Abstract

In order to compare the dynamic performance of CNC controller and robot controller for serial industrial robot. In this paper, the contouring errors and velocity of the industrial robot under different controllers are analyzed. Firstly, a method for measuring the trajectory error of the milling robot based on a laser tracker is proposed. Then, a series of experiments of the KUKA KR160 robot with KRL kernel and CNC kernel are implemented to analyze the dynamic performance of complex trajectory, considering different feedrate, smoothing methods, and parameter setting. Experimental results show that the KRL kernel with appropriate parameters can achieve the same trajectory accuracy and feedrate response as CNC kernel.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Industrial robots are recently used for machining applications like grinding, polishing, and milling due to their advantage of the large workspace, flexibility, and low cost. However, traditional industrial robots are usually designed to achieve precise point movement and repeatable tasks, while the trajectory accuracy and absolute positioning accuracy are less accurate [1, 2]. Because of their series structure and low joint stiffness, the industrial robot is prone to vibration and large deformation in the process of complex curved surface machining.

Compared to industrial robots controller, CNC controller have advantages in operability, continuous-path performance, and functionality. A CNC controller kernel was integrated on the KUKA KR C4 controller and operated through a CNC-specific user interface [3]. Wen [4] and Susemihl [5] use Siemens 840D CNC controller to control mobile robots for large component machining. Xie and Liu [6,7,8,9] proposed integrated methods combining elasto-geometrical error calibration, continuity toolpath smoothing, and real-time tracking errors compensation for improving machining precision, which was tested in a mobile parallel robot with ISG CNC kernel. However, compared with the robot controller, the CNC controller requires additional system software of robotic machining system, which increases the cost, so the robot controller is still a standard control method in many small and medium enterprises (SME). So it is necessary to compare the robot trajectory performance under the CNC controller and the robot controller to provide more choices for enterprises.

NC programs, programmed offline using a CAD/CAM system, is consisted of linear toolpath segments. CNC controller and robot controller have different toolpath smoothing algorithms to improve continuity, influencing robot trajectory accuracy and dynamic performance. Adel [10] proposed a cartesian space motion planning strategy to suppress vibration. Tunc [11] analyzed the influence of trajectory approximation method accuracy setting option on hexapod robot path contouring accuracy and feedrate. Wu [12, 13] researched the dynamic performance of the CNC kernel and KRL kernel of the KUKA robot in line path and corner path, which consider high/low running speeds and acceleration. Found that dynamic performance and trajectory accuracy of CNC kernel was better at high running speeds. However, the running speeds of the machining process are generally low, and the CNC controller provides alternative toolpath smoothing methods that need to be tested using complex curved paths.

In summary, these methods above ignoring comparing the positioning trajectory errors between CNC controller and robot controller for complex trajectory, and does not analyze the parameter settings that affect the dynamic performance of the robot controller. This paper compares the robot motion accuracy and velocity performance under different control kernels with several parameters. First, propose a method to calculate path errors of the industrial robot based on laser tracker dynamic measurement, which exactly matches the data from the measured values of the laser tracker coordinate system to the programmed points values of the workpiece coordinate system. Then, the constant load running experiments of complex toolpath in cartesian space are designed based on the KRL kernel and CNC kernel of the KUKA robot. Finally, the influence of different velocities and approximate parameters on the trajectory errors and velocity stable is studied.

2 Toolpath Contouring Errors of Industrial Robot

For identifying toolpath contouring errors of industrial robots with a laser tracker, exactly match the coordinates data from programmed points with measurement data of laser tracker is required. CAD/CAM software is usually used to generate a cutter location file containing many discrete tool position vectors and orientation vectors and then generate the processing program in the workpiece coordinate after post-processing according to the robot characteristics and the control system language.

\({{\varvec{P}}}_{\rm{code}}^{\rm{rb}}\) is the position of the programming point in the robot base coordinate system and is defined as follows

Where \({{\varvec{T}}}_{\rm{wp}}^{\rm{rb}}\) is the homogeneous transformation matrix between robot base coordinate system and workpiece coordinate system, \({{\varvec{T}}}_{{tool}}^{{wp}}\) is the homogeneous transformation matrix between workpiece coordinate system and robot tool coordinate system,\({{\varvec{T}}}_{\rm{tool}}^{\rm{fl}}\) is the homogeneous transformation matrix between robot flange coordinate system and tool coordinate system, \({{\varvec{P}}}_{\rm{code}}^{\rm{fl}}\) is the position of the programming point in the robot flange coordinate system (Fig. 1).

In order to improve the prediction accuracy of contour error, the isoparametric linear method is used to interpolate the parameter points. For the interpolation points between \({{\varvec{P}}}_{\rm{code\_}{{i}}}^{\rm{fl}}\) and \({{\varvec{P}}}_{\rm{code\_}{{i}}\rm{ + 1}}^{\rm{fl}}\)

Where \(d\) is the minimum distance of two control points. After interpolation, the number of program points is changed from \(n\) to \(n_{{in}}\).

The position of the auxiliary measurement points in the robot base coordinate system is expressed as follows

Where \({{\varvec{T}}}_{\rm{lm}}^{\rm{rb}}\) is the transformation matrix representing the pose of the laser tracker coordinate system with respect to robot base coordinate system, \({{\varvec{P}}}_{\rm{me}}^{\rm{lm}}\) is the position of the auxiliary measurement point in the robot flange coordinate system.

The orthogonal distance between the measuring point and the closest linear toolpath segments of the program and the distance between the measuring point and the closest reference point of the program, where the minimum value is taken as the contour error [14].

The position vector \({\hat{{r}}}_{\rm{p}\_j}\) from the closest programmed point to the measuring point is

The normalized toolpath segment vectors of programmed code are defined as

Where \({{\varvec{P}}}_{\rm{code\_}{{t}}}^{\rm{rb}}\),\({{\varvec{P}}}_{\rm{code\_}{{t}}\rm{ + 1}}^{\rm{rb}}\) and \({{\varvec{P}}}_{\rm{code\_}{{t}}\rm{ + 1}}^{\rm{rb}}\) are three adjacent programmed points.

The orthogonal distance \(\varepsilon_{{c1}}\) between the measuring point and the closest linear toolpath segments of the program is defined as

Moreover, the contour error is estimated as follows

3 Experiment and Discussion

In order to compare the two different control systems, a 5-axis complex curve toolpath is planned to analyze the performance of a KUKA robot under the two controllers, and a laser tracker is used to measure the toolpath contouring accuracy and feed speed. In order to avoid the influence of cutting force on the contour accuracy of the industrial robot, the measurements are performed under no-machining operational conditions.

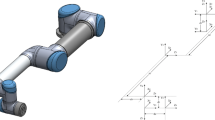

The experiment setup is shown in Fig. 2. Within the KUKA robot milling system (KR 160 R1578), an electric spindle is installed at the robot’s flange. The robot milling system's total weight is about 698 kg, and the maximum robot load is 160 kg. The position repetition accuracy can reach ±0.06 mm, and the maximum can reach 1578 mm. The CNC kernel and KRL kernel have been completely integrated into a KR C4 control system.

The CNC kernel can run NC programs directly on the KR C4 controller, and preload 150 path points to achieve more precise and efficient trajectory planning. Several path smoothing methods are provided to rounding and smoothing a programmed curve within specific tolerances, such as Contour Mode, B-Spline Method, Filter programming, Akima spline, and PSC functions. The KRL kernel implements the NC program of many short linear blocks through the LIN instruction and trajectory approximation function. The kernel only preloads five path points, which limits the robot's contour tracking performance.

The API T3 laser tracker has been used to determine the reference and the dynamic measurement of the trajectories at a sampling frequency of 100 Hz, and its accuracy is better than 0.025 mm. The laser tracker tracks the robot's movement by identifying a target ball glued to the side of the motorized spindle. Before the experiment, the actual position of the auxiliary measuring point in the robot flange coordinate system was calibrated using the reference method [5, 15]. In order to determine the influence of approximation contour method parameter settings on the densely discretized toolpath, robot Sensor Interface (RSI) is used to record the command angles and measured angles of the robot joints when using the KRL kernel. RSI is an official software provided by KUKA company, which can read the robot system parameters in a cycle of 4 ms or 12 ms.

According to G code and KRL language specification, the linear segments toolpath of the 5-axis S-shaped part [6] generated by NX is converted into an executive program of different controllers. As shown in Fig. 3, the toolpath length is 516.04 mm that contains 822 path points, the maximum interval of path points is 4.3 mm, the minimum interval is 0.071 mm, and the trajectory error tolerance is 0.05 mm.

As shown in Fig. 4, the B-spline method was used for the CNC kernel in the experiments, which needs to be determined maximum deviation (PATH_DEV) of B spline from the programmed path and maximum deviation of tracking axes (TRACK_DEV). KRL kernel adopts trajectory approximation contour method that defines the &APO.CDIS value in the program to determine the distance from the starting point to the corner point of the trajectory approach, and the trajectory approach to the endpoint depends on the speed set by the program (Fig. 5). Two values are set to see if the $APO.CDIS has an impact on the industrial robot dynamic performance. The velocity and acceleration weighting are set the same value to compare the two control systems (Table 1).

Figure 6 shows the robot's S-shaped toolpath contouring errors are similar at different experimental conditions, which are measured by laser tracker. Moreover, the feedrate commonly used in machining does not affect the toolpath contouring accuracy, which is different from [12]. Figure 7 shows the trajectory errors calculated by joint tracking errors and forward kinematics of the robot. It was found out that the cartesian tracking errors of the robot are below 0.05 mm under different parameters; however, the contouring errors are between 0.5–1.5 mm that measured by the laser tracker.

Table 2 lists the maximum error, mean errors, and standard variance. The contouring errors of the CNC kernel are not smaller than the KRL kernel based on the programmed velocities of 1500 mm/min and 3000 mm/min.

According to Fig. 8, the running time of the CNC kernel is similar to that of the KRL kernel (APO_DIS = 0.5 mm), while the running time of the KRL kernel (APO_DIS = 0.05 mm) is longer. However, it isn’t easy to reach the set value of 3000 mm/min in either controller with different parameters. Moreover, when the feedrate curve of the CNC kernel is around 15.36 s (programmed feedrate at 1500 mm/min) and 13.33 s (programmed feedrate at 1500 mm/min), the velocity of the industrial robot drops rapidly, however the velocity with the KRL kernel reduced by a smaller range. The contouring errors of the two controllers are both large.

Table 3 indicates that, at the same programmed feedrate, the minimum feedrate of the CNC kernel and KRL kernel (APO_DIS = 0.5 mm) is close, which is different from the value of the KRL kernel (APO_DIS = 0.05 mm). At different programmed feedrates, the minimum feedrate of the same kernel and parameters is close. Regardless of which controller, the measured minimum feedrate is too low compared to the programmed feedrate, which means that the serial industrial robot is difficult to use in high-speed machining of complex features. Compared with the figure and figure, the feedrate and contour error have a similar trend of change, and the feedrate mutation caused a significant path error.

The velocity is calculated by RSI measurement data (Fig. 9). It can be seen that the variation of the feedrate is close to the measurement result of the laser tracker. In the process of running, the robot's velocity cannot exceed the design value and the velocity calculation errors of the laser tracker caused by the dynamic measurement errors.

4 Conclusion

This paper focused on comparing the effectiveness of the CNC kernel and KRL kernel in reducing contouring errors and maintaining velocity constant when executing complex curves. The results suggest that different controller and parameters setting dose not affect the contour accuracy of the dense discrete toolpath, but significantly affect the dynamic feedrate response. The minimum feedrate is too low compared with the designed feedrate, making it difficult for the serial industrial robot to be used for high-speed machining of complex features.The CNC kernel provides more toolpath smoothing algorithms when there are many short linear blocks, however using the appropriate APO_DIS value can obtain the same feedrate response and contouring errors as the CNC kernel, which helps the user to select the controller and parameters setting.

References

Verl, A., Valente, A., Melkote, S., et al.: Robots in machining. CIRP Ann. 68(2), 799–822 (2019)

Tao, B., Zhao, X.W., Ding, H.: Mobile-robotic machining for large complex components: A review study. Sci. China Technol. Sci. 62(8), 1388–1400 (2019)

KUKA Roboter GmbH (https://www.isg-stuttgart.de/kernel-html5/en-GB/index.html#474914443)

Wen, K., Zhang, J.B., Yue, Y., et al.: Method for improving accuracy of NC-driven mobile milling robot. J. Mech. Eng. 57(05), 72–80 (2021)

Susemihl, H., Brillinger, C., Stürmer, S.P., et al.: Referencing strategies for high accuracy machining of large aircraft components with mobile robotic systems. SAE Technical Paper (2017)

Xie, Z., Xie, F., Liu, X.J., et al.: Tracking error prediction informed motion control of a parallel machine tool for high-performance machining. Int. J. Mach. Tools Manuf. 164, 103714 (2021)

Mei, B., Xie, F., Liu, X.J., et al.: Elasto-geometrical error modeling and compensation of a five-axis parallel machining robot. Precis. Eng. 69, 48–61 (2021)

Xie, Z., Xie, F., Liu, X.J., et al.: Global G3 continuity toolpath smoothing for a 5-DoF machining robot with parallel kinematics. Robot. Comput.-Integrat. Manuf. 67, 102018 (2021)

Luo, X., Xie, F., Liu, X.J., et al.: Kinematic calibration of a 5-axis parallel machining robot based on dimensionless error mapping matrix. Robot. Comput.-Integrat. Manuf. 70, 102115 (2021)

Olabi, A., Béarée, R., Gibaru, O., et al.: Feedrate planning for machining with industrial six-axis robots. Control. Eng. Pract. 18(5), 471–482 (2010)

Wu, K., Krewet, C., Bickendorf, J., et al.: Dynamic performance of industrial robot with CNC controller. Int. J. Adv. Manuf. Technol. 90(5–8), 2389–2395 (2017)

Wu, K., Krewet, C., Kuhlenkötter, B.: Dynamic performance of industrial robot in corner path with CNC controller. Robot. Comput.-Integrat. Manuf. 54, 156–161 (2018)

Tunca, L.T., Sapmaza, O.F.: Challenges for industrial robots towards milling applications. Dynamics 2, 4 (2017)

Erkorkmaz, K., Yeung, C.-H., Altintas, Y.: Virtual CNC system. Part II. High speed contouring application. Int. J. Mach. Tools Manuf. 46(10), 1124–1138 (2006). https://doi.org/10.1016/j.ijmachtools.2005.08.001

Klimchik, A., Furet, B., Caro, S., et al.: Identification of the manipulator stiffness model parameters in industrial environment. Mech. Mach. Theory 90, 1–22 (2015)

Acknowledgement

This work was supported by the National Key R&D Program of China under Grant 2018YFB1306800.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this paper

Cite this paper

Kenan, D., Dong, G., Shoudong, M., Yong, L. (2021). Contouring Errors and Feedrate Fluctuation of Serial Industrial Robot in Complex Toolpath with Different Controller. In: Liu, XJ., Nie, Z., Yu, J., Xie, F., Song, R. (eds) Intelligent Robotics and Applications. ICIRA 2021. Lecture Notes in Computer Science(), vol 13013. Springer, Cham. https://doi.org/10.1007/978-3-030-89095-7_10

Download citation

DOI: https://doi.org/10.1007/978-3-030-89095-7_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-89094-0

Online ISBN: 978-3-030-89095-7

eBook Packages: Computer ScienceComputer Science (R0)