Abstract

Mudrocks are the most sensitive sedimentary rocks in terms of strength, deformation and slaking characteristics against change in environmental and climatic conditions. Various worldwide recorded engineering problems (e.g., landslide, slope instability, embankment failures, open-pit and underground excavation problems and undercutting related rockfalls) generally have direct or indirect relationships with these rocks. Clay minerals that are extremely sensitive to water content change constitute the most dominant mineralogical component of mudrocks. In addition to their problematic characteristics, mudrocks have promising features for modern engineering projects. For nearly three decades, mudrocks (e.g., Opalinus Clay, Boom Clay) have been investigated for safe storage of high-level radioactive waste by considering their low hydraulic conductivity and high swelling and self-sealing potential. Furthermore, the reduction of conventional fossil fuels and worldwide high energy demands have led scientists to do more investigation to achieve alternative energy sources from mudrocks. Considering low durability and strength-dependent mudrock-based engineering problems and the importance of these rocks for extraction shale gas and storage nuclear waste, the failure, slaking and self-sealing behaviors of these clay-bearing rocks are comprehensively evaluated in this study.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Mudrocks (shale, claystone, mudstone, siltstone) form more than 60% of sedimentary rocks (Potter et al. 1980), include about two-thirds of the sedimentary section (Blatt 1982) and cover one-third of the total earth’s surface (Franklin 1983). Average mineralogical compositions of these rocks were well documented by Pettijohn (1975) as clay minerals, quartz, feldspar, carbonates and iron oxide with percentages of 58%, 28%, 6%, 5% and 2%, respectively. Mudrocks commonly known as fine to very fine-grained siliciclastic sedimentary rocks are widely encountered problematic geological materials in many important engineering projects. These rocks are recognized as problematic rocks due to their low durability, low strength and high swelling potential when exposed to moisture (Sarman et al. 1994). Various landslides and slope instabilities that have occurred until now reveal the best example of such problematic features of mudrocks (Moon and Beattie 1995). In addition, based on literature review, Erguler and Ulusay (2009a) also emphasized that mudrocks were related to many foundation, slope stability, underground excavation and embankment failure problems. Furthermore, until present day, various rockfall problems which caused loss of life and property have been recorded in many countries, particularly in the USA, due to the time-dependent disintegration and erosion of mudrocks called as “undercutting.” Also, Dick et al. (1994) stated that mudrock breakdown caused numerous problems in engineering projects such as slope instabilities, underground mining-related problems. Despite the engineering problems, mudrocks, particularly their clay minerals dominant constituents, have been known as raw material for pottery and adobe for very long time. Nowadays, mudrocks are popular for their direct or indirect usage in many areas and modern projects such as absorbents, ceramic products, primary source of oil and gas, nuclear waste disposal, landfills, etc. (Kalyoncu Erguler 2020).

The steady increase in demand for energy with each day and the reduction of conventional fossil fuels have called for more research in order to achieve alternative energy sources. As a result, significant technological developments have been acquired in extraction of gas (shale gas) trapped in mudrocks. Particularly, present advances in drilling technology and hydraulic fracturing techniques provide shale gas to be alternative geo-energy sources. Recently, geological units have been considered as repositories for nuclear wastes in developed countries, and these clay-bearing rocks (e.g., Opalinus Clay, Boom Clay) have been selected as important research topics for their low hydraulic conductivity and self-sealing characteristics of induced fractures (Kalyoncu Erguler 2020). Considering the effect of mudrocks on many engineering problems and their importance for modern engineering projects, comprehensive database on strength, deformation, disintegration and self-sealing properties of these clay-bearing rocks is discussed in this study.

2 Classification and Mechanical Properties of Mudrocks

Based on several input parameters such as percentage of clay-size component, stratification thickness, mineralogical composition, anisotropy, strength, durability, hand-texture characteristics and induration, various classification systems were previously proposed for defining mudrocks and for understanding their physical properties and mechanical behavior. However, it was found that engineering geologists mostly preferred to use the classification system, which considered engineering performance of mudrocks, recommended by Potter et al. (1980). Mudrocks have a wide range of strength and deformability properties depending on geological age, mineralogical composition, lithological properties and degree of induration (Erguler, 2018). Previous studies (Erguler and Ulusay 2009a; Czerewko and Cripps 2012) stated that the uniaxial compressive strength (UCS) values of these rocks changed between 0.6 and 100 MPa. However, their strength and deformation properties ultimately decreased with the increase in water content. Erguler and Ulusay (2009a) measured more than 90% loss in the UCS, modulus of elasticity and tensile strength of saturated mudrocks in comparison with their oven-dried conditions. They recommended general empirical models for predicting these mechanical parameters of mudrocks at any water content by taking dry unit weight, porosity and water absorption by weight as independent variables.

3 Disintegration Behavior of Mudrocks

3.1 Durability Evaluation of Mudrocks Based on Laboratory Approaches

Mudrocks generally disintegrate rapidly when subjected to physical weathering processes, particularly “freezing–thawing” and “wetting–drying” (Kalyoncu Erguler 2020). Despite of responsibility of “freezing–thawing,” “wetting–drying” and “heating–cooling” cycles (Hale and Shakoor 2003) on mudrock breakdown, previous studies (Franklin and Chandra 1972; Cripps and Taylor 1981; Moon and Beattie 1995; Dick et al. 1994) mainly developed laboratory-based approach to measure nondurable mudrock behavior under wetting–drying processes. The disintegration behavior of rocks is called “slaking”; the slaking phenomenon of rocks is determined by the slake durability (Id) (Franklin and Chandra 1972), the jar slake and the slake index tests (Kalyoncu Erguler 2020). Although Id is the most favored test to determine slaking behavior of rocks, several weakness and limitations of this method (e.g., mechanical breakdown during test, accepting fragments of various sizes retained in 2-mm mesh drum as durable) were emphasized by Erguler and Ulusay (2009c). In order to overcome the limitations related to slake durability test and to accurately simulate slaking behavior of mudrocks, Erguler and Shakoor (2009b) proposed a new quantitative method and a new durability classification system based on this method. This quantitative method quantifies the fragment size distribution of the slaked material of various sizes in terms of “disintegration ratio” (Fig. 1).

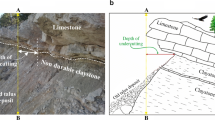

3.2 Field-Based Disintegration Behavior of Mudrocks

It is observed that the laboratory-based methodologies are not sufficient to accurately determine disintegration behavior of mudrocks at in situ conditions. Therefore, in order to incorporate the effect of all weathering processes on mudrocks and so to accurately assess the durability of these rocks, field behavior of these rocks should be considered. For this purpose, as shown in Fig. 2, the depth of undercutting at the road cuts provides a very useful database for understanding disintegration behavior of mudrocks at natural condition (Kalyoncu Erguler 2020). The direct measurement of undercutting rate of these rocks is critical for the safety of the related projects in terms of predetermination of undercutting-based instabilities and acquisition of the necessary measures in advance. It has been determined that the undercutting rates of Neogene-aged mudrocks situated in Turkey change between 1.0 and 4.6 cm/year. The total annual precipitations in this site have been recorded as a range of 36–56 cm (Ozdemir and Erguler 2022). Shakoor and Rogers (1992) and Niemann (2009) specified that differential weathering of mudrocks located in the Appalachian region, with precipitation ranging between 100 and 130 cm, was commonly recorded in the case of exposing beneath more resistant rocks. They found that the undercutting rates of these Devonian–Permian-aged rocks changed between 1.3 and 9.5 cm/year.

4 Self-sealing Characteristics of Mudrocks

The self-sealing behavior of mudrocks is geomechanical, hydro-mechanical and geochemical process-based mechanism. It is generally evaluated as a reduction in permeability (hydraulic conductivity) of rocks. Several self-sealing mechanisms are responsible for the decrease in permeability of mudrock. Bock et al. (2010) specified these significant factors as “compaction of the intact rock body,” “mechanical closure of fractures,” “physico-chemical factors (e.g., swelling, slaking),” “surface slaking, sedimentation and clogging of fractures” and “precipitation of minerals.” The effect of self-sealing processes should be defined by considering in situ stress and temperature values as well as time parameter. Therefore, a deep scientific knowledge beyond the classical geomechanical perspective on hydro-mechanical properties of shales and modernized laboratory equipment is required. Although there are some numerical approaches to be used in self-sealing behavior, these approaches can only incorporate easy and precise processes such as stress increases dependent fracture closure (Kalyoncu Erguler 2020).

The hydraulic conductivity values of mudrocks generally change between 1 × 10–13 and 1 × 10–9 m/s at atmospheric pressure (Freeze and Cherry 1979). By performing permeameter and in situ packer tests, Marschall et al. (2005) determined that this parameter ranged from 2 × 10−14 to 2 × 10−12 m/s for tectonically disturbed Opalinus Clay. Despite the low permeability values, technological advances in hydraulic fracturing and horizontal drilling provide required tools to acquire oil and gas from these impermeable geological units. In addition to mudrock importance for unconventional gas and oil production, the low permeability and good self-sealing characteristics of these rocks have led scientists to investigate their usability in safe storage of hazardous wastes such as nuclear waste disposal (Fisher et al. 2013) and sequestration of CO2. The time required for the closure of the cracks in mudrocks especially depends on the mineralogical composition and geological history of the rock. It can be concluded that while self-sealing mechanisms cause fracture closure within a short time (a few months) in plastic clays, this process may be slower and take years for more indurated mudrocks (Bock et al. 2010).

5 Conclusions

Mudrocks—known as the widespread fine-grained siliciclastic sedimentary rocks—are critical for many engineering projects for their low hydraulic conductivity, self-sealing, slaking and water content dependent strength and deformation characteristics. Particularly, in the case of achieving sufficient scientific background, their low permeability and self-sealing features are thought to be of strategic importance in hosting nuclear waste disposal. However, to accurately determine the effect of self-sealing processes of fractures on production efficiency of shale gas by laboratory experiments is challenging. The effect of these processes should be defined by considering in situ stress and temperature values as well as the time parameter. Therefore, it can be concluded that current laboratory-based approaches are insufficient to include effective self-sealing mechanisms such as time-dependent creep deformations, slaking, micro-slaking, swelling, precipitation of new minerals.

The UCS values of these rocks ranged from 0.6 to 100 MPa, but the increase in water content dramatically decreased their strength and deformation characteristics. Statistically significant empirical models were recommended to estimate water content-dependent variations in these parameter based on their physical properties.

The disintegration behavior of mudrocks could not be accurately measured by performing slake durability index test due to several limitations. Thus, a new quantitative method called as “disintegration ratio” was proposed. Mudrock disintegration caused “undercutting”-dependent instability problems for road cuts. Based on measurements directly taken from Neogene and Devonian–Permian-aged mudrocks exposed to weathering processes in different climatic conditions, it was specified that mudrock undercutting rates varied between 1.0 and 9.5 cm/year.

References

Blatt, H.: Sedimentary Petrology. W.H. Freeman and Company, San Francisco (1982)

Bock, H., Dehandschutter, B., Martin, C.D., Mazurek, M., De Haller, A., Skoczylas, F., Davy, C.: Self-sealing of Fractures in Argillaceous Formations in the Context of Geological Disposal of Radioactive Waste. NEA No. 6184 (2010)

Cripps, J.C., Taylor, R.K.: The engineering properties of mudrocks. Q. J. Eng. Geol. 14, 325–346 (1981)

Czerewko, M.A., Cripps, J.C.: Mudrocks, clays and pyrite. In: Burland, J.B., Chapman, T., Skinner, H.D., Brown, M.J.Z. (eds.) ICE Manual of Geotechnical Engineering. Volume 1 Geotechnical Engineering Principles, Problematic Soils and Site Investigation, pp. 481–516. ICE Publishing, London (2012)

Dick, J.C., Shakoor, A., Wells, N.: A geological approach toward developing a mudrock-durability classification system. Can. Geotech. J. 31, 17–27 (1994)

Erguler, Z.A.: Encyclopedia of Engineering Geology. In: Shale, Bobrowsky, P.T., Marker, B. (eds.), pp. 829–830. Springer International Publishing AG, Switzerland (2018). ISBN: 978-3-319-73566-5

Ergüler, Z.A., Ulusay, R.: Water-Induced Variations in Mechanical Properties of Clay-Bearing Rocks (2009a)

Erguler, Z.A., Shakoor, A.: Quantification of fragment size distribution of clay-bearing rocks after slake durability testing. Environ. Eng. Geosci. XV(2) (2009b)

Erguler, Z.A., Ulusay, R.: Assessment of physical disintegration characteristics of clay-bearing rocks: disintegration index test and a new durability classification chart. Eng. Geol. 105, 11–19 (2009)

Fisher, Q., Kets, F., Crook, A.: Self-sealing of faults and fractures in argillaceous formations: evidence from the petroleum industry. NAB 13-06 (2013)

Franklın, J.A.: Evaluation of Shales for Construction Projects: An Ontario Shale Rating System: Research and Development Branch, Ministry of Transportation and Research. Toronto, Report RR 229, 99 p. (1983)

Franklin, J.A., Chandra, A.: The slake-durability test. Int. J. Rock Mech. Min. Sci. 9, 325–341 (1972)

Freeze, R.A., Cherry, J.S.: Groundwater, p. 604. Prentice-Hall Inc., Englewood Cliffs, New Jersey (1979)

Hale, P.A., Shakoor, A.: A laboratory investigation of the effect of cyclic heating and cooling, wetting and drying, and freezing and thawing on the comprehensive strength of selected sandstones. Environ. Eng. Geosci. IX(2), 117–130 (2003)

Kalyoncu Erguler, G.: The failure, slaking, and self-sealing behavior of clay-bearing rocks. Arab. J. Geosci. 13, 857 (2020). https://doi.org/10.1007/s12517-020-05896-5

Marschall, P., Horseman, S., Gimmi, T.: Characterisation of gas transport properties of the opalinus clay, a potential host rock formation for radioactive waste disposal. Oil Gas Sci. Technol. 60(1), 121–139 (2005)

Moon, V.G., Beattie, A.G.: Textural and microstructural influence on the durability of Waikato coal measures mudrocks. Q. J. Eng. Geol. 28, 303–312 (1995)

Niemann, W.L.: Lessons learned from rates of mudrock undercutting measured over two time periods. Environ. Eng. Geosci. XV(3), 117–131 (2009)

Ozdemir, S., Erguler, Z.A.: Investigation of the slaking behavior of weak geological units in terms of undercutting rate. Bull Mineral Res Explor., 1–22 (2022). https://doi.org/10.19111/bulletinofmre.898013

Pettijohn, F.J.: Sedimentary Rocks, 3rd edn., p. 628. Harper and Row, New York (1975)

Potter, P.E., Maynard, J.B., Pryor, W.A.: Sedimentology of Shale, p. 553. Springer-Verlag, New York (1980)

Sarman, R., Shakoor, A., Palmer, D.F.: A multiply regression approach to predict swelling in mudrocks. Bullet. Assoc. Eng. Geol. XXXI(1), 102–121 (1994)

Shakoor, A., Rodgers, J.P.: Predicting the rate of shale undercutting along highway cuts. Bullet. Assoc. Eng. Geol. XXIX(1), 61–75 (1992)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Erguler, Z.A., Kalyoncu Erguler, G. (2022). Strength, Disintegration and Self-sealing Characteristics of Mudrocks. In: El-Askary, H., Erguler, Z.A., Karakus, M., Chaminé, H.I. (eds) Research Developments in Geotechnics, Geo-Informatics and Remote Sensing. CAJG 2019. Advances in Science, Technology & Innovation. Springer, Cham. https://doi.org/10.1007/978-3-030-72896-0_28

Download citation

DOI: https://doi.org/10.1007/978-3-030-72896-0_28

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-72895-3

Online ISBN: 978-3-030-72896-0

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)