Abstract

Within the framework of linear nonequilibrium thermodynamics, we construct a new model of the diffusion of a gas component into a solid under thermo-mechanical loads. Assuming that we have a linear elastic behaviour of the solid, we obtain a local balance equation for the diffusion of the gas component, which takes into account the stress–strain state of the solid and its mutual influence on the diffusion process, the temperature in the system, and the concentration of the gas component infiltrated into the solid. We specify the model for the case of hydrogen diffusion into metal. The solution of the obtained differential equation shows that taking into account the stress–strain state strongly affects the distribution of hydrogen inside the metal. We found that the concentration quickly increases at the boundary layer, in which the hydrogen concentration exceeds the amount in bulk by more than a hundred times, which is consistent with experimental data on the skin effect when metals are saturated with hydrogen.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

9.1 Introduction

Hydrogen embrittlement of metals has been of scientific interest for more than a hundred years [1]. Many works, including those held in recent years, consider the critical local concentrations resulting from infiltration of hydrogen into metals from the aggressive corrosive environment. The data of Safronis [2] is recognized as the main source. Quantitative measurements of microstructural distributions of hydrogen in metals are difficult. The Ag Decoration Method [3, 4] and other similar approaches cf. [5] provide only a qualitative map of the distribution of hydrogen. In the work of Safronis, the threshold local concentrations of hydrogen at which the influence of the HELP mechanism of hydrogen embrittlement begins is indicated as 0.1 H/M. This is equivalent to mass concentrations in 1500–9000 ppm range for different metals. However, this value is very high for most metals used nowadays. As technologies approach the extremely possible mechanical and chemical characteristics of metals and alloys, the maximum permissible concentration of hydrogen in modern alloys becomes about 50–100 times lower than in traditional [6]. Moreover, experiments based on mass spectrometry and electron microscopy also show that the presence of water vapour in the air, as well as aggressive environments, may serve as a source of hydrogen. Metals may absorb it, reducing their fracture toughness and strength [7].

Measurements of the hydrogen concentration profile in metals, both in aggressive environments and in the air [8,9,10,11] show that the hydrogen concentration at the boundary layer is tens or even hundreds of times higher than the concentration hydrogen in the entire volume of the metal, thereby creating some boundary layer. Recent experimental work [12,13,14] show that it is this thin layer of about 100 \(\upmu \)m that has the main impact on the mechanical and strength properties of the metal.

Thus, modelling a thin boundary layer as a result of hydrogen diffusion from the environment and describing the mutual influence of the diffusion process on the mechanical properties of the metal is of considerable theoretical and practical interest.

There are some models of diffusion in solid bodies, which describe the ordinary forms of samples in a simple and stress–strain state. These models have a simplified design with only one specific mechanism of hydrogen redistribution. However, experiments show that hydrogen not only diffuses through a crystalline matter of metal but also redistributes in trap modes. This hydrogen redistribution proceeds according to several different variants [9, 15,16,17]. Therefore, the diffusion of hydrogen in metal should be considered as multichannel. Moreover, most authors use a trap model of diffusion (the fundamental works [18, 19] and many others, for example, [20,21,22,23,24]), where micro traps have different nature and characteristics of thermo-mechanical loads applied to the material. Such models are specific and do not adequately describe all the various experimental data. This leads to the fact that the diffusion coefficients of hydrogen in reference books differ by several orders of magnitude at the same temperature (for example, [25]).

One should also note that most trap and volumetric diffusion models were verified for small gradients of hydrogen concentration in the material. This does not allow one to take into account the almost hundred times difference in the levels of hydrogen concentration inside metal samples observed experimentally and requires substantial modification of these models.

The mechanism of local hydrogen plasticity was first described in [26] (HELP model). Later, in [2] and [27, 28], based on physical considerations about the potentials of the interaction of hydrogen with dislocations, the governing equations of the material were obtained. However, there are several uncertainties in this model. In particular, the authors neglect the nonlinear dependence of the internal potential on the magnitude of the stresses and hydrogen concentration, but at the same time, they consider large local hydrogen concentrations at which all nonlinearities should play a decisive role. It should be noted that only some metals such as zirconium allow saturation with hydrogen up to the HELP mechanism triggering concentrations of 0.1 H/M and higher without spontaneous destruction. Moreover, work [29] notes that the HELP model requires significant computational resources in solving any applied problem. The solution to this problem is to use a continuum model of the development of the dislocation. However, such a replacement is often inadequate. Therefore, the authors of the HELP model reduce all hydrogen problems in modelling the development of cracks and reducing crack resistance.

Recent publications that study the deformation and fracture of metals under mechanical stress in hydrogen-containing media [30,31,32] do not consider the process of hydrogen diffusion from the external environment. The models there were obtained heuristically and therefore cannot serve in the future as a basis for developing complex models which fully describe the process of hydrogen infiltration and diffusion.

Some works consider the hydrogen diffusion in metals which is not affected by any thermo-mechanical loads [33, 34]. They are focused on the influence of large plastic deformations on the redistribution of dissolved hydrogen [35,36,37], the influence of diffusively mobile hydrogen on the hydrogen embrittlement development [38, 39].

In this work, we make the first step of building a theoretical model to describe the heterogeneous distribution of the hydrogen and formation of a thin boundary layer in metal. Within the framework of linear nonequilibrium thermodynamics, we obtain a modified local equation of balance of the diffusion component. This equation takes into account the mutual influence of diffusion and the stress–strain state, as well as the dependence of the diffusion process on temperature, gas concentration and other thermomechanical loads.

As the first attempt to start the description of hydrogen diffusion in metals and see how that approach works, we restrict ourselves to an isotropic linear continuum for the metal and abandon the diffusion of hydrogen in trap modes. The first assumption corresponds to the case when hydrogen concentrations are not large enough to cause plastic deformations. The assumption that there are no hydrogen traps in our model will not considerably affect the results since it is known mostly hydrogen with low binding energy (i.e. diffusively mobile hydrogen) affects the stress–strain state of metal [40] and vice versa, zones of tensile stresses ‘attract’ low-binding hydrogen (the so-called Gorsky effect, [41]).

The constructed model is verified on the boundary problem of determining the stress-strain state of a cylindrical sample under uniaxial tension and the distribution of gas concentration. We use the results to estimate the possibility of further complicating the model to describe the formation of the experimentally observed boundary layer.

9.2 Problem Statement and Governing Equations

9.2.1 Chemical Potential

One of the most common ways of describing the diffusion process, taking into account the effect of temperature, heat fluxes, the local concentration of the diffusion component and the stress-strain state of a solid in which diffusion occurs, is the theory of chemical potential. Introduced by Onsager and Prigogine [42, 43] for multicomponent mixtures of diffusing gases, it has been used for solids, as well as for various diffusion systems under different thermo-mechanical loads.

Within the framework of linear nonequilibrium thermodynamics, one may consider various thermo-mechanical loads which affect a system of a diffusing gas in a solid. The chemical potential can include the influence of a stress-strain state of solid, plastic deformations, heat fluxes in the system, trapping modes and other effects that influence the diffusion process. One can note that, although some phenomena cannot be introduced non-phenomenologically (for example, plasticity or the influence of trapping modes), the theory of chemical potential is the only theory that allows one to take into account all these effects within the framework of one approach. This makes it possible not to introduce additional restrictions on the range of external conditions to keep the model corresponding to the experiment. Moreover, even the phenomenological account of any effect in the chemical potential is carried out following the basic principles of mechanics and thermodynamics. For example, the effect of plasticity can be considered through the deformations (using the decomposition of the deformation gradient into elastic and plastic parts) or by introducing an additional term into the bulk energy of a solid and taking into account the dissipation of this energy under plastic effects.

In this work, we verify the basic principles of the theory of chemical potentials and consider how diffusion is affected by small linear elastic deformations in a solid material, as well as how strongly these deformations affect the diffusion process. We also want to figure out whether they can explain the skin effect, observed in the diffusion of hydrogen into metals from the environment. In this work, we neglect the phenomena of plasticity, trap modes and other phenomena.

Following the non-equilibrium linear thermodynamic approach, we define diffusion flux \(\varvec{j}\) as

where D is a diffusivity constant, c is the concentration, R is the gas constant, T is a temperature and \(\mu \) is the chemical potential of the diffusing gas. The chemical potential of the ideal gas in vacuum is equal to

Here, \(c_*\) is some concentration of normalization and \(\mu _0\)—the reference chemical potential.

The chemical potential of the diffusing constituent consists of the chemical potential of the gas itself, as well as of other terms that affect the diffusion process. They enter the Eq. (9.1) as terms in general chemical potential of the diffusing component. For now, we consider only the influence of the stress–strain state of the solid on the diffusion.

We will consider the chemical potential of the solid in its full form [44, 45], since taking into account only the first term of expansion or term, associated only with pressure (as it is done in a lot of works, for example, [46]) imposes strong restrictions on the range of external conditions. The full chemical potential of a solid is defined as the (canonical) Eshelby stress tensor

where M is a molar mass of a solid, \(\rho \) is its density, f is a density of a bulk energy (\( f = w /\rho \)), \(\varvec{F}\) is a deformation gradient and \(\varvec{S}\) is a Piola-Kirchhoff stress tensor.

Since we do not have any phase transitions or moving boundary, the diffusion flux, induced by the stress-strain state of the solid, is proportional to the trace of the chemical potential tensor [47, 48]. The full diffusion flux is equal to

9.2.2 Case of Linear-Elastic Strains

In this work, we consider the linear elastic behaviour of the solid. We do not solve any heat equations and consider temperature T as a constant, and neglect all effects of plasticity and trapping.

In the case of linear elastic strain,

where \(\eta \) is the free energy volume density of the stress-free solid (so-called chemical energy) and depends only on temperature.

Thus, we can write an expression for the \(\mu _s = tr\varvec{\mu }_s\):

Here, we denote elastic strains as \(\varvec{\varepsilon }_e\), \(\varvec{\sigma }\) is the Cauchy stress tensor and \(\varvec{C}\) is the stiffness tensor. We set \(\varvec{\varepsilon _*}\) for strains, induced by the diffused gas into the solid, \(\varvec{\varepsilon _*} = \varvec{\varepsilon _*}(c)\). Thus, following Hooke’s law for linear elastic behaviour of material, we obtain

As \(\eta (T)\) does not depend on coordinate and we consider that change of density of solid body \(\rho \) is insignificant, for the gradient of chemical potential, induced by solid body, finally we have that

As we consider our body as isotropic, we use stiffness tensor with two constants, Young’s modulus E and Poisson’s ratio \(\nu \). We also follow the ideas from the problems of thermal elasticity and set deformation, induced by the diffused gas component, proportional to the concentration: \(\varvec{\varepsilon _*} = \alpha c \varvec{E}\). So, we obtain

Finally, we recall that \(\nabla \cdot \varvec{j} = \frac{\partial c}{\partial t}\) and substitute obtained expressions for the chemical potential into the (9.4). After opening brackets, we get the diffusion equation:

where

In this new diffusion equation, the coefficient at the concentration gradient (diffusion coefficient) is not a constant value. It depends on the stress–strain state of solid, elastic constants, the concentration of the gas component in the solid (metal) and the temperature in the system. In the diffusion equation, we also obtain an additional term which is proportional to the gas concentration. The proportionality coefficient also depends on the thermo-mechanical loads in the system. This term is a force that decelerates the diffusion and rises when the concentration in the solid increases. One should also notice that all the deformations have an influence on the diffusion process, and therefore approximation with the first term of decomposition and spherical part of the Cauchy stress tensor is not relevant.

We can also note that the resulting equation does not impose any restrictions on the values of temperatures, deformations, elastic moduli, concentration values and gradients of concentration and deformations inside the body, except that we take such a deformation field to remain within the framework of the linear theory of elasticity.

9.3 Boundary-Value Problem for Axially-Symmetric Body

Since most of the experiments are performed on cylindrical samples, in which tensile stresses are applied along the axis of symmetry, we consider the boundary value problem for a cylinder under uniaxial tension. Suppose it is located so that the symmetry axis is directed along the 0z axis, and we can define the cylinder as \( z \in [-h, h]; r \in [0, r_{o}] \) (Fig. 9.1). We believe that its linear dimensions with respect to z significantly exceed the radius \( r_{o} \), and therefore, the cylindrical sample is in a plane-deformed state before the diffusion process begins. We consider that \(u_r = u_r(r)\) and does not depend on z-coordinate.

We also assume that the hydrogen infiltrates only from the side surface, and due to the stress–strain state and the symmetry concentration depends only on the r-coordinate, \(c = c(r)\).

The elasticity equation in cylindrical coordinates will look as follows:

Here, \(\sigma _r, \sigma _\varphi \) and \(\tau _{rz}\) are the components of the Cauchy stress tensor:

The boundary conditions are prescribed tensile uniaxial stress and stress-free side surface:

The diffusion equation will look as follows:

where

The boundary condition is the prescribed concentration at the outer surface of the body:

The initial condition is the absence of the concentration in the body:

One should note that we have terms that depend on the concentration in the elastic problem and the coefficients that depend on deformations (both in r- and in z-directions) in the diffusion equation. Thus, we have the coupled problem, and these two equations cannot be solved separately.

9.4 Numerical Solution and Discussion

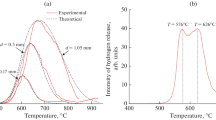

The boundary problem (both elasticity problem and diffusion equation) is solved numerically using the explicit finite difference scheme, which corresponds to the finite volume method. Experimental data is taken from [49] for steel T24. Parameter \(\alpha \) corresponding to the expansion due to the hydrogen diffusion is chosen to keep deformations in the linear elastic area. All parameters are presented in Table 9.1.

Since we consider the capabilities of the presented model, we can neglect possible inaccuracies or inconsistencies in the parameters and consider them as parameters of some model material.

We were able to perform calculations only for the timeless than 6 h: after this time the stresses near the boundary layer start to exceed linear elasticity and the stress–strain state of the steel should be described within the plasticity theory. Due to these restrictions, we investigate only the beginning of the diffusion process.

The two main parameters governing the diffusion process are the effective diffusivity coefficient \(D_{\text {eff}}\) and the coefficient at the linear concentration term V. They both depend on the hydrogen concentration and the deformation values.

The value of the diffusivity coefficient significantly depends on the hydrogen concentration and the stress–strain state of the steel, since the value of the effective diffusivity coefficient differs within the sample by almost ten times (see Fig. 9.2). It can also be noted that the effective diffusion coefficient increases with time and the rate of its growth is variable and decreases with time. The profile of the effective diffusion coefficient dependence on the coordinate practically does not change.

The concentration coefficient V in the second term of the (9.10) equation is very small (of the order of 1e5) and does not vary much with time, thus practically without exerting any influence on the diffusion process. In further studies of the model in the theory of small deformations, this term can be neglected. It should be noted that the real deformations arising from expansion due to the hydrogen infiltration into the steel are not small and exceed 3%, therefore, we can say that the coefficient V begins to influence the diffusion process at large finite deformations and significant gradients of them.

Although at short times hydrogen infiltrates into the metal rather quickly, from Fig. 9.3 we see that after some time the process of hydrogen redistribution slows down, and then with increasing time the distribution of hydrogen concentrations changes insignificantly. We can also notice that yet the diffusivity coefficient is still large at this boundary zone, the diffusivity coefficient in the bulk is significantly smaller (Fig. 9.2). This leads to the higher saturation with hydrogen of the boundary layer and not the propagation of the concentration profile deeper.

This experimentally observed effect is usually associated with the filling of hydrogen traps inside the crystal lattice of the metal. However, the experimentally observed multiple difference between the hydrogen concentration in the central and near-boundary parts of the samples is often inexplicable, since the experimental samples are made so that mechanical treatment does not violate the initial homogeneity of the metal throughout the volume of the sample. In our model, we obtain the blocking effect at saturation with hydrogen from the general propositions of nonlinear nonequilibrium thermodynamics, which was previously described only with the help of empirical or phenomenological terms introduced into the diffusion equation.

The obtained concentration profile inside the metal is highly nonuniform: the concentration values near the boundary and in a thin boundary layer are hundreds of times higher than the concentration inside the sample. This indicates the agreement of the model with the experiment and describes the experimentally observed boundary layer as part of the skin effect.

An increase in tensile axial stresses does not significantly change the diffusion process and the concentration profile (Fig. 9.4). With an increase in tensile stresses, diffusion proceeds faster, accelerating significantly at stresses close to the yield point. This is due to both the fact that the crystal lattice of the metal expands, allowing hydrogen molecules to diffuse into the metal with less resistance, and with the fact that stretching along the axis of symmetry reduces the value of the locking stresses, thereby weakening the locking effect.

9.5 Conclusions

We have built a new model of the diffusion of the gas component into a solid based on the theory of chemical potentials and the principles of linear nonequilibrium thermodynamics. We took the trace of the Eshelby energy–momentum tensor in its full form as the chemical potential of a solid body. To evaluate the effect of deformations in a solid, we considered the case of linear elasticity and did not consider plasticity, heat effects, and large deformations. We also took into account the deformations that arise as a result of hydrogen diffusion inside the solid and introduced the spherical tensor of diffusion deformations, which is linearly proportional to the concentration.

As a result, we obtained an equation for the local balance of the diffusion component, which takes into account the dependence of the diffusion process on the stress-strain state of the solid, the concentration of the gas component inside it, and other thermo-mechanical loads. The new diffusion equation is a modified Fick’s equation with a non-constant diffusivity coefficient and an additional term in the expression for the diffusion flow, which is linearly proportional to the concentration of the gas component, and the proportionality coefficient also depends on the deformations in the solid and the concentration of the gas component.

Using the finite volume method, we obtained a numerical solution of the coupled boundary value problem of determining the stress–strain state of a cylindrical steel sample under uniaxial tension and the distribution of diffused hydrogen concentration. We found that hydrogen quickly saturates a thin boundary zone, and with time the concentration profile only moves deeper practically unchanged into the sample.

As a result of hydrogen diffusion into the steel, large deformations arise inside the sample. They significantly increase the diffusion coefficient. Thus, saturation of the thin layer occurs faster, than further propagation of the concentration profile into the sample. This locking effect is also observed experimentally. Earlier in the literature, this locking effect was explained by the presence of traps which were phenomenologically introduced into the model. We describe this locking effect from the first principles.

In addition, we found that in the case of small linear deformations, the term proportional to the concentration is small and practically does not change with time, which suggests that the effect of this term in the case of small deformations can be neglected. This result can be used with further complications of the model; however, in the case of large strains and large strain gradients, this term is likely to have a significant effect.

To study the diffusion process completely, it is necessary to add plasticity to the model, since deformations corresponding to plastic deformations arise in the sample with further saturation with hydrogen. In this work, we investigated diffusion at short times (up to 6 h).

The resulting diffusion model is the first step to build a complete model of hydrogen diffusion into metals from the environment. Further improvements of the model can be taking into account plastic deformations, metal inhomogeneities and associated internal stresses.

References

Cailletet, L., et al.: First report of H embrittlement of metals. Compt. Rend 58, 327 (1864)

Sofronis, P., Liang, Y., Aravas, N.: Hydrogen induced shear localization of the plastic flow in metals and alloys. Eur. J. Mech.-A/Solids 20(6), 857–872 (2001)

Ronevich, J., Spee,r J., Krauss G., Matlock D.: Improvement of the hydrogen microprint technique on AHSS steels. Metallogr. Microstruct. Analys.1(2), 79–84 (2012)

Akiyama, E., Matsuoka, S.: Hydrogen visualization in steels using Ag decoration method. Mater. Trans. 56(6), 793–797 (2015)

Evers, S., Senöz, C., Rohwerder, M.: Hydrogen detection in metals: a review and introduction of a Kelvin probe approach. Sci. Technol. Adv. Mater. 14(1), 14201 (2013)

Nie, Y., Kimura, Y., Inoue, T., Yin, F., Akiyama, E., Tsuzaki, K.: Hydrogen embrittlement of a 1500-MPa tensile strength level steel with an ultrafine elongated grain structure. Metallurg. Mater. Trans.A 43(5), 1670–1687 (2012)

Khrustalev, Y.A., Simakov, Y.S., Glazunov, M., Gubin, V.: Formation of hydrogen under the metal friction. Zhurnal Fizicheskoi Khimii 63(5), 1355–1357 (1989)

Frolova, K., Vilchevskaya, E., Polyanskiy, V., Alekseeva, E.: Modelling of a hydrogen saturated layer within the micropolar approach. In: Abali, B., Altenbach, H., dell’Isola, F., Eremeyev, V., Öchsner, A. (eds.) New Achievements in Continuum Mechanics and Thermodynamics, vol. 108, pp. 117–128. Springer, Cham (2019)

López-Suárez, A., Valencia, C.E., López-Patiño, J., Vargas, M.C., Fuentes, B.E.: Improvement of titanium hydrogenation by low energy ion irradiation. Int. J. Hydrogen Energy 40(11), 4194–4199 (2015)

Wu, T.I., Wu, J.C.: Effects of cathodic charging and subsequent solution treating parameters on the hydrogen redistribution and surface hardening of Ti-6Al-4V alloy. J. Alloys Compounds 466(1–2), 153–159 (2008)

Martinsson, Åsa, Sandström, R.: Hydrogen depth profile in phosphorus-doped, oxygen-free copper after cathodic charging. J. Mater. Sci.47(19), 6768–6776 (2012)

Arseniev, D., Belyaev, A., Polyanskiy, A., Polyanskiy, V., Yakovlev, Y.: Benchmark study of measurements of hydrogen diffusion in metals. In: Dynamical Processes in Generalized Continua and Structures, pp. 37–61. Springer (2019)

Polyanskiy, V., Belyaev, A., Alekseeva, E., Polyanskiy, A., Tretyakov, D., Yakovlev, Y.A.: Phenomenon of skin effect in metals due to hydrogen absorption. Continuum Mechan. Thermodyn. 31(6), 1961–1975 (2019)

Andronov, D.Y., Arseniev, D., Polyanskiy, A., Polyanskiy, V., Yakovlev, Y.A.: Application of multichannel diffusion model to analysis of hydrogen measurements in solid. Int. J. Hydrogen Energy 42(1), 699–710 (2017)

Hadam, U., Zakroczymski, T.: Absorption of hydrogen in tensile strained iron and high-carbon steel studied by electrochemical permeation and desorption techniques. Int. J. Hydrogen Energy 34(5), 2449–2459 (2009)

Turnbull, A.: Perspectives on hydrogen uptake, diffusion and trapping. Int. J. Hydrogen Energy 40(47), 16961–16970 (2015)

Liu, Q., Venezuela, J., Zhang, M., Zhou, Q., Atrens, A.: Hydrogen trapping in some advanced high strength steels. Corrosion Sci. 111, 770–785 (2016)

Oriani, R.A.: The diffusion and trapping of hydrogen in steel. Acta Metallurgica 18(1), 147–157 (1970)

McNabb, A., Foster, P.: A new analysis of diffusion of hydrogen in iron and ferritic steels. Trans. Metallurg. Soc. AIME 227(3), 618 (1963)

Oudriss, A., Creus, J., Bouhattate, J., Conforto, E., Berziou, C., Savall, C., Feaugas, X.: Grain size and grain-boundary effects on diffusion and trapping of hydrogen in pure nickel. Acta Materialia 60(19), 6814–6828 (2012)

Toribio, J., Kharin, V.: A generalised model of hydrogen diffusion in metals with multiple trap types. Philos. Magaz. 95(31), 3429–3451 (2015)

Takahashi, J., Kawakami, K., Kobayashi, Y.: Origin of hydrogen trapping site in vanadium carbide precipitation strengthening steel. Acta Materialia 153, 193–204 (2018)

Depover, T., Van den Eeckhout, E., Verbeken, K.: Hydrogen induced mechanical degradation in tungsten alloyed steels. Mater. Characterization 136, 84–93 (2018)

Zhang, Z., Moore, K.L., McMahon, G., Morana, R., Preuss, M.: On the role of precipitates in hydrogen trapping and hydrogen embrittlement of a nickel-based superalloy. Corrosion Sci. 146, 58–69 (2019)

Grigoriev, I., Meylichov, E.: Phizicheskie velichiny (The physical quantities). Energoizdat, Moscow (1991)

Birnbaum, H.K., Sofronis, P.: Hydrogen-enhanced localized plasticity—a mechanism for hydrogen-related fracture. Mater. Sci. Eng.: A 176(1–2), 191–202 (1994)

Delafosse, D., and Magnin, T.: Interfaces in stress corrosion cracking: a case study in duplex stainless steels. In: Solid State Phenomena, vol. 59, pp. 221–250. Trans Tech Publ (1998)

Delafosse, D., Magnin, T.: Hydrogen induced plasticity in stress corrosion cracking of engineering systems. Eng. Fracture Mech. 68(6), 693–729 (2001)

Ignatenko, A., Pokhodnya, I., Paltsevich, A., Sinyuk, V.: Dislocation model of hydrogen-enhanced localizing of plasticity in metals with BBC latttice. Paton Welding J. 3, 15–19 (2012)

Yamabe, J., Yoshikawa, M., Matsunaga, H., Matsuoka, S.: Hydrogen trapping and fatigue crack growth property of low-carbon steel in hydrogen-gas environment. Int. J. Fatigue 102, 202–213 (2017)

Yamabe, J., Yoshikawa, M., Matsunaga, H., Matsuoka, S.: Effects of hydrogen pressure, test frequency and test temperature on fatigue crack growth properties of low-carbon steel in gaseous hydrogen. Procedia Structural Integrity 2, 525–532 (2016)

Yamabe, J., Takakuwa, O., Matsunaga, H., Itoga, H., Matsuoka, S.: Hydrogen diffusivity and tensile-ductility loss of solution-treated austenitic stainless steels with external and internal hydrogen. Int. J. Hydrogen Energy 42(18), 13289–13299 (2017)

Díaz, A., Alegre, J., Cuesta, I.: Coupled hydrogen diffusion simulation using a heat transfer analogy 115, 360–369 (2016)

Jemblie, L., Olden, V., Akselsen, O.: A coupled diffusion and cohesive zone modelling approach for numerically assessing hydrogen embrittlement of steel structures. Int. J. Hydrogen Energy 42(16), 11980–11995 (2017)

Charles, Y., Nguyen, H., Gaspérini, M.: FE simulation of the influence of plastic strain on hydrogen distribution during an U-bend test. Int. J. Mech. Sci. 120, 214–224 (2017)

Cui, T., Liu, P., Gu, C.: Finite element analysis of hydrogen diffusion/plasticity coupled behaviors of low-alloy ferritic steel at large strain. Int. J. Hydrogen Energy 42(31), 20324–20335 (2017)

Sezgin, J.-G., Bosch, C., Montouchet, A., Perrin, G., Wolski, K.: Modelling of hydrogen induced pressurization of internal cavities. Int. J. Hydrogen Energy 42(22), 15403–15414 (2017)

Saini, N., Pandey, C., Mahapatra, M.: Effect of diffusible hydrogen content on embrittlement of P92 steel. Int. J. Hydrogen Energy 42(27), 17328–17338 (2017)

Stashchuk, M., Dorosh, M.: Analytical evaluation of hydrogen induced stress in metal. Int. J. Hydrogen Energy 42(9), 6394–6400 (2017)

Polyanskiy, A.M., Polyanskiy, V.A., Yakovlev, Y.A.: Issledovaniye ppotsessov ustalosti i pazpusheniya metallicheskikh matepialov s ppivlecheniyem metoda oppedeleniya enepgii svyazi vodoroda v tverdom tele (Investigation of the processes of fatigue and destruction of metal by method for determining of the binding energy of hydrogen in solid) 3, 39–43 (2009)

Gorsky, W.S.: Theorie der elastischen Nachwirkung in ungeordneten Mischkristallen (elastische Nachwirkung zweiter Art). Physikalische Zeitschrift der Sowjetunion 8, 457–471 (1935)

Onsager, L.: Reciprocal relations in irreversible processes I. Phys. Rev. 37(4), 405 (1931)

Glansdorff, P., Prigogine, I.: On a general evolution criterion in macroscopic physics. Physica 30(2), 351–374 (1964)

Larché, F., Cahn, J.: The effect of self-stress on diffusion in solids. Acta Metallurgica 30(10), 1835–1845 (1982)

Larché, F. and Voorhees, Peter W.: Diffusion and stresses: basic thermodynamics. In: Beke, D.L. and Szabó, I.A. (eds.) Defect and diffusion forum, vol.129, pp. 31–36. Trans Tech Publ (1996)

Drexler, A., Bergmann, C., Manke, G., Kokotin, V., Mraczek, K., Pohl, M., Ecker, W.: On the local evaluation of the hydrogen susceptibility of cold-formed and heat treated advanced high strength steel (AHSS) sheets. Mater. Sci. Eng.: A 140276 (2020)

Wu, C.H.: The role of Eshelby stress in composition-generated and stress-assisted diffusion. J. Mech. Phys. Solids 49(8), 1771–1794 (2001)

Maugin, G.A.: On the thermomechanics of continuous media with diffusion and/or weak nonlocality. Archive Appl. Mech. 75(10–12), 723 (2006)

Rhode, M., Mente, T., Steppan, E., Steger, J. and Kannengiesser, T.: Hydrogen trapping in T24 Cr-Mo-V steel weld joints–microstructure effect vs. experimental influence on activation energy for diffusion. Welding in the World 62(2), 277–287 (2018)

Acknowledgements

The work was supported by the Russian Science Foundation (RCF), grant number 18-19-00160.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Grigoreva, P.M., Vilchevskaya, E.N., Polyanskiy, V.A. (2021). Influence of Linear Elastic Stresses on Hydrogen Diffusion into Metals. In: Polyanskiy, V.A., Belyaev, A.K. (eds) Advances in Hydrogen Embrittlement Study. Advanced Structured Materials, vol 143. Springer, Cham. https://doi.org/10.1007/978-3-030-66948-5_9

Download citation

DOI: https://doi.org/10.1007/978-3-030-66948-5_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-66947-8

Online ISBN: 978-3-030-66948-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)