Abstract

Nowadays, enhancing the physical abilities of able-bodied humans attracted the researchers’ attention besides the development of assistive devices for people with mobility disorders. As a result, the interest in designing of cheap and soft wearable exoskeletons called exosuits is distinctly growing. Careful investigation of the biological musculoskeletal systems reveals three essential features simplifying gait control. The first property is the embedded compliance in the muscle-tendon-complex (MTC). Force-velocity or damper-like muscle behavior is the second feature. The last useful feature is in the biological morphological design of multi-articular muscles. These properties can be implemented in passive, assistive devices in isolation or combination. In this paper, we summarize a few studies on passive lower limb assistive devices that benefit from these two design concepts. We elaborate more on the outcomes of a recent study on a lower limb exosuit design with two biarticular elastic elements that combine the two aforementioned mechanisms in a single device.

This article is partially supported by the German Research Foundation (DFG) under the Grant No. AH307/2-1.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

1 Introduction

Biomechanical models with different levels of complexity are of advantage to understand the underlying principles of legged locomotion. This is an essential step to develop machines that aim at assisting human locomotion, namely assistive devices. Nowadays, these devices assist not only impaired people, but also healthy humans by reducing metabolic cost, fatigue, or increasing comfort. Among different types of assistive technologies, passive devices became more popular due to their simple, cheap, light, and user-friendly designs. Removing electronics, including motors, sensors, and batteries from the exo design and development reduces the required effort and cost for maintenance. In short, people can wear passive wearable devices like clothes or shoes needless to charge the batteries and carry heavy backpacks. The cost for achieving this level of comfort is the lacking of energy resources, which lower the potential performance of passive devices compared to active ones, regarding metabolic consumption or supporting patients with severe disabilities (e.g., paraplegic patients). In other words, passive gait assistance devices can support energy management without energy injection.

Since passive devices can not inject energy, how can they improve energy management? The only possibilities are energy shuffling or dissipation; both are supported by biological evidence. Energy shuffling can be performed regarding time or position. In that respect, elastic elements can store energy at a specific time domain (gait phase) and return it at another time. For this, springs are essential elements in different types of passive assistive devices, from carbon foot prostheses to exoskeletons [3]. More advanced techniques of using nonlinear springs or their combinations with clutches can provide more significant advantages regarding energy management by defining more complex force-length behaviors [6]. However, this is not the only method for energy shuffling. Biarticular muscles are smart biological solutions for transferring energy between two joints. For example, using cables [4] or springs [5] in a biarticular arrangement can easily implement energy shuffling between two positions (joints) in a robot as well as in an assistive device [6]. Regarding energy dissipation, biomechanical studies demonstrated damper-like behavior in legged locomotion (e.g., knee joint in downhill walking). This energy dissipation will be costly in the human body or active assistive devices. Instead, passive dampers (e.g., hydraulics) can provide this property, which could surprisingly yield improvement in gait performance by dissipating energy [7].

In this paper, we first present a brief overview of the state-of-the-art of passive assistive devices, which are designed based on these three basic elements. Then, a recent study [2] on gait assistance with a passive exosuit having biarticular thigh elastic elements will be briefly described. These compliant elements are in parallel to the hamstring and rectus femoris muscles of the leg, which combine energy transferring within time and location.

2 Methods

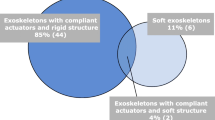

Passive assistive devices can be roughly categorized as: (1) Passive prostheses [8], (2) Exoskeletons supporting upper body (e.g., for load carrying [10]), and (3) exoskeletons for supporting lower limb in locomotion [3, 9]. The focus of this article is on the third category and also the compliance and biarticular design from the three aforementioned key features.

2.1 Compliance and Multi Articular Engagement

Employing passive devices for enabling amputees to locomote is not new [11]. The documented schematic drawing from previous centuries demonstrates the interest of researchers to facilitate locomotion for healthy subjects using assistive devices. In [1], a multiarticular bow spring with a limited range of motion exerted by cords or chains was introduced to support humans for different gaits (see Fig. 1(left). The idea of storing and returning energy with elastic elements and transferring energy between different joints provides the core concept of this invention in late 19 century. In 2003, van den Bogert introduced the exotendons as poly-articular elastic mechanisms with a significant contribution to the economy of legged locomotion [4]. This passive assistive technology is based on long elastic cords attached to an exoskeleton and guided by pulleys, which are placed at the joints. With human experiment-based simulations, he demonstrated the ability of a complex exotendon system to reduce the joint moments required for normal walking by 71% and joint power by 74% [6]. However, this amount of metabolic reduction could never be approached in reality. In [12], van Dijk et al. tested an exoskeleton with exotendons, which could reduce human mechanical work up to 40% in simulations. Contrarily, the developed device could never reduce the metabolic in human experiments [6]. In 2015, Collins et al. developed an ankle exoskeleton that could reduce the metabolic cost of healthy human walking by more than 7%. This lightweight elastic device acts parallel with the user’s calf muscles, off-loading muscle force in contractions. Using a mechanical clutch to tune engagement of the spring supports the function of the calf muscles and Achilles tendon. In another recent study, Nasiri et al. developed a passive compliant exoskeleton which benefits from energy transfer between the right and left hip joints [13]. The simple spring can generate about 8% metaboic rate reduction by shuffling the energy between the two hip joins during running at 2.5 ms\(^{-1}\). Using biarticular thigh springs, the significant advantages of biarticular springs in a new passive exosuit was demonstrated in [2]. A summary of the methods and achievements in this latter study will be presented in the following.

2.2 Case Study

(A) Design concept

Investigating joint power consumption in human locomotion (e.g., walking) shows reciprocal behavior between hip and knee joints during swing phase. This means that instead of generating and dissipating energy in two adjacent joints, shuffling energy between them using biarticular coupling is a much more efficient solution. In [2], this concept was utilized to develop a biarticular thigh exosuit, shown in Fig. 1(right). Instead of multi articular leaf springs of [1], we employed biarticular elastic rubber bands. In this bioinspired design, the passive artificial muscles (rubber bands) are utilized to mimic human rectus femoris and hamstring muscles. With these passive elements we can nicely predict human swing leg movement [14]. In [15], we showed that active control of these biarticular spring stiffness using the ground reaction force withing the FMCH (force modulated compliant hip) framework [16] can acceptably support human balancing. The FMCH method was developed to generate the VPP (virtual pivot point) as a biological posture control strategy in humans and animals [17]. Our previous studies on using constant stiffness for balance control showed that without GRF (ground reaction force) feedback in the FMCH, the VPP can still be predicted [18], but the gait will not be as robust as with the FMCH [19]. However, the passive mechanism (without feedback) could be useful to assist human gait as stability is guaranteed by human subject [20].

(B) Experiments

Eight non-impaired male subjects (age, 23–26 years; mass, 60–87 kg; height, 170–185 cm) participated in the experiments. They had no previous experience of walking with the exosuit. They voluntarily signed an informed consent form approved by the Sport Science Research Institute of Iran. The experimental setup and the developed exosuit are shown in Fig. 2.

We measured the metabolic rate to investigate the effect of the assistive device and the corresponding stiffness of the artificial muscles on energy expenditure in human walking. All participants walked on a treadmill at 1.3 ms\(^{-1}\) under different conditions: normal walking without the exoskeleton (NE for No-Exosuit); walking with the exosuit but no spring connected (NS for No-Spring); and walking with three different stiffness (low, medium and high) for each of the biarticular artificial muscles (in total 8 combinations). The measured data is from five minutes experiments for each walking condition. These conditions were randomized to prevent fatigue, learning and order effects on experimental results. Switching between NE and other cases needed wearing or taking off the exosuit preceded by two minutes warm-up walking. In addition, for measuring bias metabolic cost with and without exosuit, we consider data collection during three minutes standing still for each of the two conditions.

3 Results

We first compare the metabolic cost of the assisted test with no-Spring (NS), to realize the effect of adding the biarticular springs. Then, the results are compared to normal (unassisted) walking (NE). For each subject, we select the data of the assisted experiment (when the springs are contributing) with the lowest metabolic rate, and the “Assisted” data is the average of these trials for different subjects. This way, we demonstrate the results of the optimal stiffness arrangement (among the tested combinations) for each subject. The optimal arrangements are different for different subjects.

We present the experimental results of the average metabolic rate for the last two minutes of walking trial subtracted by standing metabolic rate. Just by wearing the exosuit without springs contributions, the metabolic rate will increase by 12.9 ± 6.5%. This could be due to the non-optimal design of the wearable parts and additional mass. Asbeck et al. showed that additional mass at different places in the legs could already increase the metabolic cost up to 8%/kg [21]. Surprisingly, comparison between assisted and NS (paired t-test with \(P = 0.0035\)) cases shows that just by adding compliance (with optimal stiffness) 14.7 ± 4.27% reduction in metabolic cost can be achieved. Compared to the normal walking without assistance (NE), the proposed passive exosuit can reduce the average metabolic rate by 4.68 ± 4.24%. More details can be found in [2].

4 Conclusion and Future Work

In this article, we summarized the key elements of designing passive assistive devices in (1) elasticity, (2) multi-articular arrangements, and (3) damping. We focused on the first two elements and, more specifically, on lower limb assistive devices. After presenting a brief overview of the developed devices and state-of-the-art, we detailed more about our passive exosuit with biarticular thigh springs.

In this device, we benefit from both elasticity and biarticular design. We showed that transferring energy from hip to knee and vice versa could result in metabolic cost reduction. In spite of about 13% increase in metabolic cost just by wearing the suit without compliant elements, involving the artificial biarticular thigh muscles (elastic bands) could reduce energy consumption even compared to normal walking (about 5%). These passive elements not only compensate for the effect of the imperfect design but also provide additional benefit for walking efficiency. We improved the design and manufacturing to minimize the effects of additional mass and other non-optimized mechanical parts of the wearable parts (without springs). The recent version was successfully tested in pilot experiments (not reported). Doing experiments with more subjects will be the next step.

In the here presented experiments, we only tested three stiffness values for each of the biarticular springs. Recently, Human-in-the-loop-Optimization (HILO) was introduced as a practical tool to optimize control parameters in the assistive devices [22]. This method can be used in the future to find the optimal stiffness with here presented exosuit.

References

Apparatus for facilitating walking, running, and jumping

H. Barazesh, M.A. Sharbafi, A biarticular passive exosuit to support balance control can reduce metabolic cost of walking. Bioinspiration & Biomimetics 15(3), 036009 (2020)

S.H. Collins, M. Bruce Wiggin, G.S. Sawicki, Reducing the energy cost of human walking using an unpowered exoskeleton. Nature 522(7555), 212 (2015)

A.J. Van Soest, A.L. Schwab, M.F. Bobbert, G.J. van Ingen Schenau, The influence of the biarticularity of the gastrocnemius muscle on vertical-jumping achievement. J. Biomech. 26(1), 1–8 (1993)

M.A. Sharbafi, C. Rode, S. Kurowski, D. Scholz, R. Möckel, K. Radkhah, G. Zhao, A.M. Rashty, Oskar von Stryk, A. Seyfarth, A new biarticular actuator design facilitates control of leg function in biobiped3. Bioinspiration & biomimetics 11(4), 046003 (2016)

A.J. Van den Bogert, Exotendons for assistance of human locomotion. Biomed. Eng. Online 2(1), 17 (2003)

S. Portnoy, A. Kristal, A. Gefen, I. Siev-Ner, Outdoor dynamic subject-specific evaluation of internal stresses in the residual limb: hydraulic energy-stored prosthetic foot compared to conventional energy-stored prosthetic feet. Gait & Posture 35(1), 121–125 (2012)

A. Naseri, M.M. Moghaddam, M. Gharini, M.A. Sharbafi, A novel adjustable damper design for hybrid passive ankle prosthesis. Actuators (2020)

M.C. Faustini, R.R. Neptune, R.H. Crawford, S.J. Stanhope, Manufacture of passive dynamic ankle-foot orthoses using selective laser sintering. IEEE Trans. Biomed. Eng. 55(2), 784–790 (2008)

M.M. Alemi, S. Madinei, S. Kim, D. Srinivasan, M.A. Nussbaum, Effects of two passive back-support exoskeletons on muscle activity, energy expenditure, and subjective assessments during repetitive lifting. Hum. Factors 62(3), 458–474 (2020)

B.F. Palmer, Artificial leg. US Patent (1846)

W. Van Dijk, H. Van der Kooij, E. Hekman, A passive exoskeleton with artificial tendons: design and experimental evaluation, in 2011 IEEE International Conference on Rehabilitation Robotics (IEEE, New York, 2011), pp. 1–6

R. Nasiri, A. Ahmadi, M.N. Ahmadabadi, Reducing the energy cost of human running using an unpowered exoskeleton. IEEE Trans. Neural Syst. Rehab. Eng. 26(10), 2026–2032 (2018)

M.A. Sharbafi, A.M.N. Rashty, C. Rode, A. Seyfarth, Reconstruction of human swing leg motion with passive biarticular muscle models. Hum. Movement Sci. 52, 96–107 (2017)

M.A. Sharbafi, H. Barazesh, M. Iranikhah, A. Seyfarth, Leg force control through biarticular muscles for human walking assistance. Front. Neurorobot. 12, 39 (2018)

M.A. Sharbafi, A. Seyfarth, FMCH: a new model for human-like postural control in walking, in 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) (IEEE, New York, 2015), pp. 5742–5747

H.-M. Maus, S.W. Lipfert, M. Gross, J. Rummel, A. Seyfarth, Upright human gait did not provide a major mechanical challenge for our ancestors. Nat. Commun. 1, 70 (2010)

M.A. Sharbafi, M.N. Ahmadabadi, M.J. Yazdanpanah, A.M. Nejad, A. Seyfarth, Compliant hip function simplifies control for hopping and running, in 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems (IEEE, New York, 2013), pp. 5127–5133

M.A. Sharbafi, A. Seyfarth, Stable running by leg force-modulated hip stiffness, in 5th IEEE RAS/EMBS International Conference on Biomedical Robotics and Biomechatronics (IEEE, New York, 2014), pp. 204–210

G. Zhao, M.A. Sharbafi, M. Vlutters, E. van Asseldonk, A. Seyfarth, Bio-inspired balance control assistance can reduce metabolic energy consumption in human walking. IEEE Trans. Neural Syst. Rehab. Eng. (2019)

A.T. Asbeck, S.M.M. De Rossi, I. Galiana, Y. Ding, C.J. Walsh, Stronger, smarter, softer: next-generation wearable robots. IEEE Rob. Autom. Maga. 21(4), 22–33 (2014)

J. Zhang, P. Fiers, K.A. Witte, R.W. Jackson, K.L. Poggensee, C.G. Atkeson, S.H. Collins, Human-in-the-loop optimization of exoskeleton assistance during walking. Science 356(6344), 1280–1284 (2017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Sharbafi, M.A. (2022). The Key Elements in the Design of Passive Assistive Devices. In: Moreno, J.C., Masood, J., Schneider, U., Maufroy, C., Pons, J.L. (eds) Wearable Robotics: Challenges and Trends. WeRob 2020. Biosystems & Biorobotics, vol 27. Springer, Cham. https://doi.org/10.1007/978-3-030-69547-7_4

Download citation

DOI: https://doi.org/10.1007/978-3-030-69547-7_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-69546-0

Online ISBN: 978-3-030-69547-7

eBook Packages: EngineeringEngineering (R0)