Abstract

The chapter provides a brief overview of the major tasks of container terminal planning as well as planning activities and results associated with task processing. Furthermore, the main causes for innovation activities of container terminals are analyzed and subdivided in three areas: changes in technology, changes in customer demands, and changes in environmental rules. For each area, typical terminal innovations before and after the global economic and financial crisis are being compared regarding their respective scale of challenge for container terminals. The results enable a better understanding of the cause-and-effect relationships of terminal innovations and the kind of relationships leading to (particularly) challenging innovation processes. Finally, the chapter provides a brief overview of the contents of all Handbook chapters.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1 Introduction

In the past few years, the environment of container seaports and their terminals have changed considerably. In many cases, this has also been associated with appreciable impact on the development of the ports and terminals themselves. After the decrease in transport volumes – due to the Global Economic and Financial (GEF) crisis – was overcome and international container transport returned back to a path of growth (see Fig. 1.1), the development of many container ports was different from before – for some rather positive but for others also negative.

Global containerized trade (1996–2018) in million TEU and percentage annual change, data for 2018 are projected figures (see UNCTAD 2018, p. 13)

At the beginning of the crisis (2008), for example, the ranking of the largest European container ports – according to handling volume – was Rotterdam, Hamburg, Antwerp, and Bremerhaven. All of these ports were also represented on the list of the world’s 20 largest container ports. After the crisis the two German ports considerably slipped down on this list and besides, Hamburg and Antwerp changed their places in the order of the largest container ports in Europe.Footnote 1

The reasons for the development are complex just as the changes container ports and terminals faced in the last years. Not all of them found (and find) the “right” answers to the emerging requirements and have lost competitiveness. In other words, those seaports and terminals which were not be able to cope with the changing conditions continued to grow more slowly or even had to accept losses in handling volume.

In many cases, the changes in structure and service provision on the liner shipping market were the driving force for new requirements (see Sect. 1.3). Shipping companies – as key customers of container ports and terminals – suffer from the fierce competition that is existing in container liner shipping for years. For this reason, they have tried (and still try) to continuously optimize the operation of their fleets by both technical measures (especially ever larger vessels using more economic propulsions) and organizational measures (e.g., slow steaming or increased formation of alliances). This behavior of the shipping companies has obviously led to new – in most cases growing – requirements for the “loop” ports and terminals called by vessels of mainliner services for discharging and loading.

Besides that, further changes in the environment of seaport container terminalsFootnote 2 have created new requirements for the facilities as they impact the service provision of terminals and thus their competitiveness as well. In this connection, in particular legal and technological conditions are subject to change. For one thing, container terminals have been continued to be confronted – as in the decades before – with emerging technological innovations and their implementation in terminal practice. For another thing, more and more new (or extended) environmental regulations and directives issued by national governments (and governments of a community of states) have to be followed and lead to additional requirements for the terminals.

The remainder of this chapter is organized as follows: Sect. 1.2 provides some basics in the field of container terminal planning. The focus is on relevant planning tasks including aspects of task processing and their classification based on existing planning dependencies and objects of terminal planning. In the following section, in a first step, the main causes for innovation activities of container terminals are analyzed and subdivided in three areas. In a second step, for each area of cause, typical terminal innovations before and after the GEF crisis are being compared regarding their respective scale of challenge for the terminals. Finally, Sect. 1.4 provides a brief overview of the contents of all Handbook chapters.

2 Basic Planning Aspects

The following considerations relate to tasks of terminal planning which may emerge during the entire life cycle of container terminals, i.e., they belong to either the design phase, construction phase or operation phase of related facilities. The focus is especially on the nature and scope of planning tasks as well as on the activities and results associated with task processing.

The tasks of terminal planning have not really changed in the past years. This is hardly remarkable if we have a look on the today’s basic conditions of container terminal planning. On the one hand, the basicstructure of the (three) main container flowsFootnote 3 passing through a container terminal is still the same just as the starting and ending points of the underlying handling processes. On the other hand, there has been no paradigm shift in the planning of terminals which is still mainly determined by the following facts:

-

The existing infrastructure (and the results from new planning of infrastructure) defines the framework for planning of terminal suprastructure,Footnote 4 while the existing suprastructure (and the results from new planning of suprastructure) in turn sets the framework for planning of terminal operation. In other words, the infra- and suprastructure being already in use and the results from new planning determine the support potential for terminal operation planning and, at the same time, restrict planning opportunities to a certain extent.

-

Considering the different customer groups of container terminals, even today in the sixth decade of international container transport,Footnote 5 the demand of shipping companies has by far the highest priority from the perspective of terminal operators (“no vessel – no handling business!”). With the growth of vessel size, the requirements for container terminals further increase and container shipping industry dominates – perhaps more than ever – the global container transport chains (“no handling capabilities for mega vesselsFootnote 6 – no/less mainliner services and possibly descent to feeder port”). To sum up, also today, planning of container terminals must primarily be geared to the customer demands at the terminal quayside.

The abovementioned determinants of terminal planning are manifested in two (widely known) planning principles for container terminals:

-

Careful analysis of existing requirements and support potentials forms the basis for sound terminal planning, both should be done “from quayside to landside,”! That is,

…beginning with quayside planning:

analyze the requirements and support potential for quayside planning alternatives and use analyzed results for new planning of quayside,

…going ahead to yard planning:

analyze requirements and support potential for yard planning alternatives and use analyzed results for new planning of yard,

…closing with landside planning:

analyze requirements and support potential for landside planning alternatives and use analyzed results for new planning of landside.Footnote 7

-

Container terminal planning should be done “from bottom-up!” That is,

…beginning with infrastructure planning:

analyze port needs and/or requirements of (planned) suprastructure and use analyzed results for planning of terminal infrastructure (e.g., length and construction of quay wall or shape and size of terminal area),

…going ahead to suprastructure planning:

analyze requirements of (planned) operation and support potential of (planned) infrastructure and use analyzed results for planning of terminal suprastructure (e.g., type and fleet size of vehicles for horizontal transport at quayside),

…closing with operation planning:

analyze customer demands and support potential of (planned) suprastructure and use analyzed results for planning of terminal operation (e.g., strategies for serving quay cranes by horizontal transport or for container stacking within the yard area).

-

Both planning principles overlap each other and describe together the complete planning process of a container terminal (in case of a “greenfield project”). That is, starting with planning of terminal infrastructure and closing with operation planning at landside:Footnote 8

planning of all areas (infrastructure)

→

planning of quayside area (suprastructure planning → operation planning)

→

planning of yard area (suprastructure planning → operation planning)

→

planning of landside area (suprastructure planning → operation planning)

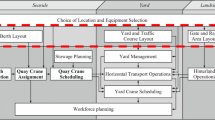

In the light of the previous discussion, the 3-level-model of terminal planning described in the first edition of this Handbook is still to be regarded as valid. The model classifies relevant tasks of terminal planning on three levels — taking the major planning objects of container terminals as a basis, namely the terminal operation, the terminal suprastructure, and the terminal infrastructure. To be more precisely, the model distinguishes the planning levels: Planning of Terminal Operation, Planning of Terminal Suprastructure, and Planning of Terminal Infrastructure (see Fig. 1.2).

Besides major tasks of terminal planning, the model levels are being attributed by relevant aspects of task processing. These especially includes the objectives, horizons, activities, and results of planning work as well as the parties in charge. Furthermore, information on structures and processes already existing at a terminal (and being relevant for re-planning) are considered on the different model levels as well. In the following, each planning level of the 3-level-model is being described by that “part” of terminal planning which is attributed to the level using some examples from practice for illustration:

-

Planning of Terminal Operation

Tasks on this level focus on the analysis of customer demands and the support potential of (planned) suprastructure as well as on the short-, medium-, and long-term planning of the operation of container terminals. Accordingly, further classification of planning tasks and associated aspects of tasks processing makes sense and leads to the determination of three additional sub-levels being outlined in the following:

-

Short-term Planning

Operational planning work concerns day-to-day operation in terms of terminal logistics (i.e., container handling, transport, and storage) as well as terminal administration (e.g., customs clearance, creating invoices or damage notifications, or processing bills of lading).

-

Medium-term Planning

Tactical planning work focuses on more “durable” operational structures (up to a few years), among others, in the field of outsourcing activities (e.g., IT support), the basic use of terminal resources (e.g., shift system or strategies for equipment control) or intercompany co-operations (e.g., labor pooling with other terminals).

-

Long-term Planning

Strategic planning work relates to the basic orientation of terminal operation over many years such as the range of terminal services (e.g., maximum vessel size considered for processing or vessel size-related commitments to berth productivity) or long-term partnerships (e.g., establishment of dedicated berths based on strategic co-operation agreements between terminal operators and shipping companies).

-

-

Planning of Terminal Suprastructure

Terminal planning on this level deals with the analysis of requirements (from the planning level of “terminal operation”) and the support potential of (planned) infrastructure as well as with the planning of terminal suprastructure. Among others, planning activities have impact on the layout design, handling equipment, manning requirements, terminal buildings and pavement as well as the supply & disposal network. Elaborated planning results form the basis for the production and procurement of terminal suprastructure. In the context of suprastructure planning, it is being determined what kinds of resources are used (e.g., equipment type) in which quantity (e.g., fleet size) for the provision of terminal services. Typically, planning needs on the suprastructure level arise in connection with greenfield projects, the evaluation of strategies for terminal expansion or the development of implementation concepts for the conversion of handling technologies.

-

Planning of Terminal Infrastructure

In a first step, terminal planning on this level also includes the analysis of requirements for the infrastructure. For this purpose, the needs of the respective port and the requirements of (planned) suprastructure are to be analyzed. Based on the analysis results appropriate planning of infrastructure resources is carried out. Planning decisions especially relate to the preparation of the terminal area (e.g., area size, shape, and altitude or quay wall length) and the connection of the handling facility to external networks (e.g., traffic, energy, and supply & disposal). Among others, this requires planning activities in the fields of land reclamation, sand dredging, and civil engineering (e.g., related to quay wall, (external) supply & disposal pipes or cables as well as traffic access routes).

As regards planning activities on the level of terminal operation and suprastructure, these are usually the responsibility of terminal operators. This is due to the fact that they must also finance the implementation of planning results and cover the costs for the following operational use and maintenance. That is, terminal operators have a direct influence on processing of planning tasks belonging to these levels and thus on the elaborated planning results. In most cases, planning of terminal infrastructure is in the duty of local communities and authorities and accordingly is supported by them financially. Thus, terminal operators usually cannot (or only indirectly) enforce planning decisions regarding the terminal infrastructure (see Fig. 1.2).

In summary, the planning work on the different planning levels may not be seen independently. There are interdependencies between them, resulting in a natural (hierarchical) order of the levels. The 3-level-model of terminal planning considers the existing relationships in two ways – for one thing by the order of planning levels (see Fig. 1.2)Footnote 9 and for another by the nature and direction of dependencies.Footnote 10

Keeping in mind the various levels of terminal planning it shall be emphasized that the Handbook with its contributions primarily focuses on planning tasks and activities on the suprastructure level of container terminals (see Fig. 1.2). In this regard, special attention is particularly given to problems and problem solving in the areas of equipment dimensioning, layout design, sea- and landside terminal access as well as developing hinterland connections of container terminals.

3 Innovation Causes and Challenges

Looking at the development of container terminals over the past years, the need to innovate is high for many facilities to stay competitive. Before the GEF crisis, scarce capacities and coping with “bottleneck problems” just like new opportunities in the field of automation drove the introduction of innovations in terminal practice. Today, the causes for innovations are more complex and attributed here to changes in three areas (see Fig. 1.3):

-

Changes in terminal technologies Container terminals are facing new technologies which promise to improve their competitiveness and – in some cases – also reduce (negative) effects of handling operations on the environment. Accordingly, a certain pressure develops to integrate related innovations in the own terminal processes. That is, they need to be customized according to the specific conditions of the terminal and smoothly put into terminal practice (ideally) without hampering day-to-day operation. In this regard, a further distinction should be made between technology changes in the field of container handling systems and technology changes in the field of Information & Communication systems (I&C systems)

-

Changes in customer demands In this area, changing demands of the main customers – the shipping companies – are of particular importance. The satisfaction of their needs determines the market success (or failure) of a terminal, and at the end of the day, its economic survival. Relevant changes in demand relate in particular to increasing efficiency and performance requirements for vessel processing at terminals due to the technical and logistic dimensions of loading and discharging processes of ever larger ships. Shipping companies use more and more Ultra Large Container Vessels (ULCV)Footnote 11 for providing mainliner services (see Merk 2018) on the intercontinental sea routes. In recent years, the competitive situation in container shipping has been extreme for various reasons. The time- and cost-related improvement of port stays during a vessel round trip is one way for shipping companies to strengthen their competitiveness on the market.

-

Changes in environmental rules Driven by societal interest and taken up by politics, a growing importance is attributed to environmental protection in container transport. Related changes are especially manifested in new (stricter) environmental regulations and directivesFootnote 12 for pollutant emissions on national level as well as on the level of community of nations (e.g., the European Union). These also apply to container logistics in ports and have led to increasing environmental requirements for the operation of container terminals as well as for the inflow and outflow of containers from/to the sea and hinterland. The set of “restrictions” to be observed in this area is often not the same in different regions of the world and depends on the respective legislation or the implementation of international law by the national legislations, respectively. Accordingly, it can even differ between ports of the same region. All in all, the impact on the competitiveness of container terminals should not be underestimated, in particular, if there are imbalances in the legal conditions (for environmental protection) between ports or regions.

Whenever changes in the environment of a container terminal affect the competitiveness of the terminal and with it its economic result they represent requirements for the facility. In these cases, innovation pressure emerges, i.e., there is a certain need for own innovation so that existing and/or upcoming requirements can be better met (see Fig. 1.3).

Innovation activities are usually associated with challenges for the innovating company and thus for container terminals as well. In many cases, the required knowledge/experience is missing (especially with high level of innovation), operational core processes are impacted or more time, budget and/or manpower are needed, etc. to smoothly perform the related innovation process, i.e., (ideally) in the same way as a standard process of the company.

Conversely, this means that challenges associated with an innovation are comparatively “high” if a company has major difficulties to create the aforesaid prerequisites for carrying out innovation activities. Challenges, on the other hand, are rather “low” if the company is economically and technologically strong, and besides is highly effective in implementing innovations. As a consequence, the scale of challenges is always to be evaluated individually based on the respective conditions of each case. Against the background of this insight it becomes clear that the attempt of classifying terminal challenges of recent years can only be of general nature and does not apply to each individual container terminal. Comparing the challenges associated with innovations since the GEF crisis with those emerging in the 10–15 years before the following should be pointed out:

Challenges due to Changes in Technology

In the past years, apart from a few exceptions, the extent of technological changes in container handling has (by far) not reached the level before the crisis. Considering, e.g., the automation of horizontal transport (by AGV) and yard crane operations (by RMG) in the 1990s or the automation of straddle carriers and use of semi-automated double-trolley or tandem-lift quay cranes in the early 2000s, the recent technological changes (and resulting terminal innovations) have been less radical in most cases. Today, the abovementioned terminal equipment is more or less regarded as a “standard product” (see PEMA 2016). During the last years, the innovation focus was more on the further development of terminal technologies (e.g., implementing Lift AGV technology or using hybrid drive engines for straddle carriers.)Footnote 13 or the transfer of proven technologies (especially in the field of I&C) to new application areas within the terminals. Examples in this regard are the use of Optical Character Recognition (OCR) systems in the portal of quay cranes and the entrance of terminal railheads for automatically reading container numbers or the application of remote control systems to remotely operate cranes at quay wall from a control center (see Holmgren 2011).Footnote 14 Accordingly, challenges for container terminals originating from these kinds of technology changes are more likely to be classified as moderate compared to those before 2008.

Nevertheless there are exceptions in the more recent development of terminal technologies where the transfer into operation practice is associated with considerable challenges for the terminal. In the field of handling technologies, this concerns, e.g., the greenfield implementation of automated Rubber-Tyred Gantry (RTG) cranes or the conversion of a yard area with manually operated RTG to automated RTG operation, just like converting a fleet of traditionally driven transport vehicles (with diesel-hydraulic or diesel-electric engines) to electric drive technology. In the former case, especially the “clash” of automated terminal equipment and manually operated road trucks in the yard area leads to challenges for terminals.Footnote 15 In the latter case, new transport equipment has to be procured or vehicles in operation need to be refitted (if possible) and, among others, new strategies for vehicle control are to be implemented (e.g., due to battery recharging times to be observed).Footnote 16 In both previously discussed examples, processing of vessels at quay wall is directly affected (and with it the interests of the terminals’ main customers), if any problems emerge with the use of new technologies. Considering the level of innovation and the possible (negative) customer impact the challenges for terminals implementing related technologies are accordingly high.

In the field of I&C technologies, it should be pointed out that besides the transfer of I&C technologies to other application areas within container terminals (see above), the systemsFootnote 17 in use for many years are continuously developed further in terms of their functionalities, decision support methods, application of advanced I&C technologies, etc. Due to many years of experiences with these systems the challenges for terminals have been rather moderate in recent times compared to the 1990s when, e.g., automated positioning systems were initially implemented on the terminals (frequently based on GPS technology). An exception in this area represents innovative conceptsFootnote 18 and I&C technologies (e.g., internet of things, cloud computing or advanced sensors, and mobile system technologies) which form the basis for the present process of digitalization or use its potentials for recent years. The level of digitalization was always high at container terminals. Nevertheless, the abovementioned concepts and technologies represent novelties for the terminals and thus they are comparatively challenging from their perspective. From the perspective of the author, the first appreciable challenge for many terminals will be to find the “right” (competent) staff for analyzing the requirements and opportunities of the current phase of digitalization and to prepare the way for implementing the related tools and/or system solutions in the own terminal processes during the next years.

Challenges due to Changes in Customer Demands

Due to economic reasons (explained in Sect. 1.2), the shipping companies are the most important customers for container terminals. Driven by their dominant position in international container transport, especially the “big ones” have always had quite high handling requirements for the terminals (costs and time) called by their mainliner services. It is important to comprehend that this is all the more the case if several terminals are located in the same region serving the same (or similar) hinterland. Accordingly, challenging requirements of their customers (at seaside) are not new for the terminals, but based on several years of experience they know to deal with it. A successful strategy was and is (so far) to continuously initiate technology- or organization-related innovation processes in defined terminal areas, so that the processes affected remain limited and possible risk manageable.Footnote 19 Analogues to the cost and time requirements mentioned above, container terminals have always had to cope with requirements resulting from the growth in vessel size.Footnote 20

But in contrast to former times (i.e., before constructing and commissioning the Maersk E-class vessels between 2006 and 2008), for some years, more and more container ports and terminals reach the limit of their abilities in vessel processing, due to the considerable size of container vessels put into service.Footnote 21 Predictions on the development of vessel dimensions show that a further capacity increase (beyond 24,000 TEU) will also lead to further (appreciable) increase in vessel dimensions (see, e.g. Park and Suh 2019). If both occurs (increase in vessel capacity and dimensions), quite a few container ports will have serious difficulties to meet the upcoming requirements as not only the terminal suprastructure will show inefficiencies (e.g., quay cranes) but also the port infrastructure. Possibly, the water depth is too low to enable calls of such Extra ULCV (EULCV) at full capacity utilization and/or the quay wall construction is too weak to take the load of larger quay cranes or other significant bottlenecks occur. With regard to the complex (and partly uncertain) influences impacting the development of container vessels in their size and dimensions, only the next few years will show where the development is going and which challenges container terminals actually have to overcome in future.

Besides the issues of vessel size and dimension, the risen number of ULCV in the fleets of shipping companies imposes additional challenges for container terminals. If you look at the development of average size of container vessels in this context, between 1995 and 2005, it increased by about 45 %. Due to the growing number of ULCV, in the following 10 years the increase significantly accelerated and, in 2015, the average vessel size was about 168% compared to the level of 2005 (see Murray 2016; Tran and Haasis 2015). This dynamic development has lasted until today and will further continue to do so most likely. In the last three years, the absolute number of ULCV has more than doubled and increased from 40 vessels at the end of 2015 to about 100 vessels at the end of 2018. The ULCV coming into operation in 2017 and 2018 alone account for a third of new vessel capacity in these years. For the year 2025, Merk (2018) assumes that around 10% of all container vessels have a capacity of 14,000 TEUs and more. To meet the high ULCV processing requirements in terms of “berthing time” and “handling volume,” the general operational approach applied by (actually all) terminals is of organizational nature. In other words, they schedule more resources Footnote 22 and try to use these resources more efficiently.Footnote 23 At terminal landside, the approach is the same but (so far) the focus is primarily on more operation efficiency (e.g., by application of slot management systems to control the arrival process of road trucks or the use of OCR systems at the truck gate and railway station). To the best knowledge of the author, so far, there is no terminal worldwide that has implemented a radical new technology for more effective handling of ULCV volumes at terminal quayside and/or landside.

Against the background of this situation, there may emerge considerable operational difficulties for terminals if several ULCV calls overlap each other. In such cases, the peak loads induced by individual ULCV add up and may lead to operational conditions which are no longer manageable for a terminal as, e.g., not enough quay cranes (and space for further ones) are available on the quay wall or yard cranes are missing and cannot be added without significant extra expenditure (especially in case of RMG cranes) or the peak situation at quayside is aggravated by peak requirements simultaneously emerging at landside. This means, if technological innovation is out of question for a terminal in this situation, at short-term, there only remains the attempt to come to an agreement with the shipping companies to reschedule the vessel call pattern. In the medium- and long-term, the extension (if possible) of the traditional terminal suprastructure will become necessary associated with high costs and low utilization. To sum up the impact of drastic growth in vessel size: The terminals will be facing with further increasing challenges also in future, but today it is not yet clear to what extent this will happen and where the limit is.

Challenges due to Changes in Environmental Rules

Considering the development of environmental requirements for container terminals in the past, it can be basically stated that regulations and directions in this area have continuously increased in their number and restrictive effects over time (especially since the 1990s). Accordingly, a distinction of time periods (before and after the GEF crisis) makes little sense to classify challenges induced by changes in regulatory rules for environmental protection. More and higher legal requirements relate to all major areas of environmental pollution, i.e., pollutant emissions to air (including noise), soil, and water. Due to the kind of service provision at container terminals, air emissions and legislative measures associated with their reduction usually have most relevance for container terminals. The handling processes of terminals are typically based on the use of large-scale equipment which is still driven by diesel or diesel-hydraulic engines in many cases polluting the air by hazardous gases as well as greenhouse gases. Additionally, there are the terminals’ customers which deploy large-scale equipment as well and in case of shipping companies even ultra large-scale equipment, namely deep-sea and feeder vessels.

Against this background, two levels of action are to be distinguished from the perspective of container terminals – for one thing, the reduction of air and noise emissions by own operation activities and for another, the limitation of emissions generated by their customers. Regarding the former, there are regulatory rules that define limit values for air emissions of terminal equipment which have to be observed when new equipment is put into operation. These rules are usually becoming stricter in several stages over time.Footnote 24 For container terminals, emerging challenges are manageable if they include changes in legal provisions in their long-term equipment procurement process. This allows them to smoothly retrofit (or replace) “insufficient” equipment step by step and avoids an “overnight” exchange of all drivetrains or replacement of all equipment units. The latter is challenging as modified (new) control strategies and/or organizational concepts may be required just like “other” know-how in terms of equipment maintenance & repair (see above).

Similar to gas emissions, challenges induced by (too) high noise emission can be considered as comparatively moderate (if included in terminal strategy in the long run). “Air pollution” by terminal noise usually “only” leads to difficulties in the proximity of urban areas and besides that, there are a variety of effective measures – on different levels – to reduce such emissions.Footnote 25

In summary, new (stricter) environmental regulations and directives continuously have led (and will continue to lead) to the need for innovation on container terminals. Nevertheless, from today’s perspective, related innovations appear manageable if container terminals (and ports) pro-actively consider the consequences of regulative changes in their suprastructure (and infrastructure) planning.

For emissions of transport vehicles owned by terminals’ customers, the vehicle owner is in charge for complying with the applicable provisions of a port (e.g., since 2010 a ship at berth in EU ports needs to use fuels with a maximum of 0.1% sulfur content). Nonetheless, it is in the interest of terminals and ports (for reasons of competition and environmental protection) to support their customers in this regard. They do so, for example, by providing shore power supply (cold ironing) allowing vessels to shut off their auxiliary engine during port stay, charging lower port dues and tariffs when burning fuels with less pollutants in ports (see Merk 2014) or implementing a slot management system to reduce truck waiting times at gate.Footnote 26

All in all, it can be concluded that the challenges for container terminals continue to be high. In comparison to former times (before 2008), in recent years they have associated less with technological innovations but more with technological enhancements and organizational innovations (e.g., serving an ULCV with 8–9 quay cranes and handling 8000 or 9000 containers per vessel call). Depending on the development of ULCV in size and number, the current level of innovation could no longer be sufficient in the future to remain competitive in the medium- and long-term.

Accordingly, terminals should increasingly investigate (or even develop) innovative container handling systemsFootnote 27 that can form the basis for new handling solutions at quay wall and the landside terminal interfaces in future. In this respect, the chapters of the Handbook provide new findings as well as innovative planning approaches and results that can serve planners as a basis and inspiration for their daily work to (better) overcome existing and upcoming challenges for container terminals.

4 Contents of the Handbook

This section provides a brief overview of the topics discussed in the different chapters of the Handbook. The book is divided into five parts: Part I with general considerations on terminal planning, innovations and challenges; Part II with basic aspects in the fields of “instruments,” “technologies,” “management,” and “environment”; Parts III–V with innovative approaches and results of terminal planning representing both concepts and solutions which have already been successfully implemented in practice.

4.1 Basic Aspects: Instruments, Technologies, Management, and Environment

A fundamental prerequisite for the generation of competitive planning results is the knowledge about relevant basic conditions of planning activities in the respective application domain (here: container terminal), such as available technologies and management concepts or legal regulations in force or to become in force. Furthermore, effective instruments are of interest which can help planners to identify, elaborate, and evaluate appropriate action alternatives. Against this backdrop, the first three chapters of Part II of the Handbook focus on instruments that support terminal planning in particular on the operation and suprastructure level. It is worth noting that these instruments can also be helpful for solving specific problems on the level of terminal infrastructure:

Chapters 2 and 3:

The contributions of Schütt and Saanen give a comprehensive overview of the support options simulation models provide and which improvements can be achieved through their use in solving planning problems on all levels of terminal planning. In this regard, the advantages of using simulation models for planning issues in the different phases of “terminal life cycle” are shown, starting with the (initial) dimensioning of infrastructure and suprastructure going ahead to detailed planning and resource commissioning up to the day-to-day operation of container terminals. Here, not only problems of equipment and layout planning are discussed, but also possibilities for the use of simulation in functional specification and validation of the terminal IT systems and their optimized configuration regarding the day-to-day operation. Based on this, Schütt additionally focuses on the application of simulation for evaluating ecological impacts and Saanen introduces concrete guidelines for using simulation on the various levels of terminal planning. Both authors see a great potential for simulation in operational planning as it allows a comprehensive view into the near future which can lead to significantly better planning decisions.

Chapter 4:

Furthermore, the contribution of Anvari et al. uses the methods Queuing Theory, Petri Networks, and Discrete Event Simulation to address the fleet sizing problem of horizontal transport vehicles at terminal quayside. The authors compare the three methods regarding their results and effort for application and recommend Queuing Theory for pre-planning issues at the beginning of terminal projects, while Discrete Event Simulation should rather be used subsequently to support detailed planning of terminal resources.Footnote 28 Regarding the Petri Net method the authors see application options for pre-planning issues as well, but first further development is required to make the method more applicable for practitioners.

With respect to issues in the field of terminal technology in particular the Chaps. 5–8 provide new findings and solutions for planners on both the suprastructure and the infrastructure level. The first three chapters relate to terminal suprastructure and discuss aspects of terminal automation in conjunction with eco-friendly drive technologies, pavement options for container terminals considering the requirements of operational use, and the digital change in ports and resulting opportunities for improved data-driven decision-making. The latter deals with the infrastructure resource “quay wall” and presents technical options for its design.

Chapter 5:

Against the background of the changes in the environment of container ports and terminals and resulting challenges for their operation (see Sect. 1.3), more and more container terminals (have) recognize(d) automation as an effective approach for cost control and performance improvement. The contribution of Rijsenbrij & Wieschemann provides an overview of the state-of-the-art of terminal automation and besides, describe short-term developments in this area along with an approach for successful implementation of automation projects at terminals. Furthermore, the authors discuss economic and technical aspects of different electric drive technologies and outline the opportunities for container terminals associated with the use of electrical powered transport vehicles.

Chapter 6:

In the context of I&C systems and their use for information processing and decision support, the contribution of Heilig et al. introduces the concept of business analytics and points out its support potential for terminal planning and management. The contribution specifically focuses on data mining approaches and provides a comprehensive overview of applications at container terminals and related research. Considering the area of decision-making and decision support, the authors establish a data-driven perspective on terminal planning and management, complementing the traditional optimization perspective.

Chapter 7:

As regards the pavement of container terminals, the contribution of Schnabel provides experiences and findings on the technical options available for terminals today. After a compilation of terminal equipment loads, the author gives an overview of practical proven pavement solutions for different operational areas of container terminals. Both advantages and disadvantages of available pavement types are summarized and suitable wearing courses for the different operational areas are proposed.

Chapter 8:

The infrastructure decision on the quay wall construction type has long-term character and is comparatively complex as many different aspects need to be considered for decision-making. The contribution of Meyer presents different quay wall construction types being relevant for container terminal operation. Furthermore, the author elaborates the most important criteria in the process of finding a preferred quay wall type.

The last two chapters of Part II of the Handbook primarily provide new findings for strategic planning of terminal operation. That is, the aspects discussed by the authors are more management-related. For one thing, they refer to the value of a cluster- and network-orientation for container terminals including opportunities to improve this orientation and for another, the focus is on environmental rules for vessel operation and the impact on container ports and terminals requiring new answers from strategic planning as well.

Chapter 9:

Many container terminals are focused today on operational excellence and put their “own processes” into the center of attention. de Langen argues in his contribution that in addition to this inward-looking view, container terminals may benefit from an orientation on the overall supply chain of which they are a part as well as an orientation on the port cluster of which they are a component. For this reason, the author discusses the embeddedness of container terminals in international supply chains, among others, with examples in the areas of information exchange and extended gates. These show the advantages for container terminals resulting from a supply chain orientation. Furthermore, the author questions the role of container terminals in port clusters with examples of how a cluster orientation is valuable for terminals. In this regard, relevant issues include, e.g., education and training, intra-port container flows, and port marketing.

Chapter 10:

The contribution of Schinas aims to examine the fundamental connections of ship-related emission regulations to container port and terminal issues. For this purpose, the author outlines the applicable international and regional regulations on air emissions from vessel operation and analyzes their impact on port and terminal decision-making and functioning. The analysis also focuses on effective solutions, especially those promoted by the port or terminal management.

4.2 Main Planning Areas

Based on the well-known terminal operation areas (quayside, yard, and landside) the Handbook differentiates three main planning areas for the handling facility “container terminal:” Seaside Access and Terminal Quayside, Terminal Yard, Terminal Landside and Hinterland Access. In a broader understanding of the boundaries of a container terminal, the seaside and hinterland access of the facility are considered as part of the Terminal Quayside/Landside planning area and thus as scope of activities for terminal planning. All topics (chapters) belonging to one planning area are provided in a separate part of the Handbook.

This means in detail, planning contents of the Seaside Access and Terminal Quayside area are summarized in Part III, contents of the Terminal Yard area in Part IV, and contents of the Terminal Landside and Hinterland Access area in Part V. For each planning area, the related part of the Handbook discusses innovative approaches and results of terminal planning representing both concepts and solutions which have already been successfully implemented in practice. Analogues to Part II of the Handbook, the focus is again on terminal planning on the suprastructure level.

Planning Area: Seaside Access and Terminal Quayside

Chapter 11chap11:

Being aware of the continuous development in size of container vessels, the contribution of Schönknecht presents a method for analyzing costs and performance of related vessels as means of transport in global transport chains for ISO containers. The rational is the continuous growth of container vessels, the infrastructure development to cater for them and the strong variations in bunker prices over the past years. The use of the method makes clear that the factors for success or lack of success for large container vessels can be found almost exclusively in the container ports and their hinterland infrastructure in combination with the general loop design.

Chapter 12chap12:

Safety of vessels is of major importance when approaching a port and berthing at a terminal. Continuously increasing vessel sizes raise the pressure on proper design of new waterborne infrastructure, but also on safety and risk assessment methodologies when applied to vessels for existing infrastructure. The contribution of Burmeister introduces international accepted approaches how to design waterborne infrastructure (especially port approaches and related maneuvering areas) for ensuring safe vessel navigation and maneuvering. Moreover, basic methods and guidelines of safety and risk assessment used for this purpose in the maritime world are presented.

Chapter 13chap13:

Ultra Large Container Vessels with high trade volumes per port are making fewer calls per round trip with more transshipment cargo and more port times at higher costs. Innovations which increase handling productivity and streamline handling operations of feeder vessels are required to avoid inefficient long stays in ports as well as to reduce the costs resulting from processing of such mainliner vessels. The contribution of March presents a solution (referred to as “Integrated Terminal Ship System”) that satisfies these requirements by the innovation of direct container handling between mainliner and feeder vessels. Basically, there are two technical solutions possible: Transshipment containers are simultaneously handled on both sides of the mainliner using two finger piers (first alternative) and im-/export containers are un-/loaded at the mainliner quayside while transshipment containers are directly handled between mainliner and feeder vessels at the mainliner waterside using one finger pier (second alternative).

Chapter 14chap14:

Besides quantitative dimensioning of terminal equipment another major task of suprastructure planning on the quayside is the layout design of the operation area. In this regard, the contribution of Ranau compares the space requirements of two operation systems for horizontal container transport and derives planning assumptions for dimensioning their terminal layout: The focus is, on the one hand, on AGV systems which perform quayside container transport, e.g., at several terminals on the Maasvlakte (Rotterdam) and, on the other hand, on automated straddle carrier systems being in operation, e.g., at container terminals in Brisbane and Los Angeles. Both system alternatives are investigated in combination with semi-automated quay cranes and automated RMG yard cranes working perpendicular to quay. Main areas for analyzing planning assumptions are the quay crane portal and backreach as well as the traffic area in front of the yard blocks. Based on the findings gained by the analysis, for both systems, the author provides a viable quayside layout and an investment comparison of the equipment required for operating a mainliner berth.

Chapter 15chap15:

Within the last 15 years the capacity of the largest container vessels has more than doubled, bringing more containers to terminals within each single call. Among the strategies to increase quayside productivity are, e.g., pooling of carrying equipment as well as dual-cycle and twin lift operation of quay cranes. The latter may be implemented with least impact on spatial and process change requirements and include the joint vertical movement of two 20 foot containers. But only if applied to operations of both lifting and carrying equipment container terminals will fully benefit from each twin move. Eisenberg et al. see a gap regarding the assessment of the potential productivity gain by twin carry operations. Their contribution wants to fill this gap by the example of the implementation of twin carry operation for straddle carriers at the HHLA Container Terminal Tollerort (Hamburg, Germany).

Planning Area: Terminal Yard

The first three chapters of this part of the Handbook highlight methods to support the short-term scheduling of yard resources. From the perspective of suprastructure planning, knowledge about related methods and their impact on yard operation is essential for an adequate evaluation of logistics capabilities and economic viability of yard equipment. Appropriate knowledge in this regard represents an indispensable prerequisite for planning of yard suprastructure that wants to meet emerging requirements.

Chapter 16chap16:

The contribution of Caserta et al. provides an updated survey on rehandling of containers at maritime container terminals. In particular, the authors review contributions with a particular focus on post-stacking situations, i.e., problems arising after the stacking area has already been arranged. Three types of post-stacking problems have been identified, namely (1) the remarshalling problem, (2) the premarshalling problem, and (3) the relocation problem. This research area has received an increasing attention since the first version of this contribution appeared in the first edition of the Handbook. Within this update, we discuss recent developments presented in literature. In particular, available solution approaches from the fields of exact and (meta-)heuristic methods are given and benchmark datasets are summarized. Moreover, an overview on extensions of post-stacking problems and according solution methods are discussed.

Chapter 17chap17:

As the interface between waterside and landside transport chains, the container yard plays a vital role for the performance and competitiveness of container terminals as a whole. Most terminals of relevant size nowadays deploy gantry cranes for container stacking operations, which are therefore key elements of modern terminal planning. The creation of an efficient terminal design therefore requires a profound understanding of the capabilities and performance of gantry cranes, which is in turn largely determined by the rules and strategies defining the way these machines are deployed in operation. Against the background of this basic conditions, the contribution of Kemme reviews academic works on container stacking and yard crane scheduling and besides, critically discusses their practical relevance. Finally, the autor explains the strategical implications of these strategies for terminal planning.

Chapter 18chap18:

The contribution of Speer & Fischer compares four different automated RMG yard crane systems with respect to their characteristics and performance. Furthermore, different approaches for their scheduling are presented: On the one hand, a branch-and-bound procedure for single yard block optimization, and on the other hand, an integrated scheduling approach which optimizes the equipment at terminal yard and waterside simultaneously. Moreover, a combination of the two approaches is studied. Using a specifically designed simulation model, both the crane systems and the different scheduling approaches are extensively examined with respect to their performance and practical use, e.g., in case of disturbances. It turns out that both approaches are advantageous compared to simple priority rules, and that the crane systems with overtaking possibility are well-adaptable, optimizable, flexible, and productive. Moreover, it can be concluded that optimization aspects should already be taken into account in the terminal planning phase, in order to reach optimal productivity levels later on.

Chapter 19chap19:

A well-designed stack layout is crucial for container terminals to maximize both the internal efficiency and the responsiveness to customers (such as vessels, trucks, and trains). One key performance indicator, influencing both efficiency and responsiveness is the container seaside lead time for unloading a container from the vessel, transporting it to the stack area, and storing it in a stack block, or vice versa, loading it in a vessel. The terminal performance depends not only on operational variables such as the location of the container in the stack, but also on design decisions, such as the type and the number of stacking cranes per stack, the type and number of internal transport vehicles, the layout of the stack (parallel or perpendicular to the quay), and the dimensions of the stack. In this chapter, Roy & de Koster present an overview of analytical models that rely on queueing network theory, for analyzing stack layout decisions in automated container terminals and summarize the design and operational insights.

Planning Area: Terminal Landside and Hinterland Access

Chapter 20chap20:

The contribution of Malchow presents the Port Feeder Barge (PFB) as “green logistic innovation” for container ports and besides that, the author describes different application areas for this particular type of barge. The PFB is a self-propelled and self-sustained container pontoon of double-ended configuration (capacity: 168 TEU). It can release the terminal gates from queuing trucks and the terminal ship-to-shore gantry cranes from inefficiently serving small inland barges. Three application areas are seen for the PFB: Shifting container haulage within ports from road to waterway, supporting feeder operation and loading and discharging inland barges. The PFB can be easily integrated in the container logistics within a port. In congested ports or ports with limited water depth and/or insufficient container handling capability even deep-sea vessels can be directly served midstream by the PFB. Hence, the barge can also be used as an emergency response vessel to quickly lighter grounded container vessels. The green potential of the PFB can be further exploited by using LNG as fuel.

Chapter 21chap21:

Ports close to cities or even embedded within a city increasingly suffer from truck traffic to and from the terminals. Especially container drayage causes high traffic peaks to serve ultra large container vessels. Citizens complain about traffic jams, hazardous emissions and noise, forcing politicians to think about restricting rules and regulations having an impact on port productivity. Sustainable mobility is not at all a new idea, however, applicable technologies to make heavy port traffic more environmentally-friendly without losing efficiency are just emerging. The contribution of Froese discusses several promising solutions in this area, noting that they are either in their early phase of introduction or currently under consideration. This explains the fact that the topic is a very dynamic one and there is a lack of references to proven applications.

Chapter 22chap22:

The aim of the contribution of Wilmsmeier & Monios is to revisit in the context of more recent work in the field the work of Cullinane & Wilmsmeier on the contribution of the dry port concept to the extension of the port life cycle (first edition of the Handbook). This extension relied on the use of vertically integrated corridors between the port and the dry port to move containers quickly and smoothly from the port to the hinterland for processing and stripping. The authors bring another layer to this conceptualization by adding the inland context, applying the intermodal terminal life cycle published by Monios & Bergqvist in 2016, in order to discuss synchronicities between the port and inland terminal (or dry port) life cycle. Both seaport and dry port in the hinterland have their own institutional governance structures, national and local policy and planning regimes etc., and these change over time according to the different life cycles. Yet the demand for improved quality of port hinterland access means that the two nodes must increasingly work together, which is already demonstrated in increasingly integrated ownership and operational models. However, for port hinterland transport to function smoothly, it is essential to understand both potential synergies and conflicts between various stages of the port and dry port life cycles.

Chapter 23chap23:

The contribution of Arendt describes the characteristics of European intermodal transport in seaport hinterland and pure inland relations (terminal-to-terminal). The market situation in these fields is assessed as well as existing problems of current intermodal services. Based on the apparent limitations of intermodal transport systems, the author describes the requirements of the market and possible factors for a more consumer-oriented intermodal service. Finally, he proposes an innovative concept for a prime service as a means of increasing the competitiveness of intermodal hinterland transports in a sustainable way.

Chapter 24chap24:

In recent decades, the intermodal container transport has emerged more and more as the basis for a globalized economy. This results in appropriate seaport container terminal requirements with terminals serving as transshipment nodes and as an important interface between different transport modes. However, the operational performance in such network nodes is only one fundamental aspect. Especially the capacities of inbound and outbound flows, i.e., the deep-sea and the hinterland transport, play an essential role, in particular because hinterland transport is a typical bottleneck. To solve these problems, the contribution of Daduna & Stahlbock presents different concepts including a dislocation of the terminal structures as well as an increased involvement of rail freight transport. However, some crucial problems and questions should be investigated. Although after the economic crisis in 2009 the international container transport increased again, it is much lower than predicted in previous years.

Notes

- 1.

- 2.

Hereinafter briefly referred to as container terminal.

- 3.

-

Transshipment container flow: Container movements between quay wall, terminal yard, and (back to) quay wall.

-

Domestic container flows:

-

Import container movements between quay wall, terminal yard, and the landside terminal interfaces (i.e., truck gate, railway station, and/or barge terminal).

-

Export container movements are in the reverse direction.

-

-

- 4.

To the best knowledge of the author, there is no official definition of “terminal suprastructure.” Within the scope of this Handbook all resources of a container terminal are classified as suprastructure which are in the principal responsibility of the terminal operator. The remainder (e.g., the quay wall) is attributed to the “port infrastructure” which is frequently in the principal responsibility of the respective port authority. In a somewhat broader sense, the “human factor” is also rated among terminal suprastructure, if the aforementioned condition is met.

- 5.

In April 1966, the shipping company Sea-Land inaugurated the first (commercial) intercontinental liner service between New York and Rotterdam, Bremen (North-West Germany), and Grangemouth (Scotland).

- 6.

- 7.

In this regard, the following aspect should be considered:

Requirements may emerge in reverse direction as well (i.e., “towards the quay wall”). This often relates to requirements between suprastructure resources used in different terminal areas, e.g., traditional rubber-tyred gantry cranes require tractor-trailer-units for horizontal transport from/to the quay wall. Even if Automated Guided Vehicles (AGV) perform just as well and (perhaps) more efficiently, their use is not possible due to safety reasons. The same applies to straddle carriers, their use makes no sense due to logistics reasons.

- 8.

In very few cases, terminal planning includes the elaboration of a completely new container terminal (“greenfield”). In very many cases, terminal planning is reduced to re-planning of a specific terminal area. Typical examples in this regard are “technology conversion projects” (e.g., change from straddle carrier operation to Rail-Mounted Gantry (RMG) crane operation in the yard area), “expansion projects” (e.g., the extension of quay- and landside interfaces like the quay wall or the terminal railhead), or “organizational restructuring projects” (e.g., the implementation of pooling strategies or dual-cycle operations for horizontal transport at quayside). In the “re-planning case,” planning work must not necessarily start “at the bottom,” but infrastructure frequently remains unchanged and suprastructure planning in the terminal area affected is the first step (or even only operation re-planning needs to be done).

- 9.

Planning of Terminal Operation on top, Planning of Terminal Suprastructure in the middle, and Planning of Terminal Infrastructure at the bottom.

- 10.

Requirements from “quayside to landside” and from “top to down”; Support Potential from “bottom to top.”

- 11.

To the best knowledge of the author, the term ultra large vessel is not officially defined. The HVCC Hamburg Vessel Coordination Center, for example, classifies ULV as vessels with a length of more than 330 m and/or a width of over 45 m (see HVCC 2019).

- 12.

A directive issued by the European Union is a legal act that formally requests the member states to achieve a particular result without determining the means of achieving this result. It is to be distinguished from a regulation, which is self-executing and does not require any specification for implementation.

- 13.

A first Lift AGV prototype has been built and tested in the year 2008. At the port of Hamburg, first straddle carriers with hybrid drive technology came into operation at the beginning of 2019.

- 14.

The original application area of OCR systems at container terminals is the truck gate. Since the early 2000s related systems have spread widely throughout the world and are today standard in truck processing procedures of truck gates. Furthermore, remote-controlled crane operation was part of automated RMG yard systems from the very beginning. Due to safety reasons (instructions), it is necessary to manually control the container handover process between automated RMG cranes and manually operated road trucks (or internal tractor-trailer-units) at the landside end of RMG blocks.

- 15.

Currently available automated RTG systems (e.g., in use at the Terminal Petikemas Semarang in Semarang, Indonesia) carry out fully automated container stacking and use remote control technology for lifting/lowering containers from/on trucks in the RTG portal.

- 16.

Electric drivetrains are now available for all widespread equipment types of horizontal container transport, i.e., for AGV and straddle carriers and terminal tractors.

- 17.

For example, terminal operating systems, positioning systems or administrative systems for customer, and freight data storage and processing.

- 18.

In many cases subsumed under the buzzwords “big data technologies” or “big data analytics.”

- 19.

For example, by using pooling strategies for horizontal transport vehicles exclusively serving the quay cranes of a (single) berth or procuring new (more advanced) quay cranes to “upgrade” a specific berth.

- 20.

Considering the largest container vessels of their time, the capacity has risen 2.2-fold from about 4,500 TEU to about 10,000 TEU between 1990 (President Truman, a C-10-class vessel) and 2005 (Gjertrud Maersk, a Maersk D-class vessel) and has risen again 2.2 fold to about 22,000 TEU in 2019 (nine CMA CGM LNG vessels are scheduled to come into service from the end of 2019).

- 21.

Vessel length of up to 400 m, maximum width between 61 m and 62 m, maximum draught of about 16 m and between 22 and 24 container rows across deck.

- 22.

This means, more cranes at quay wall, more vehicles for horizontal container transport, and more cranes for storing and retrieving containers in the yard area.

- 23.

For example, by using advanced pooling strategies at terminal quayside or implementing more powerful methods for vehicle scheduling and dispatching and — in case of automated container transport — for vehicle routing. Furthermore, effective methods for control of container stacking and rehandling within the yard area are of interest for improving resource efficiency as well.

- 24.

In Europe, for example, the EU directive 97/68/EG had to be applied for newly procured “non-road mobile machinery” (including also terminal equipment) between 1999 and 2016. The directive increasingly limited the NO x emissions (nitrogen oxide) and PM emissions (particular matter) of related equipment by following stages: Stage I (1999), Stage II (2002), Stage IIIa (2006), Stage IIIb (2011), and Stage IV (2014). Since beginning of 2017, the EU regulation 2010/26 determines the NO x and PM emission requirements for non-road mobile machinery based on emission limits of Stage V.

- 25.

For example, by direct soundproofing at engine (equipment level), by noise barriers on the terminal area (construction level) or by limiting the number and operating hours of equipment in use (operation level).

- 26.

Noting that in most cases the implementation of slot management systems is likely more driven by economic and capacity reasons.

- 27.

- 28.

Differentiating between pre-planning and detailed planning activities on the infra- and suprastructure level, the former end up with a prioritization of elaborated resource alternatives and finally lead to type-related resource decisions (e.g., use of AGV instead of straddle carriers or vice versa) including a rough estimate on the number of resource units required for day-to-day operation. The latter especially includes the specification of functional, technical, and process-related requirements for the resource type favored before by pre-planning. Results of detailed planning form, e.g., the basis for tendering processes bringing out the equipment supplier(s) and construction firm(s) chosen for a project.

References

AAPA [American Association of Port Authorities] (ed) (2008) World port ranking 2008. Data sheet. American Association of Port Authorities, Alexandria

Holmgren C (2011) Remotely controlled quay cranes: safer and more productive. Port Technol Int 50:62–63

HVCC [HVCC Hamburg Vessel Coordination Center GmbH] (ed) (2019) Ultra-large vessels. http://www.hvcc-hamburg.de/en/ultra-large-vessels/. Accessed 25 June 2019

Merk O (2014) Shipping emissions in ports. Discussion paper (No. 2014-200). International Transport Forum of Organisation for Economic Co-operation and Development (OECD), Paris

Merk O (2018) Container ship size and port relocation. Discussion paper (169 Roundtable). International Transport Forum of Organisation for Economic Co-operation and Development (OECD), Paris

Merk O, Busquet B, Aronietis R (ed) (2015) The impact of mega-ships. Project report. International Transport Forum of Organisation for Economic Co-operation and Development (OECD), Paris

Murray W (2016) Economies of scale in container ship costs. Paper to the conference shipping 2016. Connecticut Maritime Association, Stamford

Nightingale L (ed) (2018) One hundred container ports 2018. Annual report. Lloyd’s List, London

Park NK, Suh SC (2019) Tendency toward mega containerships and the constraints of container terminals. J Mar Sci Eng 7(5):13

PEMA [Port Equipment Manufacturers Association] (ed) (2016) Container terminal automation. Paper IP 12 (PEMA information paper series). PEMA – Port Equipment Manufacturers Association, Brussels

Tran NK, Haasis HD (2015) An empirical study of fleet expansion and growth of ship size in container liner shipping. Int J Prod Econ 159(C):241–253

UNCTAD [United Nations Conference on Trade and Development] (ed) (2018) Review of maritime transport 2018. Annual review. United Nations, New York

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Böse, J.W. (2020). General Considerations on Terminal Planning, Innovations and Challenges. In: Böse, J.W. (eds) Handbook of Terminal Planning. Operations Research/Computer Science Interfaces Series. Springer, Cham. https://doi.org/10.1007/978-3-030-39990-0_1

Download citation

DOI: https://doi.org/10.1007/978-3-030-39990-0_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-39989-4

Online ISBN: 978-3-030-39990-0

eBook Packages: Business and ManagementBusiness and Management (R0)