Abstract

Sewage sludge ash (SSA), which today is residual waste, can be separated into two resources, phosphorous and a particulate material for use in production of concrete or brick, by electrodialytic separation (EDS). Three SSAs from different sewage sludge mono-incineration plants were included in this investigation. Overall they had similar characteristics, but still the differences meant that the EDS process needs optimization for each ash type. Under the same experimental conditions, 80% P was recovered from two of the SSAs whereas only 65% was recovered from the third SSA. After EDS, the investigation points at a decrease in Ca and P may be beneficial if using the SSA-EDS in concrete. The investigation also showed that the investigated SSAs had high Fe contents, which may be problematic if used in brick production. In conclusion, the investigation points at a potential for SSA to be considered as secondary resource in the construction materials after EDS.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Ashes from incineration of sewage sludge (SSA) are often residual waste, i.e. removed from the overall material cycle. The ashes might be secondary resources. Research is carried out on utilization of SSA as supplementary cementitious material in concrete [1,2,3,4] or clay replacement in fired clay bricks [5,6,7,8]. However, attention should be payed to the high content of phosphorous (P), as P is a finite, essential resource, which is in list of critical raw materials for the EU [9]. The P concentration in SSA is typically 5–10 wt% [1], and even higher concentrations have been found, 11 wt% P [10], 11.9 wt% P [11] and 12.3 wt% P [12]. The P content in phosphate rock is generally reported as P2O5, and the economic grade varies from 25 to 37% P2O5 [13], corresponding to 11–16 wt% P. The P content in SSAs are thus generally lower; however, some SSAs have concentrations in the same range. Since the P concentration is high in SSA, P recovery should be considered prior to use in construction materials, otherwise P is lost for recovery. The high P content in SSA has reached awareness in some EU countries and legislation supporting/requesting P recovery, e.g. in Germany, where the sewage sludge ordinance includes requirements for P recovery from SSA [14]. Research and development are progressing to implement P recovery from SSA. The methods under development are based thermochemical treatment or acid extraction, the latter being reported most extensively in literature.

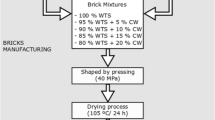

Research on recovery of P from SSA and following use of the SSA in construction materials is scarce. Donatello et al. [15] used sulfuric acid to wash out P and tested the pozzolanic activity of the SSA. The acid washing decreased the pozzolanic activity according to the SAI and Frattini tests. Kappel et al. [16] used EDS (described in Sect. 1.1) for recovery of P prior to use in mortar. They reported a loss in compressive strength from 60 to 55 MPa when 20% cement was replaced with SSA after EDS treatment (SSA-EDS) and milling. They noted that the workability of mortar with SSA-EDS decreased. Ottosen et al. [8] reported a screening with SSA-EDS as clay replacement in bricks (10–60% replacement). The apparent density decreased and the porosity increased with increasing clay substitution. When firing the brick material with 60% clay replacement at 1050 °C a significant glassy phase formed. The results generally showed that 60% replacement of clay was probably too much, but with 10% replacement, the properties were changed only slightly compared to the reference. The mentioned investigations points at potential uses for the SSA after P recovery, but the potential needs unfolding prior to a full evaluation of the options.

Evaluating the use potential for use of SSA secondary raw material includes knowledge on amounts and variety in SSA characteristics over time and between plants. Worldwide, 1.7 mio tons SSA are produced annually and the amount is increasing [17]. At a local, Danish scale, the two large (out of three) sewage sludge incinerators have an annual production of about 20,000 t SSA (containing 1000–2000 t P). Annually, 13,500 t P is applied as commercial fertilizer in Denmark [18], i.e. 8–14% of this P could be recovered from SSA. Denmark uses 4–5 mio m3 concrete annually [19] corresponding to 1–1.5 mio tons cement. After acid recovery of P, about half of the SSA is left [10], i.e. 10,000 tons in the Danish case. Thus, SSA after P recovery can replace only about 0.2% cement in average. However, the SSA has coloring potential for the concrete [2] and brick [8], which gives the construction materials with SSA new interesting aesthetical potentials, possibly adding value to these materials. To scale the use of SSA as secondary resource it is beneficial if the SSA characteristics varies only little over time and between plants so the P recovery processes and the mix design for construction materials need minimum of adjustments. In this investigation, SSA from three different mono-incineration plants were collected and treated by EDS. The aim is to investigate if the differences between the three ashes are in a range, where they can be considered being the same raw material.

1.1 Electrodialytic Separation for Recovery of Phosphorous

EDS recover P and remove heavy metals simultaneously in a two compartment electrodialytic cell [10] (Fig. 1). The compartments are separated by a cation exchange membrane, which only allows cations to pass. The SSA is suspended in water in the anode compartment. When the electric DC current is applied, the anolyte with SSA suspension is acidified due to electrolysis of H2O at the anode (H2O → 2H+ + ½O2 (g) + 2e−). During the acidification, heavy metals and P are extracted from the SSA, but whereas the cationic heavy metals are transported by electromigration over the cation exchange membrane and concentrate in the cathode compartment, the extracted P remains in the filtrate of the SSA suspension as negatively charged ions or neutral molecules. Hereby simultaneous extraction and separation is obtained. At the end of the treatment, the recovered P is in the filtrate of the anolyte and the solubilized heavy metals in the catholyte. Filtration separates SSA-EDS and the filtrate with the recovered P. Previous research has shown 80–90% recovery by EDS [10, 20].

2 Materials and Methods

The work includes SSAs from three different mono-incineration plants for sewage sludge, where the sludge was incinerated in a fluidized bed combustor. The sewage sludge incinerated originated from treatment of urban wastewater. The three ashes are: SSA-A. From Germany, SSA-B From Spildevandscenter Avedøre, BIOFOS, Denmark, and SSA-C from Lynetefællesskabet, BIOFOS, Denmark.

2.1 Ash Characterization

Concentrations of P, Al, Ca, Fe, K, Mg, Na, P, S, Cu, Pb and Zn were measured after pre-treatment (acid digestion) in accordance to Danish Standard DS259: 1.0 g ash and 20.0 ml (1:1) HNO3 was heated at 200 kPa (120 °C) for 30 min. Filtration through 0.45 µm filter. Concentrations were measured with ICP-OES in the filtrate. SSA pH was measured in suspension: 10.0 g ash in 25 ml distilled water. After 1 h agitation, pH was measured directly in the suspension with Radiometer electrodes. Loss on ignition (LoI) was found after 30 min at 550 °C. Water content was measured as weight loss after 24 h at 105 °C. Three to five replicates of each of these analyses were made. Solubility in water was evaluated as weight loss after washing 50.0 g SSA in 500 ml distilled water three times.

2.2 Electrodialytic Separation Experiments

The EDS laboratory cell following Fig. 1 was used. The compartments were separated by a cation exchange membrane (CEM) from IONICS. The electrodes were made of platinum coated titanium wire (diameter 3 mm) and the length of the electrodes inside the cell was approximately 4 cm. The power supply was Hewlett Packard E3612A. One EDS experiment was made with each of the three SSAs. The experimental conditions were similar. The SSA was suspended in tap water. The liquid:solid ratio of 14 was obtained by suspending 25 g SSA in 350 ml water. The SSA was kept suspended by an overhead stirrer (RW11 basic from IKA). In the cathode compartment 500 mL 0.01 M NaNO3 adjusted to 2 with HNO3 was circulated. The experiments were conducted at a constant current of 50 mA applied to the electrodes. The duration of all experiments was 1 week (chosen from experiences in [8]).

3 Results

3.1 Characterization of SSAs

Some characteristic of the three SSAs are in Table 1.

In general, the characteristics for the three SSAs were quite similar. The three ashes all had a distinct rusty-red color. The solubility of the SSAs was between 1.4 and 2.0% showing that the ashes contained a minor soluble fraction. They all had a low water content, which means that chemical reactions during storing have been limited. The SSAs were alkaline meaning that hydroxides were leached or formed when suspending the SSAs in water. The major differences between the SSAs (in Table 1) were: (I) The LoI was very low for SSA-A and SSA-B (0.2 and 0.3%) revealing a good incineration. LoI for SSA-C was higher (3%), (II) The Fe concentration was only half in SSA-C compared to SSA-A, (III) The P concentration was low (56.8 g/kg) in SSA-C compared to the two other SSAs (about 90 g/kg) and (IV) The Cu concentration was about 4 times higher in SSA-A than in the two other SSAs.

3.2 Recovery of Phosphorous and Separation of Heavy Metals by EDS

Table 2 shows the P recovery and mass loss from the three EDS experiments. Figure 2 shows the distribution of P, Cu, Pb and Zb at the end of the EDS experiments.

Mass balances are given as the mass of an element in different parts of the EDS cell at the end of the experiment over the mass of the element initially in the SSA. The mass balances for the different elements in the three EDS experiments were between 85 and 115% (data not shown), which are acceptable. The exceptions from this are Pb in experiment SSA-A (mass balance 145%) and Fe in all experiments (68–75%).

The P recovery was very similar in the EDS experiments B and C, where about 80% P was in the anolyte filtrate by the end of the experiments (Fig. 2). In EDS-A on the contrary, only 65% P was recovered into the anolyte and 29% remained in the SSA. The Cu, Pb and Zn released from the SSA during EDS were removed into the catholyte, and thus the separation of P and heavy metals was successful. In all three SSAs, 70–75% Pb was still in the SSA after EDS, which was the highest percentage of the three heavy metals in every of the experiments. Few percentages of more Zn than Cu was recovered in every experiment, and the order in percentages remaining in the SSA was the same for Cu and Zn: SSA-C > SSA-B > SSA-C.

3.3 Characterization of SSA-EDSs

Characteristics of the three SSA-EDSs are in Table 3. The SSAs were acidified from the original alkaline to acidic (3.4–4.2), and the acidification had resulted in a SSA mass loss of between 39 and 49% (Table 1). There is no correlation between final pH after EDS and mass loss. The major differences in the concentrations are: (I) Significantly higher Ca and P concentrations in SSA-EDS-A than in the two other SSAs, (II) The Fe concentration was about half in SSA-C compared to the two other SSAs, (III) A much higher Cu concentration in SSA-EDS-A, which was also the case before EDS (Table 1), and (IV) the Zn concentrations were different in all three ashes.

4 Discussion

The EDS recovery of P was successful (in relation to the 80% recovery target [14]) from experiments EDS-B and EDS-C, whereas only 65% P was recovered from experiment EDS-A. The P concentrations were very similar in SSA-A and SSA-B (Table 1). The experimental conditions were the same, and thus the acid production from the electrolysis at the anode was the same. The pH reached the lowest level in SSA-EDS-A (Table 3). Thus, the buffering capacity for SSA-A was less than for the two other SSAs, which corresponds well to SSA-A containing the largest the fraction not being dissolved during EDS. The difference in P extraction must be found in differences in the P speciation in the SSAs. The P speciation was not determined in the present study, but the EDS results clearly points at the importance of an increased understanding of the P speciation. Whitlockite (calcium magnesium phosphate mineral) has previously been determined in SSA [21], but otherwise little has been reported on P speciation in SSAs. The knowledge gap also includes the link between the firing characteristics at the different incinerators and incineration parameters, which are known to play a major role in the ash characteristics for another type of biomass ash, namely wood ash [22].

The distinct rusty-red color revealed a high iron oxide content. The Fe concentration in Tables 1 and 3 were measured after acid digestion, and shows the acid soluble concentration of Fe rather than the total concentration. In [23] it was found for two SSAs that the concentration of Fe was two times higher when measured as total concentration by XRF than by ICP after acid digestion after DS259 (as in the present investigation). The Al, Ca, K, Mg, P and S concentrations found with XRF were generally in good agreement with the concentrations after acid digestion according to DS259. Figure 3 shows the acid soluble concentrations of Al, Ca, Fe K, Mg and P in the investigated SSAs and SSA-EDSs found after DS259 (Tables 1 and 3).

Based on XRD analysis, Kappel et al. [16] identified quartz, feldspar and hematite in SSA and SSA-EDS (in SSA samples from the same plant as SSA-B). Cheeseman et al. [21] reported quarts, whitlockite and hematite in an SSA from UK, and Anderson [24] quartz, calcite, hematite, anhydride, feldspar and glassy phase ~70% in another SSA from UK. Thus, quartz and hematite were identified in these reported cases. The quartz may originate from the fluidized bed. The high concentration of hematite is due to the use of iron salts to precipitate P in the wastewater treatment facility, which is the most commonly used chemical. Other facilities use Al as major salt and this strongly influences the chemical properties of the SSA [5, 23].

The most significant decrease during EDS was in the Ca concentration followed by P (Fig. 3). The total Fe concentration must be expected higher than the acid soluble fraction in Fig. 3 (as mentioned in the paragraph above), but as seen the acid soluble fraction increased, however, taking the solubilized fraction during EDS into account, Fe has overall been removed from the SSAs. The elements in Fig. 3 do not account for the major mass of the SSAs. As quarts was reported present in SSAs [11, 21, 24], and since quarts sand (the part originating from the fluidized bed) is insoluble during EDS, Si must be expected prevailing in the investigated SSA and SSAs as well.

In relation to concrete, EN450-1 (2012) opens for the use of co-combustion ashes with coal and sewage sludge. The investigated ashes are though from mono-incineration of SSA. However, comparing the concentrations of Ca, Mg, P and S (calculated to oxides) to the requirements described in EN450-1 (2012) might point on limitations in the use, if the upper concentrations in the requirements are exceeded. Requirements are that the reactive Ca shall not exceed 10% CaO per mass, the total MgO content shall not exceed 4%, the total content of P2O5 not 5% and the SO3 content shall not exceed 3%. The methods prescribed used in EN450-1 (2012) are not the same as used in the present investigation, but the comparison of the measured concentrations and the prescribed limiting values points at some issues, where further investigations are needed. These points are marked in orange in Table 4, and as seen it is the content of CaO and P2O5 in all three SSAs before EDS, and P2O5 in SSA-A after EDS. Table 4 indicates that the problematic issues with high concentrations of CaO (which can potentially be reactive) and P2O5 were solved during EDS, however, a thorough investigation is needed to conclude.

In relation to brick production, the hematite content was considered responsible for formation of a glassy-like phase when clay/SSA-EDS was fired at 1050 °C, a phase strongly influenced the properties of the brick material [8]. Even though the total concentration of Fe was not determined in the investigated SSAs and SSA-EDSs, the Fe concentration was very high in all cases as the acid soluble (DS259) concentrations were between 4% (Table 1) and 9.5% (Table 3). This is thus a general point for further investigation in relation to use of SSA-EDS in brick manufacturing.

5 Conclusion

SSA is a potential resource for the critical raw material P, and some countries have legislation supporting/requesting P recovery. In Denmark, about 7–14% of the imported commercial fertilizer could be replaced with P extracted from Danish SSAs. EDS is a method under development for P recovery. The current investigation showed, that method need optimization for the actual SSA, since sufficient P was recovered from only two out of the three SSAs, when using the same experimental parameters. After P recovery, about 50–60% of the SSA remains after EDS, and this fraction was evaluated as raw material for concrete or brick on basis of the chemical composition. The SSAs all contained a high content of Fe (both prior to and after EDS), and this content should be investigated in relation to use in bricks, as iron oxide is known to form a glassy like phase in bricks, changing the properties. For use in concrete, the high concentration of Ca (which can be problematic if reactive) in SSA was decreased during EDS to a low, and likely non-problematic level. The same goes for P. The investigation points at EDS having potential to separate SSA into two resources, P and material for production of construction materials. It also points at P speciation and mineralogy/composition of the treated SSA to be major focus points in future research.

References

Cyr, M., Coutand, M., Clastres, P.: Technological and environmental behavior of sewage sludge ash (SSA) in cement-based materials. Cem. Concr. Res. 37, 1278–1289 (2007)

Kappel, A., Ottosen, L.M., Kirkelund, G.M.: Colour, compressive strength and workability of mortars with an iron rich sewage sludge ash. Constr. Build. Mater. 157, 1199–1205 (2017)

Krejcirikova, B., Ottosen, L.M., Kirkelund, G.M., Rode, C., Peuhkuri, R.H.: Characterization of sewage sludge ash and its effect on moisture physics of mortar. J. Build. Eng. 21, 396–403 (2019)

Rutkowska, G., Wichowski, P., Franus, M., Mendryk, M., Fronczyk, J.: Modification of ordinary concrete using fly ash from combustion of municipal sewage sludge. Materials 13(487), 1–17 (2020)

Wiebusch, B., Seyfried, C.F.: Utilization of sewage sludge ashes in the brick and tile industry. Water Sci. Technol 36(11), 251–258 (1997)

Lin, D.F., Weng, C.H.: Use of sewage sludge ash as brick material. J. Environ. Eng. 127(10), 922–927 (2001)

Anderson, M., Skerratt, R.G.: Variability study of incinerated sewage sludge ash in relation to future use in ceramic brick manufacture. Br. Ceram. Trans. 102(3), 109–203 (2003)

Ottosen, L.M., Bertelsen, I.M.G., Jensen, P.E., Kirkelund, G.M.: Sewage sludge ash as resource for phosphorous and material for clay brick manufacturing. Constr Build Mater 249, 118684 (2020)

COM: 490 On the 2017 List of Critical Raw Materials for the EU (2017)

Ottosen, L.M., Jensen, P.E., Kirkelund, G.M.: Phosphorous recovery from sewage sludge ash suspended in water in a two-compartment electrodialytic cell. Waste Manage. 51, 142–148 (2016)

Krüger, O., Adam, C.: Recovery potential of German sewage sludge ash. Waste Manage. 45, 400–406 (2015)

Ebbers, B., Ottosen, L.M., Jensen, P.E.: Comparison of two different electrodialytic cells for separation of phosphorus and heavy metals from sewage sludge ash. Chemosphere 125, 122–129 (2015)

Gupta, D.K., Chatterjee, S., Datta, S., Veer, V., Walther, C.: Review. Role of phosphate fertilizers in heavy metal uptake and detoxification of toxic metals. Chemosphere 108, 134–144 (2014)

Verordnung zur neuordnung der klärschlammverwertung. Bundesgesetzblatt Jahrgang Teil I Nr. 65 (2017)

Donatello, S., Freeman-Pask, A., Tyrer, M., Cheeseman, C.R.: Effect of milling and acid washing on the pozzolanic activity of incinerator sewage sludge ash. Cem. Concr. Compos. 32, 54–61 (2010)

Kappel, A., Viader, R.P., Kowalski, K.P., Kirkelund, G.M., Ottosen, L.M.: Utilization of electrodialytically treated sewage sludge ash in mortar. Waste Biomass Valor. 9(12), 2503–2515 (2018)

Donatello, S., Cheeseman, C.R.: Recycling and recovery routes for incinerated sewage sludge ash (ISSA): a review. Waste Manage. 33(11), 2328–2340 (2013)

Poulsen, H.D., Møller, H.B., Klinglmair, M., Thomsen, M.: En fosforvidenssyntese. Fosfor i dansk landbrug—ressource og miljøudfordring (in Danish). Report from Aarhus Universitet, DCE (2019)

Dansk Beton: Bæredygtig beton initiativ. Roadmap mod 2030, Halvering af CO2-udledningen fra betonbyggeri (in Danish), Copenhagen, Denmark (2019)

Guedes, P., Couto, N., Ottosen, L.M., Ribeiro, A.B.: Phosphorus recovery from sewage sludge ash through an electrodialytic process. Waste Manage. 34, 886–892 (2014)

Cheeseman, C.R., Sollars, C.J., McEntee, S.: Properties, microstructure and leaching of sintered sewage sludge ash. Resour. Conserv. Recycl. 40, 13–25 (2003)

Sigvardsen, N.M., Kirkelund, G.M., Jensen, P.E., Geiker, M.R., Ottosen, L.M.: Impact of production parameters on physiochemical characteristics of wood ash for possible utilisation in cement-based materials. Resour. Conserv. Recycl. 145, 230–240 (2019)

Ottosen, L.M., Kirkelund, G.M., Jensen, P.E.: Extracting phosphorous from incinerated sewage sludge ash rich in iron or aluminum. Chemosphere 91(7), 963–969 (2013)

Anderson, M.: Encouraging prospects for recycling incinerated sewage sludge ash (ISSA) into clay-based building products. J. Chem. Technol. Biotechnol. 77, 352–360 (2002)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Ottosen, L.M., Kirkelund, G.M., Jensen, P.E. (2021). Recovery of Phosphorous from Sewage Sludge Ash Prior to Utilization as Secondary Resource in Concrete and Bricks. In: M.C.F. Cunha, V., Rezazadeh, M., Gowda, C. (eds) Proceedings of the 3rd RILEM Spring Convention and Conference (RSCC 2020). RSCC 2020. RILEM Bookseries, vol 35. Springer, Cham. https://doi.org/10.1007/978-3-030-76543-9_28

Download citation

DOI: https://doi.org/10.1007/978-3-030-76543-9_28

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-76542-2

Online ISBN: 978-3-030-76543-9

eBook Packages: EngineeringEngineering (R0)