Abstract

The application of recycled asphalt pavement (RAP) materials in a pavement base layer as an unbound material is currently limited despite the potential for usage of lower-quality RAP materials in underlying pavement base layers. An increase in the utilization of these RAP materials can positively impact the long-term sustainability of pavement structures and is a topic that should be investigated more in-depth. These materials have been initially shown to exhibit mechanical characteristics suitable for usage in unbound pavement layers. Based on this, more information is thought to be needed to provide background information concerning the parameterization of the RAP material’s mechanical characteristics. In addition, information concerning the most appropriate methodology for the constitutive modeling and simulation of materials containing RAP for pavement design procedures should be investigated. The goal of the current preliminary study is to provide more information on the behavior of RAP material to assist in their increased implementation in unbound pavement layers. The investigation includes an initial characterization of these materials through resilient modulus testing. Based on the results, various constitutive models are investigated in order to provide an analysis and comparison of the results of the variations between models and the potential effects in predicted responses. The goal of the paper is to provide additional research that will aid in the increased adoption of more environmentally friendly pavement construction techniques, leading toward increased sustainability.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

1.1 Problem Statement

The utilization of recycled asphalt pavement (RAP) material in the bound asphalt layers is becoming more commonplace as research and in situ applications have provided evidence of its capabilities when incorporated within the upper bound layers. However, the application of RAP materials within the pavement base layers as an unbound material is more limited despite the potential for usage of lower-quality RAP materials in underlying pavement base layers. An increase in the utilization of these RAP materials will have the potential to positively impact the long-term sustainability of pavement structures and is a topic that should be further investigated. Previous research into these recycled asphalt materials has shown that they have the potential to exhibit the mechanical characteristics that are suitable for usage in underlying unbound pavement layers. Based on this, more information is thought to be needed to in order provide additional background information concerning the parameterization of the RAP material’s mechanical characteristics. In addition, information concerning the most appropriate methodologies for the constitutive modeling of the materials containing RAP for pavement design procedures is needed.

1.2 Objectives

The main objective of the current preliminary study is to provide more information on the overall behavior of RAP material to assist in their increased implementation in unbound pavement layers. The current research study is a preliminary investigation that will initially focus on the mechanical characterization of RAP materials in the base layer of flexible asphalt pavement structures through the resilient modulus behavior of the material. Based on the results of this stage of the study, several constitutive models will be investigated to provide an analysis and comparison of the results of the variations between the constitutive models and their potential effect on pavement design processes. The goal of the paper is to provide additional research that will help in the increased adoption of potentially sustainable pavement construction techniques.

2 Theoretical Background

Previous experience has shown that the utilization of RAP material is most often in the upper bound layers of pavement structures. Research and experience, however, have also shown the viability and the potential for these more sustainable materials to be reutilized in the underlying unbound granular base or subbase layers. Potential environmental and economic benefits for the incorporation of RAP in bound layers are already supported by extensive research and implementation over the years. However, similar information is still more limited for the inclusion of RAP within the unbound layers of a pavement structure. Recent trends indicate both the need and the desire for the implementation of more sustainable technique in regard to pavement design/construction. With this in mind, it is believed that RAP materials should be examined in greater detail to aid in their proper utilization and to gain a more in-depth understanding of their impact within base layers of flexible road pavements in regards the overall pavement structure.

2.1 RAP in Unbound Layers

With virgin aggregate becoming more difficult to source and more costly to implement, the need has arisen to investigate RAP-based materials for implementation within the base layers of pavement structures. The incorporation of RAP can conserve energy, lowers transportation costs required to obtain quality virgin aggregate, and overall preserves valuable resources [1]. Puppala et al. [2] investigated the sustainable reutilization of limestone quarry materials and RAP within pavement base layers and stated that even though the usage of recycled materials as pavement base layer materials has increasingly gained acceptance, comprehensive geotechnical characterization is still required. Alam et al. [3] concluded that RAP has a potential to be utilized at high percentages within pavement base layers. Thakur and Han [4] investigated RAP materials for inclusion in base layers aggregate for highway construction and stated that it was a sustainable solution. Plati and Cliatt [5] in recent research stated that RAP as a material is fully recyclable, and that additional research is vital to increase sustainability.

Multiple research studies over the years have decided upon on the mixing of virgin aggregate with RAP to reach appropriate mechanical properties [6,7,8]. Despite the existing research, the allowed percentage of RAP in base layers as well as knowledge related to the suitability for utilization in unbound base layers is not currently fully defined and/or researched. Research, for example, is limited, and knowledge is still being developed regarding the strength behavior and characteristics of RAP materials in regards to more traditionally used virgin aggregates within the base course. However, Edil et al. [9] concluded that, in comparison to conventional base layer materials, RAP has an increased modulus. Even more limited information is available concerning the effect of moisture condition on RAP-based materials. Attia and Abdelrahman [6] investigated the effect of moisture content on materials containing 50/100% RAP at OMC, plus/minus 2%. Noureldiun and Abdelrahman [10] investigated the effect of moisture percentage above/below OMC on the variables utilized to model the base material modulus containing various RAP percentages. Cliatt et al. [11] concluded that RAP material exhibited modulus values that are equivalent or exceed those of a virgin aggregate utilized for base material at OMC and below. Most other recent research regarding RAP and the resilient modulus is focused on testing only at optimum moisture conditions. Though there is research in regards to RAP in base layers, the current investigation adds to the current knowledge by combining both a laboratory-based investigation and a computer modeling of this behavior to better understand the effects of material properties on the responses of these materials within flexible pavement structures.

2.2 Constitutive Modeling and Finite Elements (FE)

A multitude of researchers have over the years developed constitutive models to characterize the behavior of unbound granular materials for usage in pavement construction. Upon a review of existing models, the following models were selected for further utilization within the scope of the current investigation due to their wide acceptance and implementation. The K-Θ model [12] is one of the initially developed and widely recognized constitutive models and still often utilized. Uzan [13] developed a model that incorporated the shear stress effect in the granular material model, to overcome potential issues of the Κ-Θ model. Uzan [14] developed/proposed an alteration to the Uzan model by replacing the deviator stress with the octahedral shear stress. The model by introducing a three-dimensional aspect through the octahedral shear stress attempts to more realistically represent actual loading conditions on the unbound material layers.

where

θ is the first invariant of the tensor stress = bulk stress.

θ = σ1 + σ2 + σ3 = σ1 + 2σ3, or alternatively (σ1 + 2σ3) or (σd + 3σ3),

σd is the deviator stress = σd = σ1−σ3,

k1, k2, and k3 are laboratory determined material constants from regression analysis,

Ρa = atmospheric pressure (kPa).

3 Materials Tested

3.1 Physical Characteristics

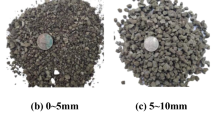

In the current study, three materials were investigated. The first of these materials is a 100% RAP material, the second is a traditional virgin aggregate (VA) material, and the third is a combination of these two materials in a 50/50 percentage ratio by weight (50/50). These materials’ physical characteristics are shown in Tables 1 and 2. Table 1 shows that the gradations for the investigated material are similar for aggregate sizes below 2 mm with an overall distribution of the materials similar overall. In order to produce these mixtures, the materials were partially graded with emphasis on the fine materials as they are known to strongly influence laboratory modulus testing results. Both the maximum dry density (MDD) and the optimum moisture content (OMC) were determined through the modified Proctor test standard—EN 13,286–2 with a type B mold.

3.2 Resilient Modulus

The resilient modulus is defined as: Mr = σd/εr where σd is the deviator stress and εr is the recoverable strain. The materials under investigation were tested according to the AASTHO T-307 (repeated load triaxial test) protocol (material type I) for determination of their resilient modulus. The materials were all tested at OMC as well as ± 2% OMC. The testing protocol consisted of 15 distinct stages of loading. The stages are defined: confining pressures—σ3 (kPa), axial stresses—σmax (kPa), cyclic stresses—σcyclic (kPa), and contact stresses—0.1σmax (kPa). The load is a haversine load with a 0.1 s duration followed by a 0.9 s rest period. Results from the resilient modulus testing formed the basis for the next stages of the investigation.

4 Finite Element Simulation

Based on the results of testing from the laboratory determination of the resilient modulus, a regression analysis was performed for each of the test combinations (material–moisture) to determine the individual regression constants (k1, k2, and k3) for each of the constitutive models (Κ-θ, UZAN, and MEPDG) to be investigated with finite element analysis. The regression analysis, for all cases, was performed for a 95% confidence level.

After the determination of regression constants for each case, an FE analysis was then undertaken to investigate the material's predicted responses. For the analysis, the ABAQUS software was utilized for the predicted responses of the pavement materials and pavement structures that are investigated in the current research effort. Before the analysis could begin, individual user MATerial subroutines (UMAT) were coded and verified for each of the constitutive laws (K-Θ, Uzan, and MEPDG) being utilized for modeling of the unbound granular materials of the pavement base layer. For the FE investigation, the critical responses were calculated and exported for further in-depth analysis. These responses included: the predicted vertical deflections u22 (μm), the predicted vertical centerline horizontal stress σ11 (MPa), the predicted vertical centerline horizontal strain ε11 (μm/m), the predicted vertical centerline vertical stress σ22 (MPa), and the predicted vertical centerline vertical strain ε22 (μm/m).

For the purposes of the finite element analysis, the representative layer moduli of the three layers (asphalt, unbound, and subgrade layers), the Poisson ratios, and other parametrical information were required for the numerical calculations. For these input parameters, previous research on relevant subjects in combination with knowledge of the investigated materials was utilized to determine appropriate input values for analysis purposes (Table 3). For the investigation, a flexible pavement structure was simulated (Fig. 1) to include an asphalt concrete (AC) layer (linear elastic) with variable thicknesses to cover multiple cases, a 30 cm unbound granular base, and a compacted subgrade (linear elastic). The overall FE model dimensions were chosen in order to eliminate potential boundary effects. Both the AC and the subgrade layers were assumed to behave linearly elastic in order to specifically focus investigation on the base layer effects. For the analysis, a circular wheel load zone was incrementally imposed on the AC surface, and the analysis was based on the modified Newton’s method with secant stiffness.

The various pavement cross sections modeled and the assumptions for the study are shown in Table 3.

5 Finite Element Simulation Results

FE results for each case (model, material, and moisture conditions) were exported for further analysis. Emphasis for the analysis was focused on critical locations in flexible pavement structure. These locations include: (1) surface deflection, (2) strain—bottom of the AC (fatigue), and (3) strain—top of the subgrade (rutting). The following section provides information on each of the investigated critical responses.

Figure 2 and Table 4 show FE-predicted vertical deflection data for the center of the loading for each cross section, model, and moisture condition investigated.

Figure 3 and Table 5 show FE horizontal strains at the bottom of the AC layer.

Shown in Fig. 4 and Table 6 are FE vertical strains at the top of the subgrade layer.

For the predicted vertical deflections u22 for all AC layer thicknesses and materials, the K-Θ model produced the largest predicted vertical deflections. For the 50 mm AC layers, the K-Θ predicted values were 15–21% higher for RAP, while for the VA, they were 26–47% higher. As the AC layer increased to 200 mm, these same variations were reduced to 0% and 2–4%, respectively. This indicates that as the AC layers increase, the importance of the model utilized is significantly reduced. In regard to the RAP materials predicted, u22 deflections versus the VA aggregate materials, as the AC material thickness increased, the variations were greatly reduced. For the 50 mm AC layer, the RAP material predicted deflections were 14, 38, and 25% (K-Θ, Uzan, and MEPDG models, respectively) greater than the VA material. While for the 200 mm AC layer, these variations were reduced to 2, 6, and 3%, respectively. This provides indications that the RAP material has predicted results similar to the VA material within larger AC layer thickness pavements. The 50/50 material produced results similar to the RAP material.

For the predicted horizontal strain ε11, it can be seen that for all AC layer thicknesses and materials that the K-Θ model produced the largest predicted horizontal strain at the bottom of the AC layer. For the 50 mm AC layers, the K-Θ predicted values were 48–60% higher for RAP, while for the VA, they were 95–110% higher. As the AC layer increased to 200 mm, these same variations were reduced to 0% and 2–7%, respectively. This indicates that as the AC layers increase, the importance of the model utilized is significantly reduced. In regard to the RAP materials predicted ε11 deflections versus the VA aggregate materials, as the AC material thickness increased, the variations were greatly reduced. For the 50 mm AC layer, the RAP material predicted horizontal strains were 12, 58, and 38% (K-Θ, Uzan, and MEPDG models, respectively) greater than the VA material. While for the 200 mm AC layer, these variations were reduced to 2, 8, and 3%, respectively. These provide indication that the RAP material has predicted results similar to the VA material within larger AC layer thickness pavements. The 50/50 material produced results similar to the RAP material.

For the predicted vertical strain ε22, it can be seen that for the 50 mm AC layer thickness and all materials that the MEPDG model produced the largest predicted horizontal strain at the bottom of the AC layer. For the 50 mm AC layers, the MEPDG predicted values were 6–15% higher for RAP, while for the VA, they were 2–17% higher. While as the AC layer was increased to 100 mm, the Uzan model predicted the highest vertical strains. Overall, the K-Θ model predicted the lowest vertical strains for all materials and AC thickness combinations.

In regard to the moisture conditions investigated, the moisture conditions had the largest influence for the RAP materials at the 50 mm AC layer for all the predicted responses. This provides an indication that moisture conditions for RAP are important in the response of pavements with lower AC layers, while as the AC layers increase to 200 mm, the RAP and the influence of moisture are more similar to the investigated VA material.

6 Discussion

Based on the results of the current investigation, the RAP and 50/50 materials produced significantly larger predicted deformations in respect to the VA materials at the 50 mm AC layer thickness. However, as the thickness of the AC layer increased to 200 mm, the variations between the VA materials in regard to deflections were limited to less than 5% greater. The 50/50 material, in general, had overall the highest predicted deformations for all cross sections and constitutive models with the variations being limited at the 200 mm AC layer pavement section.

For the RAP and 50/50, it appears that overall the RAP material exhibited the largest dependence on the moisture conditions; however, the variations at both OMC + 2% and OMC-2% were, in general, limited to ± 15% of the OMC values for the predicted strain ε11. For all investigated materials, as the AC layer increased to 200 mm, the variations with moisture were limited to ± 3% in comparison to the OMC predicted values predicted strain ε11, showing that as the AC layer increases, the choice of base materials has less effect overall. The choice of model for the RAP predicted strain ε11 had a significant impact of up to 60% variations between the K-Θ and Uzan model for the 50 mm AC section. However, the choice of model had variations approximately less than 10% for RAP at the 200 mm AC layer. The predicted RAP vertical strains ε11 between models did not show a clear variation between the AC thicknesses or the chosen constitutive model. In general, the variations were limited to less than approximately 20%.

In general, for all responses, as the AC layer increased, both the impact of moisture conditions and constitutive model were greatly reduced. This indicates that for lower AC thicknesses, the choice of model and the impact of the moisture conditions are necessary to be considered and justified for all materials including RAP. As can be seen in the investigation, the choice of model/methodology and conditions are important and often overlooked aspects for a FE analysis of pavement structures and their predicted responses. This area still requires further in-depth investigation for RAP-based unbound material to provide more information toward increasing the utilization of these materials toward the goal of increased sustainability.

References

Copeland A (2011) Reclaimed asphalt pavement in asphalt mixtures: state of the practice. In: Turner-Fairbank highway research center federal highway administration. Report FHWA-HRT-11–021, Turner-Fairbank Highway Research Center, McLean, VA, USA

Puppala A, Sireesh S, Williammee R (2011) Sustainable reuse of limestone quarry fines and RAP in pavement base/subbase layers. J Mater Civ Eng 24:418–429

Alam TB, Abdelrahman M, Schram S (2010) Laboratory characterization of recycled asphalt pavement as a base layer. Int J Pavement Eng 11:123–131

Thakur JK, Han J (2015) Recent development of recycled asphalt pavement (RAP) bases treated for roadway applications. J Transp Infrastruct Geotechnol 2:68–86

Plati C, Cliatt B (2019) A sustainability perspective for unbound reclaimed asphalt pavement (RAP) as a pavement base material. Sustainability 11:78

Attia M, Abdelrahman M (2011) Effect of state of stress on the resilient modulus of base layer containing reclaimed asphalt pavement. Road Mater Pavement Des 12:79–97

Kim W, Labuz JF, Dai S (2007) Resilient modulus of base course containing recycled asphalt pavement. J Transp Res Board 2005:27–35

Dong Q, Huang B (2014) Laboratory evaluation on resilient modulus and rate dependencies of RAP used as unbound base material. J Mater Civ Eng 26:379–383

Edil TB, Tinjum JM, Benson CH (2012) Recycled unbound materials. MN/RC2012-35, Minnsota Department of Transportation: Saint Paul, MN, USA

Noureldin E, Abdelrahman M (2013) Modeling of the resilient modulus for recycled asphalt pavement applications in base course layers. Transp Res Record 2371:121–132

Cliatt B, Plati C, Loizos A (2016) Investigating resilient modulus interdependence to moisture for reclaimed asphalt pavement aggregates. Procedia Eng 143:244–251

Hicks RG, Monismith CL (1971) Factors influencing the resilient response of granular materials. Transp Res Rec 345:15–31

Uzan J (1985) Characterization of granular material. J Transp Res Board 1022:52–59

Uzan J (1992) Resilient characterization of pavement materials. Int J Numer Anal Methods Geomech 16:435–459

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Loizos, A., Cliatt, B., Plati, C. (2022). Finite Element Simulations of Recycled Asphalt Pavement (RAP) Materials to Be Utilized in Unbound Pavement Layers. In: Tutumluer, E., Nazarian, S., Al-Qadi, I., Qamhia, I.I. (eds) Advances in Transportation Geotechnics IV. Lecture Notes in Civil Engineering, vol 164. Springer, Cham. https://doi.org/10.1007/978-3-030-77230-7_44

Download citation

DOI: https://doi.org/10.1007/978-3-030-77230-7_44

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-77229-1

Online ISBN: 978-3-030-77230-7

eBook Packages: EngineeringEngineering (R0)