Abstract

Corrugated steel plate shear walls (CSPSWs) are most commonly used as a lateral load resisting mechanism in earthquake prone areas. They are used in modular building structures (MBS) and steel structures for its high ductility, and strength. Double corrugated steel plate shear wall (DCSPSW) contains two trapezoidal corrugated steel plates that are connected together either by weld or bolts. It is most often used as an alternative for the conventional steel plate shear walls. Since openings like window and door are unavoidable, the performance of the system with and without openings must be studied. The performance and change of strength of the walls on addition of stiffeners around the openings are to be evaluated. In this paper, the seismic performance of DCSPSW with and without, openings and stiffeners are investigated and compared with that of the ordinary (single) CSPSW.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Corrugated Steel Plate Shear Wall (CSPSW)

- Double-Corrugated Steel Plate Shear Wall (DCPSW)

- Seismic performance

- Modular building structures

1 Introduction

Steel structures are commonly used in seismic hazard area, for its high strength and malleability. CSPSW are generally used as seismic resisting member principally in MBS and in steel structures in those seismic zones. It includes infill plate (stiffened or unstiffened), with and without openings, with vertical and horizontal structural components. From similar researches, the CSPSW is found to be a cost-effective economical methodology for high rise buildings than typical strategies.

Numerical studies concerning the SPSW was carried out in the past was on flat plates being used as infill plates. The corrugated steel plates are used as replacement for their high out-of- plane geometric stability. Due to the high stiffness of corrugated plates despite of its lower thickness than flat plates have been helpful for the construction of light girders [1,2,3].

The strength of the RBS shear wall could be calculated by a proposed equation, verified on comparison with the value obtained by FE analysis by providing RBS on the beam section to ensure the plastic hinges form on the beam rather on the beam span or on columns [4].

By experimental and numerical means the seismic performance of low and midrise buildings with CSPSW with slits indicated that the shear walls with perforation provided desirable ductility and strength than shear walls without perforation [5]. On application of monotonic loading on CSPSW with and without opening the parameters such as ductility, stiffness, strength and buckling stability were studied to understand the seismic performance by preparing FE models [6].

Predominantly the factor to be considered in the corrugated plates is their low stiffness is the direction perpendicular to the corrugation of the plates and the high strength to arrest the in-plane forces along the direction of the corrugation. The CSPSW in the MBS are commonly a part of the walls incorporated with openings such as doors and windows. The connection of the CSPSW in the normal and MBS make them distinct [7].

In regular structures they are connected on the edges whereas in modular structures they are connected in corners. Since the modules in MBS are connected in corners it helps in the load transfer vertically from column to column. Due to the high stiffness in MBS the CSPSW act as seismic resisting mechanism. On the studies that have been done by other researchers to understand the behavior of the CSPSW, the addition of the openings to the walls impairs the strength and performance of the element [8].

On comparison studies done by the application of pushover and cyclic loading on CSPSW and SPSW on numerous models [9]. Experimental studies on CSPSW with and without openings was carried out and addition of constructional column around the openings to arrest the buckling of the infill plate. The results showed that the initial stiffness of the models with openings are reduced when compared to the model without opening [10].

Since the slit and perforation on the walls are inevitable, small steel strips are used as reinforcement in CSPSW. They are connected, welded in perpendicular to the peak of each corrugation. Since the reinforcement are provided, they enhance the out-of-plane stiffness of the walls. They also enhance the ductility of the plates and also limit the deformation by energy dissipation betwixt the corrugations [11].

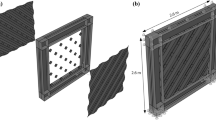

A DCSPSW was recently planned by the authors, consist of two corrugated steel plates connected together either by weld or by bolts. The general dimension of the DCSPSW as shown in Fig. 1.

An analytical formula was proposed to predict the ultimate shear strength of DSCSW. Proposal for calculation of the shear yield and the local and global shear elastic buckling were given as three analytical formulas and accuracy was defined by experimental means [12]. By the application of monotonic shear loads on finite element models the shear resisting behaviors of the double corrugated walls were investigated [13].

2 Methodology

SCSPSWs and DCSPSWs were modelled and analyzed using ANSYS 16.1 finite element software. Fixed support was provided at the bottom of the columns as a boundary condition for the wall. Monotonic loading was provided in transverse direction.

The load was provided at the top edge of the column in displacement control and in incremental manner. the elements used around the openings for this study is considered from Korean Standard (KS) profiles.

The element type used for the analysis is 20-node solid 186 element, which is higher order 3D element which exhibits quadratic displacement behavior. The 20 nodes of the element have 3 degrees of freedom i.e., translation in nodal x, y, and z direction. The element supports plasticity, hyper elasticity, creep, stress stiffening, large deflection, and large strain capabilities. The meshing used in the model is combined tetra and hexa mesh. The meshing near the opening is not refined.

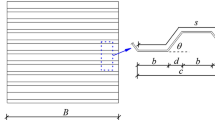

For the current study, a corrugated wall of a single-story residential building of height 3.1m and length of 4.5m from center to center was considered. The dimensional description of the beams and columns used in the study are provided in Table 1 and material properties of plates, beam and column are shown in Table 2. The material properties of the boundary elements are provided in Table 3 and cross-sectional details are shown in Fig. 2.

Geometry of the model [4]

CSPSW for the analysis was modelled by changing the corrugation angle with 0°, 45°, 90°. Angle of inclination changed with respect to X axis. The main purpose of changing angle of corrugation for selecting best angle which carrying higher ultimate strength. Some models with different openings, alignment and stiffeners are shown in Fig. 3. The dimensional details of the panel element are given in Table 4.

Study was carried out on the journal of “Alireza Farzampour (Analysis and design recommendations for corrugated steel plate shear wall reduced beam section)” and the results obtained on comparison is less than 0.5% error. Table 5 shows the dimensions of openings used for the study.

Deformation was mostly affected around the door and the window opening provided, therefore to arrest these deformations a small thickness steel element was provided around the opening and thereby improving the strength of the load carrying capacity. The size of the element provided around the opening were 120 × 60 × 4mm [10]. Steel plate shear walls with boundary elements were one in all of the advanced models.

Therefore, getting more accurate results, frame elements and infill plates were meshed separately by using different element size. The mesh size was kept 150 mm for the frame column and beam and constructional column and 100 mm for the infill plate.

3 Results

In this part, analysis and discussion on the performance of the CSPSW and DCSPSW considering both provision for perforation and without perforations, with different alignment of corrugations were carried out. The ultimate load carrying capacity of each model was different. The ultimate strength of different angle of CSPSW was shown in Tables 6, 7 and 8. The pushover curve and stiffness of the CSPSW under lateral loading are shown in Fig. 4. On incorporation of stiffeners around the window openings, the model with corrugation aligned horizontally was found to be more effective by having better load carrying capacity than other models. But when the door opening was provided with stiffeners the maximum load carrying capacity was found for the model with corrugations aligned vertically. For models with stiffeners for combined door and window opening, the maximum load carrying capacity was obtained for models with corrugations aligned horizontally with a negligible increase in strength than model of corrugation aligned vertically.

For DCSPSW, load carrying capacity of models with corrugations aligned vertically has augmented by 5% to 13% than CSPSW. Likewise, for models with corrugations aligned at 45°, the strength has augmented by 6% to 11% and with corrugations intensified horizontally the strength has increased by 7% to 9%.

As the results signify, the strength of the CSPSW have increased by providing stiffeners around the opening and additionally it can be made more effective by connecting the constructional column from top beam to bottom beam. The strength of the CSPSW have increased much more by making single corrugated plate shear wall to double corrugated shear wall, than the models with stiffeners provided around openings. Among the three-corrugation alignment the maximum load carrying capacity for the DCSPSW was obtained for the model with corrugation aligned vertically.

The addition of stiffeners adds auxiliary strength to the model as for CSPSW, since the openings on the model in real life are unavoidable, the addition of stiffeners to the models are applicable and hence it provides more strength to DCSPSW with openings. The position of the openings, i.e., providing the perforation at the center of the wall and at the end of the walls also affect the strength and stiffness of the models.

For CSPSW models, with corrugations aligned vertically, at 45° and horizontally, with the door and window openings when provided separately, the maximum loads were carried when the placement of the openings were provided at the ends. From the results obtained the maximum loads were carried when the corrugations were aligned horizontally and on the placement of the opening at the end.

On providing both the openings on the shear wall the loads were significantly reduced, and the maximum load were carried on the positioning of the openings on the ends of the plate. On providing both the openings on the same wall, the maximum load was found to be carried by the models with corrugations aligned vertically. Among the models of three configurations, on providing window and door opening separately, the plates aligned horizontally was found to be effective and for models with combined door and window opening the models with plates aligned vertically was found to be more effective under lateral loads.

For DCSPSW models, with corrugations aligned vertically, at 45° and horizontally, with the door and window openings when provided separately, the maximum loads were carried when the placement of the openings were provided at the ends.

From the results obtained the maximum loads were carried when the corrugations were aligned vertically and on the placement of the opening at the end. On providing both the openings on the shear wall the loads were significantly reduced as similar to CSPSW, and the maximum load were carried on the positioning of the openings at the ends of the plate. On providing both the openings on the same wall, the maximum load was found to be carried by the models with corrugations aligned vertically.

Among the models of three configurations, on providing window and door opening separately and for models with combined door and window opening the shear wall models with plates aligned vertically was found to be more effective under lateral loads. Addition of stiffeners to the model increases strength to shear wall as in CSPSW.

On providing stiffeners around the opening and throughout the top beam to bottom beam, the lateral out plane bucking of the plates can be arrested. On the model with window opening the maximum load was carried on the positioning of the opening on the end of plate and on models with door opening maximum load was carried by models with openings provided at the ends.

Based on the change in the alignment the maximum load was carried by the models with corrugations vertically aligned and model with combined door and window openings the maximum load was carried by the models with the positioning of the door at the middle and window at the end with the corrugations aligned vertically.

4 Conclusion

By inferring from the results, the study was carried out to identify the performance and change in strength of the models with openings, by changing the position of the opening, i.e., by providing the opening at the end and middle and by the addition of stiffeners around the opening and also providing two infill corrugated plates in CSPSW making it DCSPSW. Similarly, study on different corrugation alignment (horizontal, vertical and aligned 45°) was carried out to identify the best alignment for the shear wall to carry the maximum lateral load.

Addition of the opening to the models reduce the strength of the model and addition of the stiffeners around the opening increase the strength of the model. DCSPSW provides better strength when compared to that of CSPSW without openings and addition of stiffeners to the openings in DCSPSW increases the strength of the model to 15% to 18% than CSPSW with openings. Based on the study of change in the alignment of the corrugations the maximum load was carried by the models with corrugations aligned horizontally for models with door and window opening separately. And for models with combined door and window opening the maximum loads was carried by the models with corrugations aligned vertically.

For DCSPSW models with and without stiffeners the maximum load was carried on the arrangement of corrugations in vertical direction. On the models with door and window opening separately, and on models without stiffeners, the maximum load was carried by the models with perforations at the end of the plate of wall. On the models with stiffeners maximum load was carried by the models with corrugations vertically aligned and the model with combined door and window openings the maximum load was carried by the models with the positioning of the door at the middle and window at the end with the corrugations aligned vertically.

References

Emami F, Mofid M, Vafai A (2013) Experimental study on cyclic behavior of trapezoidally corrugated steel shear walls. Eng Struct 48:750–762

Emami F, Mofid M (2012) On the hysteretic behavior of trapezoidally corrugated steel shear walls. Struct Des Tall Spec Build 23(2):94–104

Nilsson P, Al-Emrani M, Atashipour SR (2017) Transverse shear stiffness of corrugated core steel sandwich panels with dual weld lines. Thin-Walled Struct 117:98–112

Farzampour A, Mansouri I, Lee C, Sim H, Hu JW (2018) Analysis and design recommendations for corrugated steel plate shear walls with a reduced beam section. Thin-Walled Struct 132:658–666

Zhang W, Yu C, Mahdavian M (2019) Seismic performance of cold-formed steel shear walls using corrugated sheathing with slits. J Struct Eng 145(4):04019014

Bahrebar M, Kabir MZ, Hajsadeghi M, Zirakian T, Lim JB (2016) Structural performance of steel plate shear walls with trapezoidal corrugations and centrally-placed square perforations. Int J Steel Struct 16(3):845–855

Liew RJ, Dai Z, Chau YS (2018) Steel concrete composite systems for modular construction of high-rise buildings. In: Proceedings 12th international conference on advances in steel-concrete composite structures—ASCCS 2018

Farzampour A, Laman JA, Mofid M (2015) Behavior prediction of corrugated steel plate shear walls with openings. J Constr Steel Res 114:258–268

Zhao Q, Sun J, Li Y, Li Z (2017) Cyclic analyses of corrugated steel plate shear walls. Struct Des Tall Spec Build 26(16)

Ding Y, Deng E-F, Zong L, Dai X-M, Lou N, Chen Y (2017) Cyclic tests on corrugated steel plate shear walls with openings in modularized- constructions. J Constr Steel Res 138:675–691

Dai X-M, Ding Y, Zong L, Deng E-F, Lou N, Chen Y (2018) Experimental study on seismic behavior of steel strip reinforced CSPSWs in MBS. J Constr Steel Res 151:228–237

Tong J-Z, Guo Y-L, Zuo J-Q (2018) Elastic buckling and load-resistant behaviors of double- corrugated-plate shear walls under pure in-plane shear loads. Thin-Walled Struct 130:593–612

Labibzadeh M, Hamidi R (2019) A design formula for lateral load resistance of concrete filled double-steel-plate walls with small height-to-length ratio. KSCE J Civ Eng 23(8):3493–3508

Acknowledgements

I take this opportunity to convey my deep sense of gratitude to all the staff members and students of Department of Civil Engineering, Saintgits College of Engineering, Kerala, for their cooperation and encouragement during the course of this study.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Lalu, A.V., Mathew, A.A. (2022). Seismic Resisting Performance and Strengthening of Single and Double Corrugated Steel Plate Shear Wall. In: Marano, G.C., Ray Chaudhuri, S., Unni Kartha, G., Kavitha, P.E., Prasad, R., Achison, R.J. (eds) Proceedings of SECON’21. SECON 2021. Lecture Notes in Civil Engineering, vol 171. Springer, Cham. https://doi.org/10.1007/978-3-030-80312-4_2

Download citation

DOI: https://doi.org/10.1007/978-3-030-80312-4_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-80311-7

Online ISBN: 978-3-030-80312-4

eBook Packages: EngineeringEngineering (R0)