Abstract

Based on experimental and theoretical data, the possibility of using lead oxides in the production of radiation-protective materials based on building gypsum was established. The influence of lead oxides of various compositions, such as β-PbO, β-Pb3O4, and α-PbO2, on the physical, mechanical, and radiation-protective properties of gypsum composites was studied. It is established that the physical and mechanical characteristics of composite materials significantly depend on their structure, which in turn depends on the composition of lead oxide. The material based on BG and β-Pb3O4 consists of large gypsum crystals with a layered-batch structure. In contrast, the material based on BG and α-PbO2 is represented by elongated thin prismatic gypsum crystals wrapped in a fine-crystalline mass of filler. No new compounds were found in the construction gypsum lead oxides system, which indicates a weak interaction between the filler and the binder. A composite finishing material for biological protection against ionizing radiation with a linear attenuation coefficient of 1.76–2.11 cm−1 was obtained on the basis of building gypsum and lead oxides. Composites based on BG and β-Pb3O4 have higher strength characteristics than those based on other lead oxides, which is due to their high dispersion and the presence of lead atoms in different degrees of oxidation. Compositions of composite materials are proposed.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Composite materials

- Building gypsum

- Lead oxides of various compositions

- Structure

- Texture

- Hydration mechanism

- Radiation-protective properties of composites

1 Introduction

Radioactive radiation is successfully used in industry, energy, medicine, scientific research, production of building materials, obtaining new polymer materials, detection of defects in engineering communications, and other industries. The effectiveness of its use is not questioned by either scientists or specialists. However, the problems of protecting equipment and people from radiation exposure are always relevant and are under constant attention of scientists and the public [1].

The main part of radiation exposure (85%) the world’s population receives from natural sources of radiation. Technogenic radiation sources account for about 21% of the total population exposure [2]. These include: production of electric and thermal energy at nuclear power plants and portable nuclear power plants, the nuclear fuel cycle, non-destructive testing and quality control of products in industry, sterilization and pasteurization of items and products, control of technological processes, production of radionuclides for various needs, and other processes.

For protection against radiation, lead and materials with its compounds, especially lead oxide (II), are most often used. Such materials significantly weaken photon radiation, suppress gamma radiation, and neutralize short-wave electromagnetic radiation. As binders in radiation-protective composites, both inorganic binders (Portland cement, alumina cement, magnesia cement, glycerol cement, liquid glass, etc.) are used [2,3,4], and organic binders (polyurethane foam, polystyrene, polyethylene, epoxy, furan and polyester resins, etc.) [5,6,7].

Gypsum binders, widely used for finishing works, have not found their rightful place among the binders used in the production of radiation-protective materials yet. At the same time, works on their use have recently begun to appear more often [8, 9].

Purpose of Work.

To establish the possibility of obtaining materials for protection against ionizing radiation based on building gypsum and lead oxides.

2 Materials and Methods of Research

The following materials were used in the work: construction gypsum G-4 A II of JSC “Khabez gypsum plant” (\(\beta{-}{\rm{CaSO}}_{{4}} \cdot \, 0.{\rm{5H}}_{{2}} {\rm{O}}\)), lead oxides of the c.p specification β-PbO yellow, β-Pb3O4 red, α-PbO2 brown. The initial materials and the resulting composites were studied using x-ray phase analysis on a DRON-4 diffractometer in the range 2Θ = 4–56°, scanning electron microscopy on a high-resolution scanning electron microscope TESCAN MIRA 3 LMU, and laser granulometry on a MicroSizer 201 device. The mass attenuation coefficient was determined using a dosimeter-radiometer DKS-96. Physical and mechanical properties of gypsum binders were studied in accordance with GOST.

3 Results and Discussion

At the initial stage of the work, laser granulometry of the initial lead oxides was performed, as the size of the filler plays a decisive role in the formation of the structure of composite materials (Table 1).

It is established that the dependence of the particle size distribution for β-PbO and β-Pb3O4 is monomodal, and for α-PbO2 – bimodal. β-PbO has the largest particle size and, consequently, the smallest specific surface area. In contrast, β-Pb3O4 has the smallest particle size and the largest specific surface area. α-PbO2 is an intermediate position in these indicators. The studied lead oxides can be attributed to fine fillers. They have different dispersity and should behave differently in the composition of gypsum compositions.

To study the effect of the composition and amount of lead oxides on building gypsum (BG), the following compositions were used (Table 2).

Fine fillers can both increase and decrease the water-gypsum ratio (W/G) of B G. So, fine-ground waste glass reduces W/G [10], and blast furnace slag, water removal ash, expanded clay and bricks increase W/G. All the lead oxides under study are reduced W/G of BG. When the amount of lead oxide additive is 80 wt. % this decrease is 45.5% (Table 2).

Preliminary studies showed that additives β-Pb3O4 and α-PbO2 reduce the time of setting of BG, while β-PbO additives have almost no effect on them. To increase the time of setting of the BG, borax (Na2B4O7) was selected in the amount of 0.2 wt.%. Borax additives increase the strength and time of setting of the BG.

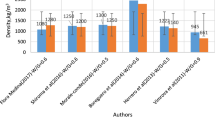

The effect of lead oxides on the mechanical compressive strength of BG is shown in Fig. 1. From the data obtained, it follows that small amounts of lead oxide additives (up to 10 wt. %) affect the strength of the BG slightly. Moreover, β-Pb3O4 and α-PbO2 increase slightly the strength of the BG. Increasing the amount of filler additive ˃ 10 wt. % leads to a decrease in the strength of BG. Composites based on BG and β-Pb3O4 have higher strength indicators than those based on other lead oxides. This is the course of the Rcom dependence. The dependence on the amount of filler additive is typical for systems with little interaction between the filler and the binder [11]. Good formability of materials based on β-Pb3O4 and α-PbO2 is noted, which is facilitated by the hydrophilicity of their surface and high dispersion. Composites based on BG and β-PbO are formed slightly worse, which is due to the large particle size of this filler.

The density of composites based on BG and lead oxides varies from 1200 kg/m3 (G-4) to 2000 kg/m3 (composition with 80% filler) and practically does not depend on the nature of lead oxide.

To analyze the phase composition of the obtained composites, x-ray analysis of BGPb-50 composites was performed. It is established that the composites consist of: gypsum (reflexes at interplanar distances, Å: 7.628; 4.291; 3.801; 3.069; 2.702); α-PbO2 (reflexes at interplanar distances, Å: 3.513; 2.801; 2.481; 1.855; 1.755); β-Pb3O4 (reflexes at interplanar distances, Å: 6.259; 3.389; 2.912; 2.793; 2.637); β-PbO (reflexes at interplanar distances, Å: 5.906; 3.074; 2.950; 2.747; 2.377). Non-hydrated BG (reflexes at interplanar distances, Å: 6.046; 3.480; 3.013; 2.810) was found in insignificant amounts in materials based on α-PbO2, and insoluble anhydrite (reflexes at interplanar distances, Å: 3.506; 2.858; 2.332; 2.209) in materials based on β-Pb3O4. At the same time, in systems based on β-Pb3O4, a certain distortion of the gypsum crystal lattice is observed which is expressed in an increase in the interplanar distance of the main reflexes on x-ray images and a change in their intensity. Thus, the RFA did not reveal the formation of new compounds in the BG-lead oxides system.

The structure of the obtained materials was studied using electron scanning microscopy. It is established (Fig. 2) that it depends on the nature of lead oxide. Thus, a material based on BG and α-PbO2 consists of elongated prismatic thin gypsum crystals, sometimes bundles of crystals, the gaps between which are filled with a fine-grained earthy mass α-PbO2 (Fig. 2 c). The structure of the composite based on BG and β-Pb3O4 is different and consists of larger plate-like gypsum crystals. The fine-crystalline mass is absent or present in insignificant amounts. There are more crystallization contacts in the material (Fig. 2 d).

At the standard water-gypsum ratio, the porosity of gypsum stone is 47–55% by volume. The structure of solidified gypsum stone is characterized by high communicating porosity. These are mostly macropores. The proportion of micropores in gypsum building materials is insignificant. Modification of gypsum binders with fine-ground fillers reduces the proportion of macropores in the material and improves the structure of composite materials.

To study the radiation-protective properties of the obtained composites, pure gypsum samples and BGPb-60 compositions were taken. The results of calculations of linear (µ) and mass (µm) attenuation coefficients are presented in Table 3.

The obtained data show that the linear attenuation coefficients of composites are one and a half or more times greater than those of BG. This allows concluding that the radiation-protective properties of composites are significantly better than those of BG.

4 Conclusion

A composite finishing material for biological protection against ionizing radiation with a linear attenuation coefficient of 1.76–2.11 cm−1 was obtained from building gypsum and lead oxides. It is shown that the nature of lead oxide affects the strength and density of composite materials to a lesser extent than their granulometry. In the process of hydration and hardening of the composite, lead oxides do not change their texture and structure, but affect the formation and growth of gypsum crystals. The material based on BG and β-Pb3O4 consists of large gypsum crystals with a layered-batch structure. In contrast, the material based on BG and α-PbO2 is represented by elongated thin prismatic gypsum crystals wrapped in a fine-crystalline mass of filler.

References

Dubrovsky, V.B.: Radiation Resistance of Building Materials. Stroyizdat, Moscow (1977)

Veselkin, A.P., Voskresensky, E.V., Egorov, V.: Research of protective properties of concrete of different compositions: monograph. Questions of reactor protection physics. Atomizdat, Moscow (1974)

Eger, T.: Concrete in the Technique of Protection from Radiation. Atomizdat, Moscow (1960)

Mashkovich, V.P., Kudryavtsev, A.V.: Protection from Ionizing Radiation. Energoatomizdat, Moscow (1995)

Li, I., Sidorov, Yu.D.: Material for protection against x-ray radiation based on a polymer composition and lead oxides. Bull. BSTU Named After V.G. Shukhov 6, 11–16 (2016)

Pavlenko, V.I., Lipkansky, V.M., Yastrebinsky, R.N.: Structural defects of amorphous-crystalline phases based on lead organosiloxanes. Radiation physics of a solid body. MIEM, Moscow (2003)

Khakimullin, Yu.N., Abdullin, I.Sh., Galimzyanova, R.u., Ruchkin, A.V.: Polymer composition resistant to ionizing radiation. Pat. 2515558 RF 13 (2015)

Khezhev, T.A., Pukharenko, Y.V., Khezhev, K.A., Klyuev, S.V.: Fiber gypsum concrete composites with using volcanic tuffsawing waste. ARPN J. Eng. Appl. Sci. 13(8), 2935–2946 (2018)

Klimenko, V.G., Chernyshev, A.Z., Strelnikov, A.I.: Modification of Magnesia Binder with Iron Ore Concentrate. Mater. Sci. Forum 974, 113–118 (2019)

Klimenko V.G., Pavlenko V.I., Gasanov S.K.: Acid-base interactions in gypsum glass systems Bull. BSTU Named After V.G. Shukhov 5, 77–81 (2015)

Klimenko, V.G.: Influence of modifying composition of gypsum binders on the structure of composite materials. J. Phys. Conf. Ser. 1118, 012019 (2018)

Acknowledgements

This work was realized in the framework of the Program of flagship university development on the base of the Belgorod State Technological University named after V.G. Shukhov, using equipment of High Technology Center at BSTU named after V.G. Shukhov.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Klimenko, V.G., Volodchenko, A.N., Sidelnikov, R.V. (2021). Lead Oxides as Fillers of Composite Materials for Protection Against Ionizing Radiation Based on Building Gypsum. In: Klyuev, S.V., Klyuev, A.V. (eds) Proceedings of the International Conference Industrial and Civil Construction 2021. ICICC 2021. Lecture Notes in Civil Engineering, vol 147. Springer, Cham. https://doi.org/10.1007/978-3-030-68984-1_30

Download citation

DOI: https://doi.org/10.1007/978-3-030-68984-1_30

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-68983-4

Online ISBN: 978-3-030-68984-1

eBook Packages: EngineeringEngineering (R0)