Abstract

This work addresses the long-term open-pit mine production planning. The solution for this problem indicates how and when the ore reserves will be extracted in order to maximize the value of the mining business, generating a promise that commits the mine production over time. Usually, due to the complexity of the problem, the planning process is divided into stages, generating three related problems that are sequentially solved to obtain a tentative production plan, that is: (i) determination of the final pit, which consists of delimiting the subregion of the mine where the extraction will be carried out; (ii) pushbacks selection, that corresponds to a partition of the final pit that allows to guide the sequence of extraction and to control the design; and finally, (iii) temporary production scheduling, which defines when the different zones will be extracted and which of them will be processed.

One of the disadvantages of the traditional methodology is the geological uncertainty is not taken into account, despite the great impact it can have on the production objectives. In this work we show some approaches to incorporate the uncertainty by means of conditional simulations to different stages of production planning, evaluating their impact. The results show that, on one hand, it is possible to increase the expected value of the business, and on the other hand, to reduce the risk of failure to meet production targets, allowing to generate more robust plans. In the case study presented, the results show that it is possible to obtain a discounted expected value increase of 2% and an uncertainty total cost decrease of 69% with respect to the usual methodology, which does not consider the geological uncertainty. Therefore, better decisions could be made in the long-term open pit mine production planning.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Open-pit mine production scheduling

- Geological uncertainty

- Stochastic mixed integer programming

- Conditional simulation

1 Introduction

Mine planning is the discipline of mine engineering that conjugates geological resources with the market to delineate the best productive business for the mining company, generating a mining plan, which defines how and when the mining reserves will be extracted, allowing to quantify the human, economic and technical resource, generating the company’s business plan. The productive promise generated in the mining plan is expressed through a production plan and is supported by a schedule, which compromises production over time. In order to generate a production plan, the orebody is discretized in blocks and the planning horizon is discretized in time periods. To generate a production plan, the planning process is divided into three stages, which are solved sequentially: (i) ultimate pit limit problem, which delimits the extraction area, (ii) pushback selection, which splits the pit limit into volumes that meet certain operational requirements, and (iii) temporary production scheduling, which assigns to each period which blocks must be extracted, respecting limits on operational resources consumption and maximizing the net present value (NPV).

Since the 1960s the methodology based on the Lerchs and Grossmann algorithm [1] has been the basis for scheduling the production of open pit mines. However, traditional methods do not consider the uncertainty associated with input parameters, such as ore grades or metal prices, which can lead to large deviations from production targets. In recent years some authors have recognized the importance of taking into account multiple sources of uncertainty and including them in the optimization of the mine production scheduling process, for example [2] have shown the consequences of considering a single block model as an input to the scheduling process, which is described as a non-linear transfer function. This is a critical issue for mine planning because the inability to quantify the impact of uncertainty on the performance of the downstream processing operations is a key reason why mining companies are often unable to meet production targets and financial forecasts [3].

Geological uncertainty represents the level of ignorance of mineralogical characterization, in particular, of the different types of material and their respective concentrations (grades), as well as of the extent and position of geological units. Since the estimates are continuous interpolations of discretely obtained data, the models do not capture the real variability of the deposit, the origin of which lies in the inherent variability of the deposit and the variability of errors in data collection, preparation and analysis. In recent years, the use of tools such as geostatistical simulation has shown better results, since they reproduce the real spatial variability of the regionalized variable. In particular, the use of conditional simulations (see, for example, [4]) has made it possible to incorporate this type of uncertainty in planning process. It has been widely reported (see [2, 5,6,7,8] and references cited there) that geology is one of the sources of uncertainty that contributes most to the differences between planned and operational solutions.

This paper assesses the impact of uncertainty in each of the three stages of the open-pit mine production planning process: (i) ultimate pit limit, (ii) pushback selection, and (iii) temporary production scheduling. Although geological uncertainty is not considered in the traditional methodology, most of the efforts made to incorporate it using optimization models have only been made within the scheduling stage, defining it within a deterministic ultimate pit, inside which there exists a set of scenarios that model uncertainty (see [9,10,11]). Moreover, these results do not even consider the selection of pushbacks as a stage within the process, going directly from a deterministic definition of ultimate pit limit to scheduling under uncertainty, which can generate impractical results. In this work we propose and evaluate a methodology that incorporates geological uncertainty in the three mentioned stages. For each one of them, the risk associated to the ignorance of the mineralized zone is considered.

2 Methodology

The methodology will be based on a sequential development for the long-term open-pit production planning process by considering the geological uncertainty represented by a series of \( \left| R \right| \) conditional simulations of the block model \( B \). This sequential methodology includes developing strategies for each of the three stages: (i) definition of the ultimate pit limit, (ii) pushback selection, and (iii) temporary production scheduling. The objective will be to successively incorporate the uncertainty along stages, in order to assess how the uncertainty impacts on the total process. The following cases will be considered:

-

Base Case: it corresponds to the process that does not consider uncertainty at any stage.

-

Case 1: it follows the approach of most of the published works, that is, incorporating uncertainty in the scheduling only (stage (iii)).

-

Case 2: it starts from a deterministic ultimate pit limit, but then incorporates the geological scenarios for selecting pushbacks and scheduling, (stages (ii) and (iii)).

-

Case 3: it incorporates uncertainty in the three stages of the planning process.

For each case, an expected NPV will be obtained, which can be used to see the effect of incorporating uncertainty in the different stages, for example, through the value of the information, which is interpreted as the cost of ignoring uncertainty in decision-making.

2.1 Ultimate Pit Limit Problem

The ultimate pit is found considering geological uncertainty by means of conditional simulations of metal grade, based on the development made by [12], who propose a multi-objective optimization model that seeks a balance between maximizing the expected benefit and minimizing the risk, expressed in terms of the Conditional Value at Risk (CVaR) [13].

It is assumed that there is a value \( v_{br} \) for each block \( b \) and each grade simulation \( r. \) A binary variable \( x_{b} \; = \;1 \) is defined if block \( b \) belongs to the ultimate pit, and zero if not. The precedence relations are coded by means of a set \( A \) of pairs of arcs \( \left( {a,b} \right) \), where to extract block \( a \), block \( b \) must first be extracted. Taking a level of confidence \( \delta \in \left( {0,1} \right] \) the ultimate pit limit problem under uncertainty is defined as:

where \( \alpha \) and \( \left( {\alpha + \frac{1}{{\left| R \right|\left( {1 - \delta } \right)}}\sum\nolimits_{r \in R} {Z_{r} } } \right) \) correspond to the discrete approximations of Value at Risk (VaR) and CVaR, respectively. It is important to note that an optimal solution \( \varvec{x}^{ * } \) to the problem (P1) determines which blocks belong to the ultimate pit so that the expected value is maximized throughout all simulations, while minimizing the risk of loss measured by the CVaR. The deterministic version of this problem (P1D) considers a single representation of grade distribution such as kriging or e-type [3, 7].

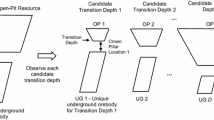

2.2 Pushback Selection Problem

Let \( B \) the ultimate pit obtained from Sect. 2.1. Applying the methodology of Lerchs and Grossmann [1] and scaling the metal price in the valorization by a series of \( n \) revenue factors \( 0 < \lambda_{1} < \cdots < \lambda_{n} \, = \;1 \), we have a value for each block \( b \), each realization \( r \) and each revenue factor \( \lambda_{i} \). Taking the average value over all realizations, we have an expected value \( v_{b}^{i} \) of each block \( b \) associated to the revenue factor \( \lambda_{i} \). To obtain the stochastic nested pits we solve \( n \) (P1D) problems, one for every revenue factor, similar to [14] for the ultimate pit limit.

To select pushbacks from the set of stochastic nested pits, the formulation given in [15] is used, where an optimization model chooses the best pushback candidates on the basis of clearly defined criteria, for example, the minimizing the gap problem [16], so that the resulting pushbacks have the minimum difference between them in ore and waste tonnages.

For the deterministic case, the same process is repeated, but the nested pits generated are not stochastic as [14], but a single valuation is generated \( v_{b}^{i} \) for each revenue factor \( i \), based on kriging or e-type model, for block \( b \). The pushback selection is done by using the same model as the stochastic case [15] for a fair comparison of pushback selection.

2.3 Production Scheduling Problem

The production scheduling model is based on a mixed integer program by considering the following features:

-

Multiperiod: The temporal dimension is included into the scheduling model, allowing to the model to decide which is the best extraction period for each block, considering a discount rate.

-

Multidestination: The destination of each block is decided in the model, therefore a variable cutoff grade is implemented.

-

Explicitly considers geological scenarios: The information given by the conditional simulations is directly an input to the model in one-run to be considered simultaneously, maximizing the expected discounted value and minimizing the deviations of the production targets along the set of realizations. Each deviated tonnage is penalized by a unitary deviation cost in the objective function. Taking an average on the realizations we penalize the expected NPV with a total cost due to uncertainty in the objective function.

-

Pushback design: The schedule respects the sequence imposed by the pushbacks. A min/max lead is imposed between bench-phases.

-

Operational resource consumption constraints: Upper and lower limits are imposed on the resource consumption such as mining and processing capacities.

-

Blending constraints: The quality of the material sent to the plant should be controlled for an optimum processing performance, such as impurities (arsenic in copper ore, or silica in iron ore).

For a detailed description of the mathematical model see [8, Section 5.3].

2.4 Case Study

The block model \( B \) corresponds to a porphyry copper deposit, known as BM. The model consists of \( \left| B \right| = 407{,}179 \) blocks of 10 × 10 × 10 m. Each block has information about spatial coordinates, density, \( \left| R \right|\, = \;50 \) realizations of copper grade, and E-Type copper grade. The parameters to generate the economic block valuation are: Price 2.5 ($/lb), Metallurgical recovery 85%, Mining cost 3.2 ($/ton), Processing cost 9.0 ($/ton), and Selling cost 0.4 ($/lb). Regarding to slope control, slope angles of 45° were considered and no additional consideration is taken over the geomechanic in the pit walls. An ultimate pit limit is computed with a \( \delta \; = \,95\% \) level of confidence.

For the generation of nested pits the same economic valuation is considered, but scaling the metal price by a series of 90 revenue factors given by \( \lambda_{i} \; = \;i/90 \) with \( i\; = \;1, \ldots , 90. \)

Finally, the additional parameters of the scheduling stage are: horizon planning 22 (year), discount rate 10%, 2 destinations (plant and waste dump), maximum mining capacity 13 (Mton/year), minimum/maximum processing capacity 6/7 (Mton/year), minimum head grade of 0.5% per year. A maximum depth of 8 benches (max lead) is allowed. The cost of under and overproduction of ore is set at 18.5 ($/ton) and the cost of underproduction of metal is set at 39 ($/ton).

3 Results

Since it is not possible to show in detail the results of tonnages, grades, operative geometries of sequences, and economic values of each stage and each case, the results will be focused individually in each stage, without considering uncertainty (deterministic) and considering uncertainty (stochastic). By sequentially doing all deterministic cases, Base Case is generated. Likewise, all stochastic stages generate the Case 3. Finally, the results of generating intermediate cases (Cases 1 and 2) are shown in Table 1 to evaluate the impact of each stage in the open-pit mine production planning process.

The ultimate pit limit for stochastic and deterministic approaches are shown in Fig. 1. Differences can be seen at the pit bottoms. Stochastic pit presents 5.3% more mineral, obtaining a larger pit when compared to deterministic approach. The economic value is almost the same, in fact, stochastic pit presents a 0.4% higher value, but the risk (CVaR) is 15.7% lower.

Figure 2 presents the main results of pushback selection. The tonnages of both approaches (stochastic and deterministic) are very similar. The same is true for the average grade per pushback. This implies that the how the uncertainty was incorporated at this stage did not have much impact on the results.

Figure 3 shows the results of the final stage, production scheduling. As usual, the results of the Best case and Case 3 are shown, both their extraction geometries and comparative production plan, where the bars represent the percentiles P5 and P95, both in tonnage (ore and waste) and head grade. The main differences are observed in the last periods of the planning horizon, especially considering that the stochastic ultimate pit limit presents greater ore tonnages: The life of the mine is extended by one year more than deterministic case. Stochastic scheduling has 3.8 (Mton) of underproduction ore and the deterministic scheduling has 15.9 (Mton).

Based on Table 1 results, we can compute the value of the information if uncertainty is incorporated in each stage: (i) Best case v/s Case 1: 10.7 (M$); Case 1 v/s Case 2: 2.4 (M$); Case 2 v/s Case 3: 6.0 (M$). Therefore, the total value of the information in this case is 19.1 (M$).

4 Conclusions

In this work we study the impact of incorporating geological uncertainty in each of the three stages that are sequentially solved to generate a production plan in strategic open-pit mines: (i) ultimate pit limit, (ii) pushback selection, and (iii) temporary production scheduling. Four cases were generated for evaluation, depending what stage the uncertainty is introduced: Base case, without uncertainty; Case 1, uncertainty included only in stage (iii), Case 2, uncertainty included in stages (ii) and (iii), and Case 3, where uncertainty is considered in all stages.

Results show that incorporating uncertainty helps to reduce risk of losses due to noncompliance with production targets. Likewise, the three stages contribute in different proportions to the total value of the information, in this case study: ultimate pit limit contributes 31.4%, pushback selection contributes 12.6%, and production scheduling contributes 56%. This is very important because it helps to identify where to concentrate efforts and up to what amounts it is justified to pay for more information to reduce this uncertainty, e.g. more drillings in specific areas of the mine.

References

Lerchs, H., Grossmann, I.: Optimal design of open-pit mines. Trans. C.I.M. 68, 17–24 (1965)

Dimitrakopoulos, R., Farrelly, C., Godoy, M.: Moving forward from traditional optimization: grade uncertainty and risk effects in open-pit design. Min. Technol. 111(1), 82–88 (2002)

Morales, N., Seguel, S., Cáceres, A., Jélvez, E., Alarcón, M.: Incorporation of geometallurgical attributes and geological uncertainty into long-term open-pit mine planning. Minerals 9(2), 108 (2019)

Emery, X., Lantuéjoul, C.: TBSIM: a computer program for conditional simulation of three-dimensional Gaussian random fields via the turning bands method. Comput. Geosci. 32(10), 1615–1628 (2006)

Ravenscroft, P.: Risk analysis for mine scheduling by conditional simulation. Trans. Inst. Min. Metall. Sect. A. Min. Ind. 101, A104–A108 (1992)

Smith, M., Dimitrakopoulos, R.: The influence of deposit uncertainty on mine production scheduling. Int. J. Surf. Min. Reclam. Environ. 13(4), 173–178 (1999)

Osanloo, M., Gholamnejad, J., Karimi, B.: Long-term open pit mine production planning: a review of models and algorithms. Int. J. Min. Reclam. Environ. 22(1), 3–35 (2008)

Jélvez, E.: Metodología multietapa para la planificación de la producción de largo plazo en minas a rajo abierto bajo incertidumbre geológica. Ph.D. thesis, Departamento de Ingeniería de Minas, Universidad de Chile, Santiago, pp. 1–189 (2017)

Godoy, M.: The efficient management of geological risk in long-term production scheduling of open pit mines. Ph.D. thesis, University of Queensland, Brisbane, pp. 1–256 (2003)

Dimitrakopoulos, R., Ramazan, S.: Stochastic integer programming for optimising long term production schedules of open pit mines: methods, application and value of stochastic solutions. Min. Technol. 117(4), 155–160 (2008)

Mai, N.L., Topal, E., Erten, O., Sommerville, B.: A new risk-based optimisation method for the iron ore production scheduling using stochastic integer programming. Resour. Policy 62, 571–579 (2018)

Jélvez, E., Morales, N., Ortíz, J.M.: Stochastic ultimate pit limit: an efficient Frontier analysis under geological uncertainty (submitted)

Rockafellar, R., Uryasev, S.: Optimization of conditional value-at-risk. J. Risk 2, 21–42 (2000)

Marcotte, D., Caron, J.: Ultimate open pit stochastic optimization. Comput. Geosci. 51, 238–246 (2013)

Jélvez, E., Morales, N., Askari-Nasab, H.: A new model for automated pushback selection. Comput. Oper. Res. (2018, in press)

Meagher, C., Dimitrakopoulos, R., Avis, D.: Optimized open pit mine design, pushbacks and the gap problem: a review. J. Min. Sci. 50(3), 508–526 (2014)

Acknowledgements

Enrique Jélvez and Nelson Morales were supported by CONICYT/PIA Project AFB180004 – Advanced Mining Technology Center – Universidad de Chile.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Jélvez, E., Morales, N., Ortíz, J.M. (2020). Impact of Geological Uncertainty at Different Stages of the Open-Pit Mine Production Planning Process. In: Topal, E. (eds) Proceedings of the 28th International Symposium on Mine Planning and Equipment Selection - MPES 2019. MPES 2019. Springer Series in Geomechanics and Geoengineering. Springer, Cham. https://doi.org/10.1007/978-3-030-33954-8_9

Download citation

DOI: https://doi.org/10.1007/978-3-030-33954-8_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-33953-1

Online ISBN: 978-3-030-33954-8

eBook Packages: EngineeringEngineering (R0)