Abstract

Small strain shear modulus, Gmax, is one of the most important parameters for the characterization of the behavior of earth structures subjected to static or dynamic loading conditions. This research presents an experimental laboratory study on the effect of non-plastic fines content and hydraulic hysteresis on the Gmax of unsaturated sandy soils. In this regard, clean Firoozkuh No. 161 silica sand which is classified as poorly graded sand was mixed with different percentages of non-plastic Firoozkuh silt. A set of bender element tests were carried out using two modified triaxial devices. The modifications on these two apparatus were to add HAV ceramic discs for air–water control of unsaturated specimens, in addition to including piezoelectric bender elements to send and receive shear waves and measure their velocities within the unsaturated silt-sand mixtures. Axis translation technique was implemented for hydromechanical purposes and bender element for shear wave velocity measurements and calculating Gmax.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Small strain shear modulus

- Bender element test

- Unsaturated sandy soils

- Fines content

- Hydraulic hysteresis

1 Introduction

Pavements, machines foundations, and shallow footings are usually exposed to low amplitude dynamic loads which in turn cause low strains in them. Also, earthquakes emit shear waves, which pass through the soil layers with different grain-size distributions. Analysis of the behavior of soil layers and overlaying structures in such loading conditions requires identifying dynamic characteristics of the soil layers in small strain situations. Shear modulus at small strains (less than 10–4%), Gmax, is considered as one of the most important dynamic characteristics of the soil. In addition, according to the recommendations of the seismic codes, engineers need information about the soil stiffness for the design of geo-structures and classification of dynamic properties of the soils [15, 20]. Also, soil stiffness is utilized for the soil-structure interaction analyses. Moreover, shear wave velocity, which has a close correlation with Gmax, is used to evaluate the susceptibility of the sediments to liquefaction. Researchers have tried to understand the behavior of silt-sand mixtures because of their liquefaction potential and compressibility. Moreover, silty sands may be used for the construction of road bases and embankments.

In recent decades, researchers have conducted numerous experiments to recognize factors that affect the small strain shear modulus of the soils. The result of these studies have shown that different parameters could affect Gmax, such as effective confining stress, p′, void ratio, e, percentage of fines content, FC, and over consolidation ratio, OCR [11, 12, 29, 30]. A significant decrease of Gmax values with the increment of the fines content of silt-sand mixtures were reported in the previous studies as well [9, 26, 31].

Results of previous studies on the Gmax of unsaturated fine soils have shown that maximum shear modulus increases with increasing matric suction in a nonlinear way. Meanwhile, the Gmax of sandy soils varies in an up and down manner [18, 24, 25, 28]. On the other hand, the results of these studies on the Gmax of unsaturated fine soils have demonstrated that fine soils possess greater Gmax values during wetting paths than drying paths. In contrast, Khosravi et al. [18] reported that the Gmax of some clean sand specimens during drying paths was lower than its values along wetting paths. They related this observation to the variation of suction stress along drying and wetting path. However, investigation on the small strain shear modulus of unsaturated silt-sand mixtures during hydraulic hysteresis is rare or nothing. In this study, the unsaturated shear modulus of an uniform clean silica sand which was mixed with different percentages of non-plastic silica silt was investigated under different matric suctions along both wetting and drying paths. The void ratio was kept constant for different mixtures during this study. In the following sections, some details of the tests and results are described.

2 Experimental Study

2.1 Tested Materials

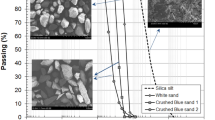

In this study, standard Firoozkuh No 161 silica sand was used as clean sand. This angular sand is obtained from Firoozkuh mine in the northeast of Tehran province in Iran. Researchers in Iran use this sand as standard sand for geotechnical testing. Also, Firoozkuh silt from the same mine was used as non-plastic fines for the experiments. The corresponding grain size distribution curves obtained by performing sieve analysis according to ASTM D6913 [4] and hydrometer analysis according to ASTM D7928 [5] are shown in Fig. 1. According to USCS, this clean sand is classified as poorly graded sand. Additionally, the specific gravity test Gs was determined in accordance with ASTM D854 [6] to be 2.65. The physical properties of the clean sand and silt are demonstrated in Table 1.

The clean sand was mixed with different percentages of silt to investigate the effect of fines content respectively on maximum void ratio, emax, according to ASTM 4254 [2] and minimum void ratio, and emin, according to ASTM 4253[1] by using vibratory table. However, both methods are limited to soils that contain up to 15% fines content, so there is no standard method to obtain these parameters beyond these limitations. Despite these recommended limitations, these methods have been used to determine emax and emax in different studies [10, 14]. Figure 2 demonstrates the variation of maximum and minimum void ratio with adding non-plastic fines contents. According to this figure, the minimum and maximum void ratio of silt-sand mixtures decreased with the increase of fines content until they reached a minimum value at a threshold fines content, which is about 30%; after that, both values increased with the increment of fines content. These results are similar to the observations of other studies [27, 30]. It is argued that before the fines content threshold, the mechanical behavior of the mixtures is sand dominant, but by adding fines particles more than threshold fines content, the behavior changes to silt-dominant behavior.

2.2 Experimental Setup

Two triaxial cells equipped with bender elements and suction control system were used to measure the shear wave velocity and Gmax of specimens during hydraulic hysteresis. Axis translation technique [13] was utilized to control and apply specific matric suctions. Each modified cells have a pair of bender elements in the bottom platen and top cap to send and receive shear waves, respectively. In this research, a signal generator was used to produce an input sinusoidal pulse. Also, the pulses were amplified up to 10 times of input signals in order to gain detectable responses while an oscilloscope, records both input and response signals.

Moreover, the changes in the level of water in graded burettes connected to the cells were recorded to measure the volume changes of specimens. These measurements were corrected according to the results of the several careful calibration tests to eliminate the errors caused by water evaporation, creep, and changes in the volume of the chambers, the pressure line tubing, and the burettes under various pressure. By the observation of graded burettes connected to the bottom of HAE ceramic disks, the variations of the volume of pore water were measured.

2.3 Specimen Preparation

The diameter and height of the tested cylindrical specimens were 60 mm and 120 mm, respectively. In order to prepare the sandy and silty samples in addition to samples with 10, 20, 30, 40, 60% non-plastic fines content, the clean sand was completely mixed with different percentages of the silts. Distilled water was added to the oven- dried soil mixtures and then was blended well. Static compaction was used to prepare the specimens with an initial desirable void ratio, which was equal to 0.7. In this regard, specimens were prepared by tamping in ten layers with different heights using under-compaction technique in a split mold, according to Ladd [21]. This method prevents excessive compaction of lower layers during the compaction of the upper layers. Interfaces between the successive layers were scarificed to establish a proper bond between layers.

2.4 Test Procedure

After placing the specimens in the cells, a vacuum was applied at the top cap to avoid deformation of the samples. A backpressure technique under 40 kPa mean net stress was used to saturate samples. In this regard, backpressure was increased in different water pressure steps, up to 340 kPa, accompanied by enough time span to dissolve air bubbles in the pore water. Skempton’s B value greater than 0.95 was considered as a saturation criterion. After specimen saturation, the mean net stressed increased to 100 kPa, so the first bender element tests were carried out in different frequencies on saturated specimens after giving enough time to obtain volume change caused by the enhancement of mean net stress.

Desirable suctions were applied by means of adjusting air, water, and confining pressure at the boundaries of the specimens. Also, enough time was given until no detectable change of the water level in burettes was observed. The acceptable hydraulic equilibrium criterion was considered in the tests to be a water volume change of equal to or less than 0.1 mL in a day. Hydraulic equilibrium used to take 2–15 days, depending on the soil type and quantity of matric suction. Therefore, each test took more than 3 months. After equilibrium at each stage, bender element tests were carried out to obtain travel time by using peak to peak method. Shear wave velocity was obtained by dividing the distance between tips of bender elements into the travel time. Consequently, the small-strain shear modulus, Gmax, was calculated by using Eq. (1) proposed in elasticity theory, in which ρ is the total density of a sample.

3 Results and Analysis

3.1 Effect of Fines Content on Soil Water Retention Curve

The soil water retention curves (SWRC) of the specimens during drying and wetting paths have been illustrated in Figs. 3 and 4, respectively. According to these figures, adding fines content has significant effects on the soil water retention curves. As shown, by increasing fines content, the specimens retained more water at equal matric suctions, and this led to the enhancement of air entry values, residual matric suctions, and water entry values. This behavior can be attributed to the fact that fines particles replenish the void spaces of the sandy skeleton of specimens and decrease the average radius of void pores, so for a given degree of saturation, the level of matric suction increases with fines content. This observation is consistent with the observations of other researchers [7, 18] and is in a line with Young–Laplace equation. This equation establishes a correlation between matric suction and the dimension of pore space. As seen in Figs. 3 and 4, the slopes of soil water retention curve decreased with the enhancement of fines content. Not only did adding fines decrease the average radius of pores, but also it increased the distribution of pores with different radius. In other words, adding fines led to decrease in the uniformity of the pores of the specimens. Moreover, as illustrated in these figures, adding fines had more profound effects on the bottom of the retention curves of the specimens. As mentioned by Lu and Likos [22], the primary mechanism which dominates suction at low degrees of saturation is short-range adsorption effects which depend on the surface of the solid particles. So, adding fines affected soil retention at relatively low values of water content more significant than retention at higher values of water content.

3.2 Effect of Fines Content on Small Strain Shear Modulus (Gmax)

Figure 5 represents the variations of Gmax of the unsaturated specimens with suction along drying path. As shown in this figure, adding non-plastic fines content led to the reduction of Gmax especially, at low matric suctions. The greatest decrease was for the specimen with low fines content (up to 20%). The given results are in harmony with the results of other studies [26, 30]. In other words, adding fines more than the threshold fines content led to the change of mechanical soil behavior and structure from sand dominant to silt dominant. On the other hand, pure silt with 0.7 initial void ratio had greater Gmax than the other specimens with non-plastic fines content. This high value of modulus for silty specimen may be related to its high relative density (about 95%) for its 0.7 initial void ratio.

As seen in Fig. 5, the Gmax value of sandy specimen increased with matric suction up to the proximity of air entry value, and then, decreased slightly with the further increment of matric suction and reached a constant value at residual matric suctions. This observation is consistent with the results reported by Khosravi et al. [18]. They correlated this up and down trend with the variation of suction stress with the matric suction. In addition, this local maximum value of Gmax at the proximity of air entry value can be observed for the specimens with 10 and 20% of fines content, although no local maximum exists for specimens with more than 30% of fines content. For higher values of matric suction, samples with fines content as low as 10% had different Gmax behavior with suction from the sandy specimen. For these specimens, the variation of Gmax values with matric suction consist of two parts; before the proximity of air entry value, in which Gmax increased in a slightly linear manner, while at higher matric suctions values, Gmax increased in a non-linear exponential manner.

The variation of Gmax with matric suction during wetting path has been illustrated in Fig. 6. According to this figure, the Gmax of the sandy specimen experienced few changes along wetting path, and its value increased slightly at the low values of matric suction. Despite the sandy specimen, other specimens had greater Gmax quantities during wetting path than drying path. There is a consensus through literature about this behavior of fine soils [19, 24, 25]. Khosravi and McCartney [16] attributed this behavior to double hardening concept proposed by Wheeler et al. [33] and Tamagnini [32].

3.3 A New Model for Prediction of the Small Strain Shear Modulus of Sand-Silt Mixtures

Lu and Kaya [23] conducted compression tests on unsaturated sandy, silty, and clayey specimens and brought them to equilibrium at different degrees of saturation in order to measure finite-strain Young Moduli. Based on the results of this study, they concluded that finite strain shear modulus has an inverse relationship with a power of effective degree of saturation, as shown in Eq. (2).

where Gmax(unsat) is small strain shear modulus at unsaturated state, β is an experimental fitting parameter, and Se is considered as effective degree of saturation, which is defined in the following equation:

where Sr is the current degree of saturation, Sr(res) and Sr(sat) are the values of degree of saturation at residual and saturated conditions, respectively.

Dong et al.[8] developed a new unified model for different types of soils reported in the literature based on Eq. (2). However, some other studies [16, 18, 28] reported that Gmax is proportional to the product of degree of saturation and matric suction in terms of effective stress equation for unsaturated soils or suction stress definition proposed by Lu and Likos [22]. Based on these different reports in the literature, the product of effective stress and degree of saturation with separate exponents is considered proportional to Gmax for the proposed model in this study.

In addition, applying hydromechanical loads may cause hardening/softening as well as irreversible changes in void ratio [32, 33]. In this study, specimens experienced maximum effective stress at the end of drying path; while, they tolerated less effective stresses along the wetting path. Besides, Hardin [12] reported that stress history (i.e., Over Consolidation Ratio) has significant effect on the measured values of small strain shear modulus. Based on the reported observations in the literature and the results of the experiments of this study, a new model was developed to predict the Gmax of sand silt mixtures in terms of effective stress history, degree of saturation, and matric suction. In this regard, the over consolidation ratio was defined in terms of effective stress history, as follows:

where P′ is the current effective stress and P′max is the maximum effective stress experienced during hydraulic hysteresis. In order to define effective stress, Eq. (5) proposed by Lu and Likos [22] was utilized.

where Pn is mean net stress and Ps is suction stress which is defined in Eq. (6).

where ψ is matric suction, and \(\chi\) is effective stress parameter which can be defined by Khalili and Khabbaz’s [10] proposed equation, as follows:

where \(\psi_{b}\) is air entry value. Based on Eq. (4), specimens are considered normally consolidated along drying path, while they become over consolidated during wetting path because of experiencing maximum effective stress at the end of drying path. Therefore, Eq. (8) is proposed to predict small strain shear modulus of silt-sand mixtures during hydraulic hysteresis.

where Gmax(unsat) and Gmax(sat) are small strain shear modulus at unsaturated and saturated states, respectively; Pa is atmospheric pressure (100 kPa), and K, β, m, and n are fitting parameters. This equation could be simplified to the model proposed by Oh and Vanapalli [28], by replacing K = 1 and n = 1. Also, this equation at saturated state is similar to the equation presented by Hardin [12] in order to predict the Gmax of over consolidated fine soils. In this study, the measured values of Gmax at saturated state are considered as Gmax(sat). Also, it is possible to use available models in literature rather than measuring of Gmax(sat).

Least square method was applied in order to determine these fitting parameters. Table 2 shows the variation of fitted parameters with fines percentages as well as coefficient of determination (R2). Based on the obtained results and this table, the suggested relationship can predict small strain shear modulus of sand-silt mixtures during hydraulic hysteresis well. According to the variation of fitting parameters, Gmax of the specimens is in inverse proportion to degree of saturation except for sandy soils, as suggested by Dong et al. [8]. Based on the determined parameters for the proposed equation, by adding fines content more than 40%, the matric suction fitting exponent (i.e. n) reached zero. In other words, when fines content was more than the threshold percentage, and the behavior of specimens became silty dominant, the effect of matric suction on soil stiffness vanished. So, degree of saturation mainly affected the variation of Gmax for unsaturated silty soils instead of matric suction. This observation is in line with the reports of Dong et al. [8] indicating that the variations of Gmax with degree of saturation for silty soils are more sensitive than sandy ones. Based on these obtained values, four equations were developed to predict the fitting parameters in terms of non-plastic fines percentage for Firoozkuh sand-silt mixtures (Table 3). Further studies should be done to determine the relationship between these fitting parameters and other soil properties such as void ratio, plasticity index, etc.

4 Conclusion

In the current study, the small strain shear modulus of sand-silt mixtures during hydraulic hysteresis was studied by using two modified triaxial cells. These cells are equipped with bender elements to send and receive shear waves, and ceramic disks to implement axis translation technique. In order to investigate the variations of Gmax along drying and wetting paths, 7 specimens with different non-plastic fines content were prepared with equal initial void ratio and tested under mean net stress of 100 kPa.

Results of this study have shown that adding fines content as low as 10% to poorly graded sands led to change in the manner of Gmax variations with suction. Accordingly, the Gmax of the specimens with fines content increased with the increment of matric suction in spite of up and down trend observed for clean sands. Moreover, these specimens had higher Gmax values along wetting path compared to those for drying path, experiencing hardening during hydraulic hysteresis. Based on these observations, a new simple model was developed to predict the small strain shear modulus of silt-sand mixtures during drying and wetting paths. This model could predict different Gmax trends of sands and silts in addition to considering double hardening during hydraulic hysteresis. According to this model, as fines percentage increases, the role of matric suction diminishes, and instead, the role of the degree of saturation on the stiffness of unsaturated soils increases during hydraulic hysteresis.

References

ASTM D4253–16 (2016) Standard test methods for maximum index density and unit weight of soils using a vibratory table. ASTM International, West Conshohocken, PA. www.astm.org

ASTM D4254–16 (2016) Standard test methods for minimum index density and unit weight of soils and calculation of relative density. ASTM International, West Conshohocken, PA. www.astm.org

ASTM D6836–16 (2016) Standard Test Methods for Determination of the Soil Water Characteristic Curve for Desorption Using Hanging Column, Pressure Extractor, Chilled Mirror Hygrometer, or Centrifuge, ASTM International, West Conshohocken, PA. www.astm.org

ASTM D6913/D6913M-17 (2017) standard test methods for particle-size distribution (gradation) of soils using sieve analysis. ASTM International, West Conshohocken, PA. www.astm.org

ASTM D7928–17 (2017) Standard test method for particle-size distribution (gradation) of fine-grained soils using the sedimentation (hydrometer) analysis. ASTM International, West Conshohocken, PA. www.astm.org

ASTM D854–14 (2014) Standard test methods for specific gravity of soil solids by water pycnometer, ASTM International, West Conshohocken, PA. www.astm.org

Benson CH, Chiang I, Chalermyanont T, Sawangsuriya A (2014) Estimating van Genuchten parameters α and n for clean sands from particle size distribution data. In: From soil behavior fundamentals to innovations in geotechnical engineering: Honoring Roy E. Olson, pp 410–427

Dong Y, Lu N, McCartney JS (2016) Unified model for small-strain shear modulus of variably saturated soil. J Geotech Geoenviron Eng 142(9):04016039

Goudarzy M, Rahman MM, Konig D, Schanz T (2016) Influence of nonplastic fines content on maximum shear modulus of granular materials. Soils Foundations

Haeri SM, Yasrebi SS (2016) Effect of amount and angularity of particles on undrained behavior of silty sands. Scientia Iranica 6(3):188–195

Hardin BO, Richart Jr FE (1963) Elastic wave velocities in granular soils. J Soil Mech Foundat Div, 89(Proc. Paper 3407)

Hardin BO (1978) The nature of stress strain behavior of soils. Earthquake Eng Soil Dyn 1:3–90

Hilf JW (1956) An investigation of pore-water pressure in compacted cohesive soils. Ph.D. Dissertation. University of Colorado, Boulder, CO, USA

Ishihara K (1993) Liquefaction and flow failure during earthquakes. Rankin Lecture Geotech 43(3):351–415

Ishihara K (1996) Soil behaviour in earthquake geotechnics. Oxford Science Publications

Khalili N, Khabbaz MH (1998) A unique relationship for χ for the determination of the shear strength of unsaturated soils. Geotechnique 48(5):681–687

Khosravi A, McCartney JS (1977) Impact of hydraulic hysteresis on the small strain shear modulus of low plasticity soils. J Geotech Geoenviron Eng 138(11)

Khosravi A, Shahbazan P, Pak A (2018) Impact of hydraulic hysteresis on the small strain shear modulus of unsaturated sand. Soils Found 58(2):344–354

Khosravi A, Rahimi M, Gheibi A, Shahrabi M (2018) Impact of plastic compression on the small strain shear modulus of unsaturated silts. Int J Geomech 18(2):04017138

Kramer SL (1996) Geotechnical earthquake engineering. Pearson Education, India

Ladd RS (1978) Preparing test specimens using undercompaction. Geotech Test J 1(1):16–23

Lu N, Likos WJ (2006) Suction stress characteristic curve for unsaturated soil. ASCE J Geotech Geoenviron Eng 132(2):131–142

Lu N, Kaya M (2013) Power law for elastic moduli of unsaturated soil. J Geotech Geoenviron Eng 140(1):46–56

Mancuso C, Vassallo R, d’Onofrio A (2002) Small strain behaviour of a silty sand in controlled-suction resonant column-torsional shear tests. Canadian Geotech J CGJ 39(1):22–31

Ng CWW, Xu J, Yung SY (2008) Determination of anisotropic shear stiffness of an unsaturated decomposed soil. Geotechnique 58(1):23–35

Payan M, Senetakis K, Khoshghalb A, Khalili N (2017) Characterization of the small-strain dynamic behaviour of silty sands; contribution of silica non-plastic fines content. Soil Dyn Earthq Eng 102:232–240

Phan VTA, Hsiao DH, Nguyen PTL (2016) Effects of fines contents on engineering properties of sand-fines mixtures. Procedia Eng 142:213–220

Oh WT, Vanapalli SK (2014) Semi-empirical model for estimating the small-strain shear modulus of unsaturated non-plastic sandy soils. Geotech Geol Eng 32(2):259–271

Qian X, Gray DH, Woods RD (1991) Resonant column tests on partially saturated sands. Geotech Test J 14(3):266–275

Ruan B, Miao Y, Cheng K, Yao EL (2018) Study on the small strain shear modulus of saturated sand-fines mixtures by bender element test. European J Environ Civil Eng 1–11

Salgado R, Bandini P, Karim A (2000) Shear strength and stiffness of silty sand. J Geotech Geoenviron Eng 126(5):451–462

Tamagnini R (2004) An extended Cam-clay model for unsaturated soils with hydraulic hysteresis. Géotechnique 54(3):223–228

Wheeler SJ, Sharma RS, Buisson MSR (2003) Coupling of hysteresis and stress–strain behaviour in unsaturated soil. Géotechnique 53(1):41–54

Wichtmann T, Hernández MN, Triantafyllidis T (2015) On the influence of a non-cohesive fines content on small strain stiffness, modulus degradation and damping of quartz sand. Soil Dyn Earthq Eng 69:103–114

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Jebeli, M., Mohsen Haeri, S., Khosravi, A. (2022). Characterizing the Effect of Fines Content on the Small Strain Shear Modulus of Sand-Silt Mixtures During Hydraulic Hysteresis. In: Tutumluer, E., Nazarian, S., Al-Qadi, I., Qamhia, I.I. (eds) Advances in Transportation Geotechnics IV. Lecture Notes in Civil Engineering, vol 165. Springer, Cham. https://doi.org/10.1007/978-3-030-77234-5_69

Download citation

DOI: https://doi.org/10.1007/978-3-030-77234-5_69

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-77233-8

Online ISBN: 978-3-030-77234-5

eBook Packages: EngineeringEngineering (R0)