Abstract

It is well understood that twinning during deformation plays an important role in deformation of Mg and its alloys [1,2,3,4,5,6,7,8]. In hexagonal close packed (HCP) Mg alloys, the dominant deformation mode at room temperature is <a> slip on the basal (0001) plane Mg [9, 10]. The other slip systems—prismatic <a> slip, pyramidal <a> slip, and pyramidal <c + a> slip—require much higher stresses to activate during deformation [11]. Mechanical twinning allows for grains to easily deform along their c-axis [12] and has been the focus of significant, active research [e.g., 13–23].

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

It is well understood that twinning during deformation plays an important role in deformation of Mg and its alloys [1,2,3,4,5,6,7,8]. In hexagonal close packed (HCP) Mg alloys, the dominant deformation mode at room temperature is <a> slip on the basal (0001) plane Mg [9, 10]. The other slip systems—prismatic <a> slip, pyramidal <a> slip, and pyramidal <c + a> slip—require much higher stresses to activate during deformation [11]. Mechanical twinning allows for grains to easily deform along their c-axis [12] and has been the focus of significant, active research [e.g., 13–23].

In unalloyed Mg and Mg alloys, with a c/a ratio less than the ideal value of 1.633, the \( \left\{ {10\bar{1}2} \right\}\langle 10\bar{1}1\rangle \) extension twinning is the dominant deformation mode, where extension along the c-axis can be accommodated, but not contractions along that same direction [16, 24]. As a result, during mechanical loading the tensile yield strength is significantly higher than the compressive yield strength resulting in a tension–compression asymmetry [25]. Begum et al., found that the tensile yield strength was much higher than the compressive yield strength during low-cycle fatigue (LCF) of an AM30 extruded Mg alloy and related this to twinning that occurs during compression and detwinning that occurs during tension [5]. During compression, twins form causing an 86.3° reorientation of the basal pole [9, 11, 15, 22]. During reversed unloading or tensile loading these twinned regions can undergo detwinning in which twins become narrower and/or disappear [11, 25, 26]. Detwinning causes a reorientation of the c-axis from the twin back to the matrix or parent grain [9, 25,26,27]. Twins can reappear upon reloading and thus, the twinning-detwinning behavior continues until the end of life [28].

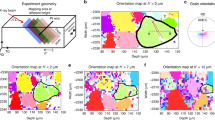

In this study, the twinning detwinning behavior of extruded, polycrystalline unalloyed Mg under cyclic loading conditions was investigated at the Cornell High Energy Synchrotron Source (CHESS) using in-situ high energy X-ray diffraction. Measurements were conducted at three different strain amplitudes. The initial crystallographic texture was such that the c-axis in most grains was normal to the loading direction and therefore, favorable for extension twinning during compressive loading. The experimental results showed that an increase or decrease in the {0002} basal X-ray peak intensity was observed during low-cycle fatigue and these changes are indicative of the occurrence of twinning and detwinning. During cyclic loading complete twinning-detwinning occurred for the first few hundred cycles where all of the twins formed in compression were removed during tensile loading of the following cycle. Eventually, this phenomenon ceases and residual twins remain in the material throughout each cycle. At strain amplitudes below 0.5%, there was no indication of twinning during compressive loading. The complete article on this study can be found in the International Journal of Fatigue [29].

References

C. Bettles, M. Gibson, Current wrought magnesium alloys: strengths and weaknesses, J. Metals 57(2005) 46–49.

Q. Yu, Y. Jiang, J. Wang, Cyclic deformation and fatigue damage in single-crystal magnesium under fully reversed strain-controlled tension-compression in the [1010] direction, Scr. Mater. 96 (2015) 41–44.

Q. Yu, J. Zhang, Y. Jiang, Fatigue damage development in pure polycrystalline magnesium under cyclic tension-compression loading, Mater. Sci. Eng. A 528 (2011) 7816–7826.

S. Begum, D.L. Chen, S. Xu, A. Lou, Low cycle fatigue properties of an extruded AZ31 magnesium alloy, Int. J. of Fat. 31 (2009) 726–735.

S. Begum, D.L. Chen, S. Xu, A. Lou, Strain-controlled low-cycle fatigue properties of a newly developed extruded magnesium alloy, Metall. Mater. Trans A 39 (2008) 3014–3026.

F. Mokdad, D.L. Chen, Strain-controlled low cycle fatigue properties of a rare-earth containing ZEK100 magnesium alloy, Materials & Design 67 (2015) 436–447.

F.A. Mirza, D.L. Chen, D.J. Li, X. Q. Zeng, Low cycle fatigue of a rare-earth containing extruded magnesium alloy, Mater. Sci. Eng. A 575 (2013) 65–73.

L. Chen, C. Wang, E.I.W. Wu, Z. Liu, G.M. Stoica, L. Wu, P.K. Liaw, Low-Cycle Fatigue Behavior of an As-Extruded AM50 Magnesium Alloy, Metall. Mater. Trans. A 38 (2007), 2235–2241.

X.Y. Lou, M. Li, R.K. Boger, S.R. Agnew, R.H. Wagoner. Hardening evolution of AZ31B Mg sheet, Int. J. Plast. 23 (2007) 44-86

C.S. Roberts, Magnesium and its alloys, Wiley, New York/London 1960

S. Kleiner, S. Uggowitzer, Mechanical anisotropy of extruded Mg-6%Al-1%Zn alloy, Mater. Sci. Eng. A 379 (2004) 258-263

M.H. Yoo, J.R. Morris, K.M. Ho, S.R. Agnew, Nonbasal deformation modes of HCP metals and alloys: role of dislocation source and mobility, Metall. Mater. Trans. A 33 (2002) 813.

M. Knezevic, A. Levinson, R. Harris, R. Mishra, R. Doherty, S. Kalidindi, Deformation twinning in AZ31: Influence in strain hardening and texture evolution, Acta Mater. 58 (2010) 6230-6242

L. Wu, S.R. Agnew, Y. Ren, D.W. Brown, B. Clausen, G.M. Stoica, D.R. Wenk, P.K. Liaw, The effects of texture and extension twinning on the low cycle fatigue behavior of a rolled Mg alloy, AZ31B, Mater. Sci. & Eng. A 527 (2010) 7057-7067.

L.Wu, A. Jain, D.W. Brown, G.M. Stoics, S.R. Agnew, B. Clausen, D.E. Fielden, P.K. Liaw, Twinning-detwinning behavior during the strain controlled low-cycle fatigue testing of a wrought magnesium alloy, ZK60A, Acta. Mater. 56 (2008) 688-695

S.R. Agnew, O. Duygulu, Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B, Int. J. Plast. 21 (2005) 1161-1193.

S.R. Agnew, C.N. Tome, D.W. Brown, S.C. Vogel, Study of slip mechanisms in a magnesium alloy by neutron diffraction and modeling, Scr. Mater. 48 (2003) 1003-1008

S.B. Yi, H.G. Brokmeier, R. Bolmaro, K.U. Kainer, J. Homeyer, The texture evolutions of Mg alloy, AZ31 under uni-axial loading. Materials Science Forum 495-497 (2005) 1665–1674

D.W. Brown, S.R. Agnew, M.A.M. Bourke, T.M. Holden, S.C. Vogel, C.N. Tome, Internal strain and texture evolution during deformation twinning in magnesium, Mater. Sci. Eng. A 399 (2005) 1–12

M.A. Gharghouri, G.C. Weatherly, J.D. Embury, J. & Root, Study of the mechanical properties of Mg-7. 7at. % Al by in-situ neutron diffraction, Philos. Mag. 79 (1999) 1671–1695

C.H. Caceres, T. Sumitomo, M. Veidt, Pseudoelastic behaviour of cast magnesium AZ91 alloy under cyclic loading – unloading, Acta. Mater. 51 (2003) 6211–6218.

D. W. Brown, A. Jain, S.R. Agnew, B. Clausen, Twinning and Detwinning During Cyclic Deformation of Mg Alloy AZ31B, Mater. Sci. Forum 539-543 (2007) 3407–3413.

A. Jain, S.R. Agnew, Modeling the temperature dependent effect of twinning on the behavior of magnesium alloy AZ31B sheet Modeling the temperature dependent effect of twinning on the behavior of magnesium alloy AZ31B sheet, Mater. Sci. Eng. A 462 (2007) 29-36

Q. Yu, J. Zhang, Y. Jiang, Q. Li, An experimental study on the cyclic deformation and fatigue of extruded ZK60 magnesium alloy, Int. J. Fat. 36 (2012) 47-58

Y. N. Wang, J. C. Huang, The role of twinning and untwinning in yielding behavior in hot-extruded Mg-Al-Zn alloy, Acta Mater. 55 (2007) 897–905,

J. W. Christian, S. Mahajan, Deformation twinning, Prog. Mater. Sci. 39 (1995) 1-157

J. Wang, I. J. Beyerlein, and C.N. Tome, Anatomic and probabilistic perspective on twin nucleation in Mg, Scr. Mater. 63 (2010) 741–746

Q. Yu, J. Wang, Y. Jiang, Inverse slip accompanying twinning and detwinning during cyclic loading of magnesium single crystal, J. Mater. 2013 (2013) 1-8

A. Murphy-Leonard, D. Pagan, A. Beaudoin, M. Miller, J. Allison, Quantification of Twinning-Detwinning Behavior During Low-Cycle Fatigue of Pure Magnesium Using High Energy X-Ray Diffraction, International Journal of Fatigue 125 (2019) pp 314-323

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Murphy-Leonard, A.D., Pagan, D.C., Beaudoin, A., Miller, M.P., Allison, J.E. (2021). Understanding Twinning-Detwinning Behavior of Unalloyed Mg During Low-Cycle Fatigue Using High Energy X-ray Diffraction. In: Miller, V.M., Maier, P., Jordon, J.B., Neelameggham, N.R. (eds) Magnesium Technology 2021. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-65528-0_12

Download citation

DOI: https://doi.org/10.1007/978-3-030-65528-0_12

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-65527-3

Online ISBN: 978-3-030-65528-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)