Abstract

Slopes in open pits exhibit fracturing around excavations, often initiated by extension strain which results from a combination of principal stresses adjacent to the slope boundaries. This extension strain is commonly described using minimum principal strain or minimum principal stress equations. These equations show that the extension strain can expand and fracturing occurs if the extension strain exceeds a critical value. Anisotropic rock masses with multiple and complex structures increase the potential of the development and coalesce of cracks with pre-existing discontinuities for further potential failure.

This paper presents finite element analysis to model the extensions strain implementing the criterion of Stacey (1981). The distributions of extension strain are predicted around slope of Handlebar Hill open pit mine at Mt Isa, Queensland, Australia. Around the pit wall, fracturing near the excavation boundary is often the result of extension strain of the rock. Through the mining activities, fractures in the slope face can manifest into slabbing and spalling. Extension strain may develop circumferential fractures close to the slope surface, the closer to the excavation perimeter, the more open the cracks. The result of the extension strain distribution simulated in this paper is in accord with failure events observed on site. The numerical modelling and the discussion of this study focused on the prediction of potential fracturing zones within the critical values of the extension strain around the slope.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Extension strain in rock can cause minor cracks (initially microscopic crack in rock) that initiated under tensile or minimum compressive stress. It may extend within the elastic zone and become an observable fracture as a result of changing in-situ stress conditions or natural softening material deformation. Deformation and strain are closely related distinct terms. Deformation describes the complete manifestation from initial to final geometry of rock, the strain describes the alterations of points in rock relative to each other.

Laboratory tests detected two main types of fractures in brittle materials including the extension fractures or so-called opening modes and shear fractures (Ramsey and Chester 2004). Other approaches with more experimental studies on rocks showed that a pre-existing fracture does not extend as a single flaw within the rock mass. For example, Brady and Brown (2006) reported that fractured rock should include a large number of very minor extensional fractures that developed before the process of the final propagating.

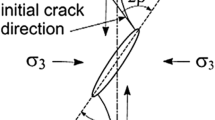

The transition of extension strain from tensile to shear fracture as being a function of confining stress by a unique laboratory uniaxial compression tests was described by Hoek (1968). It illustrates the estimated fracture condition for rock including the extension of the strain from the initiation, until the complete rock fracturing.

Stacey and de Jongh (1977) reported that the Griffith and Mohr-Coulomb criteria in terms of fracturing initiation were ineffective to predict the extent of fractures associated with underground boring in hard rock mass. An equation to calculate the extension strain magnitudes of different rocks was required. The equation has to be effective in predicting the extent of fracturing zones together with the localised orientation of these fractures around slope and underground excavations.

The rock failure criteria included only the major and minor principal stresses in their equations, in which the failure dominated by shear stress. But, in many open pit slopes and underground tunnels it was noticed there were parallel fractures near excavations like spalling or splatting. Ndlovu and Stacey (2007) reported that this rock failure shows tensile nature, but not related to shear fracturing. Several criteria were suggested to determine the rock critical strain e.g. Sakurai (1981) in underground excavation and Stacey (1981) in excavated slopes which accounts for the three principal stresses. Therefore, this criterion included that tensile failure can occur even if the applied stresses are compressive.

In studies focusing on the mechanisms of compound rock failures, Eberhardt et al. (2004) argued that processes relating to extension strain, internal degradation of rock mass strength, brittle fracture damage and shearing are also instrumental in the kinematics of step-path failure in massive rock slopes. Many studies Liang (2003), and Yang et al. (2008) presented results of triaxial extension experiments on rocks show that a continuous transition from extension strain to shear fracture with an increase in confining pressure, which formed under compression. This combined fracture mechanism has been considered under compressive and tensile stress states at critical angles to the maximum principal compressive stress.

Kwasniewski and Takashashi (2010) presented a new strain criterion to calculate the mean normal strain for conditions of low confinement. They found that the highest extension strain (the least principal strain) at strength of failure is changeable under triaxial compression with different values of confining pressure used in triaxial compression laboratory tests.

The source of stress in the slope is a combination of the pre-existing tectonic stresses and the stress reduction normal to the slope as well as stress concentration in some locations of the slope. The extensional fracturing occurs when the intermediate and major principal stress components are large enough or the minor principal stress is small enough to result in minor principal strain component to be extensional and in which exceeds a critical value.

Fracturing possibly occurs at the stage that the bench is a part of the floor, ramp or the toe of the slope. Conditions for extensional fracturing are expected within the benches in the slope when they are close to the haul road and the toe. Rock masses of fresh quality, which is existed at the west slope of the open pit, would be more susceptible to extensional fracturing.

Extension strain can be described by all three principal stresses, therefore, suggesting that tensile strain will occur when all stresses are compressive. This criterion proposed that the extension can occur through indirect tension if the tensile strain goes beyond a value, which is reliant on the condition of the rock units. While, the failure criteria developed by many authors, e.g., Mohr-Coulomb (Coulomb 1779) and generalised Hoek-Brown criteria (Hoek et al. 2002) included only major and minor principal stresses in their equations involving the rock failures by shear deformation.

Due to its development and flexibility, the finite element stress method is progressively being applied to slope stability analysis (Mahtab and Goodman 1970) and (Stacey et al. 2003). Non-linear finite element models using elastic-perfectly plastic material strength have been used to obtain factor of safety of slopes, which offers a number of advantages over general limit equilibrium method (Hammah et al. 2004).

This paper studies the application of finite element stress method to the determination of the extension strain of rock slope in open pit for which rock strength is modelled by the generalised Hoek-Brown failure criterion. The paper first utilises the standard finite element method used for slope stability analysis of Hoek-Brown slopes. It then demonstrates the distributions of extension strain through application of the method, and uses the user defined data dialog to inputs mathematically the extension strain equation of Stacy.

One of the major advantages of Phase2 finite element slope stability is the analysis parameters can be customised if required. Using the user define data after the interpretation of the finite element model to illustrate contour of user data. This code is able to create a new user data definition for variable inputs with plotting results of defined equations to solve complex non-linear problems.

Figure 1 shows a view of the Handlebar Hill open pit at Mt Isa, Queensland, Australia. The extension strain and the influence of their distribution on the stability of the pit slope stability are modelled using the finite element stress method implementing the criterion of Stacey (1981) of principal stresses.

2 Review of Extension Strain Criterain Proposed by Stacey (1981)

The extension strain criterion is a fracturing initiation criterion and not a shear strength criterion of ultimate strength. It explains that the confining stress does not cause the fracturing. Confining stress always works against the generation of rock fractures. The extension strain criterion, in fact, states that it is the lack of confining stress will result in extension strain within elastic limit of rock material. Once the extension strain exceeds a critical value, tensile fracturing can develop plastically. Therefore, the high level of confining stress detects the threshold of rocks, grain size porosity and mineralogy. This will inhibit the initiation of extension strain and, subsequently, the developments of cracking events.

Stacey (1981) described the first empirical criterion for extension strain and fracturing initiation of brittle rock. It was a new method proposed to obtain the critical value of extensions strain from many laboratory tests by plotting axial strain against lateral strain. He applied his criterion in two cases: in an open cut pit for haulage road side-wall bulging and in underground mine for rock spalling. His work proved that the extension strain could occur when the major principal stresses are compressive stresses. The initiation of a fracture in the rock mass will occur in a direction normal to the extension strain and corresponds to the least compressive stress path, when the strain exceeds a critical value, which is rock type reliant. The expression of this criterion is as follows: e > ec where (ec) is the critical or limiting value of extension strain for the rock. The extension strain may expand in different directions within rock slopes. When strain exceeds a critical value, which is a characteristic of that rock mass, imitation of extension strain will occur and the developments of these fractures are likely (Stacey 1981). However, the critical magnitudes of extension strain in rock masses could be evaluated by this criterion. This way of obtaining the extension strain can be designated crack initiation by strain as this corresponds to the stage at which the crack starts within the rock. Louchnikov (2011) stated that it has to be noted that the first term of the extension strain criterion was limiting tensile strain criterion, hence emphasising the tensile nature of the extension strain.

The criterion of Stacy for a linear elastic material is an out of plane strain analysis to define the minimum principle strain \( (\sigma_{3}) \) which calculates the three principal stresses by using the following three dimensional elastic equations:

Where σ1, σ2 and σ3 are the three principal stresses

-

Ɛ3 = Extension strain, which is the strain in the direction of the minor principal stress

-

υ = Poisson’s ratio

-

E = Modulus of elasticity.

This criterion allows defining the three-dimensional principal stress directions, including stress, displacement and strength factor and, therefore, the results are more accurate compared to the plane strain assumption. Stead et al. (2007) stated that Stacey et al. (2003) and Stacey (2006) used 3D elastic extension strain criterion in the analysis of large scale open cut slopes to present the significance of considering the extension strain as a potential rock fracture. Ndlovu and Stacey (2007) reported that this extension strain criterion can be implemented for a wide range of rocks, from strong, brittle to soft rock such as coal. Furthermore, extension strain is not limited to deep open pits and high slopes, the effect will be more noticeable in brittle rock condition in which fractures can develop rapidly (Stacey, personal communication, June 2 2015).

The extension strain criterion can be described in three dimensional strain space within a cubic state boundary surfaces condition as illustrated in Fig. 2. The inner cube presents the extension strain initiation and the outer cube describes the manifestation to crack damage strain. The principal strains are defined in terms of in plane by Ɛ1 and Ɛ3, and the out of plane strain by Ɛ2 as shown in the cubic strain spaces. Principal strains are Ɛ1, Ɛ3 and Ɛ2 (major, minor and intermediate principal strain) are oriented with respect to stresses redistribution by excavation. In the three dimensions cubic, Ɛ3 is not necessarily the minor principal strain, if the value of Ɛ2 is less than Ɛ3 at the same location, then the in plane Ɛ3 is the three dimensional intermediate principal strain.

Extension strain failure criterion in three dimensional cubic strain spaces (after Wesseloo 2000)

3 In Situ Observations

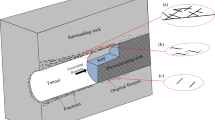

The following examples of rock failures occurred at Handlebar Hill open pit, where the extension strain expected to be developed and initiated the slope face failures. These failures included rock spalling from the face of the slope (Fig. 3), and sidewall slabbing below the ramp (Fig. 4), which involved a thin extent of detached rocks.

The fractures of rocks will progress as far as allowable by the distribution of extension strains, and their existence inhibited by the compressive confining stress. It follows that the presence of extension strain is likely to be limited to the proximity of openings in stressed rock. This happens in excavated locations of rocks and, hence, prediction of rock fracture is necessary (Stacey 1981). The extension strains then developed to rock fractures, and these fractures propagated to slope faces failure, and slabbing in the sidewall on the least compressive stress extent.

Martin et al. (1999) stated that slabbing and splatting in a rock may occur in a stable manner or violently in the form of tensile strain bursts in underground tunnels having low confining pressure similar to that at an excavated slope. These slabs can range in thickness from a few millimetres to several square metres in surface area, and the formations and thicknesses of these slabs could be related to strain energy.

The propagation of cracks extends into rock masses and may coalesce through pre-existing discontinuities during stress loading. In a heterogeneous slope, tensile cracks that propagate in their own plane and out of plane are normal to confining pressure direction (the minimum principle stress). Tensile cracking could be initiated, also, by compressive stress. Therefore, adding compressive stress on the rock masses, the possible shear movement on rock plane with less strength zones would be a potential mode of tensile failure. Hoek (1968) indicated that the tight connection of asperities can increase the differential shear stress displacement that results in the propagation of existing vertical cracks, which lead to vertical tensile rupture.

3.1 The Source of Extension Strain in Open Pit and the Orientation of Potential Fractures

The increases of confining stress inhibit fracture propagation and should induce a move of the rock towards the ductile field (Valenta 1988). In an underground mine when rock is exposed to an applied differential stress in deeper excavation, the tight connection of asperities and increased differential shear stresses can arise. The geological structure where dilation is normal to the sliding surface is restricted by adjacent blocks under high confining stresses. This confining stress is presented by several hundred meters of overlying rock resisting block mobilisations.

In open cut mines, all of the earth’s crust is in a state of three dimensional stresses. When an excavation is made, it changes the stress distribution locally and usually there is some stress concentration around the openings. It is these stresses that contribute to the confinement, or lack of it around the excavation. With regard to open pits, the geometry of the slopes in plan and section will influence the redistribution of stresses. The materials of the geological units can also influence local stresses, for example, stronger beds will attract more stress than the weaker or more ductile layers, which could lead to localised failure. In such cases, stress redistribution will extend deeper into the rock mass unaffected by blasting. However, at low confining stress, rock will be brittle and tends to crack sooner (Nelson 2003).

Extension fractures in rocks form in planes normal to the direction of the extension strain that corresponds with the direction of the minimum principal stress. In excavated slopes the directions of the minimum principal stresses are normal to the confining pressure of slope and because of the direction of the confining pressure being normal to the slope surface. Therefore, the orientations of fractures are likely to be sub-parallel to the slope surface behind the slope face and the inclined extension fractures can propagate near the slope toe. The simulated levels of extension strain contours make the development of extension fractures possible and that could considerably reduce slope stability.

3.2 Extension Strains Around Two Dimensional Numerical Models

This section describes the numerical modelling of the extension strain zones and tensile failure around the first and the second stage of slope excavation. The existence of extension strain indicates that the rock masses have the potential to expand in one or more directions in the slope. Critical extension strain will be calculated according to Stacey criterion (1981), which proposes that rock fracture can be developed from extension strains that exceed the critical value of –0.0003 or greater. The pit depth is 180 m, overall slope angle of 45° and (K) ratio, which is the horizontal to the vertical in situ stresses ratio values of 0.6 for in-plane and 0.86 for out of plan stress ratio, a value of 0.2 for Possion’s ratio, and rock mass modules of 8,248.32 MPa.

Two dimensional finite element stress elastic analysis modelled the results using Phase2 software. The simulation of the two excavation stages slope shows zones of extension strain near the slope toe and the floor of the pit. Zones of extension strain occur alongside the lower benches of the slope and upper benches located above the ramp. The extension strain is concentrated around the benches located above the ramp and behind the slope crest (Fig. 5).

The model in Fig. 6 illustrates the development of strain near the toe and along the floor surface, and zone of strain extend behind the crest of the first stage of excavation.

Although the extension strain values obtained are low, due to the limited height of pit slope, the extension strain will act normal to the foliation planes and stimulating extension fracturing (opening up deformations) on these rock planes (Stacey et al. 2003). These predicted extension strains in the pit, at any stage of excavation may change through mining operation to develop more fractures.

3.3 Tensile Stress around Two Dimensional Numerical Models

The condition of stress distribution is conductive to the propagation of the extension fracturing adjacent to the slope. The two dimensional analyses allowed modelling the tensile stress distributions and magnitudes around the slope. Zones of tensile stress are concentrated near the crest and adjacent to the upper benches of the slope of two stages of excavation as shown in Fig. 7. The tensile stress distribution within the first stage of slope excavation of 80 m height is shown in Fig. 8. The tensile stress is concentrated near the upper benches, but no tensile zones presented near the toe of both stages of slope excavation.

3.4 Combined Failure Mechanism in Open Pit Slopes

Several types of slope failures are often attributed to the development of the extension strain have other causes. In open cut pit slopes, extension strain can be considered as a contributor to slope failures. Complex rock failure involves mechanisms related to extension strain initiation around a slope, which propagates to the fracturing of intact rock and the deformation along geological structures. An example of large scale rock failure involving the extension strain in a complex mechanism of failure is the two massive rock-slides of the 1991 Randa town cliff in Switzerland. While some geotechnical investigations did not refer to the role of extension strain in the complex failure mechanisms in Randa rock failure, Sartori et al. (2003) did not identify whether these series of rock mass failure events combined, acted as an exceptional failure trigger. On the other hand, Eberhardt et al. (2004) pointed out that the results showed that the rock slope failure of Randa involved the initiation and propagation of brittle tensile fractures driven by extensional strain that interacted with natural pre-existing discontinuities to form internal shear planes.

If the role of extension strain is over emphasised, then this may lead to missing the real cause of slope failure. This suggests that more than one mechanism of rock behaviour may contribute to final slope failure. This failure is a function of combined mechanisms, namely the extension strain imposed around excavations, may, manifest itself and notch expansion through faults and joints. It is the strain, which is stored within the elastic limit of the rock. Because of the low confining pressure around slopes of an open pit, the extension strain will progress and extend to one or more directions and develop a network fracturing in the rock masses. This extension may interact with the natural large scale discontinuities to form a critical failure in the slope surface and increase slope instability. The extension strain may coalesce with minor or major geological structures in rock mass and this will possibly lead to a localised slope failure (Louchnikov 2011).

Joint sets often have deep impacts on elastic and strength properties in rock masses and then on open pit slope stability (Pariseau et al. 2008). In slopes of jointed rock mass, the extension strain is influenced remarkably by the joint orientations. Then, the joint spacing can coalesce with the opening of extension strains, and propagates within the orientations of joints. In heterogeneous rock excavations subjected to stresses, tensile cracks may not propagate in their own plane, but they may propagate near the joint surface and spacing. The extension strain that progresses to brittle fracturing in intact rock will be associated with the opening of joints. Hence, this provides the deformation of rock along the orientations of joints, bedding, geological contacts or any other discontinuities. Significant cohesion loss could occur along this path, which possibly could result in the formation of different scales of blocks, which disadvantages the slope stability.

As confining pressure decreases in excavated slope, rock permeability increases. This explains the common incidence of reducing porosity and permeability of rocks with the pit depth in sedimentary basins (England et al. 1987). Joint spacing and cracks opening escalating in response to the decreasing of applied normal stress (Brown and Scholz 1986). Rock permeability increases at highly strained slopes due to micro-cracking of extension strain at low effective pressure, therefore, slope stability could be sensitive to the growth of pre-existing micro-cracks, joints, and faults relative to the principal stresses.

4 Conclusions

This paper discussed the modelling of extension strain in the slope of Handlebar Hill open pit at Mt Isa, Queensland, Australia. The extension strain around two dimensional finite element elastic models is applicable using the criterion of Stacey (1981). This paper demonstrates that extension strain is the most probable starting point for the fracturing mechanisms. It was shown that the extension strain develops around the toe presenting in a larger magnitude behind the crest and is limited in the upper benches.

There is an agreement on the influence of the extension strains on slope stability between the in-situ observations and the predicted fracturing distributions of this study. As presented, the out-of-plane principal stresses extension strain criterion assist in understanding the probable initiation and orientation of extension fractures in the pit rock slope.

References

Brady, B.H.G., Brown, E.T.: Rock mechanics for Underground Mining, 3rd edn. Springer, Netherlands (2006)

Brown, S.R., Scholz, C.H.: Closure of random elastic surfaces in contact. J. Geophys. Res. 90, 5531–5545 (1986)

Coulomb, C.A.: Essai sur une application des règles de maximis et minimis a quelques problemes de statique. relatifs al architecture, Memoires de mathematique et de physique, presentes al Academie Royale des Sciences par divers savans, vol. 7, pp. 343–382 (1779)

Eberhardt, E., Stead, D., Coggan, J.: Numerical analysis of initiation and progressive failure in natural rock slopes – the 1991 Randa rockslide. Int. J. Rock Mech. Min. Sci. 41(1), 69–87 (2004)

England, W.A., MacKenzie, A.S., Mann, D.M., Quigley, T.M.: The movement and entrapment of petroleum fluids in the subsurface. J. Geol. Soc. Lond. 144, 327–347 (1987)

Hammah, R.E., Curran, J.H., Yacoub, T.E., Corkum, B.: Stability analysis of rock slopes using the finite element method. In: Proceedings of the ISRM Regional Symposium EUROCK 2004 and the 53rd Geomechanics Colloquy, Salzburg, Austria (2004)

Hoek, E.: Brittle failure of rock-in rock mechanics in engineering practice. In: Stagg, K.G., Zienkiewicz, O.C. (eds.), pp. 99–124. Wiley, London (1968)

Hoek, E., Carranza-Torres, C., Corkum, B.: Hoek-Brown failure criterion. Edition. In: Proceedings 5th North American Rock Mechanics Symposium, pp. 267–273. University of Toronto Press, Toronto (2002)

Kwaśniewski, M., Takahashi, M.: Strain-based failure criteria for rocks: state of the art and recent advances. In: Zhao, J. et al. (ed.) Rock Mechanics in Civil and Environmental Engineering, pp. 45–56. CRC Press/Balkema, Leiden, Netherlands (2010)

Liang, Z.Z.: Three-dimensional Numerical Modelling of Rock Failure Process, Doctoral Thesis, Dalian University of Technology (2003)

Louchnikov, V.: Simple calibration of the extension strain criterion for its use in numerical modelling. In: Potvin, Y. (ed.) Strategic versus Tactical Approaches in Mining 2011. Australian Centre for Geomechanics, Perth, Australia (2011)

Mahtab, M.A., Goodman, R.E.: Three-dimensional finite element analysis of jointed rock slopes. In: Proceedings of the Second Congress of the International Society of Rock Mechanics, Belgrade, vol. 3, pp. 353–360 (1970)

Martin, C.D., Kaiser, P.K., McCreath, D.R.: Hoek–Brown parameters for predicting the depth of brittle failure around tunnels, Application of the in plane minimum principal strain criterion. Geotech. 36, 136–151 (1999). Canada

Ndlovu, X., Stacey, T.R.: Observations of roof guttering in a coal mine. In: Proceedings of the 3rd Southern African Rock Engineering Symposium, Best Practices in Rock Engineering, Randburg, S. Afr. Inst. Min. Metall., Symposium Series S41, 2005. pp. 285–300 (2007)

Nelson, A.S.: Deformation of Rock, Lecturer in Physical Geology EENS 111, Tulane University, Louisiana, U.S.A (2003)

Pariseau, G.W., Purib, S., Schmelterc, C.S.: A new model for effects of impersistent joint sets on rock slope stability. Int. J. Rock Mech. Min. Sci. 45(2), 122–131 (2008)

Ramsey, M.J., Chester, M.F.: Hybrid fracture and the transition from extension fracture to shear fracture, Center for Tectonophysics, department of Geology and Geophysics, Texas A & M, University, College Station, Texas, USA (2004)

Sakurai, S.: Direct strain evaluation technique in construction of underground opening. In: Preceding of the 22nd U.S. Symposium on Rock Mechanics, 29 June–2 July, Cambridge, MA, pp. 278–282 (1981)

Sartori, M., Baillifard, F., Jaboyedoff, M., Rouiller, J.D.: Kinematics of the 1991 Randa rockslides. Nat. Hazards Earth Syst. Sci. V 3(5), 423–433 (2003)

Stacey, T.R.: A simple extension strain criterion for fracture of brittle rock. Int. J. Rock Mech. Min. Sci. 18, 469–474 (1981)

Stacey, T.R., De Jongh, C.L.: Stress fracturing around a deep level bored tunnel. J. S. Afr. Inst. Min. Metall. 78, 124–133 (1977)

Stacey, T.R.: Personal communication (2014–2015)

Stacey, T.R., Terbrugge, P.J., Keyter, G.J., Xianbin, Y.: A new concept in open pit slope stability and its use in the explanation of two slope failure. In: Fifth Larger Open Pit Mining Conference, 3–5 November, Kalgoorlie, WA, pp. 259–266 (2003)

Stead, D., Coggan, J., Elmo, D., Van, M.: Modelling brittle fracture in rock slopes: experience gained and lessons learned. In: Australian Centre for Geomechanics’ International Symposium on Rock Slope Stability in Open Pit and Civil Engineering, Perth, Australia, pp. 239–252 (2007)

Valenta, K.R.: Deformation, fluid flow and mineralization in the Hilton area, Mt. Isa, Australia, Doctoral Thesis of Philosophy in the department of earth science, Monash University, Victoria, Australia (1988)

Wesseloo, J.: Predicting the extent of fracturing around underground excavations in brittle rock, Technical report, SRK Consulting, Johannesburg, South Africa (2000)

Yanga, Q.S., Jianga, Z.Y., Xu, W.Y., Chen, X.Q.: Experimental investigation on strength and failure behavior of pre-cracked marble under conventional triaxial compression. Int. J. Solids Struct. 45(17), 4796–4819 (2008)

Acknowledgements

Authors wish to thank Prof. T. Stacey for kindly providing his hypothetical observations on the rock failure mechanisms occurring at the pit slopes, and being available for helpful comments.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Al Mandalawi, M., Sabry, M., Sabry, M. (2020). Initiation Mechanism of Extension Strain of Rock Mine Slopes. In: Bezvijen, A., Wittke, W., Poulos, H., Shehata, H. (eds) Latest Advancements in Underground Structures and Geological Engineering. GeoMEast 2019. Sustainable Civil Infrastructures. Springer, Cham. https://doi.org/10.1007/978-3-030-34178-7_5

Download citation

DOI: https://doi.org/10.1007/978-3-030-34178-7_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-34177-0

Online ISBN: 978-3-030-34178-7

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)