Abstract

Agriculture and food production play essential roles in defining the identity of a territory. While agrarian products are value generators for a region, the waste produced in the process is a mere byproduct with no or low value. However, in nature, the concept of waste does not exist since the residue of an organism is the nourishment for another. Being inspired by nature, the concept of ‘small is beautiful’ (Schumacher in Small is beautiful. Economics as if peoplemattered. Blond and 7 Briggs, London, UK [4]) can be reached not only through focusing on local production but also radically changing the scale, considering microorganisms as alternative production systems. As such, biotechnological developments can bring us to a new concept—‘micro is beautiful’—which aims at converting outputs of food-related production into inputs for new production possibilities through the aid of microbial activity. Today, we witness emerging design initiatives working on living matter, such as fungi, bacteria or algae, aiming to create new sustainable materials and production models. Working on this new field of design, we present the research project InnoCell, as an example of a possible micro/macro production system based in South Tyrol in Northern Italy, which valorises a local resource (agricultural food waste) through microbial intervention and aims at creating (g)local resilient production processes. It is an interdisciplinary project focusing on the potential of locally grown microbial cellulose and its diverse ‘co-products’. This microbial upcycling of local resources would provide 0 km production alternatives for various materials produced far away, enhancing territorial values, and spreading the knowledge to other localities through an open-source production system.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

By living as nomads, once we were carrying a few belongings that could safely return to nature. After becoming sedentary, we have started cultivating and producing goods from local or even from far-away resources, and therefore we had to figure out how to manage waste that is the result of our consumption habits. Over time, these dynamics resulted in the imbalanced relationship of the current throw-away society with nature. Goods are continuously manufactured through processes of over-production and consumption. This causes incredible amounts of waste and resources are inevitably exhausting. Therefore, there should be an urgent change in how waste is perceived and how this new awareness can give rise to new ways of dealing with it. This could be possible by thinking in a micro-scale to recognize the value of local resources and dynamics, but at the same time reflecting on economic, social, and environmental developments and crisis happening on a global scale to advocate for a systematic change [1].

Agriculture and food production play essential roles in defining the identity of a territory: our perception of ‘local’ is generally related to the resources that a geographical area offers. However, waste generated from agricultural practices is often seen as by-product having a lower value than the main product. Focusing on a micro-scale by involving microorganisms in the production process could help us to turn this down-cycling process into a closer-loop where each product of the production has equal value and continuously transforms into new matter as it happens in nature. In natural systems, there is no concept of waste, as a residue of an organism becomes the nourishment of another [2].

Can micro-organisms help us to design new ways of creating closed loops in our production processes? Can food scraps turn into ‘co-products’ through fermentation?

This paper addresses these questions proposing a (g)local model aiming at a ‘co-production’ of substances based on local food-system byproducts. We introduce the ongoing research project ‘InnoCell’ as a case study that takes advantage of a fermentation process through the aid of a hybrid colony of microorganisms (SCOBY) to enhance the current value of South Tyrolean food-related ‘waste’. Moreover, it addresses the ‘growth unit’ concept, which will be an open-source microbial production system to spread the knowledge about this innovative practice globally.

2 Nature as Source for Resilient Insights

2.1 Micro is Beautiful

The current status of the environment is the result of 3.8 billion years of biological adaptation to the changing planet conditions [3] therefore, the secret for survival in terms of forms, processes and ecosystems lies around us. The way organisms and natural elements adapt to changing conditions suggests nature as a perfect ally to provide insights and principles to be mimicked and adjusted for human needs. Similar to nature, where the concept of waste does not exist, our current production models should follow the same path, considering all substances generated in a process as equally valuable.

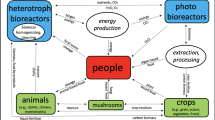

In current food production systems, while a specific product is the desired outcome, the other resulting substances are often called by-products or waste with a lower value. However, the raw resources can be considered as ‘meta-products’, capable of being transformed into a variety of possible ‘co-products’ prolonging their life cycle. Indeed, through the paradigm of ‘meta-product to co-products’, anything produced within a process will have equal value and could safely return to nature. This model can work if we change how we transform matter, shifting from mechanical or chemical transformation to biological by following the rules of life where macro-organisms mutually depend on other micro-organisms. The concept of ‘small is beautiful’ [4] can be reached not only through focusing on local production but also radically changing the scale, even considering microorganisms as production systems. Can biotechnological development bring us to a new concept—‘micro is beautiful’?

Today, we have many bio-design initiatives working with living matter. Specifically, in the growing-design field, designers cooperate with existing fungi, bacteria, algae and hybrid colonies to create novel materials for sustainable alternatives to existing matter and production processes [5]. When materials are constituted or produced by living organisms, design transcends its traditional borders and teams with experts of other scientific fields [6]. The outcomes often result in being speculative and highly holistic seeing designers playing active roles in understanding growth processes and finding effective solutions to be integrated into existing or future hypothetical systems.

2.2 Biodesign for Local Resilience Case Studies

Growing-design [7] is a branch of bio-design in which diverse organisms like bacteria, fungi or algae are used and embedded into solutions for new products, processes and systems [8] aiming at efficient ecological integration. Designers take part in interdisciplinary teams offering their creative skills in envisioning scenarios and developing proofs of concept for emerging biotechnologies and bio-inspired approaches. Moreover, they have often a hands-on approach in which they actively become ‘cultivators’ [9] by creating the optimal conditions for the microorganisms to grow and to be later implemented into diverse applications and realities.

In past decades, artists and designers have been crossing borders to other scientific disciplines resulting in more symbiotic approaches and integration of natural processes in their practices. One of the first examples of the intersection between art and biology is ‘Victimless Leather’ [10] in 2004 presenting a provocative discussion piece, a ‘semi-living’ jacket developed by an interdisciplinary team of artists and scientists. The jacket raises questions about the moral implications of animal-based leather. Few years later ‘Synthetic Aesthetics’ [11] brought together artists, designers and synthetic biologists to foster discussion and generate innovative and speculative proposals concerning the potential of synthetic biology. The outcomes were equally surprising and promising, envisioning products and scenarios for more sustainable and utopic futures. One of the proposals is ‘Packaging that creates its content’ [12] using bacteria as manufacturing systems forming a probiotic cup releasing its nutrients into the liquid when hydrated.

Currently, a broad scope of design initiatives and activities promote open-source knowledge transfer about this emerging practice. Materiom [13] is an open-source material recipe archive utilising the advantage of algae, mycelium, and other compostable sources to accelerate the use of resources and biomaterials for circular economy. Besides, microbial processes show the potential not only to substitute other environmentally inefficient production dynamics but also to produce substances as geographically close as possible to their final utilisation. For instance, Malai [14] is an activity aimed at social empowerment through bio-design, by working with local farmers and suppliers in Southern India. It makes sustainable fashion accessories with bacterial cellulose which is grown using waste coconut water collected from the local production. Similarly, Evoware [15] is an Indonesian start-up which produces edible seaweed-based packaging and food wrappings. It provides an alternative to plastic packaging proposing water-soluble items which would not only positively impact the economic situation of local seaweed farmers but also provide additional environmental value to the urban society in Indonesia.

2.3 South Tyrol and Sustainable Relevance

Focusing on the local setting of the InnoCell project, South TyrolFootnote 1 shows a general sensibility towards sustainable innovation displaying engagement on different levels to preserve its ecosystem. Proinsect [16], an innovative running project, is using the black soldier fly maggots in the process of converting urban organic waste into humus and practically eliminate almost all the residues of the process. Moreover, the Faculty of Design and Art of the Free University of Bozen-Bolzano is highly engaged in (g)local, social, and ecological issues with the master’s degree in Eco-Social Design and design projects developed in the bachelor program. One example among these projects is ‘New Menu’ [17] which focused on food waste, unpacking the potential of discarded or under-used local resources. The students opened valuable discourses between tradition and potential innovation through partnership with local farmers and food-production companies.

These examples provide some insights about how to possibly speculate and create more eco-compatible solutions acting on a local scale, starting from the resources present in the territory. The next section depicts project InnoCell with its novel perspective to enhance the value of food waste in South Tyrol by creating potential co-products obtained through microbial intervention.

3 Starting Point: From Peel to Peel

Although food consumption is a short-term activity, the related packaging is often made of long/er-lasting materials, such as plastic, paper, and diverse composites. The experimental design project ‘From Peel To Peel’ [18] was born by questioning this paradoxical situation. The project aimed to find a locally crafted alternative to disposable food packaging and disposable tableware by employing a compostable material (microbial cellulose) obtained from the fermentation of local food ‘by-products’ through a symbiotic culture of bacteria and yeasts (SCOBY). Microbial cellulose (MC) provided an alternative to enhance the relationship between content and container. Another critical point was to envision the integration of possible production systems into the current regional setting.

3.1 SCOBY: A Hybrid Character

In-depth research led to identifying the possible ways of converting by-products into useful substances. Algae, fungi, and SCOBY were compared—also to paper and plastic—in terms of characteristics, production methods and manufacturing journey. SCOBY (also called Kombucha mother) was chosen for its capability to transform sugar-rich food byproducts into two valuable co-products both compatible with edible and non-edible purposes: namely a fermented liquid and a fiber-rich substance: microbial cellulose. The SCOBY is mostly known for edible-related purposes. Namely, the Filipino dessert Nata de Coco is constituted by chunks of SCOBY cooked into coconut syrup. However, it is commonly used to ferment green and black tea mixed with sugar, generating a probiotic beverage: Kombucha tea. This naturally enriched drink dating back to 220 B.C. has recently gained a high (g)local potential given by its capability to transform by-products which we consider as waste into valuable substances with a strong regional focus. Indeed, renewable resources ‘naturally’ call for local uses [1]. The conversion process happens through fermentation in which the SCOBY is immersed into a container filled with a nourishing liquid for 12–21 days. During this time—as it happens in any other fermentation like beer brewing—the ‘mother’ consumes the sugar and reproduces itself through symbiotic processes eventually generating layers of microbial cellulose floating on the surface of the liquid, as seen in Fig. 1.

This type of cellulose is purer than the one extracted from trees and appears to have a smaller environmental impact since it is synthesized directly from food-related by-products. For these reasons, it could provide a regenerative low-km solution to substitute imported materials and ingredients used on a local level. Indeed, this novel process unpacks a variety of novel substances (co-products) to be used in different fields. In particular, it appears to be suitable for medical, cosmetic, biotechnological, food (source of indigestible fibers), novel material and compound, and even for extraction industry applications [19,20,21,22].

SCOBY was introduced into the design world by fashion designer Suzanne Lee [23] who wanted to provide an alternative scenario by raising the discourse about the polluting leather industry. She developed a collection of items of clothing in which she used microbial cellulose generated from tea fermentation to substitute more common textiles. However, microbial cellulose is highly hydrophilic, which means that it absorbs water becoming jelly-like and not suitable for clothing. The ‘Biocouture’ project was, in fact, a conversation piece. From that point in 2011 on, several design students [24,25,26] and professionals started tinkering, experimenting, and speculating [27] with the material to discover its potential. From Peel To Peel is one of these projects which brought the discourse to another field by focusing on food packaging.

3.2 Microbially-Produced Packaging

The project developed on two parallel levels: the material underwent an MDD (Material Driven Design) approach [28] to practically understand its capabilities and limits for food packaging and disposable tableware applications while the second level extended the practical findings towards a systematic introduction of the material into the local system.

MC was grown from local by-products such as scraps of apple, beetroot, potato, grapes, blueberries, hops, and mixed vegetables immersed into containers filled with a water-based solution and with SCOBY mothers. The fermentation happened in static conditions. The grown wet layers of MC were dried and used for further experimentation. They were treated in several manners acquiring different shapes and shades enabling various material applications as sheets or as substances (see Fig. 2).

The final models were representations of food packaging (Fig. 3) and disposable tableware (Fig. 4) with a familiar semantics, clear cuts, and bright shades. A particular focus was given to local food-producers proposing packaging for their specific products. Similarly, disposable trays and cups were developed for street food vendors and for hypothetical events in order to enhance the territorial identity through direct and local uses of the material.

A systemic approach was used to investigate the dynamics of the current system to speculate hypothetical ways of integration of MC production into the region of South Tyrol. In particular, the journey of food by-products was analysed from their collection from producers to their disposal into specialised centres. Visits were made to staple producers, political representatives, waste-transportation services and waste-management facilities to outline regional patterns around agri-food production systems. After framing current dynamics, two scenarios were developed proposing; first, an MC production plant integrated to the fermentation centre in charge of disposing of the urban organic waste of the city of Bolzano/Bozen (see Fig. 5). As discussed with the plant’s responsible, the current facility and the hypothetical MC production appear to be mutually nurturing.

On the other hand, the second proposal displays a scheme for an independent MC production plant (see Fig. 6).

These systemic investigations unpacked the potential of MC as a catalyser for virtuous biological cycles. The fermentation process would take advantage of both the fermented liquid and the generated microbial cellulose without leaving possibly any waste. In this way, local assets would create an industrial ecology [29] and be actively engaged in territorial value creation. These assumptions provided a ground for the following research project addressed in the next section.

4 InnoCell

In this paper, we present the project InnoCell, as an example of a new possible microbial production system based in South Tyrol. It would, on the one hand, valorise local agricultural food ‘waste’, on the other hand, it aims to propose a (g)local model which can be influential and diffused onto other local realities.

South Tyrol, the setting of the project, is the biggest apple growing area of Europe. Solely in 2018, 910.767 tons of apples were produced regionally [30] and sold as fruits or transformed into other edible products generating tons of by-products. This amount is generally down-cycled into fertiliser and animal feed.

The founding principle of InnoCell is the potential of transforming the scraps of the production of apple-related products into valuable substances. The apple is considered as ‘meta-product’ generating a variety of ‘co-products’ through transformation processes—like juice, dry apples—and through microbial intervention—such as kombucha apple juice and compostable microbial substances—for edible and non-edible purposes.

4.1 Methodology

The ongoing interdisciplinary project is led by the design team, together with food technology scientists. The partners from the food technology field are in charge of analysing the fermentation process with a growth-efficiency goal. Therefore, they selected the most efficient strains of microorganisms and defined the ideal recipe for the nourishing liquid based on apple scraps. Moreover, they will determine the most efficient parameters for the process of fermentation and for the production of the SCOBY co-products.

The design team explores the capability and potential applications of the microbial substances through practice-based design research. A DIY (do-it-yourself) growth unit is being developed in order to produce SCOBY co-products, enabling further tinkering and experimentation for possible applications. Moreover, future scenarios with a strong (g)local focus will be built through co-design workshops with partners.

4.2 DIY (Do-It-Yourself) Growth-Unit Concept

As MC introduces a relevant discourse towards the low-km production of substances, the consequent step would be to diffuse the knowledge of SCOBY fermentation to other localities to create novel product solutions. A growth-unit concept is being developed with the aim of making an easy-to-replicate system in order to enable anyone, anywhere to independently perform the process. The most commonly used growing technique is to let the SCOBY grow on the surface of the liquid in a static way, differently in our DIY growth-unit a dynamic system called rotating disk bioreactor was built based on the previous comparative studies done by other scholars and biotechnologists [19, 31,32,33] to produce an optimal amount of yield. The prototype is currently being tested with the aid of food technology partners. The goal is to create a unit to be simply replicated elsewhere with standard components and minimal assembly interventions. The unit would generate microbial cellulose substances and a fermented liquid simultaneously by using diverse food by-products coming from the local agricultural and/or food production.

5 Project Pattern: Global and Local Relevance

A relevant finding given by the ongoing research is that a systematic approach is essential when proposing novel product and production solutions. In fact, as industrial products cannot be designed as single entities, also when developing novel substances and matter, it is fundamental to consider the entire ecosystem around its life-cycle. Dynamics concerning raw materials, transformation processes, use, disposal, links, and touchpoints among stakeholders need to be investigated into current systems in order to envision meaningful scenarios of integration and/or coexistence. Indeed, desk research and design-research tools like stakeholder maps, service maps, system maps would help to visualise and to deal more efficiently with complex structures. Moreover, field research would further ground and enhance the designer's assumptions through visits to stakeholders’ facilities and advice from experts. In this way, the systematic approach would support the research hypothesis to be verified based on the existing realities, aiming to a real impact.

In analysing the project's path, a relevant pattern was framed (see Fig. 7): while project ‘Biocouture’ by Suzanne Lee raised the discourse of an alternative production in a global dimension, project ‘From Peel To Peel’ had a strong locally-oriented focus. Instead, project ‘InnoCell’ merges the two perspectives (local and global) and provides novel production solutions based on local waste, on the other hand, it aims at carrying this know-how to other localities through the open-source DIY growth-unit.

This can be identified as a generic pattern: a global-focused principle can be taken to a local level and be enhanced with a (g)local perspective. Other projects could follow a similar path unpacking and highlight promising (g)local potentials.

6 Final Assumptions

This paper reflects on the potential of SCOBY as a catalyser for resilient production from a (g)local perspective. The symbiotic colony of microorganisms is capable of transforming discarded food by-products into highly valuable substances for edible and non-edible purposes and applications. This can be possible if we adopt the formula of ‘meta-product to co-products’ which we above mentioned. The fruitful husbandry approach between microorganisms and designers as ‘cultivators’ is deepened by our project InnoCell enhancing the discourse around the (g)local potential of SCOBY co-products as drivers for enhanced territorial value creation.

Notes

- 1.

South Tyrol region is in the North of Italy, a part of the Tyrol area.

References

Manzini E (2012) Resilient systems and cosmopolitan localism—the emerging scenarios of the small, local, open and connected space. CNS Ecologia Politica

McDonough W, Braungart M (2002) Cradle to cradle: remaking the way we make things, 1st edn. North Point Press, New York, United States

Baumeister D, Tocke R, Dwyer J, Ritter S, Benyus JM (2014) Biomimicry resource handbook: a seed bank of knowledge and best practices. Montana: Missoula, United States

Schumacher EF (1973) Small is beautiful. Economics as if people mattered. Blond and Briggs, London, UK

Camere S, Karana E (2017) Growing materials for product design. In: Alive. active. Adaptive proceedings. Delft University of Technology international conference on experiential knowledge and emerging materials, Delft: TU Delft Open, June 19–20, pp 24–37

Antonelli P (2012) Vital design. In: Myers W. BioDesign. Nature, science, creativity, 1st edn. Thames & Hudson, High Holborn, UK, pp 6–7

Ciuffi V (2013) Growing design. Abitare 531:110–111

Myers W (2012) BioDesign. Nature, science, creativity, 1st edn. Thames & Hudson, High Holborn, UK, pp 8–9

Collet C (2017) Grow made textiles. In: Alive. Active. Adaptive. Proceedings. Delft University of Technology international conference on experiential knowledge and emerging materials, Delft: TU Delft Open, June 19–20, p 27

Victimless Leather, https://tcaproject.net/portfolio/victimless-leather/, last accessed 2020/05/06

Ginsberg AD, Calvert J, Schyfter P, Elfick A, Endy D (2014) Synthetic aesthetics: investigating synthetic biology’s designs on nature. MIT Press, United States Cambridge

Ginsberg AD, Calvert J, Schyfter P, Elfick A, Endy D (2014) Synthetic aesthetics: investigating synthetic biology’s designs on nature. Cambridge: MIT Press. United States, p 174

Materiom, https://materiom.org/, last accessed 2020/05/06

Malai, http://made-from-malai.com/, last accessed 2020/05/06

Evoware, https://evoware.id/, last accessed 2020/05/06

Proinsect, https://www.eco-center.it/it/attivita-servizi/ricerca-993.html, last accessed 2020/05/06

New Menu, https://issuu.com/idmcreativeindustries/docs/catalogue_cover_compressed__1_/70?fbclid=IwAR19JajNWptFgI2oQx0g2KA6DhIPJod-gN9FwT4pTk7JluiD49h1e69TbR0, last accessed 2020/05/06

Sicher E (2017) BA thesis: from Peel To Peel—an experimental design approach for packaging. UNIBZ, Bozen-Bolzano. Available online: https://ubz-primo.hosted.exlibrisgroup.com/primo-explore/fulldisplay?docid=39UBZ_ALMA_DS21151949370001241&context=L&vid=UNIBZ&lang=it_IT&search_scope=All&adaptor=Local%20Search%20Engine&tab=default_tab&query=any,contains,From%20peel%20to%20peel&offset=0, last accessed 2020/05/06

Chawla PR, Ishwar BB, Shrikant AS, Rekha SS (2009) Fermentative production and applications of microbial cellulose. Food Technol Biotechnol 47(2):107–124

Revin V, Liyaskina E, Nazarkina M, Bogatyreva A, Shchankin M (2018) Microbiology cost-effective production of bacterial cellulose using acidic food industry by-products. Braz J Microbiol 49(1):151–159

Dourado F, Gama M, Rodrigues AC (2017) A review on the toxicology and dietetic role of bacterial cellulose. Toxicol Rep 4:543–553

Cacicedo ML, Castro MC, Servetas I, Bosnea L, Boura K, Tsafrakidou P, Dima A, Terpou A, Koutinas A, Castro GR (2016) Progress in bacterial cellulose matrices for biotechnological applications. Biores Technol 213:172–180

Lee S (2020) Grow your own clothes. https://www.ted.com/talks/suzanne_lee_grow_your_own_clothes, last accessed 2020/05/06

Rykkelid E (2020) Growing products. https://growingproducts.tumblr.com/, last accessed 2020/05/06.

Janusz R (2020) MakeGrow Lab. https://www.makegrowlab.com/, last accessed 2020/05/06

Amato E (2020) Ponto biodesign. https://www.facebook.com/events/908029682970073/?notif_t=plan_reminder¬if_id=1588777207130982/, last accessed 2020/05/06

Dunne A, Raby F (2020) UMK, Biocars. http://unitedmicrokingdoms.org/bioliberals/, last accessed 2020/05/06

Karana E, Barati B, Rognoli V, Zeeuw van der Laan A (2015) Material driven design (MDD): a method to design for material experiences. Int J Des 9(2):35–54

Fiksel J (2003) Designing resilient, sustainable systems. Environmental science & technology. Environ Sci Technol 37(23):5330–5339

ASTAT, https://astat.provincia.bz.it/downloads/Siz_2018(2).pdf, p 37, last accessed 2020/05/06

Bungay RH, Serafica G, Mormino R (1997) Environmental implications of microbial cellulose. Stud Environ Sci 66:691–700

Pa’e N, Zahan KA, Muhamad II (2011) Production of biopolymer from acetobacter xylinum using different fermentation methods. Int J Eng Technol IJET-IJENS 11(5):90–98 (2011)

Bungay H, Pajuelo M, Hogg T, Vasconcelos I (2015) Lowering costs for microbial cellulose, pp 1–8

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Cohen, N., Sicher, E., Uğur Yavuz, S. (2022). From Agricultural Waste to Microbial Growth and (G)Local Resilience. In: Duarte, E., Rosa, C. (eds) Developments in Design Research and Practice. Senses 2019. Springer Series in Design and Innovation , vol 17. Springer, Cham. https://doi.org/10.1007/978-3-030-86596-2_7

Download citation

DOI: https://doi.org/10.1007/978-3-030-86596-2_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-86595-5

Online ISBN: 978-3-030-86596-2

eBook Packages: EngineeringEngineering (R0)