Abstract

To gain more information about the relationship between early cement hydration and rheological behavior of the corresponding cement paste, a new penetration test device, with the name “Multipurpose Incremental Loading device” (MILD), has been developed. The construction and the mechanical properties of the device are described in detail. Furthermore, the implementation of a measurement and first results will be discussed, and the new device is compared with the standardized Vicat test. In addition, a comparison of the measurement results with rheological investigations is made and the results of quantitative in-situ XRD and calorimetry are integrated for a deeper understanding. We show that it is possible to get more information about the structure formation with the new device than with the Vicat test. Moreover, a comparison with the rheological properties of a cement paste was done. Both methods show two periods with different rheological behavior. During the first two hours the paste shows a slow increase of viscosity which is followed by a strong increase. The results of the penetration test and the rheometer are linked with the formation of hydration products and the heat flow development. This comparison shows that the link between the two periods is the beginning of the acceleration period. Finally, it is concluded that it is possible to get precise information about the early cement hydration with a penetration test.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The early cement hydration and the developing rheological and mechanical properties of the fresh material have a significant impact on many applications of cementitious products. Nevertheless, the complex processes especially during early cement hydration are barely understood. However, in many areas, it is important to know in detail how a fresh paste or concrete will behave, and which properties can be expected. The relationships between the processes of early cement hydration and the rheological properties of a cement paste are of importance in view of the increasing development of 3D printing of concrete [1, 2]. There are several commonly used penetration tests in the field of civil engineering like the Vicat needle, the Hilti nail gun and the Gillmore needle. Moreover, there are two different types of penetration tests. Some devices measure the penetration resistance at a given speed and other devices measure the penetration depth at a given load [3]. In this paper, we will compare the new device with the most widely used and standardized Vicat test. This method measures the penetration depth whereas the Multipurpose Incremental Loading device (MILD) measure the penetration resistance. Penetration tests can also be considered as rheological investigations [4]. During penetration tests where the penetration depth is measured, the needle is hindered from further penetration by the yield point of the paste. Consequently, the resistance to needle penetration at a given speed is also affected by the yield point [3]. For this study, the chemical processes of early cement hydration are particularly important. These processes is described by Jansen et al. [5].

2 Materials

2.1 Materials

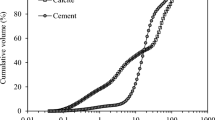

Ordinary Portland cement (OPC, CEM I 42.5 R) provided by HeidelbergCement was used and its chemical and mineral composition are given in Table 1. The specific surface measured by Blaine is 3699 cm2/g ± 23 cm2/g and deionized water was used.

2.2 Sample Preparation

Cement paste was prepared with 650 g cement and a water to cement ratio of 0.36 under 20.0 °C ± 0.3 °C and a relative humidity of 65%. A stand mixer (Kitchen Aid, Type 5K45) was used to prepare the sample with the following process: The mixing procedure started after the water addition. It started at level 1 (58 rounds per minute (rpm)) for 15 s. After that the speed was increased to level 4 (125 rpm) for 45 s and then level 10 (220 rpm) for 30 s. This was followed by a 90 s break to rid the edges of the bowl of cement paste. The last step involves mixing at level 10 for another 60 s.

3 Methods

3.1 Multipurpose Incremental Loading Device (MILD)

3.1.1 Construction

The MILD was designed and built at the TU Berlin. With this device two different measurements can be performed. The first one is a compressive strength test for small sample cubes and the second one is a penetration test with constant penetration speed. In this paper, we will focus on the penetration test of cement past. The device is combined by the following parts: The stepper motor drive, the pistil with the penetration needle, the casing of electronic control unit, the sample table and the cantilever under the table (Fig. 1a). The stepper motor drives the vertically mounted revolving ball spindle (propulsion accuracy > 200 μm). On the spindle, a head is attached with a stamp plate, which can move up and down. In this stamp different needles can be clamped (Fig. 1b). The downward movement forces the needle into the sample, which is located on the sample table. The table is fitted on a cantilever. On the top of the cantilever are electrical conductors through which an electric current flow. Stretching the cantilever also stretches the conductor. As a result, the voltage and thus the resistance increases. Once calibrated, this allows the measurement of the applied force by the analysis of the resistance. Through the progress of hydration, the resistance to penetration of the sample increases. This increasing force is measured as a function of time.

3.1.2 Implementation

For a measurement a mould with a diameter of 9 cm and a height of 3 cm was filled with cement paste directly after mixing. The measurement started 10 min after water addition. The head with the needle automatically goes up and down (speed: 0,7 mm/s). However, the sample has to be moved manually, and the needle must be cleaned after each measurement. The maximum force that can be measured is 100 N.

3.1.3 Error Analysis

When developing a prototype, taking errors into account is essential. A correct interpretation of the results can only be ensured by a comprehensive examination of the errors. A major error during a measurement is the fact that the table, which is fixed on a cantilever, travels under the load. Due to the force exerted by the needle on the mould and thus on the table and the cantilever, the table moves downwards by a certain length. Therefore, the needle does not reach the set depth, but only the depth minus the deformation of the cantilever. Consequently, it is possible that the force at the exact depth would be greater than the force at the indeed depth. To evaluate this error, the deformation of the cantilever is recorded prior to each measurement. A calculation has shown that this leads to an error of 0.5%. The measurements of the cantilever are dependent on the temperature. Since the device is operated in an air-conditioned room this error is negligible. Another error can be caused by the stepper motor drive system. There is a speed range where the motor runs smoothly. If the motor is forced to move in very high or low speeds it is possible that the motor skip steps. Due to test runs with high and low speeds, it is expected that this error is negligibly small in the performed experiments. Since the MILD is a prototype, further errors may occur which have not been considered before. For this reason, a maximum error of 0.5 is increased tenfold, so that an error of 5.0% is assumed.

3.2 Vicat

The method for the determination of the initial and the final setting of a cement paste is a standardized procedure (EN 196-3) [6]. According to this standard, the procedure must be carried out at the w/c-ratio determined by the standard stiffness, defined by the same standard, which was in this case at a w/c-ratio of 0.31. To ensure comparability with the other tests of this work, it has deviated from the standard and the Vicat method was carried out at a w/c-ratio of 0.36. In addition, the sample preparation was carried out as described in Sect. 2.2. Initial and final setting were determined as described in the standard.

3.3 Rheology

The rheological measurements are carried out using a speed controlled rotational rheometer (Viskomat NT, Schleibinger, Germany). During a measurement the cement paste flows around the stationary paddle and generates a torque, which can be measured. The measuring range of the torque is between 0 and 500 Nmm and the range of the speed is between 0.001 rpm and 400 rpm. The used geometry is a fish bone paddle. For the investigation of the early cement hydration longer measurements were performed. For this purpose, a velocity of 0.001 rpm was run every half hour. Since the first formed crystals should not be destroyed, pre-shear was waived. For each measurement a new sample was prepared and stored at 20 °C.

3.4 In-Situ QXRD

In order to examine the phase evolution in the first hours of the cement hydration in-situ XRD measurements were performed (20 °C ± 0.2 °C). The sample was covered by a 7.5 µm thick Kapton® polyimide film to avoid water evaporation and CO2 intake of the paste. The diffraction patterns were recorded every 10 min by a Bruker AXS D8 Advance diffractometer in Bragg-Brentano geometry from 7° to 55° 2Θ and a step width of 0.0236° 2Θ. Three preparations were measured over a time frame of 6 h. The Rietveld analysis was performed using the software TOPAS 5.0 (Bruker AXS). The external standard G-Factor method [7] was used to gain absolute amounts of the crystalline phases present in the paste.

3.5 Heat Flow Calorimetry

A TAM Air calorimeter was used to measure the heat flow evolution of the system at 20 °C ± 0.2 °C. A custom made InMixEr [8] device was used which allows equilibration, injection of water and mixing inside the calorimeter. This experimental setup enables the proper detection of the heat flow directly from the time of mixing on. Cement and water were mixed to a paste at 860 rpm for 1 min. Three measurements were performed.

4 Results and Discussion

4.1 MILD

Two needle sizes were tested, and the results are shown in Fig. 2. The trend line can be determined by using a power-law formula of the type \( f(x) = a*x^{b} \) [9, 10]. It is easy to see that the reproducibility of both needle geometries is very good. As expected, the figure shows that the needle geometry is directly related to the duration of the measurement. The smaller the surface of the needle, the longer a measurement takes. It can be clearly seen that the early period of the measurement can’t be described by an exponential function. Based on the results, one can therefore recognize two different periods. In the first period, the force shows a rather small increase and after a certain time, the force increases significantly faster. The second period can be described by an exponential function. A distinction in these two periods was also done by Mantellato et al. [10]. At this point, it can be stated that needle 1 is advantageous if a longer period is interesting. On the other hand, it is less sensitive during the first hours of cement hydration. In this period needle 1 shows almost a plateau. Needle 2 is advantageous if the early cement hydration is important. In the first period it shows a steady increase. The influence of the surface and the angle of the needle tip must be further investigated.

4.2 Comparison to Vicat

Figure 3 shows the result of a Vicat-test and the fitted curves of the MILD. Based on the Vicat-test the initial setting (IS) and the final setting (FS) can be determined. The IS occurs after about 4.8 h and ends after 6.5 h. Up to a time of about 4.5 h, nothing can be measured with the Vicat method. The surface of the needle is too small and fully penetrates the paste. From the IS the penetration decreases, which ends with the FS.

In comparison one can get more information about the structure formation and the following increase of the strength and viscosity with the results of the MILD. In the test results of the MILD no significant points can be seen at the time of the initial and final setting determined by Vicat. For that reason, one can conclude that the setting according to Vicat is not caused by a signification change of the structure [11].

4.3 Rheological Measurements

The rheological measurements were carried out up to 4 h after water addition and with a speed of 0.001 rpm. Saake et al. found out that at low speeds it is possible to measure the elastically deformation of the first formed hydration products till they reach their elastic limit and the bonds start to break [12]. Such a measured curve can be seen in Fig. 4a. Based on this investigation, we assume that we can use this method to measure the microstructure formation (mainly ettringite). However, the peak as shown in Fig. 4a can’t be seen so clearly in every measurement. For this reason, the mean of the five last values is used for the evaluation. The results of the rheological measurement show an increasing curve with two different periods (Fig. 4b). The first period starts after the water addition and ends after about 2.15 h. This period is characterized by a rather slow increase in torque and thus in viscosity. The second period starts after about 2.15 h. This period shows a large increase in torque over time. It is interesting to see that the rheological measurement shows the same kink at about 2.15 h like the MILD results.

4.4 In-Situ XRD and Calorimetry

Figure 5 shows the phase development measured by in-situ QXRD and the heat flow evolution of the cement paste during the first 6 h of hydration. In the first 2.15 h no significant decrease in the amount of alite can be observed. Afterwards it shows a steadily increasing reaction rate. In the first hours there is no significant precipitation of portlandite. The determined contents are below the detection limit of 0.5 wt%. Over the whole measured time frame no C-S-H-Phase can be detected, even though it can be expected from the dissolution of alite and portlandite precipitation. This is caused by the used phase model published by Bergold et al. [13] for the Rietveld refinement which is just capable for the dimeric or “long-range ordered” C-S-H. The earlier precipitated monomeric or “short-range ordered” C-S-H can’t be detected by this model [14], but occurs simultaneously with alite dissolution and portlandite precipitation [15].

The onset of the acceleration period of the silicate reaction is related to the beginning of the second heat flow event. After a very high initial heat flow and a subsequent period of low heat release the heat flow starts to increase at 2.15 h. The experimental results so far show no evolution in the silicate reaction (dissolution of alite respectively precipitation of CH and C-S-H) in the first 2.15 h. Alite content is constant up to 2.15 h. The only phase which develops considerably during this period is the hydration product of the aluminate reaction, ettringite. The precipitation of ettringite starts directly after the addition of water. After around 2.15 h the second period starts. Ettringite content is still increasing during that period. Now alite is dissolving after about 2.15 h and the formation of portlandite can be detected after 3.5 h indicating the start of the formation of C-S-H.

5 Conclusion

5.1 Advantages of the New Penetration Test Device

In this study a new penetration test device was investigated. Based on the results, the development of early cement hydration can be better investigated than with the standardized Vicat test. It is possible to measure the early and sensitive phase formation with a penetration test device and to determine the beginning of the acceleration period. By being able to use different needle geometries very sensitive changes in cement hydration can be measured. The results correlate perfectly with those of other measurement methods such as rheometry, QXRD and calorimetry (Fig. 6). Consequently, this device can lead to a better understanding of early cement hydration.

5.2 Comparison with the Formation of Hydration Products

According to the present data two periods of different rheological regimes can be observed by either MILD or rheometer as shown in Fig. 6. Period 1 (0–2.15 h) with low slope for MILD and rheometer measurements is due to formation of ettringite. Period 2 (2.15 h–6 h) with high slope for MILD and rheometer measurements is correlated with ongoing formation of ettringite and additionally related to the C-S-H formation (indicated by dissolution of alite).

References

Wangler T, Lloret E, Reiter L, Hack N, Gramazio F, Kohler M, Bernhard M, Dillenburger B, Buchli J, Roussel N, Flatt RJ (2016) Digital concrete: opportunities and challenges. RILEM Tech Lett 1:67–75

Roussel N (2018) Rheological requirements for printable concretes. Cem Concr Res 112:76–85

Lootens D, Jousset P, Martinie L, Roussel N, Flatt RJ (2009) Yield stress during setting of cement pastes from penetration tests. Cem Concr Res 39:401–408

Boujlel J, Coussot P (2012) Measuring yield stress: a new, practical, and precise technique derived from detailed penetrometry analysis. Rheol Acta 51:867–882

Jansen D, Naber C, Ectors D, Lu Z, Kong X-M, Goetz-Neunhoeffer F, Neubauer J (2018) The early hydration of OPC investigated by in-situ XRD, heat flow calorimetry, pore water analysis and 1H NMR: learning about adsorbed ions from a complete mass balance approach. Cem Concr Res 109:230–242

Deutsches Institut für Normung (2017) Prüfverfahren für Zement: Teil 3: Bestimmung der Erstarrungszeiten und der Raumbeständigkeit; Deutsche Fassung EN 196-3:2016

Jansen D, Goetz-Neunhoeffer F, Stabler C, Neubauer J (2011) A remastered external standard method applied to the quantification of early OPC hydration. Cem Concr Res 41:602–608

Hertel T, Neubauer J, Goetz-Neunhoeffer F (2016) Study of hydration potential and kinetics of the ferrite phase in iron-rich CAC. Cem Concr Res 83:79–85

Flatt RJ, Larosa D, Roussel N (2006) Linking yield stress measurements: spread test versus Viskomat. Cem Concr Res 36:99–109

Mantellato S, Palacios M, Flatt RJ (2019) Relating early hydration, specific surface and flow loss of cement pastes. Mater Struct 52:5

de Oliveira Romano RC, Hark Maciel M, Pileggi RG, Alba Cincotto M (2017) Monitoring of hardening of Portland cement suspensions by Vicat test, oscillatory rheometry and isothermal calorimetry. Appl Rheol 27:28–37

Saak AW, Jennings HM, Shah SP (2001) The influence of wall slip on yield stress and viscoelastic measurements of cement paste. Cem Concr Res 31:205–212

Bergold ST, Goetz-Neunhoeffer F, Neubauer J (2013) Quantitative analysis of C-S–H in hydrating alite pastes by in-situ XRD. Cem Concr Res 53:119–126

Bergold ST, Goetz-Neunhoeffer F, Neubauer J (2015) Mechanically activated alite: new insights into alite hydration. Cem Concr Res 76:202–211

Jansen D, Goetz-Neunhoeffer F, Lothenbach B, Neubauer J (2012) The early hydration of Ordinary Portland Cement (OPC): an approach comparing measured heat flow with calculated heat flow from QXRD. Cem Concr Res 42:134–138

Acknowledgement

The author would like to thank the German Research Foundation (DFG) for funding the priority program Opus Fluidum Futurum – Rheology of reactive, multiscale, multiphase construction materials (SPP 2005) (STE 1086/181; NE 813/7-1) and HeidelbergCement for providing the materials.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 RILEM

About this paper

Cite this paper

Pott, U., Ehm, C., Jakob, C., Stephan, D. (2020). Investigation of the Early Cement Hydration with a New Penetration Test, Rheometry and In-Situ XRD. In: Mechtcherine, V., Khayat, K., Secrieru, E. (eds) Rheology and Processing of Construction Materials. RheoCon SCC 2019 2019. RILEM Bookseries, vol 23. Springer, Cham. https://doi.org/10.1007/978-3-030-22566-7_29

Download citation

DOI: https://doi.org/10.1007/978-3-030-22566-7_29

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-22565-0

Online ISBN: 978-3-030-22566-7

eBook Packages: EngineeringEngineering (R0)