenario building is the project definition by determining the object of investigation and recording the current status. As the approach is particularly created for product allocation and global network configuration, the object will usually be a specific product group or business unit. For the current status, a recent order list is needed together with the underlying assumptions. In addition, a decision concerning the time frame for the modeling of the scenarios and the planning is required.

The second step deals with the definition of different relevant change drivers, which affect the demand development. The aim of this phase is to map individual conceivable developments of various influencing factors in a machine-readable format. To ensure speed, change drivers are obtained as far as possible with secondary data (e.g. customers, variants etc.) and supplemented with expert interviews to guarantee accuracy.

The starting point is the order list identified in phase one as the as-is state, and the drivers represent a deviation from the assumptions contained therein. To define the change drivers, the probability of occurrence, the influence on the number of units, possible occurrence times and the affected orders have to be specified for each factor. Furthermore, drivers can be interrelated or mutually exclusive. This allows not only changes in the number of units, but also shifts in the demand for certain variants can be modeled, which is required for the flexibility of the production network.

The last step of the scenario building is a Monte Carlo analysis. A scenario is created by simulating the occurrence of the individual change drivers and their combined effects on the output scenario. With the scenario tool several scenarios are generated to representatively map the scenario funnel and statistically validate the result [14].

The third part of the approach deals with the creation of a limited number of representative scenarios by the reduction of the simulated scenarios. One possibility is to adjust the distribution of the scenarios to the objective value (e.g. costs). However, since the information about the achieved value is only available after optimization and it is impossible to optimize all scenarios, this is not feasible. Instead, other criteria must be defined that determine the difference between the scenarios and are relevant for product location or network design. For this purpose, a two-stage approach is used in which first general criteria are defined based on the existing order data and then independent relevant factors are formed employing a principal component analysis (PCA).

To keep it simple and fast for the user, only basic categories that are present in the order data need to be defined. The calculation of the values per scenario is done automatically. This already results in a large number of possible clustering criteria through the definition of a few categories. To reduce noise in the data, new independent factors are now formed within a PCA, which influence on the main difference (in the form of the highest variance) between the scenarios. For a better comparability, the criteria are scaled. After the PCA the number of factors to keep is selected by the literature approved “Elbow criterion”. An explanation and comparison of different approaches for determining the number of factors to retain can be found in [15].

Now the scenarios are grouped by using a k-means clustering approach. The goal is to pool similar scenarios together, while scenarios in different clusters should be as different as possible. The resulting factors of the PCA are used to define the scenarios in a multidimensional space. The euclidean distance between two scenarios defines their similarity. The k-means algorithm uses the error sum of squares as an assignment criterion and is applied due to its high speed and high prevalence. For a more detailed explanation of this cluster algorithm see [16]. The number of clusters is equivalent to the resulting number of representative scenarios and has to be determined by the user.

The third step is to select a representative scenario for each cluster. In the k-means algorithm, the centroid is representative of a cluster [16]. However, the centroid represents a point in the multidimensional space and usually not a possible scenario. Therefore, for each cluster, the scenario closest to the centroid is chosen as representative. Moreover, a weighting for each representative is calculated, which indicates the number of scenarios represented by the representative.

The representative demand scenarios are now used for the optimization and robust decision making for the allocation and network configuration. For this purpose, an automated deterministic optimization model based on the developments of [17] is used in this work to enable short-cycled planning by ensuring speed and limited computing time. By the automated optimization of the scenarios, the result is a production plan for each representative scenario, with the utilization of individual lines in the global production network and additional upgrade decisions taking into account several cost terms and restrictions. After the sequential optimization, the optimal results of each scenario are jointly observed. This allows to identify decisions that lead to good outcomes for the majority of scenarios. Furthermore, a conclusion about the possible cost distribution can be drawn on this basis. The information gained about uncertainty can thus be taken into account in the decisions on allocations, production system configuration and the final production plan. For the creation of a robust production plan based on the individual results, reference is made to the approach of [17] as a possible procedure.

4 Application

The validation of the developed approach takes place in a series production for automotive components and is part of a research partnership with the objective to design an agile production system. The partnership consists of the wbk Institute for Production Technology at the Karlsruhe Institute of Technology (KIT) and the central department Connected Manufacturing of the Bosch Powertrain Solutions division.

The scenario building starts with the project definition. The object of investigation is a product group with about 200 variants, which have to be allocated on 13 global distributed production lines. The lines are at significantly different stages of expansion in terms of their capabilities and can therefore only produce certain variants. Moreover, operating costs, cycle times, and capacities differ between the lines. However, it is possible to upgrade lines at certain costs. At present, planning is based on an order list with over 1000 orders for a period of seven years. Half-yearly demand predictions and order-specific information are available.

Around 150 change drivers are specified which are uncertain and affect the demand of orders. Therefore, existing data about the acquisition chance is used for each not already accepted order. Furthermore, change drivers and their characteristics (like probability, affected orders etc.) are determined by expert interviews. Thereby, also the connection between drivers are specified, e.g. if A occurs B does not. Based on the defined change drivers 100.000 demand scenarios are simulated by a Monte Carlo analysis.

To ensure applicability and manageability in optimization, the creation of a limited number of representative scenarios is now conducted. To enable a comparison, different numbers of representants (4, 8, 10, 12, and 15) are created. Existing information is used to create possible clustering criteria. In the use case, the total number of parts, the number of parts per period, customer, and country of delivery as well as the number of different variants in a scenario is employed to create 106 different criteria.

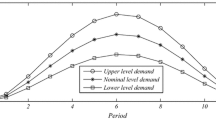

By applying a PCA and the elbow criterion, the reduction to seven factors occurs in the use case. Based on these factors, clustering is now performed using the k-means algorithm. The resulting number of ten clusters corresponds to the number of desired representative scenarios. These are each chosen as the scenario closest to its centroid. Figure 2 shows the resulting scenario funnel of ten representative scenarios with respect to the criterion “number of pieces” and the probability of the occurrence of the underlying cluster (thickness of the line) in comparison to the scenario funnel of 1000 randomly simulated scenarios.

Now the serial optimization and robust decision making for the representative scenarios takes place using the deterministic model of [17]. In addition to the representative scenarios, a reference of 100 random scenarios is optimized to be able to evaluate the approach. While the optimization of the representative scenarios can be done overnight even for fifteen scenarios, the reference needs more than three days, which is inapplicable in a short-cycled planning process. To estimate the goodness of the representative scenarios in the use case, a cost distribution is first created based on the reference. Then, the cost distribution is calculated using the representative scenarios and the overlap of these distributions with the reference is used as a measure of goodness. The calculation also takes into account the weightings of the representatives. Figure 3 shows the results and additionally the distribution based on different samples of ten random scenarios each. The use of ten random scenarios leads to a large scatter and on average to significantly worse results even than four representative scenarios.

In the use case, it can even be seen that ten representative scenarios lead to a significantly better result than 95% of the random samples. A second evaluation is done by comparing the line upgrade decisions, which would be done with the reference of 100 scenarios, the representative scenarios, and the current (initial) planning scenario. In the use case these upgrades, e.g. buying a station at a line, come with high investments. The result, which is displayed in Fig. 4, shows that the representative scenarios would lead to the same decision as the reference while the initial plan seeming to be an edge scenario, which would differ here.

Already these evaluations show the representativeness of the scenarios in the described use case which leads to more robust decisions. For the creation of an entire robust production plan based on scenarios, please refer to [17].

5 Conclusion and Outlook

This paper presents a new methodology for hedging short-cycle and automated production network planning against uncertainty. It consists of three parts of which the first phase is scenario building with the project and change driver definition as well as a Monte Carlo simulation. The second part is the representative reduction to a manageable number of scenarios by using a PCA and a k-means cluster algorithm. The last step is the application and examination of the scenarios in an optimization model to build robust allocation and network configuration decisions.

The results show that the supposed method can be applied to an industrial problem and support robust decision making. Furthermore, at least for the considered use case, it is possible to obtain a representative mapping with less scenarios and thus to reduce the effort with low decrease in quality compared to the reference of 100 scenarios.

To validate the approach and prove general applicability, it has to be applied to more use cases. Moreover, further research is needed to implement other risk factors than demand uncertainty in the model like capacity uncertainty. As an outlook, it could be interesting to also add the possibility to identify risk and chance drivers in a production network by combining the scenario analysis with a sensitive analysis.

This research was funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) - DFG “Dynamic Allocation Planning” – 408367989.

References

Wiendahl, H.-P., et al.: Changeable manufacturing - classification, design and operation. CIRP Ann. 56(2), 783–809 (2007). https://doi.org/10.1016/j.cirp.2007.10.003

Francas, D., Kremer, M., Minner, S., Friese, M.: Strategic process flexibility under lifecycle demand. Int. J. Prod. Econ. 121(2), 427–440 (2009). https://doi.org/10.1016/j.ijpe.2006.12.062

Lanza, G., et al.: Global production networks: design and operation. CIRP Ann. 68(2), 823–841 (2019). https://doi.org/10.1016/j.cirp.2019.05.008

Mietzner, D.: Strategische Vorausschau und Szenarioanalysen: Methodenevaluation und neue Ansätze. Gabler Research, Wiesbaden (2009).https://doi.org/10.1007/978-3-8349-8382-4

Klein, R., Scholl, A.: Planung und Entscheidung: Konzepte, Modelle und Methoden einer modernen betriebswirtschaftlichen Entscheidungsanalyse. Franz Vahlen, München (2012). https://doi.org/10.15358/9783800658855

Mariel, K., Minner, S.: Strategic capacity planning in automotive production networks under duties and duty drawbacks. Int. J. Prod. Econ. 170, 687–700 (2015). https://doi.org/10.1016/j.ijpe.2015.05.033

Claus, T., Herrmann, F., Manitz, M. (eds.): Produktionsplanung und – steuerung. Springer, Heidelberg (2015). https://doi.org/10.1007/978-3-662-43542-7

Bihlmaier, R., Koberstein, A., Obst, R.: Modeling and optimizing of strategic and tactical production planning in the automotive industry under uncertainty. OR Spectr. 31(2), 311–336 (2015). https://doi.org/10.1007/s00291-008-0147-2

Staehr, T., Englisch, L., Lanza, G.: Creation of configurations for an assembly system with a scalable level of automation. Procedia CIRP 76, 7–12 (2018). https://doi.org/10.1016/j.procir.2018.01.024

Buergin, J., et al.: Robust assignment of customer orders with uncertain configurations in a production network for aircraft manufacturing. Int. J. Prod. Res. 57(3), 749–763 (2018). https://doi.org/10.1080/00207543.2018.1482018

Khatami, M., Mahootchi, M., Farahani, R.Z.: Benders’ decomposition for concurrent redesign of forward and closed-loop supply chain network with demand and return uncertainties. Transp. Res. Part E Logistics Transp. Rev. 79, 1–21 (2015). https://doi.org/10.1016/j.tre.2015.03.003

Baringo, L., Conejo, A.J.: Correlated wind-power production and electric load scenarios for investment decisions. Appl. Energy 101, 475–482 (2013). https://doi.org/10.1016/j.apenergy.2012.06.002

Santoso, T., Ahmed, S., Goetschalckx, M., Shapiro, A.: A stochastic programming approach for supply chain network design under uncertainty. Eur. J. Oper. Res. 167(1), 96–115 (2005). https://doi.org/10.1016/j.ejor.2004.01.046

Hahn, G.J.: Sample sizes for Monte Carlo simulation. IEEE Trans. Syst. Man Cybern. SMC-2, 678–680 (1972). https://doi.org/10.1109/TSMC.1972.4309200

Zwick, W.R., Velicer, W.F.: Comparison of five rules for determining the number of components to retain. Psychol. Bull. 99(3), 432–442 (1986)

Han, J., Kamber, M., Pei, J.: Data Mining: Concepts and Techniques, 3rd edn. Elsevier Professional, Amsterdam (2011)

Bruetzel, O., Kueppers, F., Overbeck, L., Verhaelen, B., Stricker, N., Lanza, G.: Eine automatisierungsgerechte robuste Produktionsplanung. ZWF 116(1–2), 1–5 (2021)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Springer Nature Switzerland AG

About this paper

Cite this paper

Bruetzel, O., Voelkle, D., Overbeck, L., Stricker, N., Lanza, G. (2022). Automated Production Network Planning Under Uncertainty by Developing Representative Demand Scenarios. In: Andersen, AL., et al. Towards Sustainable Customization: Bridging Smart Products and Manufacturing Systems. CARV MCPC 2021 2021. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-90700-6_52

Download citation

DOI: https://doi.org/10.1007/978-3-030-90700-6_52

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-90699-3

Online ISBN: 978-3-030-90700-6

eBook Packages: EngineeringEngineering (R0)