Abstract

The fundamental concepts in the field of water-energy systems and their historical evolution with emphasis on recent developments are reviewed. Initially, a brief history of the relation of water and energy is presented, and the concept of the water-energy nexus in the 21th century is introduced. The investigation of the relationship between water and energy shows that this relationship comprises both conflicting and synergistic elements. Hydropower is identified as the major industry of the sector and its role in addressing modern energy challenges by means of integrated water-energy management is highlighted. Thus, the modelling steps of designing and operating a hydropower system are reviewed, followed by an analysis of theory and physics behind energy hydraulics. The key concept of uncertainty, which characterises all types of renewable energy, is also presented in the context of the design and management of water-energy systems. Subsequently, environmental considerations and impacts of using water for energy generation are discussed, followed by a summary of the developments in the emerging field of maritime energy. Finally, present challenges and possible future directions are presented.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Water-energy nexus

- Hydropower

- Energy hydraulics

- Hydroelectric design

- Uncertainty in water energy-systems

- Environmental impacts

- Maritime energy

1 Introduction

1.1 A Brief History of Water and Energy

From the dawn of humanity, people had to ensure access to water and food for their survival. Solar energy was nourishing the Earth, triggering the hydrologic cycle, supporting the production of vegetation via photosynthesis and offering humans light and warmth during sunny days. At these early periods humans were mainly gatherers, as they collected water from its natural sources (rivers, lakes and springs) and consumed raw fruits gathered from local flora. Gradually, they utilized stone, wood and animal’s bones to make tools and weapons that improved the efficiency of hunting. As they were yet unable to produce energy from other sources, they used the energy of their own bodies and muscles, acquired from food and water via metabolism, for all their activities.

Exploitation of natural resources to control the energy production, where term “production” is used as shorthand for transformation to a usable form or release from a stored form, was essential for humankind throughout its existence. Although water and food were the two basic requirements for survival, energy was essential to (a) ensure the supply of water and production of food and (b) support domestic, manufacturing and transportation activities of developing human societies.

When humans controlled fire (about 70 000–100 000 years ago), they had managed to exploit fuels for energy production for the first time. Wood was the first fuel used and, practically, remained the main one until the twentieth century, despite the increased use of coal from the eighteenth century. Fire changed the style and quality of life, as it provided warmth, light, a better diet (cooked or grilled meals) and protection from wild animals. Fire also triggered human development, as people gained a small amount of control over nature and extended their activities. They could now harden primitive wooden tools and weapons, work during nights, inhabit dark places (caves) and finally migrate from Eastern Africa to areas with colder climates as Europe and Asia.

At some point during the late Neolithic period, a new human activity emerged, agriculture. People shifted from gathering and hunting activities, characterized by high insecurity, to agriculture in stable fields that improved food safety. This change, known as the Neolithic Revolution (McClellan and Dorn 2015), started at about the 10th millennium BC. Somewhere around this period groups of people concentrated in a zone of hills extended from what is today Syria to the foot of Taurus and Zagros mountains, an area known as the Fertile Crescent. In this area the winter rainfalls favoured the natural growth of wild cereals, such as barley and wheat. These early communities organized cultivations, developed the first agricultural methods, domesticated animals, and constructed the first small scale hydraulic works for water exploitation. During the 8th to 5th millennium BC, the population began to increase and spread to the nearby river alluvial valleys (Nile, Tigris, Euphrates, Indus and Yellow river). The growth of agricultural activity at the new areas caused a significant increase of the water needs. However, the water was abundant and ensured by the nearby large rivers. These were the valleys where the first cities rose during the period known as Urban Revolution, offering a more civilized life to these early societies. Domestic water use, irrigation for food production and flood protection became essential for these developing civilizations. Large scale hydraulic works were constructed for collecting, transferring and storing water, as well as for urban and rural drainage (Angelakis et al. 2012; Bazza 2007). The main source of energy that supported this extended agricultural activity (planting and ploughing, transporting crops, manufacturing, lifting water from wells or rivers) remained the chemical energy utilized through human and animal muscles. The first device for lifting water was shaduf, a long wooden pole that operates like a seesaw. Its use is widespread in Mesopotamia and Egypt from 5th millennium BC until today.

As civilizations developed, a new energy source came into use, the wind. Sails on boats were possibly used for the first time around 10th millennium BC, but as the technology was improved, marine transportation expanded further to support commerce. As the use of continental roads for the transportation of goods and people was hard, ships with sails opened up new maritime trade routes. On the other hand, sailors could not control wind energy to sail against the wind and thus they also had to paddle. The technology to sail into the wind was optimized and spread several centuries later.

As metallurgical activity expanded, energy needs were substantially increased. Although Neolithic societies used soft metals such as gold, silver, lead and copper, gradually they discovered harder metals or alloys to produce tougher tools and weapons. For example, the production around the 3th millennium BC of bronze, a hard alloy of copper and tin, improved the metal industry significantly. The melting of metals consumed large amounts of thermal energy produced exclusively from wood burning. During the Iron Age around the 3th millennium BC, the need to melt harder metals, such as iron, led to production of charcoal, a partially new and artificial fuel that is widely used even today. Charcoal was made by burning wood in a low oxygen environment, a process that lasted a few days. As charcoal contains more carbon, it produces higher and steadier temperatures, than wood.

Coal, oil, natural gas and their calorific attributes were known in antiquity, but their use as fuels was quite limited. Coal was used as a fuel in a consistent way from 4th millennium BC in modern day Mongolia and China (Dodson et al. 2014). It is also mentioned by Theophrastus (4th century BC) in his treatise On Stones. He says that “anthrax” (Greek word for coal) was excavated from the ground, was burned like charcoal and was used for heating by copper workers. Coal was also used extensively in Roman Britain, where several exposed coalfields were exploited. It was transported to distant sites, such as London, although wood and charcoal remained the main fuels (Dearne and Branigan 1995).

Petroleum is mentioned by Herodotus (5th century BC) and Plutarch (1th century AD). Herodotus (Book 6, 119) describes wells near Susa (today central Turkey) which were used to extract “oil”; it was black with strong smell and was stored in vessels. From the same wells asphalt was extracted. In another Herodotus’ book (Book 4,185) the presence of asphalt in the Island of Zakynthos is described. Plutarch (Parallel Lives, Life of Alexander, 35) describes a chasm of fire at Ecbatana (today Iran) that streamed as a spring, while the abundant liquid naphtha was stored nearby. He mentions that naphtha was like asphalt but more flammable. Also, Plutarch narrates that “barbarians” impressed Alexander the Great by lighting the road that led to his lodging. Generally, the use of petroleum as fuel in antiquity was rare. On the other hand, the use of asphalt was widespread in almost all civilizations as waterproof material, mainly in vessels but also as mortar in buildings and pottery.

In several ancient sources, seeps from which gas escapes are mentioned. Several oil and natural gas seeps, especially in the Mediterranean area, are cited by Pliny the Elder (1th century AD) in his treatise History of Nature. The temple of Hephaestus, the Greek god of fire, was built next to such a burning gas seep in Chimaera, in modern day Turkey (Etiope 2015).

From the Iron Age to the Industrial revolution during the 18th century AD, most things related to water and energy management, remained almost stagnant. Wood, charcoal and wind were the main energy sources, and surface and ground water were the main water resources. As water and energy management followed the ups and downs of civilizations, few essential developments were achieved as summarized below:

-

(a)

Devices and mechanisms for lifting water. Several devices were used throughout history for lifting water, as comprehensively reviewed by Yannopoulos et al. (2015). The most important, Archimedes’ screw and Noria, were invented around 3th century BC. Archimedes’ screw was the predecessor of the modern pump, and it was powered by human or animal force. The modern version of this device, powered by thermal or electric energy, is used in many contemporary water projects. Noria is also a very important invention, as the machine worked with hydraulic power. It is a wooden waterwheel, powered by flowing water and fitted with buckets that lifted water to another collector out of the river. Finally, it is worth to mention that the inverted siphon technology was achieved at a rather large scale in some ancient aqueducts starting from the Hellenistic period, even though this is not actually lifting of water.

-

(b)

Construction of hydraulic works. All civilizations constructed extensive hydraulic works to manage water, such as aqueducts, cisterns, qanats, tunnels and dams (Angelakis et al. 2006, 2013; Feo et al. 2013). Other kinds of hydraulic works were also built with the purpose of draining cultivation areas, flood protection and river navigation. Especially, Mediterranean civilizations, that flourished in an environment of water scarcity, exploited available water resources extensively and built admirable hydraulic works.

-

(c)

Water use for energy production. During the 1th millennium BC, water mills were invented to grind the grain and olives for flour and olive oil production, respectively. Olive oil became the main fuel for home lighting for several centuries and was used in most civilizations (in specific areas animal fat was used instead). Around the 7th century AD wind mills were invented in Persia, and they were used until the twentieth century all over the world to grind cereal, pump water and even drain land, like, for example, in the Netherlands.

-

(d)

Birth of science for understanding and control of natural powers. As societies became more and more dependent on the natural resources, early scientists tried to understand the relevant environmental processes and describe their laws. Nature was now more predictable and hence more controllable. The first scientific theories of natural phenomena were formulated around the 6th century BC by Greek philosophers from Ionia (Koutsoyiannis et al. 2007). During the next centuries Greeks advanced the existing knowledge and defined the scientific method. Aristotle (4th century BC) codified the existing information for several natural sciences. Also he defined the way to understand nature, introduced the formal study of logic and, in particular, the methods of deduction and induction. It is worth mentioning that Aristotle first distinguished the terms energy (ενέργεια) and power (or “potential”; δύναμις) with the former being the existence of something and the latter is the potential to be something (Metaphysics Book 9, 1048a). Thus, in the context of the Aristotelian philosophy, energy is regarded as the action needed to materialize a potentiality. During this period there was significant progress in mathematics, physics, astronomy and technology. A fascinating technological achievement was the use of steam for production of mechanical motion that was discovered during 2th century BC by Heron in Alexandria. Although the invention was applied in the construction of a few amusing mechanisms, it was more than 2000 years later that the reinvented stream engine would start to play an important role in human development.

At the beginning of the 18th century, societies remained rural, and the majority of the population was involved in agriculture. The manufacturing activity was limited to small factories, cottages and urban craft shops. At the middle of the 18th century, a transition from manual labour manufacture to centralized, standardized and organized production was made. The Industrial Revolution began in England and spread to the rest of Europe and North America. In about one century, the factory system was developed, machines and tools were invented, and iron, chemical, shipping and textile industries were blooming. As wood and charcoal were the main fuels used in these developments, large quantities of wood were consumed very quickly and forests were depleted. A new fuel was used to replace wood, coal and its processed form, coke (charred coal). As coal consumption increased, surface deposits were exhausted, and deep mines were constructed. Deep galleries were flooded by groundwater, which was a big problem. The problem was resolved by an engine, called the “Miner's Friend”, which replaced traditional animal-driven pumps. This pump was a great invention as it used thermal energy to convert water to steam, which under pressure produced mechanical work to remove water from mines. Later in 18th century more advanced steam engines were produced and were used in several industrial applications. However, the most important application of steam engines was in the transportation sector. During this period trains and ships moved using coal and wood as fuels.

Also, during the Industrial Revolution, the use of hydropower for industrial activities begun. Iron waterwheels were built, and water powered devices operated a variety of industrial applications, mainly in the textile industry.

At the end of the 19th century internal combustion engines which used petroleum and gas were invented. During the 20th century most human activities expanded thanks to these engines. The transportation sector in particular boomed, as cars, aircrafts and boats were now used extensively to transport people and goods. Petroleum and its derivatives, such as gasoline, kerosene and, diesel, were the main fuels for this activity, while natural gas was also available but less frequently used. During the early 20th century, the gas that was released during petroleum mining was usually burned at the fields, as it was considered very expensive to transport or to store for later use. Very soon, devices were invented to exploit gas, e.g., for heating and cooking in the domestic sector. At the end of the 20th century natural gas was already exploited extensively. Finally, the liquefied natural gas (LNG) is another common method used to facilitate conveyance.

While phenomena connected with electricity had been known since antiquity, in the 19th century a steady stream of inventions led to a multitude of practical applications, and by the end of that century electricity had transformed the world. Electricity could now be stored, transported, and transformed into other types of energy with relative ease. This led to rapid growth of the type and number of everyday life applications. During the 20th century electricity transmission networks were installed all over the Earth. In 1980 the electrical energy corresponded to 30% of the total energy consumed, and in 2015 this percentage was about 40%. Water power was one of the first resources (alongside coal and petroleum) that were used for electricity production. As electric energy needs expanded, hydropower became of great importance, and thousands of hydroelectric power plants were constructed all over the world. Their reservoirs were not only used to manage energy production but also to provide irrigation water, domestic water supply, and flood protection. In the 1950s, when the controversial nuclear technology emerged, it began to be used extensively for electricity production, using radioactive fuels such as uranium and plutonium. After the oil crisis of 1970s, societies started to explore renewable resources for electric energy generation. At the beginning of the 21th century, wind, geothermic fields, biomass, and solar energy began to be used more extensively for electricity generation.

The 20th century is also characterized by the improvement of water facilities and new related technologies, as well as the introduction of environmental protection in water management. Hydraulic works were constructed mainly for (a) collecting, transferring and distributing water from sources to end users, (b) storing water for later use, (c) cleaning potable water and managing waste waters, (d) exploiting hydropower for electricity, (e) protecting from floods, and (f) ensuring river navigation. At the end of the century, desalination plants were constructed in coastal areas, and the terms “waste water recycling” and “environmental flow” were introduced.

Table 20.1 lists some of the most important historical events that influenced water and energy management.

1.2 Water and Energy at the Beginning of the 21th Century

At the beginning of the 21th century, the world population exceeded 6 billion (while in 2019 it exceeded 7.7 billion) distributed among about 200 countries. In 2014 and 2015 the mean annual water consumption and energy production per capita were estimated to about 550 m3 and 25 MWh, respectively. During the 20th century enormous infrastructures were constructed to ensure access to water, energy and sanitation to the majority of the world population. The progress of science and technology improved the design, operation and management of hydraulic works and power plants. On the other hand, many developing countries still lack these basic facilities. In Fig. 20.1 the percentage of the population that has access to potable water, electricity, and sanitation in the years 2000 and 2014 is depicted for each country.

Access to a potable water, b electricity and c sanitation (% of the population of each county) in the year 2000 (left) and 2014 (right) (constructed from data of World Bank; https://data.worldbank.org/)

From Fig. 20.1a-left, referring to the access to potable water in 2000, it is evident that in several countries all over the world a significant (more than 10%) percentage of the population had no access to potable water. The problem was more severe in some African countries where the majority of the population had no access to water. Regarding access to electricity (Fig. 20.1b-left) and sanitation facilities (Fig. 20.1c-left), the situation seems even worse. It is evident that several African and Asian countries had serious difficulties in covering these basic needs.

From the right panels of Fig. 20.1, which refer to 2014, it becomes obvious that during 21th century the living standards in many of these countries did not change drastically. Some improvement is visible in potable water access, but better access to electricity would help with both potable water and sanitation, overall there is a long way ahead for humanity to ensure decent living conditions for all.

1.2.1 Water Use

According to World Bank data for 2014, the world’s annual water consumption was estimated to about 4000 km3; this corresponds to about 550 m3 per person. Five countries (India, China, USA, Pakistan and Indonesia), whose population amounts to 30% of the global, were responsible for more than 60% of the total global water consumption. From the total amount, 70% was used for irrigation, 19% for industrial, and 11% for domestic use (a mean value of 170 L/d per person). These uses are classified as consumptive, as water is removed from its initial environment or its quality degrades to a state that it requires treatment for reuse. The water consumption quantities are estimated on a country basis based on data from free web databases maintained by organizations such as the Food Agricultural Organization (FAO; https://www.fao.org/nr/water/aquastat/data/query/index.html) and the World Bank (https://data.worldbank.org/indicator).

Irrigation refers to water used to assist in growing crops, to protect plants against frost or to remove salts from the crop root zone. Industrial use refers to water used in industries for purposes such as processing, cleaning, diluting and cooling. Domestic use refers to water that is used in households for everyday needs, such as drinking water, food preparation, bathing, washing clothes and dishes, flushing toilets, and watering gardens. In addition to the main three water uses mentioned above, there are a few more specific consumptive water uses, including (a) commercial (water for hotels, office buildings, and other commercial facilities), (b) livestock (water for stock animals, dairies, fish farms, and other nonfarm needs), and (c) mining (water for the extraction of minerals such as coal and ores, crude petroleum, and natural gas).

On the other hand, there are several non-consumptive uses, where the water remains in the natural environment. The main non-consumptive water uses are: (a) hydroelectric energy production, (b) river navigation, (c) recreational activities (fishing, sailing, swimming), and (d) preservation of the environment. The latter use includes mainly water releases from reservoirs in order to (a) help fish reproduction, (b) restore natural river flow regime, and (c) provide water to wetlands to protect their ecosystems.

To cover all these water demands, a large amount of available water resources has to be exploited by constructing the appropriate hydraulic works. Potentially, water can be found in the (a) ground (aquifers), (b) surface of the earth (rivers, lakes), (c) atmosphere (rain, water vapour) and, (d) sea (after desalination). Alternative sources could be the transfer of water from other areas or reusing the outflows of drainage networks or waste water treatment plants. The atmospheric water is exploited as a source only on a small scale mainly by harvesting rain water and humidity condensation installations such as fog collectors.

1.2.2 Energy Use

According to the United States Energy Information Administration data (EIA 2017) the total world primary energy production in 2017 was about 14 000 Mtoe (million tons of oil equivalent). Here one toe is the quantity of energy that is released from the combustion with 100% efficiency of a ton of crude oil; this corresponds to 41.9 GJ or 11.6 MWh. The world primary energy was mainly produced from coal, petroleum and natural gas and consumed in the industrial, transportation, domestic, and commercial sectors. The distribution of primary energy (TWh) by source and use in 2017 is shown in Fig. 20.2a. Some of the electricity used by the different sectors was originally generated from fossil fuels. Hydropower and nuclear power have a significant share in electrical energy production as well. Apart from hydropower, other renewable energy sources such as wind, (direct) solar radiation, biomass and biofuels, geothermal, and marine energy (waves, tides, currents) have a small but increasing share. Biomass and geothermal energy are widely used as thermal energy sources, especially in the industrial and domestic sectors. Notably, the conversion efficiency of fossil fuels for electricity production is generally low (35% for coal to 55% for natural gas) when compared to the conversion efficiency of hydropower (more than 85%).

a Distribution of primary energy (TWh) by source and use (constructed from data from EIA); b World electric energy mix for 2017 (constructed from data from BP British Petroleum 2018)

The total electricity produced globally in 2017 was about 25 500 TWh (2200 Mtoe) and the consumed fuels (mostly fossil) were about 6000 Mtoe. The world electric energy mix for 2017 is presented in Fig. 20.2b. From the end of the 20th century the fear of exhausting fuel reserves combined with environmental concerns triggered an effort to increase the share of renewable energy sources in electricity production (Fig. 20.2b). Also, the technique of coproduction of thermal energy from electric power plants was widely used and increased the efficiency of the systems to more than 70%.

The industrial sector consumed 53% of the total global energy production and was proportionally fed by petroleum, coal, natural gas and electricity. The transportation sector consumed 25% of the total energy and was almost exclusively fed by petroleum. Finally, domestic and commercial sectors consumed the 22%, and were mainly fed by electricity, natural gas and petroleum.

Fossil fuels (petroleum, natural gas and coal) produced 65% of electrical energy, while hydropower and nuclear energy were also very important for power generation as they were responsible for 26% of electrical energy production.

2 Water-Energy Nexus

Water and energy systems interrelate in multiple ways that are both complex and dynamic. For example, energy is used for abstracting, purifying, distributing and disposing water, while water is indispensable for various energy production phases, including, among other processes, oil drilling, biofuel production, thermal plant cooling and hydropower. Accordingly, problems with one may directly or indirectly affect the other, e.g. water shortage having negative knock-on effects on energy production. These close relationships belong to the so-called ‘water-energy nexus’, a term coined to describe the multiple interactions between the two systems. Some of the earliest attempts to investigate water-energy interdependencies in the economy and water sector, thus introducing a joint approach into policy planning, were made in the United States in 2006 (US DoE 2006). Langhamer et al. (2010) discussed the scientific and technological aspects of water and energy and explored related research challenges. During the first two decades of the 21th century, a growing body of research acknowledged the water-energy nexus complications and its relevance to the economy. However, the identification of these relationships and their impact remains a field largely underexplored till now.

2.1 Water Used for Energy Production

According to Spang et al. (2014), approximately 52 km3 of freshwater are consumed annually for energy production, excluding hydropower (which in fact does not consume water). Yet this number is an approximate estimate coming from countries with greatly diverse economies and energy sectors. In the United States the energy sector is regarded to be the biggest consumer of water resources (Carter 2010). The U.S. is also the most important consumer on a global scale, followed by China, while for instance, northern Africa has a minimal contribution to the global amount of water used in the energy domain. Apparently, these statistics should be viewed with caution as the assumptions behind them may vary substantially, while also they are changing over the years due to reforms in the energy sector and emergence of more water-efficient technologies that reduce the pressure on regional water resources.

To trace the water used for energy production in a more systematic way, Hoekstra and Hung (2002) introduced the concept of the ‘water footprint’ of a country, i.e. “the volume of water needed for the production of goods and services consumed by the inhabitants of the country”. The water-footprint has been further specified to denote three distinct types of water use: ‘blue water’, referring to consumption of groundwater and surface water; ‘green water’, denoting the amount of rainwater required for a product, e.g. rain-fed agriculture; and ‘grey water’, representing the amount of freshwater required to dilute pollutants to maintain water quality according to certain standards (Hoekstra and Chapagain 2006). This concept has also been used in energy production and supply in order to identify impact of trading relationships on water resources. For example, petroleum products heavily contribute to the water footprint for energy production in Thailand, but very little to the water footprint for energy supply, since related energy is mostly exported, while the opposite is true for the country’s crude oil water footprint (Okadera et al. 2014).

It is also useful to differentiate between two types of water use for energy, i.e. ‘water withdrawal’ and ‘water consumption'. The first denotes the amount of water removed or diverted from a source for use. The second is a part of the first and denotes the water withdrawn that is evaporated, transpired, incorporated into products or crops, or otherwise permanently removed from the immediate water environment (Kenny et al. 2009). Most relevant studies focus on water consumption.

The following sub-sections refer to operational uses of water excluding indirect uses of the life-cycle, for instance, water used in energy stations auxiliary facilities, e.g. sanitary facilities.

2.1.1 Fossil Fuel

Crude oil production requires water for processes including onshore oil exploration, onshore oil extraction and production, enhanced oil recovery, water injection (water-flooding), thermal steam injection, oil refining, and other plant operations. The amount of water required is regionally varied, mainly according to the combination oil recovery techniques used in each case. For example, primary oil recovery, by means of the natural pressure of the well, is much less water-intensive than secondary oil recovery, including water-flooding, whereas varied estimates are reported for enhanced oil recovery techniques such as CO2 injection (Wu et al. 2008). Excluding enhanced oil recovery, median values of 0.081 m3/GJ and 0.040 m3/GJ are reported (Spang et al. 2014; Wu et al. 2008) for conventional oil extraction and refining, respectively. These estimates differ, in general, for less common crude oil production, such as oil sands and shale oil, though altogether tend to decrease over the years as energy technologies become more water efficient and employ other sources than freshwater, e.g. saline or brackish water (Wu et al. 2008).

Coal consumes water for surface or underground mining, beneficiation, slurry pipelines, and other plant operations, while natural gas requires water for the processes of onshore exploration, onshore extraction, natural gas processing, gas pipeline operation, and other plant operations. Shale gas is even more water intensive requiring water for the process of hydraulic fracturing (fracking) with estimates ranging in the United States from 1136 m3 per well to 34 069 m3 per well in 2012 (Meldrum et al. 2013). Reported median global estimates are 0.043 m3/GJ, 0.004 m3/GJ and 0.017 m3/GJ, for coal, natural gas and shale gas production, respectively (Meldrum et al. 2013; Spang et al. 2014).

In the fossil fuel industry, water consumption is globally dominated by the oil industry where water is used for crude oil extraction and refinement processes, except for China, India, Indonesia and Australia, where coal is the greater consumer of water among the fossil fuels (Spang et al. 2014). The natural gas industry has a minor contribution in water consumption worldwide, with Russia and the United States being the major contributors.

2.1.2 Nuclear Fuel

Water is required for many processes involved in the production of nuclear fuel, including uranium mining, milling, conversion, enrichment, fabrication, and reprocessing phases. A median water consumption estimate of 0.105 m3/GJ is reported for these processes (Meldrum et al. 2013; Spang et al. 2014).

On a global level, water requirements for nuclear fuel production are estimated an order of magnitude lower than that of fossil fuels (Spang et al. 2014), which is both a result of the limited availability of uranium deposits and the restricted nuclear fuel production worldwide.

2.1.3 Biomass Production and Processing

Biomass may refer to (a) food crops, such as sugarcane and rapeseed, (b) energy crops as poplar and miscanthus, as well as (c) various types of organic waste from agriculture processes, e.g. manure and crop-residues (Gerbens-Leenes et al. 2009). Biomass is often subsequently processed to biofuels such as biodiesel, ethanol, and biogas. For example, the United States and China produce maize-based ethanol, India uses rapeseed to produce biodiesel, and Brazil depends on sugarcane to produce ethanol. Water for biofuels relates both to the water required for the cultivation of biomass, in the case of crops, and to water required for its processing. Biofuels are mainly first-generation, including biodiesel, ethanol, and biogas, and second-generation, including energy crops and waste products.

In case of first-generation biofuel, water is primarily required for cultivation of biomass. This type of biomass production is generally considered the most water-intensive energy production process due to its dependence on irrigation. Relevant estimates are highly regionally varied and uncertain, since they heavily rely on the crop type, irrigation system, and climatic conditions (Mielke et al. 2010). Subsequently, ethanol production from biomass requires water associated to grinding, liquefaction, fermentation, separation, and drying processes (Wu et al. 2009).

Second-generation biofuels require water mostly for conversion of cellulosic ethanol to ethanol through biochemical or thermochemical processing (Naik et al. 2010). In general, second-generation biofuels do not require incremental irrigation if grown in their native ground, and water use estimates are usually omitted, though some energy crops may need additional irrigation (Wu et al. 2009).

In 2016, biofuels yielded only a small amount of the total energy production (957 TWh), according to data from BP Statistical Review of World Energy (British Petroleum 2017); however, they are a growing energy pathway (Berndes 2008). For instance, in Thailand energy from biofuels had already reached 18% of total energy supply in 2010 (Okadera et al. 2014).

2.1.4 Electricity

Electricity has the most diverse profile of water consumption owing to the variety of pathways for electricity production in terms of fuel, generator type, and cooling type. Spang et al. (2014) classify these in eight major categories: coal-based steam turbine (ST), gas- and oil-powered ST, nuclear ST, biomass and waste heat ST, geothermal ST, solar ST, combined cycle, and gas turbine. The majority of water used in the production of electricity refers to water used for thermoelectricity processes, i.e. freshwater used for cooling the steam after exiting the turbine generator. The cooling water that is needed by thermal power plants is estimated to be around 76–190 m3/MWh (Kohli and Frenken 2011). Geothermal technologies differ in the usage of water due to differences in technology configurations and regional characteristics (Clark et al. 2010), and may require further water usage for generation of electricity (Macknick et al. 2012).

Hydroelectricity provides 16% of the total world electric energy production, which corresponds to 80% of renewable sources. For some countries (Albania, Norway, Paraguay and Congo), it is almost the only resource in their electric energy mix. During the twentieth century, the extensive use of hydroelectricity revealed issues of great importance to the operation of water-energy systems. Hydroelectric energy is produced by the falling of a water volume from a certain height. The main method to exploit the hydropower of a river is to build a dam that forms an upstream reservoir, which regulates river flow. At certain time periods, water is released under pressure to produce electric energy. However, allocation of water consumption for hydropower is generally avoided in the literature, since water is not actually consumed. Hydroelectric dams are usually multi-purpose works, serving simultaneously flood control and water supply purposes, so assigning, for instance, evaporation losses solely to hydropower is ambiguous and misleading.

For other electricity technologies such as photovoltaic (PV) plants and wind power production, water is mostly associated with occasional life-cycle requirements of washing PV panels and wind turbine blades. Thus these present the lowest withdrawal and consumption rates (Macknick et al. 2012), and also rank low on the global scale of water use in the energy sector (Spang et al. 2014).

2.2 Energy Intensity of Water Sector

At the start of the 21th century and considered on a global scale, water is an important input for nearly all forms of energy (International Energy Agency 2016). Although the water sector is not yet a significant user of energy on a global level, in light of energy reforms towards a ‘greener’ economy and increasing use of desalination plants, this is likely to change. Recent important developments involving the use of novel desalination methods, such as nanoporous graphene sheets as well as capacitive deionization, which are much more energy efficient compared to the reverse osmosis method, could further increase the spread of desalination plants (Aghigh et al. 2015; Copeland and Carter 2014; International Energy Agency 2016). According to the International Energy Agency (2016), the global energy consumption in the water sector reached approximately 5 × 109 GJ (1390 TWh) of energy in 2014, about 60% of which is in the form of electricity.

In the United States, past analysis has shown that over 3% of the national electricity consumption is used for water-related purposes (Cohen et al. 2004). However, these aggregate estimates do not show the large variability of the energy-intensity on the regional scale, e.g. California uses 19% of its electricity and 32% of its natural gas resources for services related to the water sector (Klein et al. 2005; Stokes and Horvath 2009).

Energy for the water supply sector has been classified into ‘physical energy’ (the amount of energy applied to produce and transport water supplies to meet demand within each hydrological region) and ‘embedded energy’ (the actual amount of energy needed in other regions to produce and deliver water that is consumed within that region). Specifically, the energy embedded in water is defined as “the amount of energy that is used to collect, convey, treat, and distribute a unit of water to end users, and the amount of energy that is used to collect and transport used water for treatment prior to safe discharge of the effluent in accordance with regulatory rules” (Park and Bennett 2010). The term ‘energy intensity’ refers to the average amount of energy used for these processes on a per unit basis.

2.2.1 Urban Water and Wastewater

Energy estimation for the urban water cycle can be segmented into the phases of supply, conveyance, treatment and distribution of water, and waste water treatment (Park and Bennett 2010).

The supply phase may include surface water, groundwater, desalinated water, and recycled water. Due to their increasing importance, desalination plants are examined separately below. Relevant energy consumed in the supply process is driven by the type of the source water, the technology used in each case, and the regional regulatory standards. In essence, exploitation of groundwater requires a supply of energy determined by the pumping method and efficiency, the depth of the well, and the volume of the pumped water. About 800 TWh (3% of the total world electric energy production) are required to pump water from deep aquifers (e.g. 80 m). For example, in Greece, a country where groundwater is extensively used for irrigation, 5% of total electricity was consumed in water pumping. In some agricultural regions, in which deep wells are used, this percentage is up to 15%. Recycled water’s energy intensity is driven by the wastewater discharge standards and the level of additional treatment that is required in order to bring the water into an acceptable quality for the specific purpose of interest. The extraction of surface water and groundwater generally accounts for the 40% of the electricity used in the water sector (International Energy Agency 2016).

Energy intensity of water conveyance and distribution by means of pumping depends on the topography, the geometric and hydraulic properties of the pipe system, and the requirements of consumers in terms of discharge and pressure.

Energy intensity of water treatment is subject to the type of treatment technologies used, the water quality standards, the initial quality of the raw water, as well as the treatment plant configurations. For example, energy-intensive methods include reverse-osmosis, ozonation, and ultraviolet light rays.

Finally, the energy consumed in the waste water treatment plants is determined by the plant capacity, the level of treatment, the technology used, the wastewater influent quality, and the discharge standards (primary, secondary or tertiary). In 2014, it was estimated that a quarter of the electricity consumed by the water sector was used for waste water collection and treatment. This electricity demand is projected to increase by 60% or even more up to 2040, as more wastewater will be collected and treated (International Energy Agency 2016). Yet, in some cases, the use of the produced biomass from waste covers a significant part of the thermal and electric energy needed for treatment.

2.2.2 Agricultural Uses and Irrigation

Irrigation is a dominant consumer of energy. Energy required depends on (a) the type of source water used (surface water or pumped groundwater), (b) the type of irrigation methods (surface, drips, sprinklers), and (c) the water requirements of the crop. In South Asia, and particularly in India, irrigation heavily depends on groundwater pumping and is energy-intensive to such a degree that it is frequently described by the term the ‘energy-irrigation nexus’ (Shah et al. 2004).

In the first decades of the 21th century, alternative sources to produce electricity for irrigation have been explored. For instance, renewable resources, especially photovoltaic panels, are used to produce energy for pumping (Chandel et al. 2015).

2.2.3 Desalination Plants

Desalination refers to the process of converting non-usable water resources into usable by removing excess salts and minerals. The energy intensity depends on the volume of water being desalinated, the quality of the source water, and the specific desalination technology. For example, processing brackish water, containing moderate amounts of salts and minerals, is not as energy-intensive as processing sea water, containing very high quantities of salts and minerals. Desalination technologies utilize either thermal energy, e.g. in multi-stage flash systems, or mechanical energy as in reverse osmosis, the most commonly installed technology (International Energy Agency 2016). The reduction of energy-intensity of water desalination technologies is a very active research field with reverse-osmosis desalination plants showing the most growth and concentrating engineering focus worldwide (Peñate and García-Rodríguez 2011), while new graphene-based technologies also have a great potential (Aghigh et al. 2015). It is highly likely that in the future desalination will be a viable alternative to mitigate water scarcity due to limited water resources or during drought periods. Although desalination is a very energy consuming process (3.5–5 kWh/m3 for reverse osmosis), the resulting world energy demand is low. The desalination plants have a global annual water production of about 6 km3 and consume about 30 TWh of energy, a value that corresponds to the 0.1% of total electricity production (see FAO database mentioned above). Desalination processes accounted for roughly 5% of the electricity used in the water sector in 2014 (International Energy Agency 2016), and it is projected to rise to more than 20% in 2040.

2.3 Synergies and Trade-offs

The various interdependencies of the water-energy systems often lead to competitive uses of the naturally constrained resources, thus rendering the management of these systems challenging. The competitive nature of the resources may have detrimental effects on the economy and water sector if ignored in the management strategy, while, on the other hand, an integrated approach creates opportunities for mutually beneficial situations.

McCornick et al. (2008) reviewed interesting case studies; among them the case of Ethiopia. In spite of water abundance and great hydropower potential, Ethiopia lacks relevant infrastructure and is very dependent on unsustainable biomass growth, leading to poverty, water insecurity, energy deficiency and destruction of forests, among others. The use of hydropower dams as a means for integrated management of water-energy systems has long been advocated (Koutsoyiannis et al. 2003, 2009; Nalbantis and Koutsoyiannis 1997) with an emphasis on the necessity of large scale projects to increase energy-efficiency and enable reliable multi-purpose operation (Koutsoyiannis 2011a; Koutsoyiannis et al. 2003; Nalbantis and Koutsoyiannis 1997).

At the beginning of the 21th century, environmental or climate concerns and efforts to reduce economy’s dependence on fossil fuels engendered an increase in the use of renewable resources, including biomass. However, these policies, being highly dependent on existing water and land resources, have sometimes been criticized of disregarding the latter, placing pressures on stressed water resources and leading to land degradation, and thus having opposite effects to the ones intended (Pittock 2011). Concerns about the shift towards biomass have also been expressed due to substitution of water and land resources from food production to energy production, i.e. a ‘water for food’ versus a ‘water for energy’ competition (Dalla Marta et al. 2011; Gerbens-Leenes et al. 2009).

Eventually, we should be able to increase efficiency in both sectors and achieve water and energy security by better informed integrated policies together with technological innovations. An important reflection on the regional nature of the water-energy stresses and on the limits of future progress is provided by Bazilian et al. (2010, 2011). The study notes that arising inequalities in terms of present and future access to water and energy should be examined in political terms as well as in terms of environmental and technological constraints, and therefore, political prioritization is also required.

3 Energy Hydraulics

3.1 Governing Equations

In order to extract energy from water or to add energy to water, we use hydrodynamic machines called turbines and pumps, respectively.

The governing equation for electric power production via transformation of the dynamic and kinetic energy of water is

where ρ is the water density with a typical value for clean water of 1000 kg/m3; g is the gravity acceleration with a typical value of 9.81 m/s2; Q is the discharge; \({H}_{\mathrm{n}}\) is the net or effective head, i.e. the dynamic energy, expressed as elevation difference, after subtracting the hydraulic losses across the water transferred to the turbine, which depend on Q; and η is the turbine efficiency that changes with Q, according to a function which is a characteristic of the turbine. Both \({H}_{\mathrm{n}}\) and Q may vary in time, and therefore so does P. By applying the SI units for Q (m3/s) and \({H}_{n}\) (m), the power P is expressed in Joules per second (J/s) or Watts (W).

Similarly, the governing equation for estimating the power consumed by lifting water at head \({H}_{\mathrm{m}}\) through pumping is given by

where \({H}_{\mathrm{m}}\) is the so-called manometric head, and η is the pump efficiency, which is a function of Q that is a characteristic of the pump. The manometric head is the sum of the elevation difference Δz plus the hydraulic losses across the pipeline system, where Δz = z2 − z1 , with z1 and z2 being water elevations before and after the pump (typically z1 < z2).

The energy produced or consumed during a time interval [t1, t2] is the integral of P, i.e.

After simplifications, we get the following formula, expressing the average energy produced over a specific time interval

where V is the water volume that passes through the turbines during the time interval [t1, t2], and \({\overline{H}}_{\mathrm{n}}\) and \(\stackrel{-}{\eta }\) are the net head and efficiency during this period, respectively, averaged over time.

Similarly, the consumed energy over a specific time interval due to pumping is approximated by

where the symbols have the same meaning as above.

3.2 Key Concepts of Hydropower Technology

Hydropower is generally produced either through hydroelectric dams or run-of-river plants. The former take advantage of the height difference that is artificially generated due to the rise of the river level upstream of the dam, and they also take advantage of the regulation capacity of the reservoir, which allows for storing the surplus flows and releasing them according to the time-schedule imposed by the reservoir management policy. On the other hand, run-of-river plants do not have significant storage capacity, and thus they operate with the available natural flow, which is irregularly varying. There are also other types of hydropower plants which make use of wave and tidal energy, but they are based on the same energy transformation laws.

Figure 20.3 illustrates a sketch of a conventional hydroelectric work, comprising the dam, the intake system, the conveyance pipe, called penstock, the turbine station, the outflow pipe, called draft tube, and the channel conveying water to the river, called tailrace. The dynamic energy of water is expressed by means of the so-called gross head, which is determined by the reservoir level upstream \({z}_{1}\), and the outflow level downstream \({z}_{2}\), i.e. H = \({z}_{1}\) − \({z}_{2}\). The reservoir level ranges between a minimum and a maximum value, i.e. the intake level and the spill level, respectively. The outflow level may also vary (e.g., outflow to a river), yet its fluctuation is generally very small, if compared to the variability of the upstream level, thus it is usually neglected in computations.

As the flow is conveyed from upstream to downstream, the available dynamic energy is decreased due to frictional and local energy losses that occur along the flow conveyance from the intake to the turbine. Therefore, the available energy to be converted, expressed by means of kinetic and pressure energy, is reduced by the quantity of losses (ΔH = H − \({H}_{n}\)), while the amount of mechanical energy that is finally available as electric power is further reduced by the factor 1−η.

Key design objective is to minimize the hydraulic losses and maximize the turbine efficiency in order to exploit as much of the gross head as possible. The overall design of the hydropower system is in fact a challenging optimization problem, involving the construction and maintenance costs of hydraulic and power infrastructures, and the benefits of energy production. Typically, conventional large-scale hydropower systems exploit 80–85% of the gross head, where 3–10% of head reduction is due to hydraulic losses and about 10% to conversion losses.

3.3 Hydraulic Losses

Frictional losses across the penstock as well as local energy losses that occur due to the changes in the flow geometry contribute to gross head reduction.

For given discharge Q and pipe diameter D, the flow velocity is given by

For the above flow characteristics, the energy gradient J across the pipe is typically estimated by the so-called Darcy-Weisbach formula

where f is a (dimensionless) friction factor. The latter is given by the Colebrook–White equation

where Re ≔ V D/ν is the Reynolds number and ε/D is the relative roughness, both dimensionless, whereas ε is the absolute (surface) roughness of the specific pipe and ν is the kinematic viscosity of water, which is function of temperature; e.g., for T = 15 °C, ν = 1.1 × 10–6 m2/s.

For a pipe of length L and diameter D, assuming steady uniform flow with discharge Q, the friction losses \({h}_{\mathrm{f}}\), which are the main component of the total hydraulic losses, are given by

Due to the complexity of friction loss calculations based on (20.6), a number of simplified formulas have been developed in the literature (e.g., the Hazen-Williams expression), which are however noticeably less accurate than the Darcy-Weisbach equation. A more consistent and accurate approximation is offered by the so-called generalized Manning equation, introduced by Koutsoyiannis (2008):

where β, γ and N are coefficients depending on roughness, for which Koutsoyiannis (2008) provides analytical expressions that are valid for specific velocity and diameter ranges. In particular, for the large diameters (i.e., D > 1 m) and velocities (i.e., V > 1 m/s) that are typically applied in hydropower systems, we get:

where \({\varepsilon }_{*}:={\varepsilon }_{0}\) is the so-called normalized roughness and \({\varepsilon }_{0}:={({\nu }^{2}/g)}^{1/3}\) = 0.05 mm, for temperature 15 °C.

The roughness coefficient \(\varepsilon\) is a characteristic hydraulic property of the pipe, mainly depending on the pipe material and age, where aging is mainly associated with pipe erosion due to the presence of sediments. For design purposes, it is recommended to apply quite large roughness values, e.g. \(\varepsilon =1\) mm, in order to account for all above factors at the end of time life of the penstock. For the above value, we get \({\varepsilon }_{*}\)= 1/0.05 = 20, and thus β = 0.262, γ = 0.009, and N = 0.0131.

On the other hand, local losses, also referred to as minor hydraulic losses, are occurring at every change of geometry and thus change of the flow conditions (e.g. flow entrance through the intake, change of diameter, flow split, elbow, etc.). Each individual loss is generally estimated by

where k is a dimensionless coefficient, depending on geometry. Classical hydraulic engineering handbooks (e.g., Roberson et al. 1998) provide analytical relationships, empirical formulas and nomographs for estimating k as function of local geometrical characteristics (e.g., ratio of upstream to downstream diameter). Typical values that are applied in hydroelectrical system components moving from upstream to downstream are:

-

k = 0.04 for intakes;

-

k = 0.10–0.15 for grates;

-

k = 0.08 for contractions;

-

k = 0.10 for elbows;

-

k = 0.10–0.20 for fully open valves;

-

k = 1 for outflow to the tailrace.

In preliminary design studies, local loss calculations are generally omitted, since the geometrical details are not yet specified, or they are roughly estimated, by considering an aggregate value of k for all types of local losses.

3.4 Turbines

A hydraulic turbine (from the Latin turba, meaning vortex, transliteration of the Greek τύρβη, meaning turbulence) is a rotary mechanical structure that converts the available kinetic and pressure energy of water (i.e. the net head) into mechanical work, which is next used for generating electrical power, when combined with a generator. Early turbine examples are waterwheels and windmills.

In large hydroelectric systems, turbines are generally classified into two categories, namely impulse and reaction (Fig. 20.4). In an impulse turbine, a jet of water passing from a contracting nozzle enters the curved (double) buckets of the turbine wheel to produce energy as the runner rotates. After impinging the buckets, the water outflows freely (i.e. under atmospheric pressure) to the downstream channel (Fig. 20.4, left). Since the jet flow is not axisymmetric, and only part of the runner is activated (typically only two or three out of a total of about 20 buckets are simultaneously hit), impulse turbines are also referred to as partial admission. They are also called Pelton wheels, in honour of the American engineer Lester Allan Pelton, who invented this machine in the 1870s (apparently by streamlining the traditional windmill technology). As shown in Fig. 20.4 (left), the objective is to convert the available dynamic energy (net head) into kinetic energy by substantially increasing the flow velocity from \({V}_{1}\) to \({V}_{2}\), where \({V}_{1}\) is the velocity through the penstock with diameter \({D}_{1}\), and \({V}_{2}\) is the velocity through the nozzle with diameter \({D}_{2}\) << \({D}_{1}\). If Q is the discharge, then from the continuity equation we get

Sketches of impulse (left) and reaction (right) turbines (adapted from Leon and Zhu (2014))

Generally, \({V}_{1}\) ranges from 4 to 6 m/s, while \({V}_{2}\) may exceed 100 m/s. Impulse turbines are applied in the case of significant heads (H > 250 m) and relatively small discharge. Large units may have multiple impinging at different locations of the wheel.

There also exist other types of impulse turbines that are applied for low heads and large discharges, e.g. the Turgo turbine, which uses single instead of double buckets on the wheel that are shallower than the Pelton ones, and where the jet is horizontal. Another example is the cross-flow turbine (Fig. 20.5, right), in which the water passes through the turbine transversely or across the turbine blades, and after passing to the inside of the runner, it exits on the opposite side. Passing through the runner twice provides additional efficiency, and also allows for self-cleaning from small debris, leaves etc. Another advantage of cross-flow turbines is the practically flat efficiency curve under varying loads, which makes them ideal for run-of-river plants.

In contrast to impulse turbines, which operate under atmospheric pressure, in reaction turbines, the flow is under pressure, since the chamber of the runner remains completely filled by water. In this case, the runner consists of several guide vanes, which change the direction of flow, thus producing forces due to change of momentum, which in turn make the runner rotate. After leaving the runner, the water enters the draft tube, before being extracted to the tailrace. The objective of the draft tube is to convert the mechanical (hydraulic) energy into rotational energy of runner-generator system, while reducing the flow velocity and hence the kinetic energy at the outflow section, i.e. the tailrace. As shown in Fig. 20.4 (right), this energy is subtracted from the gross head, thus it is a hydraulic loss in the system.

There are two main types of reaction turbines, the so-called Francis machine, which is suitable for a wide range of discharge and head conditions (and thus applied in the majority of hydroelectric dams, worldwide), and the propeller (also known as Kaplan) turbine, which is employed in cases of high-flow and low-head power production, e.g. tidal stations.

Turbines are also classified according to the main direction of flow in the runner as tangential-flow (Pelton), radial-flow (Francis), mixed-flow (cross-flow) and axial-flow (Kaplan). The selection of the turbine type is driven by the available head and discharge. Within preliminary investigations, we may refer to nomographs, such as in Fig. 20.6. Actually, the overall design of a large-scale turbine system is a very challenging task, also requiring laboratory experiments to identify the geometrical details and assess the hydraulic performance of the specific machine. One of the most important issues to account for within design is cavitation, affecting runners in reaction turbines, in which the relative pressure at the discharge ends of the blades is negative (Novak et al. 2006).

Since the flow conditions differ across different turbine types (e.g., atmospheric pressure for impulse turbines, pressurized flow for reaction turbines) and their geometrical details also differ, the turbine characteristics affect the net head estimations and, consequently, the determination of the optimal diameter of the penstock (Leon and Zhu 2014).

3.5 Efficiency of Hydroelectric Systems

The total efficiency (or simply efficiency) η of a hydroelectric plant for a given head and load is the ratio of the electric energy, which is provided to the electricity grid, to the hydraulic energy, i.e. the available net head. The value of η depends on scale (expressed in terms of discharge, since higher discharges ensure larger efficiencies) and the type of the turbine. Very large installations may reach efficiencies up to 95%, while small plants, with output power less than 5 MW, may have efficiencies between 80 and 85%, which again are quite high compared to other types of energy converters (see Sect. 20.1.2.2).

The total efficiency may be considered as the product of four individual components

where \({\eta }_{\mathrm{T}}\) is the efficiency of the turbines; \({\eta }_{\mathrm{G}}\) is the efficiency of the generator; \({\eta }_{\mathrm{TR}}\) is the efficiency of the transformer, and \({\eta }_{\mathrm{E}}\) is the efficiency of the transmission lines. Typical values for the latter three are 0.96, 0.98 and 0.98, respectively.

The turbine efficiency is defined as the ratio of the mechanical energy provided by the turbine to the net head. The difference between the two energy quantities is due to:

-

Hydraulic losses, which refer to friction losses of the fluid layers in motion, friction losses due to water crash on blades, local losses due to changes of tube section, etc.;

-

Volumetric losses, which are only occuring in case of impulse turbines, and they are due to small amounts of water that are extracted to the atmosphere, without crashing on the blades;

-

Mechanical losses that are developed in the rotating parts of the turbine.

Therefore, \({\eta }_{T}\) is also derived as the product of three components, i.e. hydraulic, volumetric, and mechanical efficiency, with typical values 0.90–0.96, 0.97–0.98 (only for impulse turbines) and 0.97–0.99, respectively.

Although in preliminary design and common management studies the efficiency is considered constant, it is actually a complex function of head and load. In real-world conditions, e.g. in case of large hydroelectric dams, the two aforementioned quantities are varying in time, since they depend on the reservoir level and the discharge, which are also evidently varying. As shown in Fig. 20.7, the variation of efficiency against head and discharge for different gate opening ratios is typically expressed by means of nomographs, which are experimentally derived and provided by the manufacturer of the turbine. For a specific turbine, there exists a theoretically optimal efficiency that is achieved for a specific combination of head and discharge. However, the actual optimum may differ, since the operation of the turbine is determined by the head-discharge relationship of the penstock, i.e. \({H}_{\mathrm{n}}\) = H − \(h\)(Q) (where h = hf + hL), dictating the feasible operation range. Since across this range the efficiency may differ significantly, also taking quite low values, a key design objective is to ensure that the turbines will mostly operate as close to the optimal efficiency value as possible. In hydroelectric reservoirs, this is achieved by properly tuning the opening of turbine gates, thus adapting the outflow to the given head conditions.

3.6 Pumps and Pumping Systems

Pumps convert mechanical energy to hydraulic energy, thus allowing to lift water from a lower to a higher elevation or to increase the discharge capacity across a water-transportation system (or even to boost water conveyance from a higher to a lower elevation by adding energy for the increased frictional losses). Pumps are classified into two categories, namely positive displacement pumps, which deliver a fixed amount of water with each revolution of the rotor, and rotodynamic or kinetic pumps, which apply energy to the water by accelerating it through the action of a rotating impeller. Archimedes’ screw pumps (see Sect. 20.1.1) are also another category, still in use, but it is not examined here. Rotodynamic pumps are the most usual type used in water resource systems (Chin 2006). The pipe upstream and downstream of a pumping system are called suction and delivery pipes, respectively, conveying water from an upstream level \({z}_{1}\) (water source) to a downstream level \({z}_{2}\) (destination tank).

As shown in Fig. 20.8, the total energy head provided by the pump, called manometric head, is the sum of the following components

where \({h}_{\mathrm{L}}\) are local head losses at the pump; \({h}_{\mathrm{f}}\) are friction losses across the suction and delivery pipes, which are estimated by Eq. (20.9) as function of the diameter, roughness and discharge, and \({V}^{2}/2g\) is the kinetic energy at the downstream end, e.g. the destination tank (which is another local head loss). Equation (20.15) represents the hydraulic operation of the pipeline system, expressing the manometric head \({H}_{\mathrm{m}}\) as function of the discharge Q.

Each pump also has a characteristic curve or performance curve, showing the relationship between the manometric head \({H}_{m}\) and the discharge Q. Thus, a combination of a specific pump with a specific pipeline has a unique operation point, which is determined by the intersection of the two curves (Fig. 20.9).

Usually, a pumping station comprises a set of pumps that are put either in series (multistage pumps) or in parallel. In multistage pumps two or more impellers are arranged in series with the discharge from the first impeller entering the eye of the next one and so on. This layout is preferred when large heads are required, e.g. in a case of deep underground abstractions. In that case, considering N similar pumps, the total head is divided by N, while the total flow is conveyed through all individual pumps. On the other hand, in the parallel configuration, the discharge is divided by N, where the total manometric head is estimated by summing each of all individual pumps. We remark that whenever a pump in series or in parallel is added to the system, the operation point of the pumping system changes accordingly.

3.7 Reversible Turbines

Reversible turbines are specific types of hydrodynamic machines that can operate both as turbines and pumps. Such systems are typically installed in pumped-storage plants, which allow to pump water to an upstream location by consuming the available excess of electric energy (or low-price energy, e.g. during night), so to be retrieved later as hydropower. The importance of these systems has increased significantly due to the great expansion of renewable energy sources, such as solar and wind energy, which are highly-uncertain as the energy generation depends each time on current meteorological conditions (Koutsoyiannis et al. 2009). In this context, pumped-storage systems are essential to regulate the excesses and deficits of energy production through renewable sources, as discussed further in following sections.

4 Design and Operation of Hydroelectric Systems

4.1 Classification of Hydroelectric Systems

Hydroelectric systems comprise a wide range of layouts, from large-scale reservoirs to minor run-of-river plants, which take advantage of the available dynamic and kinetic energy of water across rivers and streams. These may be classified into categories (a) to (g), according to a number of criteria that are listed below, which also dictate the design and management of such systems.

-

(a)

Based on their installed capacity:

-

Large hydro plants for P > 15 MW;

-

Small hydro plants for P < 15 MW;

-

Micro hydro plants for P = 5 to 100 kW;

-

Pico hydro plants, for P < 5 kW.

-

The thresholds used may differ worldwide; for instance, the threshold for large and small plants typically ranges from 5 to 20 MW. Usually, but not exclusively, large plants are installed downstream of dams, to take advantage of the regulating capacity of the reservoir. Small plants may or may not have storage capacity, while micro and pico hydro plants only capture the kinetic energy of small streams to provide electricity to isolated homes or small communities.

-

(b)

Based on their head:

-

Large head for H > 200 m;

-

Medium head for H = 30 to 200 m;

-

Small head for H < 30 m.

-

As explained in previous section, the available head combined with discharge determines the selection of the turbine type.

-

(c)

Based on the location of the power station:

-

Power stations installed close to the dam;

-

Power stations installed at a significant distance downstream of the dam;

-

Power stations installed at an adjacent river basin (interbasin water transfer).

-

The typical case is the first, thus involving a penstock of relatively small length, in order to minimize the friction losses and the environmental impacts. Yet, there are cases where it is more advantageous to construct the power plant at a downstream location in order to increase the available head. Apparently, such a layout is economically efficient only when the river slope is large, so that the gains from elevation difference exceed the hydraulic losses due to the water being transferred at a long distance. An important issue to account for is the environmental impacts, since the water does not return to the river just downstream of the dam, as happens in typical configurations where the power station is located close to the foot of the dam.

Another case is the installation of the power station in a neighbouring basin, where the water is transferred through a pipeline connecting the two basins. This layout is preferred when there is a significant elevation difference between the upstream catchment, in which the water is gathered, to the one downstream, where the power station is installed. Typically, in large-scale interbasin systems, Pelton type turbines are used, as this option becomes economically efficient when the head is large enough. However, if the transfer is implemented for other reasons (e.g. if the principal objective is the transfer of water per se), then the head may be small.

-

(d)

Based on the type of the hydrodynamic machine:

-

Action turbines;

-

Reaction turbines;

-

Reversible turbines.

-

As already explained, action turbines are applied only in case of relatively small discharges and large heads, while reaction turbines are employed in any other case. Reversible turbines are applied within pumped storage systems, which require a cascade of two storage components, one upstream and one downstream. Although any combination of storage systems is generally valid, the most usual case is when a large hydroelectric reservoir (typically called head reservoir) is located upstream to implement long-term flow regulations, and a small-one downstream. Another widely used scheme comprises a reservoir, installed across the river, connected with a run-of-river tank, installed at a relatively small distance but at a higher elevation.

-

(e)

Based on the reservoir scale:

-

Large-scale reservoirs, having storage capacity larger than the mean annual inflow, thus ensuring multiannual regulation of the river flows;

-

Medium-scale reservoirs, providing seasonal regulation of inflows;

-

Small-scale reservoirs that are constructed to create an artificial head, but have minimal regulation capacity;

-

Run-of-river plants without storage capacity.

-

-

(f)

Based on the time-schedule of turbine operation:

-

Continuous (or almost continuous) operation to provide base-load electricity;

-

Intermittent operation to provide peak-load electricity;

-

Pumped-storage operation to regulate energy production excesses and deficits from other sources.

-

It is well-known that a major advantage of (hydro) turbines is their almost immediate response, as they can be activated very quickly to adapt to changing energy demands. In this context, hydroelectric works are the most flexible source of electricity. In particular, large and medium-scale reservoirs may provide both base and peak load, since they offer enough storage capacity to operate independently of the inflows. However, in the current energy scene, comprising multiple energy sources, the typical operation of such works is for fulfilling peak energy demands by releasing water only during a few hours per day (a tactic called hydropeaking).

Small hydroelectric works with minimal or negligible storage capacity do not offer the opportunity to regulate outflows and they may also have intermittent operation. Actually, the energy production follows the variability of input process (in this case, streamflow), similarly to other renewables such as solar, wind and wave plants.

-

(g)

Based on the water uses served by the reservoir:

-

Single-purpose use, i.e. exclusively for hydropower generation;

-

Multiple-purpose use.

-

Often, hydroelectric reservoirs serve additional water uses, such as water supply and irrigation, and also provide flood control. Environmental constraints are also imposed to the operation of existing and new dams, typically by means of releasing a constant (or sometimes varying) flow rate downstream of the dam to maintain riverine ecosystems. Such uses do not allow fully exploiting the hydrodynamic potential of the reservoir system, because water abstractions, water level regulations or water release schedules differ from the ones maximizing power production. In many hydroelectric reservoirs worldwide, recreation activities and associated touristic infrastructures have been developed as result of the generation of an artificial landscape and ecosystem of important aesthetic and environmental value, thus introducing additional constraints to the primary water use, which is energy production. Nevertheless, as multipurpose hydroelectric reservoirs are by definition subject to complex and generally contradictory objectives, a rational management policy is essential to ensure an optimal balancing of the associated conflicts (Christofides et al. 2005; Efstratiadis and Hadjibiros 2011).

4.2 Hydrological Analysis

For an assessment of an existing or planned hydroelectric system, it is essential to estimate the available water yield from the upstream catchment, as well as its variability, at multiple temporal scales. The surface runoff produced by the catchment is either directly available, by means of flow observations at the site of interest, or estimated indirectly, through a hydrological model. In the literature, numerous modelling approaches are available, of different levels of complexity.

The time scale of hydrological analysis depends on the scope of the study, but also depends on characteristic scales of the hydroelectric system. For the simulation of large reservoirs, a monthly time scale is typically adopted, while for small hydroelectric works the recommended temporal scale of hydrological analysis is daily. However, other aspects of the overall design and management may require another temporal resolution, for example, hourly or finer for flood analysis purposes, and daily for environmental flow assessment.

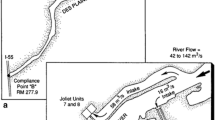

There are two ways of expressing the variation in river flow over the time period of interest, namely the hydrograph and the so-called flow duration curve (FDC), which is none other than the empirical exceedance probability plot (EEPP) of observed flows. The hydrograph (flow time series) depicts the evolution of flow for a specific time scale (annual, monthly, daily, hourly) over a specific time period. In case of hydroelectric works with non-negligible storage capacity, the sequence of flows plays a crucial role on the energy production, as it determines the required flow regulation by the reservoir.

The FDC (EEPP) is constructed by sorting the flow data in descending order and assigning an empirical exceedance probability based on the order of each value. Thus, the vertical axis represents the flow value and the horizontal axis the percentage of the time that the flow exceeds the given flow value. As the FDC (EEPP) expresses the distribution of flow values over a time period, a flatter curve corresponds to a more even spread of the annual inflow over the year. On the empirical probability distribution function, a proper theoretical model can be fitted using the typical probabilistic methodology. In this respect, the FDC (EEPP) of the river inflow at a specific site can be mathematically modelled as

where Q is the discharge; P is the exceedance probability of the value Q (also thought of as the fraction of time in which Q is exceeded), and F is the probability distribution function.

Figure 20.10a illustrates the hydrograph of 21 years of daily flow data. Based on it, one can recognize the seasonal variability of flows and the sequence of wet and dry periods. Figure 20.10b depicts the FDC (EEPP) constructed from the same data. As an example, from the FDC we easily see that the flow rate that is available for at least 30% of the time period is about 1.0 m3/s; likewise, a flow rate exceeding 2.0 m3/s is available in 15% of the time period.

4.3 Hydroelectric Reservoirs