Abstract

Special applications like pumping, spraying or printing of concrete require the precise adjustment of very specific rheological properties at different time steps during the casting process. Superplasticizers such as polycarboxylate ethers (PCE) can be used to obtain the required flowability, which, possibly in combination with additional rheology modifying admixtures, generate the required specified consistency. However, after the application, the concrete should change the rheological properties immediately in order to avoid deformations at rest. Therefore, the use of accelerators can be effective. Accelerators influence the hydration of cementitious materials, and thus the rheological properties over the course of time and the setting.

In this paper, the influence of different accelerators on the rheology and early hydration of cement paste as well as the interaction of accelerator and PCE are presented. Methods like rheometry, needle penetration tests and practical tests like spread flow were applied. The used accelerators showed accelerating behavior on the cement pastes without and in the presence of PCE. At the same time an influence on the rheology could be observed. This effect was less in the mixes with PCE, especially at the highest water/cement ratio (w/c).

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The rheological properties of cementitious materials change very fast in the first minutes after water addition and they are important for special applications like spraying, pumping or printing of concrete [1]. Especially accelerators (ACCs) can cause rapid changes of the early properties. Therefore, it is necessary to understand the early hydration of those systems and the respective rheological behavior.

Accelerators affect the hydration rate and can shorten the setting time and/or increase early strength development [2]. However, in this study only setting accelerators were investigated. Typical accelerators are based on calcium chloride and thiocyanate [3]. For applications, which are sensitive to chlorides, accelerators like calcium nitrate can be employed [4]. Calcium nitrate can be also used as a multifunctional concrete admixture with corrosion inhibiting and rheology modifying properties depending on the dosage [4]. Bost et al. [5] investigated different accelerators and found out that stabilized C-S-H seeds show acceleration of Portland cement hydration. Also, pure synthesized C-S-H seeds can accelerate cementitious materials, like Land and Stephan [6] presented. In the future, the combination of accelerators and superplasticizers plays an important role, due to the need of specific rheological properties at different time steps. While for example for printing and spraying often the concrete needs an initially flowable consistency but already a few minutes later a certain stability is required. In order to tailor the rheological properties for special applications, a lot of different superplasticizers as well as accelerators are available on the market. Since, fresh concrete properties become more and more important for future technologies, it is imperative to better understand the systematic behavior between superplasticizers and accelerators.

2 Experiments

Cement pastes with various water/cement ratios were used for the different investigations of early performance properties. The effect of accelerators was studied without and in the presence of superplasticizers.

2.1 Materials

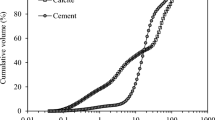

Cement paste was made with Portland cement CEM I 42,5 R from HeidelbergCement, Germany and deionized water at 20 °C. Two different commercial accelerators, MasterSet AC 555 and X-Seed 100 by BASF were used to influence the setting of the paste. AC 555 is based on calcium nitrate and will be abbreviated with CN.

X-Seed (XS) contains C-S-H-seeds for the hydration acceleration. It additionally contains PCE to stabilize the solution. The superplasticizer that was used is a polycarboxylate ether provided by BASF. The physical properties of the materials are shown in Table 1.

2.2 Methods

2.2.1 Sample Preparation

The pastes were mixed in a mixer according to DIN EN 197-1. The mixing procedure is shown in Table 2. If contained in the mixture, PCE was always added before the accelerator. Certainly, the order of admixture addition can have a strong effect on the efficiency of each admixture. Here, it was important to understand the effect of the accelerators in robust reference systems. Thus, if contained, first the PCE was dosed and the accelerator was added with a considerable delay to ensure that the PCE was well dispersed in the paste.

2.2.2 Spread Flow

Spread flow was performed using a Haegermann cone on a spread flow table. The used cone has a lower diameter of 100 mm and an upper diameter of 70 mm with a total height of 60 mm. The procedure for obtaining the spread flow was done according to DIN EN 1015-3:2007 [7].

The determined value is the average of the perpendicular diameters measured from the spread of the paste. The spread flow was measured for every mixture 15 min after addition of water, in order to avoid effects of the rapidly changing cement chemistry over the first minutes after contact of cement and water.

2.2.3 Rheometric Measurement

The rheometric investigations were conducted with a Couette type rheometer (Schleibinger, Viskomat NT) with a basket cell [8]. The chosen profile for the measurement is only 4.25 min to avoid long shearing and is shown in Fig. 1.

2.2.4 Setting Time

The setting time was determined with an automatic Vicat device with 11 slots. The material was filled in molds according to DIN EN 196-3. The needle penetration was recorded over the course of time and the initial setting time was defined as the time when a penetration depth of 6 mm was reached.

3 Results and Discussion

3.1 Spread Flow

The results of the spread flow are presented in Fig. 2 and Fig. 3 without and in the presence of PCE, respectively. The figures show pastes with three different w/c ratios, without and in the presence of PCE, CN and XS.

The reference mixes with w/c ratio = 0.40, 0.42, 0.44 have spread flows of 136 mm, 155 mm and 175 mm, respectively. It seems, that the difference between w/c ratio 0.40 and 0.42 is smaller than between 0.42 and 0.44. The accelerator XS increases the spread flow of the pastes. An additional increase of the dosage of XS leads to higher spread flow, which is caused by the contained PCE in the XS. This effect is even stronger with higher w/c ratios. In contrast, the addition of CN decreases these values.

By adding PCE to the reference systems, the diameters increase to 265 mm, 287 mm and 320 mm, respectively. With a combination of XS and 0.1% PCE the spread flow decreases with a low dosage of XS, but then increase again with 0.5% of XS and leads to the highest spread flow of 327 mm for w/c ratio 0.44. Due to the seeding effect of XS, the building of C-S-H is more prominent at low dosages and the reduction of the spread flow can be explained. However, high dosages of XS cause a higher total amount of ions in the system, which can be seen by higher flow values. The paste with CN in the presence of PCE show lower flowability. With increasing concentration of ACC to 0.5%, the spread flow also increases. However, the value for the reference mix with PCE cannot be reached again. A hypothesis for this observation can be, that the calcium nitrate brings more calcium ion in the system, which may slightly reduce the charges of the PCE and thus reduce their capacity to adsorb on surfaces, which eventually causes the reduced flowability. With higher amounts of CN, the nitrate content also increases prominently, and the nitrate can work like a sacrificial ion, which causes that more PCE could be adsorbed at outer surfaces, so that the polymers’ efficiency can be increased.

3.2 Rheometric Results

From the measured rheometer data, a mean value of the last 10 measuring points of each plateau was calculated. The results of the rheometric measurements are given in the Figs. 4 and 5. Figure 4 provides information about the flow curve of the paste for the reference, mixes with CN and XS for three w/c ratios and three different dosages (0.1%, 0.5%, 1.0%) of accelerator. For Fig. 4(a) it can be seen, that the addition of CN causes only a minimal change in the yield stress. There is no systematic change in the viscosity at shear rate range from 12 to 50 s−1 for the different dosages of CN depending on the w/c ratio. However, the range of the viscosities within one group of mixes with the same w/c ratio does not vary strongly. The highest viscosity is achieved for w/c ratio = 0.40 and the medium dosage (0.5%) of CN. The effect of the different w/c ratios is significantly stronger than the influence of the dosages of CN. This observation corresponds to the results of the spread flow presented in the Figs. 2 and 3.

The flow curves in Fig. 4(b) show that XS has a higher influence on the rheology than CN. With an increasing dosage of XS, the apparent viscosity decreases compared to the reference mix without any accelerator. The dosages of XS can have effects that are in the order of magnitude of changes in the water content. The yield stress is generally lower with XS than for the mixes with CN. This is most likely caused by the PCE that is used to stabilize the particles.

Figure 5(a) displays the flow curves for the pastes in the presence of 0.1% PCE for CN and Fig. 5(b) for XS, respectively. Since in the presence of PCE for some mixes the additional PCE content from the XS caused severe segregation, here, only the results of a maximum dosage of 0.5% are presented. The highest yield stress and viscosity for the mixes with ACC + PCE was reached for the mix with w/c ratio 0.40 and 0.1% CN and 0.1% PCE. The mix with w/c ratio 0.44 and 0.1% PCE leads to the lowest values. The higher the w/c ratio, the more overlapping can be observed for the flow curves for CN in the presence of 0.1% PCE. The flow curves in Fig. 5(b) show, that the viscosity decreases with increasing dosages of XS at w/c ratio 0.40. With higher water cement ratios, a similar behavior as CN can be observed. There is no big difference in the flow curves in Fig. 5 at the highest water amount. This is in line with former research, where it was shown that admixture interactions with PCE occur more pronounced at higher particle solid volume fractions [9]. This means, that the w/c ratio affects influence of the ACCs on the rheology in the presence of PCEs. This effect is relatively small for CN but prominent for the XS accelerator.

The fact that PCE is added to the systems, changes the rheological properties the most. However, there is a minor influence on rheology with calcium nitrate in comparison to XS, which could be explained already before. At the same time, it seems that the PCE from the XS may compete with the other PCE, which is responsible for the increase at low XS dosage and the decrease of the apparent viscosity at the higher dosage.

Figure 6 provides initial setting times of pastes with different w/c ratios (0.40, 0.42, 0.44), without and in the presence of PCE, CN and XS. The different w/c ratios influence the initial set. The higher the water amount, the higher the initial set. The set retardation effect of PCE on the systems without ACC is approximately 4 h regardless of the w/c.

It can be observed that the use of accelerators causes faster initial setting for both ACCs. Increasing dosages of CN cause a set acceleration that is slightly stronger in the presence of PCE, for example at a dosage of 0.5% the initial set takes place approximately 1 h earlier, while in the presence of PCE the same dosage causes an approximately 2 h earlier setting. This effect can be caused by the supplementary adsorption surfaces available from the accelerator for PCE to be adsorbed, so that once the rapid C-S-H hydration sets in lower amounts of PCE interfere with the hydration. A similar effect was shown before for PCE in the presence of stabilizing agents that interfere with the cement hydration process [10, 11].

The accelerating effect with XS is stronger without and with PCE. For example, without PCE the dosage of 0.5% XS causes a set acceleration of approximately 3 h. In the presence of PCE the same dosage of XS causes an acceleration of 4.5 h. The latter acceleration is significantly stronger than in the system without PCE. Without PCE the retarding effect of the PCE incorporated only from the XS may overlap with the accelerating effect of the C-S-H seeds. In the presence of PCE the supplementary PCE from XS is negligible compared to the initial PCE dosage, thus, the effects of the additional polymers do not become effective, while the accelerating effect of C-S-H seeds remain unaffected. Hence without the overlapping retarding effect of the PCE from the XS, the effect of the C-S-H seeds on the set acceleration is more pronounced than without PCE.

4 Conclusions

The present study shows the accelerating effect of CN and XS. At the same dosage, XS causes a higher acceleration, but leads to stronger influence on the rheology of the pastes at very early age, which is induced by the contained PCE.

Without PCE increased dosages of CN showed influence on the apparent viscosity but yield stress was not significantly affected, which is confirmed by the spread flow results. However, for the comparable systems with XS, both apparent viscosity and spread flow were affected, which is caused by the incorporated PCE from the accelerator.

In the presence of PCE the effect of the accelerator on the rheology was strongly depending on the w/c. The higher the w/c the lower the accelerators’ effect.

The systems without PCE have earlier setting times, but the relative set acceleration of both ACCs is stronger in the presence of PCE. XS has a stronger accelerating effect than CN, but without PCE its effect is overlapped by the retarding effect of the PCE molecules contained in the admixture as stabilizing agent.

Future experiments should also include the influence of the addition time of the different admixtures on rheology and setting. A better understanding of the effect of calcium nitrate can be obtained by zeta potential measurements. In addition, the use of pure C-S-H seeds without PCE as stabilizers is scheduled.

Furthermore, the influence of various temperatures and lower w/c ratios have to be considered, as well as the supplementary effects of coarser particles like sand and aggregates.

References

Roussel N (2012) Understanding the rheology of concrete. Woodhead Publishing, Sawston

Myrdal R (2007) Accelerating admixtures for concrete

Justnes H, Nygaard EC (1995) Technical calcium nitrate as set accelerator for cement at low temperatures. Cem Concr Res 25:1766–1774

Justnes H (2010) Calcium nitrate as a multifunctional concrete admixture. https://de.scribd.com/document/311682442/Calcium-Nitrate-as-a-Multifunctional-Concrete-Admixture

Bost P, Regnier M, Horgnies M (2016) Comparison of the accelerating effect of various additions on the early hydration of Portland cement. Constr Build Mater 113:290–296

Land G, Stephan D (2015) Controlling cement hydration with nanoparticles. Cement Concr Compos 57:64–67

DIN (2007) Methods of test for mortar for masonry - Part 3: determination of consistence of fresh mortar (by flow table). In: EN 1015-3, ed. European committee for standardization, Brussels

Vogel R (2008) A measuring cell for special mortars. Concr Plant + Precast Technol 1:124–126

Schmidt W, Brouwers HJH, Kühne H-C, Meng B (2014) Influences of superplasticizer modification and mixture composition on the performance of self-compacting concrete at varied ambient temperatures. Cement Concr Compos 49:111–126

Schmidt W, Brouwers HJH, Kühne H-C, Meng B (2017) Interactions of polysaccharide stabilising agents with early cement hydration without and in the presence of superplasticizers. Constr Build Mater 139:584–593

Stroh J, Schlegel MC, Schmidt W, Thi YN, Meng B, Emmerling F (2016) Time-resolved in situ investigation of Portland cement hydration influenced by chemical admixtures. Constr Build Mater 106:18–26

Acknowledgement

The author would like to thank the funding from German Research Association (DFG) for the project program Opus Fluidum Futurum – Rheology of reactive, multiscale, multiphase construction materials (SPP 2005) (Project number 387092747) and the supply of cement and superplasticizer from HeidelbergCement and BASF, respectively.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 RILEM

About this paper

Cite this paper

Leinitz, S., Lu, Z., Becker, S., Stephan, D., von Klitzing, R., Schmidt, W. (2020). Influence of Different Accelerators on the Rheology and Early Hydration of Cement Paste. In: Mechtcherine, V., Khayat, K., Secrieru, E. (eds) Rheology and Processing of Construction Materials. RheoCon SCC 2019 2019. RILEM Bookseries, vol 23. Springer, Cham. https://doi.org/10.1007/978-3-030-22566-7_13

Download citation

DOI: https://doi.org/10.1007/978-3-030-22566-7_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-22565-0

Online ISBN: 978-3-030-22566-7

eBook Packages: EngineeringEngineering (R0)