Abstract

The paper presents examples of the possibility of an application of gas flow simulation results in the pipeline network to transport natural gas under low pressure. The study was carried out for a selected existing low-pressure network and real data, taking into account the variability of network load depending on the ambient temperature. The methodology of network characteristics preparation based on the results of gas flow simulation in the network and development of equations for estimating gas demand depending on the heating degree days index is presented. Next, two examples of practical application of flow simulation results in gas network calculations are presented. The first example presents the development of relationships between the minimum overpressure of the supply stream and the size of that stream, which makes it possible to maintain a lower overpressure in the whole network. The second example concerns the analysis of the storage capacity of the gas pipeline network for alternative gaseous fuels produced from surplus energy from renewable sources.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

1 Introduction

Pipeline networks, commonly used to transport gaseous fuels over long distances, have a very complex structure and fluid dynamics that are difficult to describe. An additional difficulty in flow analysis is variability of the transported stream over time, depending on weather (temperature), calendar (day of the week, hour of the day) and economic (national income) factors. On the other hand, literature reports show that well-designed and optimally utilized network capacity may contribute to the reduction of gas transport costs, reduce gas losses resulting from network leakage or pipeline failure and have a positive impact on the environment.

One of the ways to obtain information about the dynamics of complex network systems operating in different conditions is to simulate the flow of gas in the network pipelines and to verify the results obtained with the actual data collected during system operation in given conditions. To describe changes occurring in network pipelines, depending on the level of gas overpressure in the network, classical equations of numerical fluid dynamics in differential form are used. The use of transient models is necessary for analyzing gas flow in the high-pressure network, while simpler steady state models can be used to describe changes in the low-pressure pipeline flow (Osiadacz 1987). However, regardless of the form of the equations adopted, the network model consists of more or less detailed forms of the mass, momentum and heat balance equations and the flow equations. Osiadacz and Chaczykowski (2001), Chaczykowski (2010) analyzed the influence of thermal model type or state equation on the basic parameters characterizing the flow (pressure drop and gas temperature) and the accuracy of the numerical solution in a high-pressure gas pipeline. On the other hand, Matko et al. (2000) analyzed the influence of the model type (linear or nonlinear distributed parameter or linear lumped parameter) on the differences between the values of gas streams and pressures at the end of a high-pressure pipeline, obtained during simulation and using actual data.

The results of gas flow simulation in a gas pipeline or pipeline network provide a lot of information about changes in the flow and distribution of basic parameters characterizing the stream. Askari et al. (2015), Szoplik (2015) demonstrated that the results of gas flow simulation in the network can be used, for example, for fuel demand forecasting and pipeline capacity planning, while Monforti and Szikszai (2010), Lochner (2011), Voropai et al. (2012), Szoplik (2016; 2019) show that the results of the simulation can be used to increase network capacity and improve transportation. In turn, Reddy et al. (2006), Sun (2012) and Damavandi et al. (2011) indicate the possibility of using the results of the simulation to detect pipeline damages and localize gas leakages from the network. The vast majority of examples analyzed in the literature of numerical methods application in the calculation of gas networks are aimed at reducing the costs of gas transport to the consumers. Optimization of the gas network structure is based on minimizing the costs of gas transport and at the same time maximizing the efficiency of the network (2000), therefore, it is advisable to conduct research on lowering the costs of maintenance of the most energy-consuming elements of the network equipment. Depending on the structure and complexity of the network, the authors used various additional detailed models, which, in their opinion, have a significant impact on the modeling results obtained. Gato and Henriques (2005) stated that atypical changes in the gas flow may depend on the type of characteristics of the regulator or valve used in the calculations. Fasihizadeh et al. (2014) proposed a change in the network structure and basic input parameters, which was reflected in a reduction in the costs of gas transport. Nguyen and Chan (2006) used artificial intelligence methods to optimize the operation of compressors in high-pressure gas compressor stations. In turn, Staibach (2007) studied the effect of compressor switching on and off and valve opening and closing on the cost of fuel consumption in a gas compression plant. Simulation methods can also be used to increase the capacity of long-distance pipelines (Voropai et al. 2012) or to identify bottlenecks (Lochner 2011) that may arise in the future due to the growing demand for gas in Europe, while Lise and Hobbs (2008) analyzed the impact of changes in gas sales on the price and security of gas supply to Europe.

A brief description of the low-pressure pipeline network used to transport fuels, a methodology for preparing input data to simulate gas flow and two examples of practical use of the results of flow modeling in the network to control the gas flow in the network in order to minimize gas losses in case of pipeline failure and to estimate the storage capacity of the network for other gaseous fuels obtained from alternative energy sources will be presented. The analysis was prepared on the basis of actual gas pipeline network and data on network load.

2 Methods of Natural Gas Transport

Depending on the distance between the place of natural gas production and consumption and its composition, gaseous fuel may be transported in liquefied form by sea by methane carriers or in gaseous form by pipelines located below the surface of the earth (Thomas and Dawe 2003). However, regardless of the method of gas transporting to the country, gas is transported to final consumers via a three-stage pipeline network. The main streams of gas supplied to Poland are distributed throughout the country by means of a network of high-pressure pipelines (Szoplik 2012). Then, at the gas reduction station, the overpressure of the gas stream is reduced to the average value and the transport of gas through the medium-pressure network begins. Another reduction of the overpressure of the gas stream from medium to low value takes place in the second stage gas station, which is the beginning of the low-pressure gas network. The limitation for each network is the overpressure of the gas stream and the velocity of the stream in the pipeline. In the case of low-pressure network, the maximum gas velocity is 5 m/s and the gas overpressure can vary from 1700 Pa to 2500 Pa.

Failure to meet the condition of gas overpressure in the low-pressure network results in malfunctioning of the gas appliances installed in the customers, while the amount of gas overpressure in the network pipelines depends directly on the network load.

The diagram of the existing low-pressure gas network with one supply point (reduction and measurement station of the second stage GRS) and 354 exit points (end users) is shown in Fig. 1. The network is mostly made of steel gas pipelines (about 70% of the total length of the network) and polyethylene gas pipelines. The total length of all gas pipelines in the network is approximately 14.5 km of pipelines with nominal diameters ranging from 45 mm to 250 mm.

3 Preparation of Network Characteristics

The characteristics of the gas network are prepared on the basis of the results of gas flow simulation and are a map of the gas dynamics in the network pipelines, on the basis of which it is possible to analyze the operation of the network in different conditions. On the basis of data collected during many years of research and published in works (Szoplik 2012; 2015; 2016; 2019), it can be concluded that the network load is strongly dependent on the air temperature and time of day. Significantly higher network load is characteristic for days with lower temperature and in the morning hours compared to the network load at night on the days of the summer season. Example results of annual and daily variability of network load in one of the small towns are shown in Fig. 2.

Simulation of gas flow in the gas network (Fig. 1) requires the preparation of input data in the form of hourly gas streams drawn from the network at 354 exit points for different ambient temperatures. The daily demand for natural gas by the customer (Q(NG) [m3/day]), depending on the air temperature T, can be presented by means of Eq. (1), which should be determined individually for each exit point from the network, because each customer has a different gas consumption characteristic.

Air temperature T in Eq. (1) is presented as an indicator of heating degree days (Sd = 18 − T), which presents the demand for energy necessary to heat a room from temperature T to temperature 18 °C. The Sd value is greater than zero when T < 18 °C or Sd = 0 when T > 18 °C. It was assumed in the calculations that the demand for gas in the connection depends on the air temperature (Eq. 1) only in case of recipients heating apartments, whereas for recipients who use gas only for the preparation of meals, the Eq. (1) is simplified to Q(NG) = b. Parameters a and b of Eq. (1) are determined on the basis of the actual demand for natural gas in the connection registered in different periods of the year and for the actual air temperatures. The methodology of determining the parameters of the model (1) is presented on the example of data characterizing the gas consumption by the customer, which is settled on the basis of only three bills issued by the seller in a given calendar year. Table 1 summarizes the data necessary to determine the parameters of the model. The absolute term b represents gas consumption independent of the ambient temperature, so it is calculated as the quotient of gas consumption in the summer period (Sd = 0) and the number of days in that period (b = 88/61 = 1.44). The directional coefficient of the model (1) represents the gas consumption depending on the ambient temperature and, based on the data from Table 1 is calculated as follows:

Based on Eq. (1), it is possible to estimate the daily gas demand in the network connection for any ambient temperature T (Sd = 18 − T).

Equation (1) enables to estimate the demand for natural gas (NG) by a customer or a group of customers depending on the temperature T of air (Sd = 18 − T) during a 24-h period, whereas hourly streams of gas taken in individual network connections from Fig. 1 are determined on the basis of hourly flow characteristics of gas through a reduction and measurement station supplying a given network. The methodology of determining hourly demand for gas in any network connection is described in detail in the following work (Szoplik 2016).

An example of the annual variation in gas demand by all consumers taking gas from the network as shown in Fig. 1 and the variation in ambient temperature (Sd index) on subsequent days of the year is shown in Fig. 2a. Higher gas demand is observed on days with lower air temperatures, which correspond to higher Sd values. On the other hand, the variability of gas demand by the customer in the connection (determined on the basis of relationship 1 and the characteristics of the flow through the station) in the following hours of the day for three selected days with different air temperature is shown in Fig. 2b. Lower demand for gas is characteristic for night hours (between 11 p.m. and 5 a.m.).

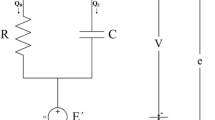

On the basis of data on network load depending on ambient temperature, simulations of natural gas flow in the network were carried out and the characteristics of the network operating in various conditions were developed. Modeling of gas flow in the network was performed in GasNet program, in which the calculation of gas streams and overpressure in the network pipelines was carried out using the mesh method based on the analogy to the current flow in electrical circuits. The result of flow simulation is the distribution of streams, velocities and overpressure of gas in all gas pipelines of the network. Simulations carried out for different input data sets made it possible to determine the minimum overpressure of the gas stream feeding the network, at which the gas of specified quality parameters can be transported to all customers under overpressure greater than the minimum of 1700 Pa. In this way, the minimum gas overpressure at the entry to the network was determined for various gas streams collected at 354 exit points from the network (depending on the ambient temperature and time of day) and for various gas quality parameters (heat of gas combustion of Hs).

4 Steering of Gas Flow in the Network

One of the parameters determining the proper operation of the network and safe transport of gas to consumers is the overpressure of gas in the network. The amount of overpressure of gas stream in low-pressure network pipelines should be in the range from 1700 to 2500 Pa. From a practical point of view, it is beneficial to maintain the lowest possible overpressure in the network, as the potential gas losses caused by pipeline failure, leakage of the network or methane penetration through the pipeline walls will be the lowest. The value of overpressure of the gas stream feeding the network depends on the network load, i.e., gas consumption by consumers, and is higher the higher the gas consumption from the network, i.e., in the winter season and in the morning hours. The paper (Szoplik 2016) describes examples of methods of adjusting the overpressure of the supply stream depending on the size of this stream. Figure 3 shows a schematic representation of the methodology of gas overpressure control in the network in order to reduce it to the minimum level under given conditions of network operation. The GRS gas reduction station supplying the sample network is supplied with a flow of gas with a constant overpressure (e.g. Pin = 2.5 bar) and a time-varying flow (Qin ≠ const). At the GRS station, the overpressure of the stream Pin is reduced to values in the range (1700 ÷ 2500 Pa) depending on the size of the stream Qin according to an experimentally determined control algorithm (Szoplik 2016):

As a result, the gas stream Qout leaving the GRS reduction station is not only characterised by a lower overpressure (in relation to Pin), but above all by the fact that it is dependent on the size of the gas stream Qin.

Parameters a, b and c of the control algorithm (2) can be determined only on the basis of the results of simulation of gas flow in the network, performed for various ambient temperatures, during which the minimum overpressure of the gas supplying the network is selected, depending on the size of gas streams collected from the network. The control algorithm shall be developed individually for each gas network on the basis of the actual network load data. Figure 4 shows a fragment of the overpressure and gas flow change record directly before and after the introduction of the developed algorithm for controlling the overpressure in the network. Analyzing the data from Fig. 4 one can notice a dynamic change of the stream overpressure (red line) leaving the GRS station depending on the stream size (pink line). Thanks to this, the overpressure of the supply stream will be maintained at a minimum level, depending on the size of the supply stream, i.e., the total volume of gas streams received at 354 points of exit from the network. In the paper (Szoplik 2016) it was shown that the application of such a pressure control method allows to reduce the annual gas stream entering the network by about 0.4%. It can be assumed that the savings resulting from the use of such a control system will be greater the larger the network and the higher the permissible overpressure of gas in the network (medium or high pressure network).

5 Storage Capacity of Alternative Gaseous Fuels in the Gas Pipeline Network

Storage of alternative gaseous fuels (af) in the gas network consists in the continuous or periodic addition of gaseous fuels from surplus energy generated from renewable sources (sun, wind, biomass) to the natural gas transported through the pipeline network. Examples of alternative gaseous fuels that can be fed into the natural gas network are, for example, biomethane from biomass gasification or hydrogen from water hydrolysis using surplus electricity from renewable sources.

The paper (Szoplik and Stelmasińska 2019) analyzed two possible ways of biomethane introducing to the low pressure gas network as shown in Fig. 1 and showed that regardless of the network load, biomethane can constitute approximately 39% of the regasified LNG and biomethane mixture stream and approximately 29% in the case of the natural gas and biomethane mixture stream. In this case, the size of the biomethane stream entering the network depended on the size of the natural gas stream supplied to consumers (i.e., the ambient temperature). On days with a lower ambient temperature, significantly more biomethane can be introduced into the network, as the network load is higher on these days.

The size of a mixture of natural gas and any alternative gaseous fuel Q(NG-af) entering the network depends on the heat combustion value of the gas biofuel (Hs(af)) and the natural gas (Hs(NG)). Assuming that gas network in Poland can transmit gas fuels with a minimum value of combustion heat Hs(NG-af) = 34 [MJ/m3], it is possible to estimate the stream of the mixture of natural gas (or regasified natural gas) and alternative gaseous fuel with a value of combustion heat known from the following relationship:

Assuming that the daily demand for natural gas Q(NG) for any ambient temperature can be determined from the model (1), the maximum share of yaf gaseous alternative fuel (biomethane or hydrogen) in the mixture of natural gas and biofuels can be estimated from the heat combustion values of natural gas (Hs(NG)), biofuels (Hs(af)) and mixtures (Hs(NG-af)) based the following relationship:

Figure 5 shows the results of calculations in the form of the size of the mixture of natural gas and hydrogen Q(NG-H2) and hydrogen Q(H2) stream, which can be fed into the network (from Fig. 1) on the following days of the year (assuming Hs(NG-H2) = 34 [MJ/m3], Hs(NG) = 41.306 [MJ/m3], Hs(H2) = 12 [MJ/m3]). The percentage share of hydrogen in the mixture of natural gas and hydrogen estimated from the relationship (4) is 25%, whereas in the mixture of regasified liquid natural gas and hydrogen the share of hydrogen is greater and amounts to 34%. Based on the data presented in Fig. 5, it was found that in the low pressure network from Fig. 1, the maximum storage capacity is about 427459 m3 of hydrogen in natural gas and 439455 m3 of hydrogen in regasified LNG. The advantage of alternative fuels storage in low-pressure networks is that alternative fuels do not need to be compressed to high pressures (which is the case with high-pressure networks) and that alternative fuels can be produced in close proximity to low-pressure networks. Such a way of hydrogen introducing into the network is beneficial for the network operator because it allows to generate a mixture of gases with a constant value of combustion heat over time, which makes it much easier to account for the consumed energy. However, from the point of view of the alternative fuel manufacturer, such a way of fuel supplying may be burdensome because the production of alternative fuel is not constant over time.

Alternative gaseous fuels (hydrogen, biomethane) have a much lower heat combustion value than natural gas (natural gas or regasified liquid natural gas) transmitted through the network, which always results in a reduction in the quality of the mixture produced and the transport of larger streams of the mixture of fuels and an increase in the pressure drop in the network. The results of the simulation in the form of overpressure distribution (Fig. 6a and b) of natural gas Q(NG) and mixture of natural gas and hydrogen Q(NG-H2) in the network pipelines on a day of temperature T = −17 °C clearly show the increase of network load and decrease of overpressure in the network in case of alternative fuel introducing into the network. In this case, the use of flow simulation is necessary to analyze the storage capacity of the network for alternative fuels, as it may be that an increase in the gas mixture streams collected from the network may require the use of too much overpressure in the low-pressure network supply stream. This must result in the alternative fuel stream being reduced to a value that allows the mixture to be transported under appropriate overpressure.

6 Summary

Simulations of gas flow in network pipelines provide data on the most important flow characteristics (flow, velocity and overpressure distribution) from which it is possible to map the network and estimate the maximum capacity of the network to store alternative gaseous fuels produced indirectly from renewable energy sources. In turn, the results of simulating the flow of gas or gas/alternative fuel mixtures in the form of a minimum overpressure of the supply stream can be used to develop the relationship between overpressure and supply stream, so that the lowest possible overpressure can be maintained in the network. In addition, flow simulations may be a good method for testing the behavior of the network under different operating conditions of the system and for planning the possible expansion or modernization of the network.

References

Askari, S., Montazerin, N., Fazel Zarandi, M.H.: Forecasting semi-dynamic response of natural gas networks to nodal gas consumptions using genetic fuzzy systems. Energy 83, 252–266 (2015)

Chaczykowski, M.: Transient flow in natural gas pipeline–the effect of pipeline thermal model. Appl. Math. Model. 34(4), 1051–1067 (2010)

Damavandi, M.Y., Kiaei, I., Sheikh-El-Eslami, M.K., Seifi, H.: New approach to gas network modeling in unit commitment. Energy 36, 6243–6250 (2011)

Fasihizadeh, M., Sefti, M.V., Torbati, H.M.: Improving gas transmission networks operation using simulation algorithms: case study of the National Iranian Gas Network. J. Nat. Gas Sci. Eng. 20, 319–327 (2014)

Gato, L.M.C., Henriques, J.C.C.: Dynamic behaviour of high-pressure natural-gas flow in pipelines. Int. J. Heat Fluid Flow 26, 817–825 (2005)

Lise, W., Hobbs, B.F.: Future evolution of the liberalised European gas market: simulation results with a dynamic model. Energy 33, 989–1004 (2008)

Lochner, S.: Identification of congestion and valuation of transport infrastructures in the European natural gas market. Energy 36(5), 2483–2492 (2011)

Matko, D., Geiger, G., Gregoritza, W.: Pipeline simulation techniques. Math. Comput. Simul. 52, 211–230 (2000)

Monforti, F., Szikszai, A.: A Monte Carlo approach for assessing the adequacy of the European gas transmission system under supply crisis conditions. Energy Policy 38, 2486–2498 (2010)

Nguyen, H.H., Chan, Ch.W.: Application of artificial intelligence for optimization of compressor scheduling. Eng. Appl. Artif. Intell. 19, 113–126 (2006)

Osiadacz, A.J.: Simulation and Analysis of Gas Networks. Gulf Publishing Company, Houston (1987). ISBN 9780872018440

Osiadacz, A.J., Chaczykowski, M.: Comparison of isothermal and non-isothermal pipeline gas flow models. Chem. Eng. J. 81(1), 41–51 (2001)

Reddy, H.P., Narasimhan, S., Bhallamudi, S.M.: Simulation and state estimation of transient flow in gas pipeline networks using a transfer function model. Ind. Eng. Chem. Res. 45, 3853–3863 (2006)

Steinbach, M.C.: On PDE solution in transient optimization of gas networks. J. Comput. Appl. Math. 203, 345–361 (2007)

Sun, L.: Mathematical modeling of flow in a pipeline with a leak. Math. Comput. Simul. 82, 2253–2267 (2012)

Szoplik, J.: The gas transportation in a pipeline network. In: Al-Megren, H. (ed.) Advances in Natural Gas Technology. InTech (2012). ISBN 978-953-51-0507-7. https://doi.org/10.5772/36902. http://www.intechopen.com/books/advances-in-natural-gas-technology/the-gas-transportation-in-a-pipeline-network

Szoplik, J.: Forecasting of natural gas consumption with artificial neural networks. Energy 85, 208–220 (2015)

Szoplik, J., Stelmasińska, P.: Analysis of gas network storage capacity for alternative fuels in Poland. Energy 172, 343–353 (2019)

Szoplik, J.: Improving the natural gas transporting based on the steady state simulation results. Energy 109, 105–116 (2016)

Thomas, S., Dawe, R.A.: Review of ways to transport natural gas energy from countries which do not need the gas for domestic use. Energy 28, 1461–1477 (2003)

Voropai, N.I., Senderov, S.M., Edelev, A.V.: Detection of “bottlenecks” and ways to overcome emergency situations in gas transportation networks on the example of the European gas pipeline network. Energy 42, 3–9 (2012)

Acknowledgements

The calculations presented in the paper were made on the basis of the results provided by the Gas Plant in Szczecin, during my internship stay carried out in the framework of the project “Time for an internship. Science and Business Cooperation”.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Szoplik, J. (2020). Application of Flow Simulation Results in the Calculation of Gas Networks. In: Ochowiak, M., Woziwodzki, S., Mitkowski, P., Doligalski, M. (eds) Practical Aspects of Chemical Engineering. PAIC 2019. Springer, Cham. https://doi.org/10.1007/978-3-030-39867-5_48

Download citation

DOI: https://doi.org/10.1007/978-3-030-39867-5_48

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-39866-8

Online ISBN: 978-3-030-39867-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)