Abstract

Field fill materials often contain gravel particles larger than the allowable limit for standard laboratory compaction tests. In such cases, the maximum dry density (ρd)max of a material containing large gravels is obtained by correcting laboratory test results for specimens without large gravels. Usually, the Walker–Holtz (WH) method is used for this correction, but there are many materials whose gravel ratio (P) is 0.3 − 0.4, which is usually considered to be the application limit. Moreover, accurate stress-strain properties under field compaction conditions are necessary for relevant stability analysis of soil structures including embankments. However, with unbound granular materials, it is difficult to obtain undisturbed samples for laboratory tests or to carry out field shear tests. Also, large-scale triaxial compression tests on specimens containing large gravels are difficult to perform in ordinary engineering practices. In this study, a series of laboratory compaction tests were performed changing the maximum particle size (Dmax), compaction energy level (CEL) and P to examine the validity of the WH method and a series of drained triaxial compression tests were performed varying the Dmax and the degree of compaction. Based on the test results, a method to modify the WH method is proposed to properly estimate the (ρd)max value after adding or removing gravel particles when compacted at a certain CEL. Also, a method is proposed to correct the strength for a given gravel ratio to estimate the in-situ strength from the strength obtained from laboratory tests.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In the conventional control of field soil compaction of embankments for roads, railways and residential and industrial areas, etc., the dry density ρd and the water content w are measured in the field and controlled based on the maximum dry density (ρd)max and the optimum water content wopt obtained by standard laboratory compaction tests performed on representative samples of the field fill material at a specified compaction energy level (CEL) (usually Standard or Modified Proctor, 1Ec or 4.5Ec). Field fill materials often contain large particles, such as gravels and rock fragments, the size of which exceeds the allowable limit for standard laboratory compaction tests. In this case, it is necessary to estimate the values of (ρd)max and wopt of the field fill material by correcting the values obtained by laboratory compaction tests on samples obtained by removing gravel particles of which the sizes exceed the allowable limit. When the gravel ratio P (will be described later in Chap. 2) of a given field fill material is lower than 0.3 or 0.4, the Walker–Holtz (WH) method [1, 2] is usually used for this estimate. The WH method assumes that the ρd value of the fine particle portion inside the whole sample after adding large particles is the same as the value of the sample comprising only fine particles compacted at the same CEL. However, it is known that, with an increase in P of the whole sample, the CEL transmitted to the fine particle portion inside the whole sample decreases, therefore the ρd value of the fine particle portion decreases. Besides, this trend may not be negligible even when P is lower than 0.3 or 0.4.

In addition, stability analysis of soil structure requires relevant shear strength values of compacted fill material. Because the stability may decrease as a fill material becomes wet or saturated, the strength under wet or saturated conditions is usually used in design. Like the laboratory compaction tests, the shear strength characteristics are often evaluated by performing triaxial compression (TC) tests on samples obtained by removing gravel particles of which the sizes exceed the allowable limit for standard TC tests.

There are studies that approach each problem [3, 4], but there are few researches that studied these two issues related to each other by performing compaction tests and TC tests on the same soil type compacted in the same way. In this research, a set of samples having different maximum particle diameters Dmax were prepared by consecutively removing larger particles from a typical field fill material. A series of laboratory compaction tests were then performed on these samples at CEL = 1Ec and 4.5Ec to evaluate the effects of P on the value of (ρd)max for various values of Dmax and CEL. Also, a series of laboratory consolidated-drained TC tests were performed on these samples to evaluate the effects of P on the shear strength characteristics of specimens compacted otherwise under the same conditions.

2 Walker–Holtz Method

In the WH method, the dry density ρd′ of a sample after adding large gravel particles with the same CEL as a sample before adding gravel particle is obtained by Eq. (1):

where ρd is the dry density of the sample before adding gravel particles; ρs is the density of gravel particles; and P is the mass ratio of the added gravel to the whole sample after adding gravel particles. In this study, it is reasonably assumed that the density of particles other than the gravel particles is the same as ρs. In addition, the Sr value does not change by adding gravel particles when following Eq. (1). In the WH method,

On the other hand, the dry density ρd′′ of the portion composed of fine particles not containing large gravel particles inside the whole sample containing large gravel particles compacted at a certain CEL is correctly obtained by Eq. (2):

where ρd is the dry density of the whole sample before removing the gravel particles; and P is the mass ratio of gravel particles to the whole sample. Note that we need no assumption to derive Eq. (2).

3 Soil Samples and Test Methods

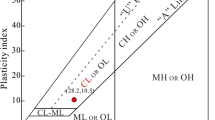

The field fill material used to construct a road embankment in Kamaishi City, Iwate Prefecture, Japan (hereafter called Kiten soil) was used in this study. Figure 1 shows the grading curve of the field material with Dmax = 75 mm. A set of samples with Dmax = 53 mm, 37.5 mm, 19 mm, 9.5 mm 4.75 mm, and 2 mm were produced by consecutively removing larger gravel particles.

The mold having an inner diameter of 15 cm and a volume of 2209 cm3 was used for laboratory compaction tests on samples with Dmax = 37.5, 19, 4.75, and 2 mm. A 2.5 kg rammer was dropped freely from a height of 30 cm, and the number of tamping was 55 for each of in total three layers. The CEL, in this case, is 1Ec, and Ec is the energy per unit volume and is calculated by Eq. (3).

where WR is the weight of the rammer; H is the drop height of the rammer; NL is the number of layers; NB is the number of tamping per layer; and V is the volume of mold.

Furthermore, a 4.5 kg rammer was dropped freely from a height of 45 cm and tamped 55 times for each of in total 5 layers. The CEL in this case is 4.5Ec. A mold having an inner diameter of 30 cm and a volume of 25,000 cm3 was used for samples with Dmax = 75 and 53 mm. For 1Ec, a 10 kg rammer was dropped freely from a height of 45 cm. The number of tamping was 104 times for each of in total 3 layers. For 4.5Ec, a 10 kg rammer was dropped freely from a height of 45 cm and the number of tamping was 468 times for each of in total 3 layers. The total mass of a whole compacted sample was measured before and after oven-drying.

A series of drained TC tests were performed on specimens with Dmax = 19, 9.5, and 4.75 mm. Table 1 shows the compaction conditions of the specimens having different Dmax values. [Dc]1Ec in the table represents the degree of compaction at 1Ec. The specimens were prepared by compaction in 5 layers in the mold. In order to evaluate effects of Dmax on shear strength at the same ρd value, the tests were performed on specimens compacted to ρd = 1.872 g/cm3 and Sr = 80% for each Dmax. The specimens were 100 mm in diameter and 200 mm in height for Dmax = 19 mm; and 75 mm in diameter and 150 mm in height for Dmax = 9.5 mm and 4.75 mm. After saturation, the specimen was consolidated to an effective confining pressure of 50 kPa with a back pressure of 300 kPa, and loaded monotonically at an axial strain rate of 0.01%/min under drained conditions.

4 Results and Discussions (Laboratory Compaction Tests)

4.1 Results

Figure 2 shows the compaction curves for 1Ec and 4.5Ec of the samples having different Dmax values. The (ρd)max value increases as the Dmax value increases and as CEL increases. In comparison, the Sr value when ρd = (ρd)max along each compaction curve, which is defined as the optimum degree of saturation (Sr)opt [5], is quite independent of Dmax and CEL and has value of 81%.

In Fig. 3a, the curves with data points are the measured compaction curves of the specimens with Dmax = 75, 53, 37.5, 19, 9.5, 4.75, and 2 mm of Kiten soil compacted at 1Ec. The set of solid curves are the compaction curves of the specimens are those calculated by Eq. (1) when adding particles larger than 2 mm in diameter to the basic specimen with Dmax = 2 mm. It may be seen that the (ρd)max value for 1Ec is over-estimated by Eq. (1) to a larger extent with an increase in Dmax (i.e., with an increase in the mass ratio P of particles larger than 2 mm to the whole sample containing these added large particles). On the other hand, the compaction curves of the portion of fine particles with Dmax = 53, 37.5, 19, 9.5, 4.75, and 2 mm inside the basic sample with Dmax = 75 mm compacted at 1Ec were calculated by Eq. (2). In Fig. 3b, these calculated compaction curves are compared with the measured curves of the specimens comprising fine particles that were compacted at 1Ec. The (ρd)max value calculated by Eq. (2) becomes smaller than the measured one obtained by compaction at 1Ec. This means that the (ρd)max value for 1Ec is under-estimated by Eq. (2) to a larger extent with an increase in Dmax.

a Compaction curves for 1Ec of the specimens obtained by adding large particles to the basic sample with Dmax = 2 mm calculated by Eq. (1) and measured curves of these samples compacted at 1Ec; b Compaction curves of the fine particle portion inside the basic specimen with Dmax = 75 mm compacted at 1Ec calculated by Eq. (2) and measured compaction curves of specimens composed of the same fine particles compacted at 1Ec

4.2 Modification of the WH-Method

It is seen from Fig. 3a that it is necessary to modify Eq. (1) to obtain the correct ρd value of a specimen after adding larger particles that are compacted at a certain CEL from the ρd value of the basic specimen compacted at the same CEL. It is seen from Fig. 3b that it is also necessary to modify Eq. (2) to obtain the correct ρd value of a specimen after removing larger particles that is compacted at a certain CEL from the ρd value of the basic specimen compacted at the same CEL. To unify these trends of behavior in a single framework, the maximum dry density ratio X was defined as the ratio of the (ρd)max value when compacted at a certain CEL calculated by Eqs. (1) or (2) to the measured (ρd)max value of the same sample compacted at the same CEL.

In the top–right quarter zone of Fig. 4, the X values of the specimens to which different amounts of gravel particles larger than 2 mm in diameter were added to the basic specimen with Dmax = 2 mm are plotted against the gravel mass ratio P of these specimens after adding particles larger than 2 mm. These data were obtained from those plotted in Fig. 3a. The X value increases consistently from 1.0 as P increases from zero. That is, as P increases, the (ρd)max value after adding gravel particles when compacted at a certain CEL is over-estimated to a larger extent than if calculated by Eq. (1) based on the (ρd)max value of the basic specimen compacted at the same CEL. Importantly, X is noticeably higher than 1.0 when P = 0.3 − 0.4, which is conventionally considered as the upper limit for the application of the WH method.

X–P relation from data for compaction at 1Ec in Fig. 3a, b

In the bottom-left quarter zone of Fig. 4, the X values of the specimens from which different amounts of gravel particles smaller than 75 mm in diameter were removed from the basic specimen with Dmax = 75 mm are plotted against –P, where P is the mass ratio of the gravel particles that were removed from the basic specimen with Dmax = 75 mm. These plots were obtained from the data presented in Fig. 3b. The X value decreases consistently from 1.0 as P increases. That is, as P increases from zero, the CEL transmitted to the fine particle portion becomes smaller than 1Ec, which was applied to the whole of the basic specimen containing gravel particles. By this mechanism, the calculated dry density becomes smaller than the value obtained by compaction at 1Ec.

Figure 5 shows the X–P relations obtained for the two different CELs (1Ec and 4.5Ec) and different basic Dmax values equal to 75, 53, 37.5, 19, 9.5, 4.75 and 2 mm. It may be seen that the X–P relations for these different CEL and basic Dmax values are rather unique. This result is consistent with the results of the previous experimental study [6] showing that the X–P relation is rather unique regardless of the basic Dmax value and CEL, and regardless of the different soil types with similar particle size distributions.

The results shown above indicate that to obtain the correct value of (ρd)max for a given value of CEL after adding large gravel particles, the value obtained by Eq. (1) should be divided by the factor X obtained from the curve shown in Fig. 5. Similarly, to obtain the correct value of (ρd)max for a given value of CEL after removing large gravel particles, the value obtained by Eq. (2) should be divided by the factor X obtained from the curve shown in Fig. 5.

4.3 Estimation of ρd Other than (ρd)max

It is often required to estimate a ρd value other than the (ρd)max value after adding gravel particles to a given sample. In this respect, Fig. 6 shows the [Dc]1Ec–Sr relation of the samples having different Dmax values obtained from the data presented in Fig. 2. Even if Dmax changes, the optimum degree of saturation (Sr)opt does not change noticeably, while the [Dc]1Ec–Sr relation still remains rather unique. These results are consistent with the findings reported by Tatsuoka [5] that the (Sr)opt value and this relation are rather insensitive to changes in the soil type and CEL. The result presented in Fig. 6 suggests that ρd values after adding gravel particles to, or removing gravel particles from, a given sample are correctly estimated by modifying the values obtained by Eqs. (1) or (2) and applying the same X–P relation for (ρd)max as presented in Fig. 5.

To confirm this point, X–P relations other than the one for (ρd)max were examined. To this end, X was defined as the ratio of the ρd value when compacted at a certain CEL and a certain Sr. Then the X values were obtained from the ratio of the ρd value calculated by Eqs. (1) or (2) to the measured value of the same specimen compacted at the same CEL and Sr. Figure 7a and b show the X–P relation when compacted to Sr = 72% and 88%. From Fig. 7a for Sr = 77%, which is lower than (Sr)opt = 81%, the X–P relation is rather unique and in fact it is nearly the same as the relation shown in Fig. 5. In contrast, in Fig. 7b for Sr = 88%, which is higher than (Sr)opt = 81%, the relation is not as unique as the one shown in Fig. 5. This trend corresponds to the fact that the Dc–Sr relation scatters in has relatively largely scatter when Sr > (Sr)opt.

In summary, we can conclude that the X–P relation for (ρd)max is rather unique even when Dmax changes exceeding the maximum allowable particle size for the mold of the laboratory compaction tests. Also, the X–P relation for ρd other than (ρd)max is nearly the same as that for (ρd)max corresponding to the fact that the Dc–Sr relation is rather unique regardless of Dmax.

The detailed procedure based on the analysis described above to obtain the degree of compaction of the field sample that includes large gravel particles is described below.

4.4 (ρd)max of Field Sample Including Large Gravel Particles

The degree of compaction for 1Ec of fill material compacted in the field, hereafter denoted by [Dc]1Ec.A, is obtained by Eq. (4):

where (ρd)A is the field dry density, and [(ρd)max.1Ec]A is the (ρd)max of the field fill material compacted at 1Ec. When laboratory compaction tests cannot be performed on a given field fill material due to the inclusion of gravel particles too large in size, [(ρd)max.1Ec]A is usually estimated by Eq. (1) (i.e., the WH method) from the maximum dry density [(ρd)max.1Ec]F obtained by laboratory compaction tests at 1Ec on the specimen obtained by removing large gravel particles from the original sample of field fill material. It may be seen from Figs. 4 and 5 that, in the case of adding gravel particles to a given basic material, even when P is in range of 0.3–0.4, X is approximately 1.1. This means that the field degree of compaction [Dc]1Ec.A is under-estimated by a factor of approximately 1/1.1 ≈ 0.9. This difference of 10% in [Dc]1Ec.A is not negligible in usual geotechnical engineering practice. In view of the above, it is proposed that even when P is lower than 0.3 or 0.4 and always when P is higher than 0.3 or 0.4, Eq. (1) is replaced by Eq. (5) to obtain a proper value of [(ρd)max.1Ec]A for use in Eq. (4):

In this case, the X value is obtained by substituting the P value of a given field fill material into the X–P relation relevant for the given type of field fill material (such as the one presented in Fig. 5). In this way, it becomes possible to avoid an unreasonable underestimation of the field degree of compaction.

5 Results and Discussions (Triaxial Compression Tests)

From the TC test results, the internal friction angles ϕ0peak = sin−1{(σ1f − σ3f)/(σ1f + σ3f)} (for c = 0) were obtained, where σ1f and σ3f are the axial and lateral stresses at the peak deviator stress. Figure 8 shows the ϕ0peak–Dmax relation for [Dc]1Ec = 95% for three different Sr values. Regardless of the value of Sr, the ϕ0peak value increases as Dmax increases. The ϕ0peak value at Sr = 70% is slightly higher than that at Sr = 80%. However, when compared under the same CEL, the [Dc]1Ec value at Sr = 80% becomes higher than the value at Sr = 70% and the ϕ0peak increases correspondingly. As a result, under the same CEL, there is nearly no difference between the ϕ0peak values at Sr = 70 and 80%. On the other hand, even for the same [Dc]1Ec, the ϕ0peak at Sr = 60% is clearly lower than that of the specimens at Sr = 70 and 80% and this difference increases as Dmax increases. These results support the proposal by Tatsuoka and Correia [7] that the field compaction target is set at Sr = (Sr)opt to ensure high strength and stiffness after wetting or saturation.

Figure 9 shows the ϕ0peak–[Dc]1Ec relation at Sr = 80% for three different Dmax values. When compared at the same [Dc]1Ec, the ϕ0peak value noticeably increases as Dmax increases. It is likely that this trend is due to the fact that, as Dmax increases, the uniformity coefficient of specimen increases, which results in an increase in (ρd)max therefore an increase in ρd for the same [Dc]1Ec. On the other hand, Fig. 10 shows the ϕ0peak–ρd relation at Sr = 80% for the three different Dmax values. It may be seen that the ϕ0peak value is determined by ρd regardless of Dmax. It seems that this result is due to that the effects of the following factors are cancelled: (1) as Dmax increases, [Dc]1Ec for the same ρd value decreases due to an increase in (ρd)max (Fig. 2); while (2) as Dmax increases, the ϕ0peak at the same [Dc]1Ec increases (Fig. 8).

It is known that, for a wide range of grading characteristics, the ϕ0peak − ρd relation is not unique. However, if such a unique ϕ0peak–ρd relation as the one shown in Fig. 9 is confirmed under certain limited conditions, we can determine design strength parameters by referring to such a ϕ0peak–ρd relation shown in Fig. 10. Otherwise, it is recommended to determine a design strength parameter by referring to the ϕ0peak–[Dc]1Ec relation obtained by TC tests performed on samples after removing large gravel particles with necessary correction for Dmax. The results shown in Fig. 9 indicate that it is on the safe side when the effects of Dmax are ignored. When the [Dc]1Ec value ensuring a given design strength parameter can be determined following such a procedure as explained above, the target value of [Dc]1Ec in field soil compaction control is determined by referring to this [Dc]1Ec value.

6 Conclusions

The following conclusions can be derived from the results of a series of laboratory compaction tests and drained triaxial compression tests on a set of specimens having different maximum particle sizes Dmax obtained by consecutively removing larger particles from a field fill material:

-

When assuming that the same CEL as the one applied to the whole sample is transmitted to the portion with fine particle (i.e., the WH assumption), the dry density ρd at a certain Sr (including (ρd)max at (Sr)opt) of soil containing large gravel particles compacted at a certain CEL is over-estimated when estimated from the ρd value at the same Sr of the specimen after removing gravel particles compacted at the same CEL. Similarly, when based on the WH assumption, the ρd value at a certain Sr of the gravel-removed sample compacted at a certain CEL is under-estimated when estimated from the ρd value at the same Sr of the specimen containing gravel particles compacted at the same CEL. In both cases, the error is not negligible even when the gravel mass ratio P is lower than 0.3–0.4.

-

In order to appropriately estimate the ρd value at the same CEL of a specimen after adding gravel from the ρd value compacted with a CEL of the specimen before adding gravel particles, it is necessary to modify the conventional equation based on the WH assumption by incorporating a correction factor X that is a function of the gravel mass ratio P. This method is applicable over a wide range of P, from below 0.3 to higher than 0.4.

-

The following findings were made from drained TC tests on saturated specimens of gravel-removed samples having different Dmax values:

-

When compacted at the same values of [Dc]1Ec and Sr, the angle of internal friction \(\phi\)0peak noticeably increases as Dmax increases. This is due likely to the fact that, as Dmax increases, the uniformity coefficient of the sample increases, which results in an increase in (ρd)max, thereby an increase in ρd for the same [Dc]1Ec. This result indicates that it may be on the safe side to estimate the ϕ0peak value of fill material which includes large gravel particles from the value of gravel-removed specimens for the same [Dc]1Ec. This effect may be taken into account when necessary.

-

As Sr becomes noticeably lower than the optimum degree of saturation (Sr)opt, the ϕ0peak value for the same CEL becomes lower than the value when Sr = (Sr)opt. This fact supports compaction control setting the field compaction target at Sr = (Sr)opt.

-

With the same ρd, the [Dc]1Ec value decreases with an increase in Dmax. Due to the combined effects of this factor and factor a) above, when compacted at the same ρd value, the ϕ0peak value becomes rather independent of Dmax. At least within the test conditions employed in this study, taking advantage of this simple empirical rule, the ϕ0peak value of gravel-including field fill material can be estimated from the value of gravel-removed sample for the same ρd value.

References

Walker FC, Holtz WG (1953) Control of embankment material by laboratory testing. Trans Am Soc Civ Eng 118(1):1–25

Holtz WG, Lowitz (1957) Compaction characteristics of gravelly soils. Bureau of Reclamation, Earth laboratory report, No. EM-509

Mitsuo T (2004) Comparison between laboratory and field compaction characteristics on coarse-grained materials. J Jpn Soc Dam Eng 14:20–30

Uemoto Y, Shibuya S, Yosuke H, Kawai S (2011) Influence of grain size distribution characteristics on compaction and deformation-strength characteristics of gravelly fill material. Jpn Geotech J 6(2):181–190

Tatsuoka F (2015) Compaction characteristics and physical properties of compacted soil controlled by the degree of saturation, Keynote Lecture, Deformation characteristics of geomaterials, Proceedings of 6th international conference on deformation characteristics of geomaterials, Buenos Aires, pp 40–78

Ihara S, Noda S, Kikuchi Y, Tatsuoka F (2019) Experimental evaluation of the effects of gravel particles on the dry density of compacted soil. In: The 4th international conference on geotechnics for sustainable infrastructure development, Hanoi

Tatsuoka F, Gomes Correia A (2018) Importance of controlling the degree of saturation in soil compaction linked to soil structure design. Transp Geotech 17:3–27

Acknowledgements

This research is part of the joint research with Hazama-Ando Corporation. The authors sincerely appreciate their help in performing this study.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Ihara, S. et al. (2022). An Experimental Study on the Estimation of Field Compaction States and Stress-Strain Properties of Unbound Granular Materials from Laboratory Test Results. In: Tutumluer, E., Nazarian, S., Al-Qadi, I., Qamhia, I.I. (eds) Advances in Transportation Geotechnics IV. Lecture Notes in Civil Engineering, vol 166. Springer, Cham. https://doi.org/10.1007/978-3-030-77238-3_12

Download citation

DOI: https://doi.org/10.1007/978-3-030-77238-3_12

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-77237-6

Online ISBN: 978-3-030-77238-3

eBook Packages: EngineeringEngineering (R0)