Abstract

Nowadays, packaging is a crucial step to ensure the preservation of beverages during storage, transport, distribution, retailing and consumer handling. The drawbacks of traditional materials and the increasing demand for higher quality and safe products by consumers has led the packaging industry to develop new packaging systems. Many of the advances have been focused on active packaging, which aims to prolong shelf life, ensure food quality and safety and reduce the environmental impact of the packaging industry. This chapter will be focused on the main applications of the releasing active packaging systems in different beverages. Antioxidant and antimicrobial applications stand out, since oxidative reaction and microorganisms’ growth are the major causes of beverage deterioration and spoilage. Regarding antioxidant packaging, several extracts and natural antioxidants have been effectively included and intentionally released from packaging. Similarly, a great variety of compounds have been employed in antimicrobial packages, like metal nanoparticles, bacteriocins or natural antimicrobials. In addition, other type of applications could be described. Functional applications, which aim to improve the organoleptic characteristics of the product and/or bring health benefits to the consumers. Some examples are the gas releasing in beer or the nutrient release in different drinks. Finally, self-cooling packages for beer and soft drinks and self-heating packages for chocolate, soup and coffee have been developed, but some of these advances have not obtained a great commercial reception. This great variety of applications show that active packaging is a promising industrial sector, which is expected to continue growing an incorporating new scientific advance.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

1.1 History, Role and Other Implications of the Beverage Packaging

Food and beverage industry are continuously growing and developing new products thanks to the new advances in food technologies and also to the increasing demands of consumers, whose interests change depending on their preferences, publicity and progressively more on product’s health properties and their environmental implications (Hao et al. 2019). Although packaging is not the industry most striking at first sight, it is a powerful and competitive sector as every item produced by food and beverage industry needs to be packaged in order to store and protect the product (Chen et al. 2017). From a simple point of view, packaging needs to fulfil three objectives: food protection, identification and labelling, and marketing purposes. However, consumer demands are evolving to other interests. Nowadays, they seek healthier foods, more sustainable, improved food safety and quality, and waste reduction (Borah and Dutta 2019). This change on their preferences has led companies to face the continuous challenge of satisfying consumers’ requirements. Currently, companies are forced to explore new shapes, sizes, materials and functions of packaging to boost their productivity, improve their processes and the end of the process, find the most convenient products for consumers. In general terms, packaging can be defined as a way for presenting, protecting, identifying, containing and providing compliance for a product through the different processes until they reach consumer hands (Borah and Dutta 2019). Food supply chain is usually formed by independent processes that could be group in five steps: raw material collection, food or beverage processing, distribution, retailing and consumer handling. Packaging procedure occurs during the second step and so, the product must pass through the remaining sections once it is packaged. Therefore, packaging is a crucial step as it must ensure the preservation of the product during storage, transport, distribution, retailing and consumer handling (Hao et al. 2019). By packaging, products are closer to reach higher food quality and prolong their shelf life. Food quality is modified by different parameters, fundamentally, biological factors (i.e. spoilage microorganisms), time and environmental conditions (i.e. temperature, humidity, light, contaminants presence, etc.) that can lead to product degradation, and this can be avoided by the type of packaging (Van Der Vorst et al. 2010).

The history of beverage packaging first started linked to prehistoric times when humans left their nomadic lifestyle to become a sedentary society, thus packaging arose as a technique for preserving food. Firstly, beverages were storage into wooden barrels, due to its low cost manufacturing. Later, glass containers were developed (Butler and Joseph 2008). Particularly, glass has a long history as packaging material as it guarantees healthy taste, it offers great protection due to its inflexibility and it is recyclable, among other properties. This material was one of the first used for beverage packaging and is still used today. Then, metal came and since its appearance, it has been widely employed and sometimes even categorized as the most adaptable material for its blending properties (Boarca et al. 2019). At last, plastic arrived hand in hand with the carbonated refreshment industry, particularly, in 1970 by Pepsi® who presented the 2 L bottle made of polyethylene terephthalate (PET). From this moment, plastics became the most employed materials for packaging due to their properties, as they are very malleable and synthetically safe and therefore, they have low production cost. However, plastic has shown a series of drawbacks as its variability in terms of vapors, light, gases and low molecular size particles penetrability (Borah and Dutta 2019). But most important, its widespread use has been questioned during the last years because of the ecological implications of its excessive use. For this reason, different organizations such as World Economic Forum or Ellen MacArthur Foundation have claimed that innovation systems could solve this problem (Cordier and Uehara 2019). At this context, biopolymers have been presented as an alternative for plastics as they are biodegradable, ecofriendly and an excellent vehicle for carrying substances with active properties as antimicrobial, antioxidant or food supplements. Unfortunately, these polymers do not show the key properties that plastic offers and thus, their use has been limited (Borah and Dutta 2019).

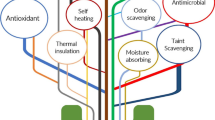

Beverages market is constantly growing and therefore, companies compete for distinguish their products, among others. New packaging approaches and trends are a promising option for increasing the products attractiveness (Borah and Dutta 2019). Traditional packaging acts as a passive barrier, but now manufacturers are intended to find modern and safe packaging systems (Boarca et al. 2019). Active packaging is aimed to prolong shelf life, ensure food quality and safety, reduce environmental impact and increase product attractiveness (Fang et al. 2017). The term refers to an active system that can influence and improve the product’s quality, solving the interactions among the packaging, the product and the environment. In general, active packaging allows to control and modify the product atmosphere by means of two strategies: absorbing (scavengers) or releasing (emitters) molecules. For instance, it can act as oxygen (O2) scavenger, carbon dioxide (CO2) scavenger or emitter, moisture regulator, flavor or odor liberator or absorber and emitter of other compounds with bioactive properties such as antioxidant or antimicrobial (Borah and Dutta 2019; Boarca et al. 2019). A schematic picture of how molecules are absorbed or released is presented in Fig. 13.1. In summary, it is responsible for releasing or absorbing substances in a controlled way to add extra functions and improve product functionality at the same time that product deterioration is decreased and spoilage microorganisms growth is inhibited (Boarca et al. 2019). In addition, a third category has been noted: immobilized, where active agents linked by covalent bounds interact with the packaged beverage (Romani et al. 2020). Among active packaging releasing strategies, the most studied have been the controlled release of antioxidant and antimicrobial substances, since oxidative reactions and spoilage microorganisms are the main causing agents of degradation in beverages (Ho et al. 2004; Gómez-Estaca et al. 2014).

Schematic picture of how molecules are absorbed or released in active packaging systems. (Modified from Ahmed et al. 2017)

1.2 Legislation

As active and intelligent packaging are relatively new in food and beverage industry, legislation is needed to accomplish the requirements of safety and quality. In this regard, a brief revision of the regulations in Europe and United States (US) is presented in the following lines. In general terms of the European Union (EU), containers must fulfil the Directive 2001/95/EC known as the General Product Safety Directive that provides the guidelines for safety requirements and the related responsibilities of ensuring products safety by the producers (Cushen et al. 2012). There are also general regulations for classification, labelling and packaging of substances and mixtures, regulated by Regulation (EC) No 1272/2008 (Cushen et al. 2012). In EU, the first regulation that explicitly mentions active and intelligent packaging is the European Regulation on Materials and Articles Intended for Food Contact (EC) No 1935/2004. This regulation gives the legal frame for food packaging, also including active food contact materials (FCMs). This is a new type of material that maintains or improves the condition of the product. It regulates the use of active and intelligent packaging due to its beneficial properties on food safety, quality and shelf life. It also refers to the risk of migration of constituents that could damage human health or deteriorate food quality. In addition, products should accomplish with the Food Additive Directive (89/109/EEC) in relation to labelling of the authorized compounds allowed to be released from the active FCMs (Cushen et al. 2012; Dainelli 2015). More recently, the specific regulation (EC) No 450/2009 on Active and Intelligent Materials and Articles Intended to Come in Contact with Food was adopted in active packaging legislation. In this case, it regulates that, if the product is submitted to a legislation that limits the total quantity of a substance in a product, the released substance by the active FCMs must appear in the ingredients list. It also points out the migration issue that must undergo the same safety assessment that plastic materials, according to the European Food Safety Authority (EFSA) evaluation and an European Community (EC) authorization (Cushen et al. 2012). At this regulation is also stated the definition of active packaging system as “deliberately incorporate components that would release or absorb substances into or from the packaged food or the environment surrounding the food” (Yildirim et al. 2018). It is worth to mention that depending on the material where the active or intelligent system is incorporated, packaging must accomplish with the corresponding associated legislation. For instance, if this material is plastic, it should fulfil Regulation (EC) No. 10/2011 and its amendments (Dainelli 2015). Moreover, legislation can vary among different countries. For instance, in the case of US there is no specific regulation about active packaging, although their use is regulated by the normative provided by the FD&C Act, Section 201(s) (21 U.S.C. 321) (1958) as they act as food indirect additives and their approval is submitted to the Food and Drugs Administration (FDA) (Dainelli 2015). However, even though the regulations on the EU and in the US have been developed independently, general requirements are quite similar. Moreover, there is still an open via for further regulations and in general, future challenges in terms of legislation, innovation and risk assessment of the use of these new active packaging systems (Restuccia et al. 2010).

2 Packaging Technology

As stated before, packaging industry moves huge amounts of money annually and is subject to continuous technologic progress with the aim of reducing costs, improving preservation or being a distinctive brand, making a product recognizable just by looking at the package. This progress allows us to distinguish between traditionally used packages and those developed in recent decades.

2.1 Typical Materials Used in Beverages Packaging

Several packaging materials can be used in beverages such as plastic, paper, paperboard, cardboard based packaging, wood, metal or glass, having all been used over many years. However, despite this great variety of materials not all can be used with all beverages. A suitable choice of packaging material is essential to better preserve the food during its shelf life. The different advantages and disadvantages of each type of packaging material , summarized in Table 13.1, are of great interest for the choice of material. In many cases, to avoid the inconveniences, several materials are combined to obtain better packaging characteristics. In this way, protection is increased due to the application of a multilayer system.

One of the containers with the worst opinion by the consumer is plastic. Despite the risks present in plastic, it is still the most widely used material in beverages not only for being economical, but also for its mechanical properties that make it easy to manipulate (heat seal, optical properties, moldable) (Farmer 2013). In fact, if the most common way to see plastic packaging is in a bottle, there are also packaging in the form of bags consisting of several heat-sealed layers, used to package beverages such as milk, wine or teas (Ghoshal 2019). This material has the advantage of being able to be applied in multilayers, which reduces part of the drawbacks it presents. Its main drawbacks are a variable permeability to light, gases, vapors, and low molecular weight molecules. Different types of plastic have been developed and each one has its own characteristics and properties that will determinate its application. The most used are PET, high-density polyethylene, polycarbonate, low-density polyethylene (LDPE), polyvinyl chloride and polystyrene, being all polymeric materials (Núñez et al. 2015) (Table 13.2). Among all these types, the most suitable is usually PET, since it allows hot filling, a technique that permits sterilization and increases the shelf life of the packaged product. In addition, it is cheaper than other types of packaging. PET have less barrier toward O2, which may be corrected by using flexi composite combination such as metalized polyester/polyester/polyethylene. Thermoplastic along with paperboard and aluminum foils are used in aseptic packaging, which also act as a strong barrier to O2 and light. These packages are characterized by being stable at room temperature (Welle 2011).

Other common materials in beverage packaging are glass and metal. The first one is used in the production of bottles for the packaging of fruit drinks, especially for those of higher quality. Furthermore, the drinks packaged with this material are usually gourmet or alcoholic. However, more and more juice is produced in bricks (Ghoshal 2019). This material has the advantage that it can be melted and re-molded as many times as desired, and glass can also be reused. Fusion process is carried out at relatively low temperatures, so it does not entail a high energy expenditure either. The latest advances in this field have also reduced the thickness of the material, reducing not only the weight of the containers, but also CO2 emissions (Vinci et al. 2019). Regarding the second one, several metal materials have been used in beverage packaging. For example, steel is frequently used to make beverage bottles, while aluminum is typical used in carbonated refreshments to make coatings or layers. Aluminum presents the advantage of being moldable and light (Borah and Dutta 2019). Nevertheless, this material cannot be used in all beverages. For example, in wine, it develops sulfur smells. Corrosion problems can be avoided by making containers of several pieces that also prevent the release of aromas (Deshwal and Panjagari 2020). The case of alcoholic beverages is especially interesting because consumers believe that the type of packaging has a great influence on its flavor. However, different studies have not shown significant differences (Barnett et al. 2016).

2.2 New Technologies and Materials for Beverage Packaging

The increasing demand for higher quality and safe products by consumers has led the packaging industry to make some significant changes in the use of ingredients and processing systems. This last section has generated great interest since consumer’s demand minimally processed, natural and fresh products, a challenge that has increased with the current globalization. Different advances have allowed to satisfy many of these needs as well as lengthening the useful life of the product (Dávila-Aviña et al. 2015). The most recent advances in packaging are not only focused on the application of multilayer systems, but also an in-depth investigation on active or intelligent packaging and materials with lower environmental impacts is being carried out (Marsh and Bugusu 2007). Therefore, the new advances are focused on changing the structure of the packaging material and the development of new systems (active or intelligent). In Table 13.3, the advantages and disadvantages of the emergent packaging systems have been summarized. The hot filling technique is based on filling the container with the hot drink (70–93 °C), and then sealed and kept it at that temperature for about 10 min, which sterilizes the product. This method is used especially for acid or acidified beverages and it has been described to improve their shelf life up to 6 months (Grumezescu and Holban 2019). Another packaging technology consists in the use of modified atmospheres. This method entails the exchanging of the gas surrounding by introducing a gas mixture in the container, optimizing the preservation of the beverage. There are different forms, being the most applied in drinks the gas-flushing and the compensated vacuum (Emblem 2013). But the systems that are grabbing the most attention are active and intelligent packaging. As mentioned before, active packaging is intended to extend the shelf life of a food, mainly achieved by controlling the permeability to O2 and moisture as these factors facilitate microbial growth, increase oxidative reactions and induce the development of off-flavor and color changes. Thus, it allows to improve the preservation of beverages due to interactions with the product or its environment (Dombre et al. 2015). This packaging system can be applied to different products, like concentrated milk, fermented milk, probiotic-rich fermented beverage, fruit juice, wine, beer, tea, coffee and others (Ghoshal 2019). Several examples of active packaging technologies are O2, CO2 and ethylene scavengers, antimicrobial component releasers, moisture, flavor and odor absorbers, and ethanol emitters (Sahu 2016). The addition of active substances through the packaging instead of directly to the food may be more efficient, thus reducing the amount of compound necessary, since most degradative processes take place on the surface of food. In addition, when added to the packaging, interactions with food compounds that may inhibit or reduce their activity or be lost during food processing are avoided (Yildirim et al. 2018). Other emergent technology is the use of intelligent systems, based on the use of components that monitor the condition of packaged food or the environment surrounding the product during transport and storage (Commission E 2011). Therefore, this system allows the users to obtain reliable and accurate information about food conditions, the environment and/or the packaging integrity (Vanderroost et al. 2014).

Regarding new advancements in packaging materials, numerous biopolymers have been developed, as well as nanoparticles, used to improve the mechanical and barrier properties of packaging materials (Borah and Dutta 2019). Other challenge for packaging industry is the reduction of the waste generated. As a possible solution, edible films and coatings are being developed. However, this type of coating still requires some of the other packaging (Malhotra et al. 2015). All these new advances mean that the standards and the requirements to be met by packaging are constantly changing and updating. It is important to point out that, before its application, toxicological studies should be carried out to demonstrate the safety of the packaging used. Different surveys carried out among consumers showed that they are willing to change the packaging so that it is more sustainable as long as neither the taste nor the price of the product is changed. This last factor may be due to the belief that individual actions are not enough to contribute to a greener world (van Birgelen et al. 2009).

3 Releasing Active Packaging Applications in Beverages

Nowadays, active packaging is one of the most promising fields in beverage packaging. Examples of active packaging technologies include absorbing systems (i.e. oxygen scavengers, humidity absorbers, etc.) and releasing systems. The last one is a new generation of materials that possess the ability to release active compounds, such as antioxidants or antimicrobials, at controlled rates. The packaging material acts as reservoir of the active compound, released into the food in a controlled manner during the expected storage time of the product. These active molecules need to be encased appropriately, to assure the release is not too slow or too fast (Farris and Piergiovanni 2012). Numerous applications and studies based on the release of compound have been developed. Some examples are described in Table 13.4. Generally, these applications are focused in the preservation of beverage against oxidation and the action of foodborne microorganisms, but several applications search enhancing the organoleptic qualities (flavor, taste or color of the product) or provide beneficial properties for the consumers.

3.1 Antioxidant

Antioxidant packaging aims to prevent or slow down the oxidation of beverage compounds, which causes the deterioration of physical characteristics (such as flavor and color). Generally, two basic methodologies to obtain antioxidant packaging systems have been described: (1) Independent devices like sachets, pads or labels, which contain the antioxidant agent separately from the food product, added to a conventional package, and (2) Antioxidant compounds included (directly or in combination with a releasing system, such as emulsions or encapsulated) in the manufacture of the package, so these compounds further migrate into the beverage (Gómez-Estaca et al. 2014). However, sachet scavengers loss their activity rapidly when they get wet (Butler and Joseph 2008). Thus, the second option is the most used among the bibliography. The chosen antioxidants must provide no color or odor and should be thermally resistant, so it do not degrade during the processing (Lagarón and Busolo 2012).

Nowadays, there is a tendency to substitute chemical synthetized antioxidant compounds used in food and beverages, such as butylated hydroxyl anisole and butylated hydroxyl toluene, by natural ones, because the first are suspected of damaging the health of consumers. Vitamins C and E and also phenolic compounds have been used as antioxidant additives. These antioxidants may prevent the oxidation of the product by different ways, such as scavenging reactive oxygen species or chelation of transition materials (Ephrem et al. 2018). This switch could have advantages to the packaging producer’s awareness and favor strategies more sustainable. For example, the project PHBOTTLE aims to develop polyhydroxybutyrate (PHB)-based materials with antioxidant properties made from sugars and carbon, nitrogen and O2-rich residues found in the waste water from juice bottling industries (Ramos et al. 2015). Numerous scientific studies have been focused on the development of new systems that effectively release antioxidants to protect different beverage product. Although some studies have not tested the systems in beverages, some of them employed aqueous models. The positive results suggest that they could be really useful for the beverage industry. For instance, green tea extracts were added to ethylene–vinyl alcohol (EVOH) copolymer films (López De Dicastillo et al. 2011). Green tea extract is rich in flavonoids and is currently considered a safe food additive. Flavonoids, like other phenolic compounds, have gained a great attention in the last years, due to their wide range of activities, including antioxidant and antimicrobial, among others. Furthermore, they present beneficial effects on the consumers’ health. The antioxidant properties of the material were evaluated by ABTS (2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) and DPPH (2,2-diphenyl-1-picrylhydrazyl radical) scavenging assays. The results showed that the extract was effectively released into the aqueous model and the material was able to reduce DPPH and ABTS radicals (López De Dicastillo et al. 2011). A similar study incorporated flavonoid rich cocoa extracts into ethyl EVOH copolymer (Calatayud et al. 2013). The antioxidant properties of the released compounds were evaluated by ABTS scavenging activity assay, using an aqueous model. The results showed that the films exerted antioxidant properties directly proportional to flavonoid content. In addition, the cocoa extract also protected Caco-2 human epithelial colorectal adenocarcinoma cell against oxidative stress induced by H2O2, without any cytotoxic effect. These results revealed that the developed films may be applied in the package of beverage as effectively antioxidant packaging (Calatayud et al. 2013). Novel active packaging materials have been developed by the covalent bonding of polyacrylates to tyrosol and hydroxytyrosol, two natural antioxidants compounds. The antioxidant properties of the materials were evaluated by DPPH assay and also in fresh orange juice. The last analysis indicated the ability of both polymers to inhibit the oxidation of ascorbic acid. However, more studies are needed, to assess the safety of the migrating compounds prior to its application in the beverage industry (Fazio et al. 2017). Other example is the incorporation of two natural antioxidant compounds, carvacrol and thymol, into polypropylene films. The migration pattern was evaluated in aqueous models and the antioxidant activity was assessed by DPPH assay. The results showed that both compounds incorporated into the films (at 80 g/kg) were effectively released in the models. Furthermore, they still remaining in the material after 15 days, showing a great potential for antioxidant packaging (Ramos et al. 2014).

The diverse application of nanotechnology in the food and beverage sector have been widely recognized. Some examples are the enhanced encapsulation of selected compounds or development of innovative active packaging systems. Recently, the interest of the food and beverage industry in nanoemulsions and nanoencapsulation has increased, since they can carry and release functional lipophilic compounds. This is the case of vitamin E acetate nanoemulsions, produced using edible mustard oil and surfactant Tween-80. The antioxidant activity of these material was evaluated by DPPH, to check its potential use in beverages. The positive results showed that the nanoemulsions could be used as beverage preservative (Dasgupta et al. 2015). Other studied have employed zein and cyclodextrins to encapsulate α-tocopherol (a type of vitamin E) to improve the shelf life of fruit juices (Saldanha do Carmo et al. 2017). The antioxidant activity was estimated by the oxygen radical absorbance capacity assay and shelf-life stability tests were conducted in strawberry juice. Despite the reduced antioxidant capacity observed, the α-tocopherol-zein-cyclodextrin nanoparticles enhanced significantly the shelf life of the juice. In addition, the particles do not induced cytotoxicity, thus, they are safe to be used in the beverage industry (Saldanha do Carmo et al. 2017). Trans-cinnamaldehyde has been recognized as a safe substance and has been applied in different food applications. This compound has been encapsulated, using chitosan-alginate nanoparticles and the antioxidant activity of the nanoparticles was evaluated by DPPH assay. The nanoparticles showed a concentration dependent antioxidant activity in apple juice, compared with free trans-cinnamaldehyde (Loquercio et al. 2015).

3.2 Antimicrobial

The antimicrobial active packaging is an emerging market sector in beverage packaging, principally because it faces the primary responsible factor of food spoilage: microbial spoilage. Studies in active packaging have focused in the incorporation of antimicrobial compounds to eliminate or reduce the growth of pathogens, extending the shelf life of the beverage. The release rate of the antimicrobial compounds should be controlled to maintain them at a specific range, providing an equilibrium between effective inhibition of microorganisms and preservation of the quality and safety of beverages (Boarca et al. 2019; Haghighi-Manesh and Azizi 2017). Most releasing systems with antimicrobial properties include metal nanoparticles (silver, gold, copper and zinc), natural antimicrobial compounds (nisin, chitosan, essential oils, etc.) and their combinations (Palomero et al. 2016).

Nanomaterials may improve the packaging properties and provide interesting properties, including antimicrobial (Ríos-Corripio et al. 2019). In the past years, several products whose package contain nanoparticles have arrived at the market. For instance, silver and zinc oxide nanoparticles have been demonstrated to extend the self life of apple and orange juice (Cushen et al. 2012; Yildirim et al. 2018). In numerous studies, nanoparticles have been employed in combination with cellulose. For instance, silver/cellulose composite were used in the packaging of melon and kiwi juice. The results demonstrated that this system reduces the microbial growth of selected bacteria, molds and yeast during manipulation and storage (Lloret et al. 2012). Copper/cellulose composites have shown antifungal activity in pineapple and melon juice, obtaining four log cycle reductions of spoilage-related yeasts and molds, so it could be an interesting matrix for beverage packaging (Llorens et al. 2012). In addition, sub-lethal concentrations of copper inhibited the growth of Salmonella spp. and Escherichia coli if combined with lactic acid in carrot juice. Nevertheless, worldwide regulatory agencies should study the potential migration ions into the beverages and the possible health risks for the consumers before the industrial application of nanomaterials (Ríos-Corripio et al. 2019).

Several natural compounds have been used in active packaging to kill and inhibit the growth of microorganisms, being two of the most used nisin and chitosan. Bacteriocins are antimicrobial peptides synthesized from bacteria that have gained attention in the last years and several studies have demonstrated their potential in active packaging. Nisin is the most used bacteriocin, employed in packaging applications in numerous countries and has been approved by the FDA. The antimicrobial activity of nisin has been tested against different food pathogens. For example, this bacteriocin has been used in a soy protein film to inhibit the growth of Lactobacillus plantarum (Boarca et al. 2019). Nisin has been employed in the package of egg white and orange juice, showing inhibitory effects against bacteria and yeast and the consequent improvement of the self-life of the product (Boarca et al. 2019; Yildirim et al. 2018). Nisin/polylactic acid films have been designed for their use as packaging materials or coating on the surface for bottles to reduce the growth of microorganisms in fruit juice packaging (Jin and Zhang 2008). The effectivity of chitosan and carrageenan nanocapsules containing nisin has been evaluated in tomato juice. The releasing studies conducted in vitro showed that the particles released the nisin slowly and continuously during 2 weeks. Also, the antibacterial properties of the nisin were remained intact, since it inhibited the growth of M. luteus, P. aruginosa, S. enterica and Enterobacter aerogenes, even in the sixth month of storage (Chopra et al. 2014). A recent study has developed nanofibers using amaranth (Amaranthus hypochondriacus) protein isolate and pullulan with the ability to encapsulate nisin. The releasing kinetics of the nisin and the antimicrobial properties were assessed in apple juice. The fibbers effectively released the bacteriocin into the juice. In addition, the nisin maintained its antimicrobial properties, showing activity against L. monocytogenes, Leuconostoc mesenteroides and S. Typhimurium (Soto et al. 2019). The promising results suggest that this innovative material can be used in future active packaging applications. Nevertheless, other bacteriocins could be suitable for beverage protection. For example, pimaricin (natamycin) nanohydrogels have been applied in grape juice to control the microbial spoilage. The gels effectively released the piramicin and protected the juice against fungal degradation. Authors have stated the possibility of using this system, incorporating it into packaging materials to extend the shelf life of beverages (Fuciños et al. 2015).

Natural compounds and extracts with proven antimicrobial properties have been employed in active packaging applications . In the previously mentioned study of a new material based on the incorporation of cocoa extracts into EVOH polymer, the antimicrobial activity was assessed against the foodborne pathogens S. aureus, L. monocytogenes, E. coli and S. enterica. The results showed that films containing a 10%, 15%, and 20% of cocoa extract totally inhibited the growth of all microorganisms tested (Calatayud et al. 2013). The antimicrobial activity of the vitamin E acetate nanoemulsions, earlier mentioned, has been also assessed in mango juice. The nanoemulsion enhanced significantly the shelf life of the product, which was attributed to the antibacterial properties (Dasgupta et al. 2015). For years, essential oils have been used in the nutraceutical, cosmetic and pharmaceutic applications, due to its antimicrobial, antioxidant and flavoring properties. However, their inclusion in aqueous food is difficult, since they poorly soluble in water (Char et al. 2016). To solve this problem, different systems have been developed. Some examples which have proven their efficacy in different fruit juices will be described below. A nanoemulsion of orange essential oil has been formulated to prevent the spoilage of beverage produced by the yeast Saccharomyces cerevisiae. Its antimicrobial activity was tested in apple juice. In the highest concentrations of the nanoemulsion (8–2 μg/mL), no growth was observed during incubation. Carvacrol, a component from the essential oil of different plants, has been incorporated into carrot, apple and orange juices by emulsification. The antimicrobial activity of this compound were not altered by the process, so authors considered that the emulsions could be interesting for juice packaging (Char et al. 2016). In another study, thymol, a phenolic compound found in the essential oil of thyme, was stabilized in combination with nisin in oil-in-water emulsions, using starch octenyl succinate. The antimicrobial activity of the system was assessed in cantaloupe juice. The emulsion retained and protected the compounds effectively during the storage time. In addition, the antimicrobial properties of the compounds were not altered, since the growth of L. monocytogenes and S. typhimurium was inhibited (Sarkar et al. 2017). The antibacterial activity of chitosan-encapsulated and unencapsulated emulsions of the essential oil isoeugenol has been evaluated in carrot juice. Both systems presented antibacterial efficacy, quantified as the minimal bactericidal concentration against E. coli, being the encapsulated emulsion the most effective (Krogsgård et al. 2016). Other interesting compounds, chitosan and its derivatives, have been proposed for application in the beverage industry due to its antioxidant and antimicrobial, film-forming capacity, biodegradability, and recyclability. Paper-boards covered with a mixture of chitosan and/or nisin and a thermoplastic material have demonstrated to suppress the growth yeast on orange juice at low temperatures (<10 °C) (Ho et al. 2004). Recently, chitosan nanofibers were incorporated into poly(butylene adipate-co-terephthalate) films, which showed antibacterial activity against foodborne pathogens . Thus, this material is a promising option for active packaging for beverage industry (Rocha et al. 2017).

3.3 Functional

Functional packaging has gain attention in the recent years in the beverage industry. It consists mainly in the maintenance or improvement of characteristics of the packed beverage through different mechanisms. Sometimes, if a certain active packaging system implies that the beverage has beneficial properties for the health of consumers, some authors speak of the term “bioactive packaging” (Lopez-Rubio et al. 2006; Majid et al. 2018). Research and progress in this field include the development of functional beverages, nutrient delivery systems and methods for optimizing beverage characteristics, such as color, flavor and consistency (Butler and Joseph 2008). Some examples of releasing functional packaging are the gas release in beer; flavor releasing in chocolate or bottled water; nutrient release in health, wellness and sports drinks; or probiotics encapsulation into fruit juices (Ramos et al. 2015; Nualkaekul et al. 2012).

Numerous active packaging applications are based in the release of compounds to enhance the organoleptic beverage properties. Gas releasing “widget” is one of the most known applications, developed initially for canned and bottled beer products, such as Guinness®. The widget releases CO2 to create a creamy and thick head, similar to the draught beer experience. Other breweries have adopted this system, and also other beverages, like coffee or shakes. Furthermore, the widget could prolong bubble release and generate other ‘theatre effects’ at the time of consumption. Beverages like fruit juices and coffee are expected to have a fresh aroma that replicates or evokes memory of the likely flavor of the product. Incorporating aromas into the packaging material may be employed to attract consumers when the container is open and balance any detrimental aroma loss. For instance, a chocolate aroma has been used in PET packaging of chocolate-flavored products. This strategy has been also applied in bottled water, to give different fruit smell to the product (Butler and Joseph 2008). Another example is the WO patent 2013032631 A1, which involves the encapsulation of aromatic compounds from essential oils in gelatin capsules. The gelatin capsules are broken when the package is opened, so the aroma compounds are released, causing a positive response from consumers (Zanetti et al. 2018). Regarding flavor improvement, several systems have been developed. In the beverage industry, enzymes are used to improve the yield and the organoleptic characteristics of the product, to appeal the consumer (Speranza et al. 2017). However, the inclusion of these compounds before packaging can be detrimental to the product. Thus, the idea of producing systems that allow the controlled release of these enzymes into the product has raised (Ramos et al. 2015). In the juice processing, the enzyme β-glucosidase is commonly use to hydrolyze the glycoside precursors of the aroma compounds, what enriches the aroma and flavor of the juice (Speranza et al. 2017). Calcium-alginate beads have been employed to encapsulate β-glucosidase and its stability was investigated in sugarcane juice. The results showed that the enzyme was more stable to temperature and pH variations and its ability to hydrolyze the glyosidic linkage between sugars and phenolic compounds remained intact. Other enzyme widely used in the beverage industry is the naringinase, which eliminates the bitterness of juices, specially of the citrus one. This enzyme has been encapsulated into κ-carrageenan beads and added to grape juice, decreasing the bitterness of the juice (Ephrem et al. 2018). Finally, some beverages contain nanoclusters that allow to enhance the taste of the product without having to add sugars to the drink (Pradhan et al. 2015).

Cyclodextrins have been considered useful compounds for the beverage industry and numerous studies have demonstrated that they protect interesting bioactive compounds, specially phenolic compounds, the antioxidant properties and, in some cases, the color and the organoleptic characteristic of beverages (Astray et al. 2020). In this aspect, a recent study evaluated the use of β-cyclodextrin to encapsulate the pigments of yellow bell pepper to provide color to isotonic beverages. Analysis demonstrated that the color provided by the encapsulated pigments were more stable than the pigment extract without cyclodextrins (Lobo et al. 2017). Other important characteristic that influences consumer’s appealing is the turbidity. The turbidity and cloudy appearance of some products, specially fruit juices, is caused by the presence of polysaccharides, that usually settle during storage, leading to a decrease of product quality. Enzymes are also used to clarify juices and appeal the consumer (Speranza et al. 2017). For example, the use of hydrogels to encapsulate ligninolytic enzymes has been considered. The results showed that the encapsulation improved the thermal stability of the enzyme in a wide range of temperatures (4–75 °C). In addition, the clarification of berry-pomegranate juice was higher with encapsulated enzymes than with the free ones (Gassara-chatti et al. 2013). Similarly, encapsulated xylanase was more efficient to clarify pineapple juice, obtaining a product less viscous and with few suspended solids (Speranza et al. 2017). Recently, a study immobilized a pectinase on modified montmorillonite clay by covalent binding. The immobilization did not alter the stability of the enzyme. Furthermore, the immobilized pectinase achieved a higher clarification rate, compared with the free enzyme. Thus, this system could be helpful for the fruit juice industry (Mohammadi et al. 2020).

As it is generally known, the interest in products more natural and with beneficial properties has growth in the last years. Numerous “bioactive packaging” applications have been developed and implemented at industrial level in recent years. This packaging can be performed using diverse mechanisms: (1) The regulation of the controlled release of compounds with bioactive properties; (2) Encapsulation of bioactive agents; and (3) Use of enzymes to transform particular beverage components. To our knowledge, most of these types of applications in beverage focus on the first two mechanisms. The first one allows to release nutrients which cannot be preserved in liquids, discharging them in the product just before consumption (Majid et al. 2018). The controlled release of the bioactive compound presents several advantages such as less degradation by light and O2 of the compound or less variation in the organoleptic properties of the products. For instance, the enterprise Atlantic Multipower Germany, Europe’s leading supplier in the sports food sector, has developed a ready-to-drink creatine drink. The product has 4.6 g creatine citrate, a natural dietetic supplement that enhances the performance in sports involving intensive muscle workout. With wedge support, the dried creatine is freshly mixed with the drink when the can is opened. This system is a more comfortable way to consume creatinine, since, traditionally, this compound is sold in the form of powder or tablets that must be dissolved to be ingested. Portola company has produced the “Fusion cap”. By twisting the cap, the consumers add flavors or vitamins to the bottled beverage. This two-piece, resealable cap is designed to keep the compounds powdered, tablet, or liquid separate from the beverage until the consumption time. Many different products with similar systems have been developed, controlling the release of vitamins, minerals and other compounds (Butler and Joseph 2008). Probiotics could be also released in a controlled way into the product. This is the case of a fruit drinkable yogurt packaged in a regular single-serve carton with straws. The interesting active system of this product is that the probiotic bacteria are attached inside the straw, so they are only releases into the product when liquid passes through the straw at the moment of consumption (Butler and Joseph 2008).

Encapsulation is an attractive tool when adding compounds to a beverage. This technique allows to introduce low soluble or non-stable compounds in the product, control their release and prevent their deterioration. In addition, they avoid the possible changes in the organoleptic properties associated with the incorporation of the desired compounds (Ur Rahman et al. 2019). In the literature, diverse delivery systems have been developed, including liposomes, emulsions, cyclodextrins, or nanocapsules, among others. Microencapsulation is useful for the fortification of beverage with probiotics, since it helps to protect the microorganisms against bacteriophages and contaminant yeasts and also during the processing, the storage and further passage through the gastrointestinal tract. Different polymers could be used, such as alginate, pectin, casein or starch derivatives. This technique has been employed in both in dairy and non-dairy products, mainly in fruit juices. For example, alginate beads coated with chitosan have been demonstrated to increase the survival of the probiotic bacteria L. plantarum during the simulated digestion of pomegranate juice. In addition, microencapsulation allowed cells to be detected until the sixth week of storage, while in the absence of the beads, the probiotic bacteria died by the fourth week (Nualkaekul et al. 2012). Other probiotic bacteria, such as Bifidobacterium adolescentis, L. casei or L. acidophilus, have been effectively encapsulated in fruit and vegetable juices (Ephrem et al. 2018). Nanoencapsulation has been employed to fortify different beverages, mainly fruit juices, by transporting fat-soluble compounds, such as vitamins, carotenoids, fatty acids, steroids, minerals and other compounds of interest (Ríos-Corripio et al. 2019; Musthaba et al. 2009). Diverse vitamins and lipophilic compounds have been encapsulated and the suitability of the encapsulates has been evaluated. For example, chitosan-sodium alginate based nanoliposomes have been employed to encapsulate vitamin C and fortify mandarin juice. Compared with uncoated nanoliposomes, the first ones produced less changes in organoleptic characteristics, like color, pH or acidity. Furthermore, the rate of lipid peroxidation was reduced and the vitamin C was protected after 90 days of storing (Liu et al. 2017). A similar study has stabilized vitamin C using liposomes, reducing its oxidation rate significantly in apple juice (Wechtersbach et al. 2012). Vitamin D has been encapsulated using potato proteins as protective nanovehicle. The nanoencapsulation significantly protected vitamin D and reduced its loss during pasteurization and also during simulated shelf life tests, imitating storage conditions. Thus, this system could be useful to fortify beverages and promote human health (David and Livney 2016). Different studies have developed systems to encapsulate vitamin E that could be employed in the beverage industry, using nanocapsules, nanoemulsions and cyclodextrins (Dasgupta et al. 2015; Saldanha do Carmo et al. 2017; Katouzian and Mahdi 2016; Hategekimana et al. 2015). Cyclodextrins, in combination with Arabic gum and sodium caseinate, have been also employed to encapsulate kenaf seed oil, rich in beneficial monounsaturated and polyunsaturated fatty acids, to develop functional beverages (Chin et al. 2018). Finally, the fatty acids eicosapentaenoic acid and docosahexaenoic acid, obtained from fish oils, were successfully encapsulated in sodium caseinate and gum Arabic nanoparticles to fortify fruit juices. According to the authors, this enrichment did not cause changes in the organoleptic characteristic (Assadpour and Jafari 2018). Several studies have been focused in the encapsulation of phenolic compounds. As mentioned before, these compounds present a wide range of interesting biological properties, thus, their use in functional packaging is of great interest. For example, anthocyanins have been demonstrated to possess interesting bioactive properties to combat neurodegenerative disorders, diabetes or cancer, among other diseases. However, these compounds present low stability and bioavailability. To protect these compounds, they were encapsulated into chitosan nanoparticles and its stability was studied in simulated gastrointestinal fluid and during the storage of a model beverage. The results showed that the nanoparticles significantly protected the anthocyanins (He et al. 2017). A similar strategy has been employed with the flavonoid quercetin. This compound has been demonstrated to possess beneficial properties, such as antioxidant, anti-inflammatory, cancer prevention and cardio-protective effects. Nevertheless, this compound presents a low solubility, stability and little absorption in the gastrointestinal tract, which limits its activity when consuming. Thus, nanoencapsulation of quercetin is an interesting option to improve its stability before consumption and also its gastrointestinal absorption. Lecithin and chitosan-based nanoparticles have been employed successfully to encapsulate quercetin. The stability evaluation demonstrated that the encapsulated compound was stable between 5 to 70 °C and pH 3.3 to 5.0. Furthermore, the antioxidant activity of the encapsulated compound was assessed by DPPH assay, showing better results that free quercetin. The results suggests that the nanoencapsulation of quercetin could be used to develop new nutraceutical beverages (Souza et al. 2014). Finally, cyclodextrins have been used to encapsulate caffeic acid, enhancing its solubility and antioxidant capacity. This system could be used in the development of functional food enriched in this phenolic compound (Astray et al. 2020).

3.4 Self-Cooling and Self-Heating

The use of packages that causes physical alterations is a curious case in the active packaging of beverage. Self-cooling packages for beer and soft drinks and self-heating packages for chocolate, soup and coffee have been one of the first developments of this field. However, some of these advances have not achieved a great commercial reception. The first self-cooling packaging was the Instant Cooling Can, created for soft drinks by Tempra Technologies and Crown Cork and Seal in 2006. It is based on vacuum heat pump technology. It uses the latent heat of evaporating water to produce the cooling effect. The water is bound in a gel layer that lines a separate container inside the beverage can and is in close thermal contact with the beverage. The system is activated when the consumer twists the base of the can to open a valve, exposing the water to the desiccant held in a separate evacuated external chamber. The water evaporates at room temperature, achieving a cooling effect as the heat is removed from the system (Ramos et al. 2015). Nowadays, self-cooling packages in larger volume formats have been designed, mostly based in endothermic reactions of ammonium nitrate (NH4NO3) or ammonium nitrite (NH4NO2). When dissolved in water, these compounds absorb heat from the system (Palomero et al. 2016). On the other hand, the self-heating packages use the exothermic hydration reactions of calcium monoxide (CaO) or magnesium monoxide (MgO). When dissolved in water, these monoxides are transformed into calcium hydroxide (Ca(OH)2) and magnesium hydroxide (Mg(OH)2), respectively. When using CaO, the container must show high barrier properties against water vapor passage, to avoid the hydration of lime and the rendering of the package useless. In addition, there should be enough space to contain the entire device. Another self-heating systems are based in the reaction between glycerol and potassium salt. In these case, it is necessary to adapt the heat generation, in order to control the rate of the reaction, to introduce a lag before it initiates, and to regulate the final temperature reached by the product (Ramos et al. 2015). Regarding self-heating packages , an example is a Dutch star-up, which allows to contain a dehydrated or dried drink (like coffee or tea) to infuse in a separate compartment. This system improves the shelf life of the product and the sensory characteristics of the final product, while reduces the use of preservatives (Palomero et al. 2016). In Fig. 13.2, a schematic representation of the self-cooling and self-heating packages is presented.

Schematic picture of the self-cooling and the self-heating systems. (Adapted from Palomero et al. 2016)

4 Future Trends in Active Packaging

The field of beverage packaging technologies is continuously increasing, with the main goal of developing more effective systems to preserve beverage quality. Recent developments have focused on two main types: (1) packaging systems, mainly plastics and metallic materials for bottles and cans, with scavenging compounds located in their crowns and (2) new active materials, usually natural compounds or synthetic plastic films (Palomero et al. 2016). Several active materials have gaining attention in the last years, such as stimuli-responsive polymeric materials, edible films or biodegradable packages. The former ones present several advantages, such as unique properties and compliance with the current packaging regulation. Polymeric materials can release specific targets through external stimulus, which could be temperature, pH, or adjustments carried out in the chemical composition. These type of molecular structures have been only recently manufactured, due to their complex structure (Boarca et al. 2019). The second ones, edible films, are also an interesting advance in active packaging. This technology may offer future possibilities to satisfy the consumers’ demands for eco-friendly, green foods. Edible films should present certain characteristics: (1) act as a barrier against CO2, O2, water and oil leakages, (2) microbial, biochemical, and physicochemical stability, (3) safe for the consumers and (4), reduced-cost production. In addition, edible films should be compatible vehicles for antioxidants, antimicrobials, flavor, color and nutritional additives. It has been proposed that edible films may increase the time of storage and improve the shelf life of beverage, acting as barrier against gases and moisture. In addition, they can enhance microbial resistance, by incorporation of antimicrobial compounds. However, it should be highlighted that edible films do not eliminate the necessity of traditional packaging, but they could work as a complement. Edible coatings or films are manufactured from agricultural wastes produced by industrial food production, thus, they increase the value of biomass and favor the circular economy. Several polysaccharides such as cellulose, chitosan or alginates can be used to make edible coatings. Moreover, the use of these films and coatings may help to reduce the price of traditional packaging (Boarca et al. 2019). Finally, several projects have been focused on the development of efficient biodegradable packages, that retain the freshness and nutritional composition of the beverage, while also reduce the amount of waste produced by the packaging industry. This is the case of the project PHBOTTLE, previously mentioned, which develops biodegradable materials using fruit by-products (Ramos et al. 2015).

Application of nanotechnology is also a leading theme in active packaging. However, for a successful application it is necessary to deliberate about regulations, focusing in their safety/toxicology and environmental impact. Currently, there is not any international regulation of nanotechnology or nano-products and just a few organizations from particular countries have established standards and regulations to define and control the use of nanotechnology. In the US, nanofoods and most of the food nanopackages are regulated by the FDA. Regarding EU; since 2010, the EFSA created a network between member states for risk assessment of nanotechnologies in food and feed. Some nanoforms have been approved to be used in the manufacture of plastic materials (amendments of Regulation N° 10/2011 on plastic materials and articles intended to come into contact with food) but their use must respect restrictions. In 2011, the EC suggested a definition of “nanomaterial”. Later, in 2014, the FDA elaborate guidance documents for industry, recommending premarket safety assessments of the FDA-approved products that either apply nanotechnology or if the engineered product shows properties attributable to the nanoscale. The US also implemented mandatory changes to their food labeling law in 2014, which requires that all nanomaterials have to be included on the list of ingredients, followed by the term “nano” in parenthesis (Ríos-Corripio et al. 2019).

5 Conclusions

The global packaging industry is continuously introducing new technical advances, while also meeting consumer demands and the regulations established. From traditional materials, such as wood, glass or metal, this industry has evolved towards more efficient strategies to package beverage, such as the hot filling technology or the use of modified atmospheres. Nowadays, active packaging is considered as innovative field in beverage packaging, which allows preserving beverages in a more efficient way, maintaining their properties and increasing their shelf life. Currently, numerous applications of releasing active packaging have been developed and employed in different beverage (beer, shakes, fruit juices, etc.) being the most prominent the packages with antioxidant and antimicrobial activity. Antioxidant strategies are focused in the use of natural extracts and compounds with antioxidant properties, which are included in different materials and have demonstrated to prevent oxidative reactions that cause the deterioration of the product. Regarding antimicrobial applications, numerous compounds have been used to prevent microorganisms’ spoilage, such as metal nanoparticles, enzymes, nisin and other natural compounds with antimicrobial properties. Several functional applications have been developed. Some of them aim to improve the organoleptic characteristics of the product, like the gas release in beer or the flavor releasing in bottled water. Besides, the objective of other applications, also known as “bioactive packaging”, is bringing health benefits to consumers. This is case of the fortification of beverage with different Innutrients, such as vitamins or phenolic compounds. Probiotics could be also encapsulated and released fruit juices. Finally, several self-cooling and self-heating packages have been developed, but do not always have a good commercial reception. Considering the great variety of applications developed and their excellent results protecting beverages, the active packaging industry is a sector on the rise. It is expected to continue growing in the following years, exploring new natural compounds and towards materials such as edible films or a greater inclusion of nanotechnology. Nevertheless, since active packaging is a relatively new field, a global legislation should be established to regulate the requirements of safety and quality.

Abbreviations

- EC:

-

European Commission

- EFSA:

-

European Food Safety Authority

- EU:

-

European Union

- FCMs:

-

Food contact materials

- FDA:

-

Food and Drugs Administration

- UHT:

-

Ultra-high temperature

- US:

-

United States

- ABTS:

-

2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid

- DPPH:

-

2,2-diphenyl-1-picrylhydrazyl radical

- EDTA:

-

Ethylenediaminetetraacetic acid

- EVOH:

-

Ethylene–vinyl alcohol

- LDPE:

-

Low-density polyethylene

- PET:

-

Polyethylene terephthalate

- PHB:

-

Polyhydroxybutyrate

References

Ahmed I, Lin H, Zou L, Brody AL, Li Z, Qazi IM, Pavase TR, Lv L. A comprehensive review on the application of active packaging technologies to muscle foods. Food Control. 2017;82:163–78. https://doi.org/10.1016/j.foodcont.2017.06.009

Assadpour E, Jafari SM. A systematic review on nanoencapsulation of food bioactive ingredients and nutraceuticals by various nanocarriers. Crit Rev Food Sci Nutr. 2018;59:3129–51. https://doi.org/10.1080/10408398.2018.1484687

Astray G, Mejuto JC, Simal-gandara J. Latest developments in the application of cyclodextrin host-guest complexes in beverage technology processes. Food Hydrocoll. 2020;106:105882. https://doi.org/10.1016/j.foodhyd.2020.105882

Barnett A, Velasco C, Spence C. Bottled vs. canned beer: do they really taste different? Beverages. 2016;2(25) https://doi.org/10.3390/beverages2040025

Boarca B, Lungu I, Holban AM. Bioactive packaging for modern beverage industry. In: Trends in beverage packaging. Elsevier Inc.; 2019. p. 51–71.

Borah H, Dutta U. Trends in beverage packaging. In: Trends in beverage packaging. Elsevier Inc.; 2019. p. 1–19.

Butler P, Joseph K. Smart packaging technologies for fast moving consumer goods. Chichester: Wiley; 2008.

Calatayud M, López-de-dicastillo C, López-carballo G, Vélez D, Hernández P, Gavara R. Active films based on cocoa extract with antioxidant, antimicrobial and biological applications. Food Chem. 2013;139:51–8. https://doi.org/10.1016/j.foodchem.2013.01.097

Char C, Cisternas L, Pérez F, Guerrero S. Effect of emulsification on the antimicrobial activity of carvacrol. CYTA - J Food. 2016;14:186–92. https://doi.org/10.1080/19476337.2015.1079558

Chen JC, Chen TL, Harianto H. Capacity planning for packaging industry. J Manuf Syst. 2017;42:153–69. https://doi.org/10.1016/j.jmsy.2016.12.007

Chin S, Ping C, Lin K. Microencapsulation of refined kenaf (Hibiscus cannabinus L.) seed oil by spray drying using β -cyclodextrin/gum arabic/sodium caseinate. J Food Eng. 2018;237:78–85. https://doi.org/10.1016/j.jfoodeng.2018.05.016

Chopra M, Kaur P, Bernela M, Thakur R. Surfactant assisted nisin loaded chitosan-carageenan nanocapsule synthesis for controlling food pathogens. Food Control. 2014;37:158–64. https://doi.org/10.1016/j.foodcont.2013.09.024

Commission E. EU guidance to the commission regulation ( EC ) No 450 / 2009 of 29 May 2009 on active and intelligent materials and articles intended to come into contact with food. 2011. p. 1–26.

Cooper TA. Developments in bioplastic materials for packaging food, beverages and other fast-moving consumer goods. In: Trends in packaging of food, beverages and other fast-moving consumer goods (FMCG). Woodhead Publishing; 2013. p. 108–52.

Cordier M, Uehara T. How much innovation is needed to protect the ocean from plastic contamination? Sci Total Environ. 2019;670:789–99. https://doi.org/10.1016/j.scitotenv.2019.03.258

Cushen M, Kerry J, Morris M, Cruz-Romero M, Cummins E. Nanotechnologies in the food industry - recent developments, risks and regulation. Trends Food Sci Technol. 2012;24:30–46. https://doi.org/10.1016/j.tifs.2011.10.006

Dainelli D. Global legislation for active and intelligent packaging materials. In: Global legislation for food contact materials. Elsevier Ltd.; 2015. p. 184–99.

Dasgupta N, Ranjan S, Mundra S, Kumar A. Fabrication of food grade vitamin E nanoemulsion by low energy approach, characterization and its application. Int J Food Prop. 2015;19:700–8. https://doi.org/10.1080/10942912.2015.1042587

David S, Livney YD. Potato protein based nanovehicles for health promoting hydrophobic bioactives in clear beverages. Food Hydrocoll. 2016;57:229–35. https://doi.org/10.1016/j.foodhyd.2016.01.027

Dávila-Aviña JE, Solís-Soto LY, Rojas-Verde G, Salas NA. Sustainability and challenges of minimally processed foods. In: Siddiqui MW, Rahman MS, editors. Food engineering series. Springer; 2015. p. 279–95.

Deshwal GK, Panjagari NR. Review on metal packaging: materials, forms, food applications, safety and recyclability. J Food Sci Technol. 2020;57:2377–92. https://doi.org/10.1007/s13197-019-04172-z

Dombre C, Rigou P, Chalier P. The use of active PET to package rosé wine: changes of aromatic profile by chemical evolution and by transfers. Food Res Int. 2015;74:63–71. https://doi.org/10.1016/j.foodres.2015.04.026

Emblem A. Modified atmosphere packaging and other active packaging systems for food, beverages and other fast-moving consumer goods. In: Trends in packaging of food, beverages and other fast-moving consumer goods (FMCG); 2013. p. 22–34.

Ephrem E, Najjar A, Charcosset C, Greige-gerges H. Encapsulation of natural active compounds , enzymes, and probiotics for fruit juice fortification , preservation, and processing: an overview. J Funct Foods. 2018;48:65–84. https://doi.org/10.1016/j.jff.2018.06.021

Fang Z, Zhao Y, Warner RD, Johnson SK. Active and intelligent packaging in meat industry. Trends Food Sci Technol. 2017;61:60–71. https://doi.org/10.1016/j.tifs.2017.01.002

Farmer N. Trends in packaging of food, beverages and other fast-moving consumer goods (FMCG): markets, materials and technologies. Elsevier; 2013.

Farris S, Piergiovanni L. Emerging coating technologies for food and beverage packaging materials. In: Emerging food packaging technologies: principles and practice. Woodhead Publishing Limited; 2012. p. 274–302.

Fazio A, Caroleo MC, Cione E, Plastina P. Novel acrylic polymers for food packaging: synthesis and antioxidant properties. Food Packag Shelf Life. 2017;11:84–90. https://doi.org/10.1016/j.fpsl.2017.01.002

Fuciños C, Fuciños P, Fajardo P, Amado IR, Pastrana LM, Rúa ML. Evaluation of antimicrobial effectiveness of pimaricin-loaded thermosensitive nanohydrogels in grape juice. Food Bioprocess Technol. 2015;8:1583–92. https://doi.org/10.1007/s11947-015-1499-7

Gassara-chatti F, Brar SK, Ajila CM, Verma M, Tyagi RD, Valero JR. Encapsulation of ligninolytic enzymes and its application in clarification of juice. Food Chem. 2013;137:18–24. https://doi.org/10.1016/j.foodchem.2012.09.083

Ghoshal G. Recent development in beverage packaging material and its adaptation strategy. In: Trends in beverage packaging. Elsevier; 2019. p. 21–50.

Gómez-Estaca J, López-de-Dicastillo C, Hernández-Muñoz P, Catalá R, Gavara R. Advances in antioxidant active food packaging. Trends Food Sci Technol. 2014;35:42–51. https://doi.org/10.1016/j.tifs.2013.10.008

Grumezescu AM, Holban AM. Preservatives and preservation approaches in beverages. In: Volume 15: The science of beverages. Academic; 2019.

Haghighi-Manesh S, Azizi MH. Active packaging systems with emphasis on its applications in dairy products. J Food Process Eng. 2017;40 https://doi.org/10.1111/jfpe.12542.

Hao L, Li Y, Gong P, Xiong W. Material, process and business development for 3D chocolate printing. In: Fundamentals of 3D food printing and applications. Elsevier Inc.; 2019. p. 207–55.

Hategekimana J, George K, Ma J, Zhong F. Encapsulation of vitamin E: effect of physicochemical properties of wall material on retention and stability. Carbohydr Polym. 2015;124:172–9. https://doi.org/10.1016/j.carbpol.2015.01.060

He B, Ge J, Yue P, Yue X, Fu R, Liang J, Gao X. Loading of anthocyanins on chitosan nanoparticles influences anthocyanin degradation in gastrointestinal fluids and stability in a beverage. Food Chem. 2017;221:1671–7. https://doi.org/10.1016/j.foodchem.2016.10.120

Ho C, Jin H, Lee DS. Influence of antimicrobial packaging on kinetics of spoilage microbial growth in milk and orange juice. J Food Eng. 2004;65:527–31. https://doi.org/10.1016/j.jfoodeng.2004.02.016

Jin T, Zhang H. Biodegradable polylactic acid polymer with nisin for use in antimicrobial food packaging. J Food Sci. 2008;73 https://doi.org/10.1111/j.1750-3841.2008.00681.x.

Katouzian I, Mahdi S. Nano-encapsulation as a promising approach for targeted delivery and controlled release of vitamins. Trends Food Sci Technol. 2016;53:34–48. https://doi.org/10.1016/j.tifs.2016.05.002

Krogsgård C, Kjems J, Mygind T, Snabe T, Schwarz K, Serfert Y, Louise R. Enhancing the antibacterial efficacy of isoeugenol by emulsion encapsulation. Int J Food Microbiol. 2016;229:7–14. https://doi.org/10.1016/j.ijfoodmicro.2016.04.002

Lagarón J-M, Busolo MA. Active nanocomposites for food and beverage packaging. In: Emerging food packaging technologies. Woodhead Publishing Limited; 2012. p. 55–65.

Liu W, Tian M, Kong Y, Lu J, Li N, Han J. Multilayered vitamin C nanoliposomes by self-assembly of alginate and chitosan: long-term stability and feasibility application in mandarin juice. LWT - Food Sci Technol. 2017;75:608–15. https://doi.org/10.1016/j.lwt.2016.10.010

Llorens A, Lloret E, Picouet P, Fernandez A. Study of the antifungal potential of novel cellulose/copper composites as absorbent materials for fruit juices. Int J Food Microbiol. 2012;158:113–9. https://doi.org/10.1016/j.ijfoodmicro.2012.07.004

Lloret E, Picouet P, Fernández A. Matrix effects on the antimicrobial capacity of silver based nanocomposite absorbing materials. LWT - Food Sci Technol. 2012;49:333–8. https://doi.org/10.1016/j.lwt.2012.01.042

Lobo FATF, Silva V, Domingues J, Costa V, De LKG. Inclusion complexes of yellow bell pepper pigments with β -cyclodextrin: preparation, characterisation and application as food natural colorant. J Sci Food Agric. 2017;98:2665–71. https://doi.org/10.1002/jsfa.8760

López De Dicastillo C, Nerín C, Alfaro P, Catalá R, Gavara R, Hernández-Muñoz P. Development of new antioxidant active packaging films based on ethylene vinyl alcohol copolymer (EVOH) and green tea extract. J Agric Food Chem. 2011;59:7832–40. https://doi.org/10.1021/jf201246g

Lopez-Rubio A, Gavara R, Lagaron JM. Bioactive packaging: turning foods into healthier foods through biomaterials. Trends Food Sci Technol. 2006;17:567–75. https://doi.org/10.1016/j.tifs.2006.04.012

Loquercio A, Castell-perez E, Gomes C, Moreira RG. Preparation of chitosan-alginate nanoparticles for trans -cinnamaldehyde entrapment. J Food Sci. 2015;80:N2305–15. https://doi.org/10.1111/1750-3841.12997

Majid I, Thakur M, Nanda V. Innovative and safe packaging technologies for food and beverages: updated review. In: Innovations in technologies for fermented food and beverage industries. Cham: Springer; 2018. p. 257–87.

Malhotra B, Keshwani A, Kharkwal H. Antimicrobial food packaging: potential and pitfalls. Front Microbiol. 2015;6:611. https://doi.org/10.3389/fmicb.2015.00611

Marsh K, Bugusu B. Food packaging - roles, materials, and environmental issues: scientific status summary. J Food Sci. 2007;72:R39–55. https://doi.org/10.1111/j.1750-3841.2007.00301.x

Mohammadi M, Rezaei R, Shahvalizadeh R, Sarabandi K. Immobilization and stabilization of pectinase on an activated montmorillonite support and its application in pineapple juice clarification. Food Biosci. 2020;36:100625. https://doi.org/10.1016/j.fbio.2020.100625

Musthaba SM, Baboota S, Ahmed S, Ahuja A, Ali J. Status of novel drug delivery technology for phytotherapeutics. Expert Opin Drug Deliv. 2009;6:625–37. https://doi.org/10.1517/17425240902980154

Nualkaekul S, Lenton D, Cook MT, Khutoryanskiy VV, Charalampopoulos D. Chitosan coated alginate beads for the survival of microencapsulated Lactobacillus plantarum in pomegranate juice. Carbohydr Polym. 2012;90:1281–7. https://doi.org/10.1016/j.carbpol.2012.06.073

Núñez O, Gallart-Ayala H, Martins CPB, Lucci P. Fast liquid chromatography-mass spectrometry methods in food and environmental analysis. World Scientific; 2015.

Palomero F, Morata A, Suárez-Lepe J, Calderón F, Benito S. Antimicrobial packaging of beverages. Elsevier Inc.; 2016.

Pradhan N, Singh S, Ojha N, Shrivastava A, Barla A, Rai V, Bose S. Facets of nanotechnology as seen in food processing, packaging, and preservation industry. Biomed Res Int. 2015;2015. https://doi.org/10.1155/2015/365672

Ramos M, Beltrán A, Peltzer M, Valente AJM, Garrigós C. Release and antioxidant activity of carvacrol and thymol from polypropylene active packaging films. LWT - Food Sci Technol. 2014;58:470–7. https://doi.org/10.1016/j.lwt.2014.04.019

Ramos M, Valdés A, Mellinas A, Garrigós M. New trends in beverage packaging systems: a review. Beverages. 2015;1:248–72. https://doi.org/10.3390/beverages1040248

Restuccia D, Spizzirri UG, Parisi OI, Cirillo G, Curcio M, Iemma F, Puoci F, Vinci G, Picci N. New EU regulation aspects and global market of active and intelligent packaging for food industry applications. Food Control. 2010;21:1425–35. https://doi.org/10.1016/j.foodcont.2010.04.028

Ríos-Corripio RCMA, López-Díaz AS, Ramírez-Corona N, López-Malo A, Palou E. Metallic nanoparticles: development, applications, and future trends for alcoholic and nonalcoholic beverages. Elsevier Inc.; 2019.

Rocha MAM, Coimbra MA, Nunes C. Applications of chitosan and their derivatives in beverages: a critical review. Curr Opin Food Sci. 2017;15:61–9. https://doi.org/10.1016/j.cofs.2017.06.008

Romani VP, Martins VG, Goddard JM. Radical scavenging polyethylene films as antioxidant active packaging materials. Food Control. 2020;109:106946. https://doi.org/10.1016/j.foodcont.2019.106946

Sahu JK. Introduction to advanced food packaging processing technologies. CRC Press; 2016. p. 302–9.

Saldanha do Carmo C, Maia C, Poejo J, Lychko I, Gamito P, Nogueira I, Bronze MR, Serra AT, CMM D. Microencapsulation of a-tocopherol with zein and b-cyclodextrin using spray drying for colour stability and shelf-life improvement of fruit beverages. RSC Adv. 2017;7:32065–75. https://doi.org/10.1039/c6ra25946d

Sarkar P, Bhunia AK, Yao Y. Impact of starch-based emulsions on the antibacterial efficacies of nisin and thymol in cantaloupe juice. Food Chem. 2017;217:155–62. https://doi.org/10.1016/j.foodchem.2016.08.071

Soto KM, Hernández-Iturriaga M, Loarca-Piña G, Luna-Bárcenas G, Mendoza S. Antimicrobial effect of nisin electrospun amaranth: pullulan nanofibers in apple juice and fresh cheese. Int J Food Microbiol. 2019;295:25–32. https://doi.org/10.1016/j.ijfoodmicro.2019.02.001

Souza MP, Vaz AFM, Vicente AA, Carneiro-da-cunha MG. Quercetin-loaded lecithin / chitosan nanoparticles for functional food applications. Food Bioprocess Technol. 2014;7:1149–59. https://doi.org/10.1007/s11947-013-1160-2

Speranza B, Petruzzi L, Bevilacqua A, Gallo M, Campaniello D, Sinigaglia M, Corbo MR. Encapsulation of active compounds in fruit and vegetable juice processing: current state and perspectives. J Food Sci. 2017;82:1291–301. https://doi.org/10.1111/1750-3841.13727

Sugumar S, Singh S. Nanoemulsion of orange oil with non ionic surfactant produced emulsion using ultrasonication technique: evaluating against food spoilage yeast. Appl Nanosci. 2016;6:113–20. https://doi.org/10.1007/s13204-015-0412-z

Ur Rahman U, Sahar A, Ishaq A, Khalil AA. Design of nanoparticles for future beverage industry. In: Nanoengineering in the beverage industry. Academic; 2019. p. 105–36.

van Birgelen M, Semeijn J, Keicher M. Packaging and proenvironmental consumption behavior: investigating purchase and disposal decisions for beverages. Environ Behav. 2009;41:125–46. https://doi.org/10.1177/0013916507311140

Van Der Vorst JGAJ, Van Der Zee DJ, Tromp SO. Simulation modelling for food supply chain redesign; integrated decision making on product quality, sustainability and logistics. In: Delivering performance in food supply chains. Woodhead Publishing Limited; 2010. p. 387–415.

Vanderroost M, Ragaert P, Devlieghere F, De Meulenaer B. Intelligent food packaging: the next generation. Trends Food Sci Technol. 2014;39:47–62. https://doi.org/10.1016/j.tifs.2014.06.009

Vinci G, D’Ascenzo F, Esposito A, Musarra M. Glass beverages packaging: innovation by sustainable production. Trends Beverage Packag. 2019;16:105–33. https://doi.org/10.1016/b978-0-12-816683-3.00005-0

Wechtersbach L, Ulrih NP, Cigic B. Liposomal stabilization of ascorbic acid in model systems and in food matrices. LWT - Food Sci Technol. 2012;45:43–9. https://doi.org/10.1016/j.lwt.2011.07.025

Welle F. Twenty years of PET bottle to bottle recycling - an overview. Resour Conserv Recycl. 2011;55:865–75. https://doi.org/10.1016/j.resconrec.2011.04.009

Yildirim S, Röcker B, Pettersen MK, Nilsen-Nygaard J, Ayhan Z, Rutkaite R, Radusin T, Suminska P, Marcos B, Coma V. Active packaging applications for food. Compr Rev Food Sci Food Saf. 2018;17:165–99. https://doi.org/10.1111/1541-4337.12322

Zanetti M, Carniel TK, Dalcanton F, dos Anjos RS, Gracher Riella H, de Araújo PHH, de Oliveira D, Antônio Fiori M. Use of encapsulated natural compounds as antimicrobial additives in food packaging: a brief review. Trends Food Sci Technol. 2018;81:51–60. https://doi.org/10.1016/j.tifs.2018.09.003

Acknowledgements

The research leading to these results was funded by FEDER under the program Interreg V Spain-Portugal by POPTEC, IBERPHENOL Project (ref. 0377-Iberphenol-6-E) and by NANOEATERS Project (ref. 0181-NANOEATERS-01-E) that supports the pre-doctoral work of C. Jimenez-Lopez; by MICINN supporting the Ramón&Cajal grant for M.A. Prieto (RYC-2017-22891); by Xunta de Galicia and University of Vigo supporting the post-doctoral grant for M. Fraga-Corral (ED481B-2019/096), and the pre-doctoral grants for A.G. Pereira (ED481A-2019/0228) and P. García-Oliveira (ED481A-2019/295); by the company AlgaMar (www.algamar.com) and Axudas Conecta Peme (Xunta de Galicia) supporting the IN852A 2018/58 NeuroFood Project that financed the pre-doctoral grant for C. Lourenço-Lopes; EcoChestnut Project (Erasmus+ KA202) for supporting the work of M. Carpena; Ibero-American Program on Science and Technology (CYTED – AQUA-CIBUS, P317RT0003) and UP4HEALTH Project (H2020-BBI-JTI-2019) for financial support.

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG