Abstract

Non-axenic microalga Chlorella sorokiniana was cultivated in batch cultures, and its total sugar composition was determined. The microalga under study showed a total sugar concentration of 21.44 ± 0.46% (w/w). The effects of freeze-drying, oven-drying, freezing and thawing, chemical and the combination of hydrothermal and chemical pretreatments were evaluated. In the combined pretreatment different concentrations of H2SO4 and reaction times were also optimized. It was possible to determine that the sugar extraction yields more significant were 59.5% for the lyophilization, 6.2% with 6 cycles of freeze and thawing and around 100% for 2 and 4% (v/v) of H2SO4 at 121 °C for 30 min. Some of the methods that were described in this study are interesting to facilitate cost-efficient conversion of microalgal biomass into biofuels.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Recently microalgae have been considered an alternative sustainable resource, for high-value bioproducts and a promising third-generation (3G) feedstock for biofuels production. Biofuels derived from microalgae biomass have received a great deal of attention, owing to their high potentials since they are sustainable, renewable, cost‐effective and environmentally friendly [1]. Some LCA studies, for greenhouse gases emissions from different biofuels, showed that due to the CO2 recycling for microalgae cultivation, the algal biodiesel has lower emissions than the corn bioethanol [2, 3]. A sustainable biofuel production requires a biorefinery approach, to ensure that all cellular components of the microalgae are converted into high-value bioproducts and biofuels [4].

Microalgae do not require arable land to grow up and easily develop in natural or engineered systems. Can be cultivated in different types of water such as wastewaters, fresh brackish and marine waters. They are able to fix dissolved inorganic carbon and CO2 to synthesize chemical energy via autotrophic and heterotrophic metabolisms. Have higher, photosynthetic efficiency (3%–8%), biomass yield (more than 50%) and CO2 caption (10–50 times), when compared terrestrial plants [4].

According to the growing conditions they can accumulate different quantities of lipids, proteins, carbohydrates (starch) and other high value products [5]. The main part of these components can be found intracellularly, 20 to 60% of lipids, 20 to 50% of starch in the plastids and 20 and 50% of other bioproducts [6].

The cell wall has the function of provide rigidity and recalcitrance to microalgal biomass biodegradability, its structure and composition is also impressive. It is primarily composed by cellulose, pectin and sulfated polysaccharides.

Pretreatment methods emerged as mechanisms to overcome the complex and recalcitrance nature of the cell wall components. Thermochemical methods were thoroughly investigated, but there are furthermore technical, environmental and economic issues that should be regarded. Therefore, it is necessary to study sustainable pretreatment technologies, suitable to the specifics of each microalga. An integrated biomass pretreatment and biorefinery concept are essential to promote a production of biofuels in a cost-effective and eco-friendly manner [4, 7].

Microalgae cell disruption is an integral part of the downstream operation required to increase the accessibility to the intracellular compounds and the cell wall components. In order to produce bioethanol, it is necessary the hydrolysis of cell wall polysaccharides (cellulose and hemicellulose) and intracellular carbohydrates, present in the form of starch, to release monosaccharides for its later fermentation into bioethanol. Biomass pretreatments is a necessary stage to increase the surface area, to enhance sugars solubility and to improve substrate digestibility [8].

Diverse types of pretreatments are currently used including chemical, thermal, mechanical, enzymatic, and their combinations, which can promote cell disruption, facilitate extraction, and result in the modification the structure of carbohydrates as well as the production of fermentable sugars [6]. The choice of the method should take into account the contribution of the method to the cell biodegradability, which varies according to the cellular structure of the microalgae species under study.

Pretreatment for cell disruption were studied on non-axenic microalgae Chlorella sorokiniana using combinations of thermal, hydrothermal, mechanical and chemical methods. Thermal pretreatment is based on applying heat to microalgal biomass to disrupt chemical bonds in the cell wall and to improve solubilization of cell components. Thermal pretreatment can be applied by inserting only heat to microalgae biomass and hydrothermal pretreatment by inserting heat combined with pressure. Chemical pretreatment is based on introducing alkaline, acidic oxidative chemicals, or organic solvents to solubilize polymers and enhance biodegradation. Mechanical pretreatment promotes the destruction of the cell wall through mechanical forces, by the action of microwave, glass beads or ultrasound and increases the substrate accessibility to enzymes [5]. Different pretreatment methods can be applied in combination to reduce the cost and increase efficiency of pretreatment.

In this work, the effects of freeze-drying, oven-drying, freezing and thawing, chemical and the combination of hydrothermal and chemical pretreatments were evaluated. In the combined pretreatment different concentrations of H2SO4 and reaction times were also optimized.

2 Materials and Methods

2.1 Strains and Culture Conditions

The non-axenic culture of Chlorella sorokiniana 211-32 [9] was obtained from the culture collection of the Institute of Plant Biochemistry and Photosynthesis, IBVF, (Seville, Spain). Tris-acetate-phosphate (TAP) medium at pH 7.2 was used for C. sorokiniana culturing [10]. The microalgal strain was inoculated from a 2% (w/v) agar plate into 50 mL flasks with TAP medium and precultured. When the cultures reached the exponential growth phase, they were sequentially scaled up until reaching 3 L of culture with a cell concentration of 1.5 g/L. The cultures were photomixotrophically grown at 25 °C with aeration under continuous white light irradiation of 100 μE m−2s−1. Microalgal growth was followed by spectrophotometrical measurement of the optical density at 750 nm (GBC DBUV instrument Cintra 202, Australia). The microalgal biomass was harvested at the end of the exponential phase using a centrifuge (Hettich Zentrifugen Universal 320, Germany) at 4470 G for 10 min.

2.2 Pretreatment Conditions Tested

For oven drying (Binder FD 115, Germany), about 100 ± 5 mg of microalgal biomass was weighed out into a pre-weighed crucible (Precisa XB 120A, Switzerland). The samples were placed into a convection drying oven at 60 °C ± 1 °C at atmospheric pressure for 24 h. samples were withdrawn, allowed to cool to room temperature in a desiccator and weighed [11].

Microalgal biomass was lyophilized (Labconco FreeZone 2.5, USA) at −70 °C, until a constant weight was reached. After oven drying and lyophilization, the biomass was macerated in a mortar.

The freezing and thawing cycles were repeated 6 times, each one for 24 h at −21 °C on wet and lyophilized biomass.

The chemical pretreatment was done at room temperature with 4% (v/v) H2SO4 and 50 g/L of microalgal biomass with agitation (IKA KS4000i, Portugal) for 20 and 90 min.

The combination of hydrothermal and chemical pretreatment was completed in an autoclave (Raypa AE8, España) at 121 °C with 50 g/L of microalgal biomass. Two variables were studied, the concentration of H2SO4 (2, 4, 7 and 10% v/v) for 30 min and the reaction time (20, 30, 45, 60 and 90 min) with 4% (v/v) H2SO4. All the assays were performed in triplicate with a control using water. The Fig. 1 shows a graphical representation of the tests performed.

2.3 Analytical Procedures

Total carbohydrates of microalgae biomass were measured by anthrone method [12] and total reducing sugars content of microalgae hydrolysates were determined with dinitrosalicylic acid (DNS) method, using the calibration curve equation of y = 0.3010 x + 0.0177 with R2 > 0.99, prepared with glucose standards ranging from 0.2 to 2 g/L [13].

The total reducing sugar content in % (g reducing sugar/g dry biomass) was calculated by:

The sugar extraction yield was calculated by:

2.4 Statistical Analysis

All experiments were conducted in triplicates and the data were expressed as the mean ± SD. One-way analysis of variance (ANOVA) followed by Tukey’s multiple comparison test was used to examine the difference among individual treatment and optimum condition. GraphPad Prism version 8.0 for Mac (GraphPad Software, Inc., USA) was used for all statistical analysis and difference in the variables was considered significant at the P < 0.05 of confidence.

3 Results and Discussion

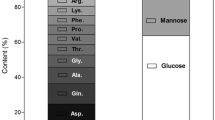

Through the anthrone method it was possible to determine, that the non-axenic C. sorokiniana microalga has 21.44 ± 0.46% (w/w) of total sugars. All extraction yield calculations were performed taking into account this value.

From the pretreatments developed by oven drying and freeze drying it was possible to obtain a total reducing sugars content of 9.17 and 12.55% (w/w), respectively. The freeze drying, with an extraction yield of 58.5% is the pretreatment method with better performance.

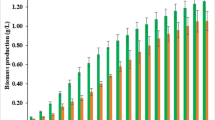

Due to its simplicity and capacity of mechanically breaking the cell walls, the freezing and thawing cycles were also evaluated. According to Fig. 2, it can be established that the increase from 1 to 2 and 4 freeze and thawing cycles, did not released more reducing sugars. The transition from 1 to 6 cycles is the most striking, with a total reducing sugar content increase of 17.8 times for wet biomass and 15.5 times for lyophilized biomass.

Although the release of sugars is higher with the increase of cycles, the maximum extraction yield achieved with 6 cycles of freeze and thawing in wet biomass is only 6.2%.

The chemical hydrolysis of non-axenic C. sorokiniana microalga biomass was carried out for 20 and 90 min at room temperature with shaking and a concentration of 4% (v/v) H2SO4. As illustrated in Fig. 3, in the reaction time of 20 min there was no hydrolysis of the biomass, since there is no significative difference between the control and the assay with 4% (v/v) H2SO4.

When the reaction time was increased from 20 to 90 min, there was a decrease of 2.6 times in the total reducing sugar content. In conclusion, the hydrolysis under these conditions, with 90 min of exposure time to 4% (v/v) leads to the degradation of the released sugars.

Given the lack of hydrolysis from the chemical pretreatment, the combination with hydrothermal conditions was crucial. Reaction time is a variable that has a significant effect on sugar extraction. The hydrolysis of non-axenic C. sorokiniana was carried out at different reaction times from 20 to 90 min with 4% (v/v) H2SO4 at 121 °C. Analyzing the Fig. 4A it is possible to distinguish, that the total reducing sugars content of 20 and 30 min assays are respectively circa, 6 and 9 times higher than the control. From 20 and 30 min of reaction there is an increase of sugar content of about 7.5% (g reducing sugar/g dry biomass). At 30, 45 and 60 min there is no difference between tests. The reaction time that best promotes the extraction of reducing sugars is 30 min, achieving a yield of 100%. When the pretreatment takes place for 90 min, there is a decrease in the content of reducing sugars. Exposure over a long period of time and under the action of acid may cause some degradation of reducing sugars.

Variation of total reducing sugar content (% g reducing sugar/g dry biomass) from the combination of hydrothermal and chemical pretreatment methods. (A) Variation of reaction time with 4% (v/v) H2SO4. (B) Variation of H2SO4 concentration with a reaction time of 30 min. Values represent mean (n = 3) ± SD. Columns with the same letters are not significantly different (P < 0.05) according to the Tukey’s test for mean comparisons.

A range of H2SO4 concentrations from 2 to 10% (v/v) at 121 °C for 30 min was also evaluated. Analyzing Fig. 4B there is, a circa 20 times increase of the total reducing sugar content between the control and 2, 4, 7 and 10% (v/v) H2SO4 tests. No significant differences between the 2 and 10% (v/v) H2SO4 tests were registered. Increasing the H2SO4 concentration from 2 to 10% (v/v) does not promote a higher extraction of the reducing sugars. This increase, in acid concentration, can also, enhance sugar degradation during the pretreatment, causing a loss of substrate as well as, undesirable production of inhibiting substances. In conclusion, the combination of hydrothermal and chemical pretreatment method with 2% (v/v) H2SO4 is the one that best promotes the availability of sugars, achieving an extraction yield of 97.8%.

According to studies performed by Miranda et al. [14] on Scenedesmus obliquus microalga, the combination of hydrothermal and chemical pretreatment under the conditions 5% (v/v) H2SO4 at 120 °C for 30 min allowed an extraction yield of 96%. This yield is very close to the one obtained for non-axenic Chlorella sorokiniana microalga, at 2% (v/v) H2SO4 at 120 °C for 30 min. The specific recalcitrance of each microalga can explain the difference between the yield in the study of Miranda et al. and the yield present in this work of 100% with 4% (v/v) H2SO4, at 120 °C for 30 min [14].

In some pretreatments it was possible to verify the existence of sugar degradation. Glucose yields and sugar decomposition products largely depend on reaction time, acid concentration and reaction temperature. As a result of this sugar decomposition, depending on the acidic conditions, some undesirable byproducts emerge such as furfural and 5-hydromethylfurfural (5-HMF) [15]. Levulinic acid, formaldehyde, and formic acid are also produced as the decomposition progress [16, 17]. These byproducts are known to inhibit the ethanol producing microorganisms in the fermentation process [18].

Studies of enzymatic hydrolysis are already under way. The pretreatment defined in this study, will be the step that precedes the studies of enzymatic hydrolysis, where the conditions for the maximum production of fermentable sugars are being optimized for the production of bioethanol.

4 Conclusions

Physical, chemical and hydrothermal combined with chemical pretreatments of non-axenic microalgae C. sorokiniana were evaluated. From this work we can conclude that the following conditions, room temperature, 4% (v/v) H2SO4 for 90 min lead to the degradation of sugars. It was possible to determine that the sugar extraction yields more significant were around 100% for 2 and 4% (v/v) of H2SO4 at 121 °C for 30 min.

Overall, some of the methods that were described herein may be valuable to facilitate cost-efficient conversion of microalgal biomass into biofuels.

References

Odjadjare, E.C., Mutanda, T., Olaniran, A.O.: Potential biotechnological application of microalgae: a critical review. Crit. Rev. Biotechnol. 37(1), 37–52 (2017). https://doi.org/10.3109/07388551.2015.1108956

Garlapati, V.K., Tewari, S., Ganguly, R.: Chapter 19 - life cycle assessment of first-, second-generation, and microalgae biofuels. In: Hosseini, M. (ed.) Advances in Feedstock Conversion Technologies for Alternative Fuels and Bioproducts, pp. 355–371. Woodhead Publishing. (2019). https://doi.org/10.1016/B978-0-12-817937-6.00019-9

Zabed, H.M., Akter, S., Yun, J., Zhang, G., Awad, F.N., Qi, X., Sahu, J.N.: Recent advances in biological pretreatment of microalgae and lignocellulosic biomass for biofuel production. Renew. Sustain. Energy Rev. 105, 105–128 (2019). https://doi.org/10.1016/j.rser.2019.01.048

Mishra, S., Mohanty, K.: Comprehensive characterization of microalgal isolates and lipid-extracted biomass as zero-waste bioenergy feedstock: an integrated bioremediation and biorefinery approach. Biores. Technol. 273, 177–184 (2019). https://doi.org/10.1016/j.biortech.2018.11.012

Kendir, E., Ugurlu, A.: A comprehensive review on pretreatment of microalgae for biogas production. Int. J. Energy Res. 42, 3711–3731 (2018). https://doi.org/10.1002/er.4100

Velazquez-Lucio, J., Colla, L.M., Rodríguez-Jasso, R.M., Sáenz-Galindo, A., Cervantes-Cisneros, D.E., Aguilar, C.N., Fernandes, B.D., Ruiz, H.A.: Microalgal biomass pretreatment for bioethanol production: a review. Biofuel Res. J. 17, 780–791 (2018). https://doi.org/10.18331/BRJ2018.5.1.5

Ahmad, E., Pant, K.K.: Lignin conversion: a key to the concept of lignocellulosic biomass-based integrated biorefinery. In: Bhaskar, T., Pandey, A., Mohan, S.V., Lee, D-J., Khanal, S.K., (eds.) Waste biorefinery 2018, pp. 409–44. Elsevier, Amsterdam (2018). https://doi.org/10.1016/b978-0-444-63992-9.00014-8

Hernández, D., Riaño, B., Coca, M., García-González, M.C.: Saccharification of carbohydrates in microalgal biomass by physical, chemical and enzymatic pre-treatments as a previous step for bioethanol production. Chem. Eng. J. 262, 939–945 (2015). https://doi.org/10.1016/j.cej.2014.10.049

León-Vaz, A., León, R., Díaz-Santos, E., Vigara, J., Raposo, S.: Using agro-industrial wastes for mixotrophic growth and lipids production by the green microalga Chlorella sorokiniana. New Biotechnol. 51, 31–38 (2019). https://doi.org/10.1016/j.nbt.2019.02.001

Harris, E.: The Chlamydomonas Sourcebook, 2nd edn. Academic Press, San Diego (2009)

Van Wychen, S.; Laurens, L.M.L.: Determination of Total Solids and Ash in Algal Biomass. NREL/TP-5100-60956. National Renewable Energy Laboratory, Golden (2015)

Hedge, J., Hofreiter, B.: Estimation of Carbohydrate. Methods in Carbohydrate Chemistry, p. 17. Academic Press, New York (1962)

Miller, G.L.: Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959)

Miranda, J.R., Passarinho, P.C., Gouveia, L.: Pre-treatment optimization of Scenedesmus obliquus microalga for bioethanol production. Biores. Technol. 104, 342–348 (2012). https://doi.org/10.1016/j.biortech.2011.10.059

Lenihan, P., Orozco, A., O’Neill, E., Ahmad, M.N.M., Rooney, D.W., Walker, G.M.: Dilute acid hydrolysis of lignocellulosic biomass. Chem. Eng. J. 156, 395–403 (2010). https://doi.org/10.1016/j.cej.2009.10.061

Iranmahboob, J., Nadim, F., Monemi, S.: Optimizing acid-hydrolysis: a critical step for production of ethanol from mixed wood chips. Biomass Bioenergy 22(5), 401–404 (2002). https://doi.org/10.1016/S0961-9534(02)00016-8

Zhang, Y.H.P., Ding, S.Y., Mielenz, J.R., Cui, J.B., Elander, R.T., Laser, M., Himmel, M.E., McMillan, J.R., Lynd, L.R.: Fractionating recalcitrant lignocellulose at modest reaction conditions. Biotechnol. Bioeng. 97(2), 214–223 (2007). https://doi.org/10.1002/bit.21386

Jeong, T.S., Kim, Y.K., Oh, K.K.: Two-stage acid saccharification of fractionated Gelidium amansii minimizing the sugar decomposition. Biores. Technol. 102(22), 10529–10534 (2011). https://doi.org/10.1016/j.biortech.2011.09.017

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Rodrigues, B., Borges, R., Castro, M., Constantino, A., Raposo, S. (2020). Chemical and Physical Pretreatments of Microalgal Biomass. In: Monteiro, J., et al. INCREaSE 2019. INCREaSE 2019. Springer, Cham. https://doi.org/10.1007/978-3-030-30938-1_32

Download citation

DOI: https://doi.org/10.1007/978-3-030-30938-1_32

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-30937-4

Online ISBN: 978-3-030-30938-1

eBook Packages: EnergyEnergy (R0)