Abstract

This study was conducted to investigate the effect of using a mix of Lactobacillus (L.) plantarum, L. casei and Saccharomyces cerevisiae as silage inoculate to meadow grass on silage fermentation characteristics, silage quality and aerobic stability. A sample of Meadow grass (MG) was collected directly from the forage harvester during a first cut harvest. The fresh, chopped MG sample was divided into 2 equal portions and either treated with the test additive (EM) or received an equal volume of water (control). The dosage of EM Silage was based on 80 ml per ton product. Samples were analysed statistically as randomise complete (1 × 2) design using an ANOVA procedure of Genstat 15. Ensiled sample was found to have lower dry matter (DM), crude protein (CP), water soluble carbohydrate (WSC) and yeasts count, and higher mould count compared fresh samples. Additionally, treating MG with EM increased concentration of total volatile fatty acids (tVFA), acetic and propionic acids and total alcohol by approximately (25, 27, 47, 300% respectively) and reduced lactic acid by approximately 13% compared to control samples. Aerobic stability results showed that control MG treatment reached a temperature 3 °C above ambient in ~6.8 days whereas the EM treated MG took approximately 14 days get to the same temperature after exposing to air. Therefore, using this mix of inoculate would enhance silage quality and protect silage from aerobic deterioration.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Silage defined as a highly fermented water-soluble carbohydrate in the forage to lactic and butyric acid resulting reduction of pH and used for animal feeding when fresh forage is scarce [1]. In Europe, silage industry increased by approx. 160 million ton per year of forage dray matter since the mid of the last century [1]. Nowadays, silage may represent more than 80% of winter forages in ruminant diets in the UK [2]. The ensiling process could be divided into three different steps: initial aerobic step, fermentation step and second aerobic step [3]. Silage fermentation was undertaken by different species of microflora associated silage herbage and was largely left to chance to represent an uncontrolled process [4]. However, using different silage additives and/or physical approaches (wilting) plus clamp management would enhance fermentation process resulting an improvement in silage quality [1]. This aim could be achieved by using silage additive especially silage inoculate [5]. Silage inoculants have been developed for their ability to promote a beneficial fermentation that maximizes the nutritive value of the silage for ruminant animals [1]. Since the beginning of the last century, silage inoculations have been successfully used in France and other European countries [6]. Supplemented inoculated bacteria to forage at ensiling would cause a rapid reduction of the silage pH and prevent the growth of undesirable microorganisms such as clostridia [7]. In addition, supplemented inoculated bacteria at ensiling would reduce DM losses during the fermentation period [7]. Hence, the used of inoculated bacteria as a silage additive has been widely increased [6].

Lactic acid bacteria (LAB) are the common commercial silage additives used globally [8]. Lactic acid bacteria such as Lactobacillus (L.) buchneri, L. plantarum and L. casei were developed as silage inoculant to enhance silage fermentation increasing acetic acid concentration and improve the aerobic stability of the silage [9]. Merry and Davies [1] outlined that LAB could be divided into two groups: homo-fermentative and hetro-fermentative LAB. Homo-fermentative LAB contained one or more strains species: L. plantarum, L. lactis, Pediococcus spp. and Enterococcus spp. The main final product of these species is lactic acid. Hetro-fermentative LAB such as L. buchneri, which produce lactic acid, acetic acid, ethanol and carbon dioxide as a final product [10]. Homo-fermentative LAB caused a rapid decrease in silage herbage pH and reduced losses of DM to a minimum level (2–3%) [11]. Moreover, these strains of LAB are the traditional inoculant bacteria used in the market [12]. In addtion, the fast decrease in pH prevents the growth of many undesirable microorganisms inside the silo such as clostridia, which are responsible for producing butyric acid. Mixing different strain of silage inoculate may act synergistically with each other and improved silage quality and aerobic deterioration [13]. Yeasts such as Saccharomyces spp. are used in food science to improve fermentation such as yoghurt making [9]. Several studies [9, 11, 12] showed that using Saccharomyces spp. might improve feed conversion ratio, reduce ruminal acidosis, and mitigating methane emissions. A lack of studies for using yeasts especially Saccharomyces spp. mixed with LAB as silage inoculate for enhancing silage quality either ensiling or after air exposure. Therefore, the objective of this study was to investigate the effect of using a mix of L. plantarum, L. casei and Saccharomyces cerevisiae as silage inoculate to meadow grass on silage fermentation characteristics, silage quality and aerobic stability.

2 Materials and Methods

A sample of meadow grass (MG) was collected directly from the forage harvester during a first cut harvest on 1st May 2017. The fresh, chopped MG sample was divided into 2 equal portions and either treated with the test additive (EM treated; batch No. 1509010001) or received an equal volume of water. The dosage of EM silage was based on 80 ml per ton product. Product microbial composition was Lactobacillus casie 137 × 108 bacteria/ml, Lactobacillus plantarum 865 × 104 bacteria/ml and Saccharomyces cerevisiae 26 × 105 bacteria/ml. The inoculate treatment was prepared by dissolving 2 g of a mix of freeze-dried inoculated bacteria and 30 g of table sugar (as media) in 1000 ml deionised water and incubate for 16 h at 30 °C. Mini silos were created in six replications for each of the two experimental treatments. During the filling of the mini-silos, subsamples (fresh material) were collected for each min-silo. Fresh material subsamples were vacuum packed and stored at −20 °C for proximate analysis. Each experimental silo was lined with a plastic bag and filled with approximately 1.5 kg from either treated or control MG and consolidated well. The neck of the plastic bag liner was then sealed using silage tape and approximately 0.5 kg of sand was placed on the top of each mini-silo. The weight of each mini-silos before and immediately after filling with MG and sealing were recorded. Following a 100-day ensiling period the mini silos were weighed (in order to calculate DM loss), opened and silage samples were taken. Ensiled samples were vacuum packed and stored at −20 °C for proximate analysis and fermentation characteristics.

All frozen ensiled samples for both treatments were defrosted at 4 °C for 16 h and analysed for proximate analysis and fermentation characteristics. The ammonia nitrogen (NH3-N) concentration was measured according to MAFF [13] using a Buchi AutoKjeldahl Unit K-370 (buchi labortechnik AG CH-9.0, Flawil, Switzerland), and pH determined by the method of MAFF [13] using a pH meter (Jenway, Stone, Staffordshire) with calibration using pH 4 and pH 7 buffers. Water-soluble carbohydrate (WSC) concentration was determined by spectrophotometrically (at wavelength 620 nm) as the blue-green complex which is formed when carbohydrate is heated with Anthrone in sulphuric acid using MAFF [13]. Defrosted samples of both fresh and ensilage forage from each mini-silo were oven dried at 105 °C overnight according to method number 935.29 [14]. Dried samples were milled through a 1 mm screen and used to determine ash by using 1 g of dried sample in a muffle furnace at 550 °C for 5 h and crude protein (CP) using a C/N analyser [type FP-528, LECO Instruments, St. Joseph, MI, USA] operating the Dumas method number 990.03 [14]. Samples of fresh and ensiled grass were vacuum packed and sent to an approved laboratory [Sciantec, UK or Northern Hygiene, UK for Lactic Acid Bacteria counts] to analysis manually for mould, yeast and lactobacilli counting according to method published by Borreani and Tabacoo [15]. Silage samples were analyzed additionally for silage characteristics including lactic acids (using HPLC machine according to method published by Canale et al. [16]) total and individual volatile fatty acid (VFA) (using gas chromatography machine according to method published by Cruwys et al. [17]) and total and individual alcohol concentration (using HPLC according to method published by Borreani and Tabacoo [15]) at the same laboratory.

Aerobic stability of the ensiled material was determined by temperature difference to ambient. Approximately 500 g of ensiled MG samples from each of 12 experimental mini-silos were placed individually in insulated boxes open to the atmosphere at 18–20 °C for 20 days. One themochron iButtons [iButton THERMO-S-KIT Thermochron Starter Kit] was stuck in each box and another one in the silos storage room to record temperature every 10 min. The temperature of ambient and each box were observed continuously during the aerobic stability period (20 days).

All obtained data were analysed statistically using an ANOVA procedure of Genstat (GenStat version 15, VSN International Ltd., UK). Proximate analysis of silage samples was analysed using randomise complete (1 × 2) design.

3 Results and Discussion

3.1 Chemical Analysis

The chemical analysis results of both fresh and ensiled forage are shown in Table 1. Target DM for the crop was achieved with a mean DM for the fresh material of 370.8 g/kg. The enisled material was found to have a lower DM value (341.6 g/kg) compared to fresh forage (370.8 g/kg) which probably due to evaporative and volatile losses during the ensiling phase. The silages were kept in a plastic bag inside mini-silos, and the integrity of the bags would inhibit effluent escape. Mayne and Gordon [18] suggested that DM losses could occur in three ways: effluent escape, surface waste and invisible losses. The invisible losses could include fermentation characteristic and plant respiration during the fermentation period especially the initial fermentation phase [18]. Therefore, the DM losses in the present study could be due to an invisible loss according to Mayne and Gordon [18]. In addition, silage DM losses could be affected by the activity of some microorganisms in the silage clamp such as Enterobacteria [5]. A similar result was found by Wambacq et al. [19] who reported that ensiled mix of alfalfa and ryegrass had a lower DM compared to fresh forage. They went to show that the losses of DM bases could be due to the effect of microbial activity inside silage silos during the fermentation period. Similarly, Taha [5] also found that ensiled bean, pea and grass reduced DM compared to fresh forages by approximately 18, 20 and 14% for bean, pea and grass respectively. However, in the current study treated MG forage with test additive EM had no effect on DM of ensiled forage compared to untreated silage samples. Reich and Kung [20] highlighted that one of the disadvantages of using LAB, as a silage additive would be their effect on increasing silage DM losses at fermentation process.

Forage CP was found to be low, but this can only be attributed to the nature of the material harvested compared to other finding. Ensiling the MG significantly reduced the CP content of the ensiled material by ~5.7%, which is within normal levels of expectation.

Crude protein hydrolyses may occurs inside silage clamp during fermentation period which might be due to either the activity of proteolysis plant enzymes and/or plant endogenous micro-organisms, resulting a reduction in CP and increase in NH3-N concentration of produced silage [1, 6]. Water-soluble carbohydrate values were found to be significantly lower in the ensiled material but treating the fresh, MG with EM Additive had no effect on the use of WSC as a substrate for microbial activity during the ensiling process. Wilkinson and Davies [6] reported that during the fermentation process at ensiling most of forage WSC convert to fermentation acids mainly lactic and butyric acids. This could be the reason for reducing the WSC concentration at ensiling samples from 72.9 g/kg DM inside fresh samples to 12.1 g/kg DM inside ensiled samples of our study. Using the mix of two strains of LAB and S. cerevisiae had no effect on all studied proximate analysis in the present study (Table 2). Same results were found by several researchers [9, 21,22,23]. While other studies found that LAB reduced (P < 0.05) WSC concentration, which could be that most of WSC were fermented to acids compared to untreated forage silages [24, 25].

3.2 Fermentation Characteristics

Meadow grass samples were found to ensiled well as indicated by a low mean pH of ~4.14 and NH3-N ~1.2 g/kg TN concentration, which refer to a good ensiled technique. However, using EM treatment as a silage additive had no effect on the final silage pH. Using different LAB strains and S. cerevisiae as silage inoculate showed a trend (P = 0.09) to reduce silage pH with no (P > 0.05) effect on NH3-N. Shah et al. [23] found that using inoculate (LAB) as silage additives significantly reduced silage pH, acetic acid and butyric acid while silage inoculate had no effect on DM content of produced silage. Amanullah et al. [9] reported that using homo-fermentative LAB rapidly dropped silage pH and reduced the concentration of NH3-N. Duniere et al. [8] noticed the highest concentration of lactic acid and lowest pH when they used LAB as inoculated bacteria after 7, 14, 28 and 56 days of ensiling whole crop corn silage.

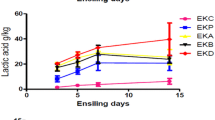

Treating the fresh, chopped MG sample with EM additive resulted in a reduction (~13%) of lactic acid in the final silage. The results obtained from this research showed that using EM did not show any negative effect on fermentation products or nutrient content of produced silage. A similar result was observed by Duniere et al. [8] when they used three different strains of Saccharomyces as silage inoculate to treat corn silage after 90 of the ensiling periods. Pedroso et al. [26] reported that Saccharomyces spp. can convert WSC into CO2 and ethanol under anaerobic condition. These products are undesirable product inside silage and could be toxic to ruminant animals. This could be the reason of increasing the level of ethanol when grass treated with a mix of yeast and inoculation bacteria in the current study (Table 2). In contrast to our results, Duniere et al. [8] noted that the level of ethanol did not increase by using a mix of Saccharomyces spp. The concentration of acetic acid, propionic acid, ethanol and total and individual alcohols were found to be increased by silage inoculate that used on our study (Table 2). The formation of acetic acid and 1,2-propanediol from lactic acid might be due to the activity of L. buchneri and would lead to increase the formation of CO2 and this would lead to extra DM losses [10]. Thus, the DM losses in the current study would be due to hetro-fermentative that appear as a result of the activity of L. buchneri. Shah et al. [23] and Zhang et al. [25] also observed that using inoculated bacteria enhanced ethanol concentration in produced silage either after 30 or after 100 days.

Mould and yeast counts were found to be affected by the ensiling process, ensiled MG had higher mould and lower yeast counts compared to fresh forages. However, the use of the EM additive had no effect on the mean of mould or yeast (Table 1). Lactobacilli numbers were found to be significantly lower (~48.9%) in the MG sample treated with the EM additive. Yeasts and mould contamination either for fresh or ensiled forage were generally in low level (>3.2 log10 CFU/g) when compared to yeasts and mould contaminations with other studies [10, 19, 27]. The effect of fermentation process on yeast counting could be due to the reduction of silage pH which has an inhibitory effect on yeast counting, hence decrease their number in ensiled MG. Driehuis et al. [27] showed that the presence of L. buchneri inside silage silo can convert part of fermented lactic acid to acetic acid and 1,2-propanediol which has an inhibitory effect on yeasts and mould during primary fermentation under anaerobic conditions. Conversely adding the EM treatment to the fresh MG sample resulted in an elevated total volatile fatty acid concentration by ~34%. Elevated tVFA related to a ~38% increase in acetic acid and ~89% increase in propionic acid as shown in Table 2. No other VFA were affected by the EM treatment and the relative proportion of the individual VFA. The total alcohol concentration of the ensiled material was found to increase (~228%) as a result of EM treatment. Elevated alcohol concentration related to increases in ethanol (~143%), propane-1-ol (~294%) and propane-1,2-diol (~389%). The relative proportions of the different alcohols were also found to be affected by EM treatment. The addition of EM additive significantly reduced the relative proportion of ethanol whilst increased the relative proportion of propane-1,2,-diol as shown in Table 2.

4 Aerobic Stability

The addition of EM treatment at ensiling resulted in a more aerobically stable silage. Aerobic stability result from the current study showed that untreated silage samples needed (6.83 days) to increase the silage temperature 3 °C above ambient (Table 2 and Fig. 1), while treating grass silage with EM was increased the time required approximately 100% to reach the same temperature above ambient, which give an indication the EM had enhanced aerobic stability of produced silage. Li et al. [28] reported that aerobic spoilage occurred within 7 days after air exposure. Silage spoilage occurs when the silage exposed to oxygen and the activity of undesirable aerobic microorganisms is started, hence the pH and the silage temperature will increase [1]. Spoiled silage is undesirable for feeding animals, and this could be attributed to that, spoiled silage has poorer quality, lower digestibility and high risk of diseases and hence has a negative effect on animal performance. Several studied [20, 23, 29, 30] reported that silage aerobic stability was enhanced when the different stain of LAB alone or mixed were used as silage additive. Opening the silage silo and exposure to air can enhanced yeast growth, reduce the level of lactic acid and increasing silage pH, and tolerate aerobic microbes to grow such as mould causing silage deterioration [8]. A similar result was noticed by Duniere et al. [8] who reported that using a mix of different LAB species or homofermentative LAB were reduced the susceptibility of grass silage to aerobic deterioration.

5 Conclusion

Meadow grass samples ensiled well in the mini-silos resulting in a final pH of ~4.1 with very low NH3-N%TN values. Using a mix of S. cerevisiae, L. plantarum and L. casei treatment elevated LAB populations [log10 CFU/g] but resulted in a reduction lactic acid concentration. Elevated VFA and alcohol concentrations were observed as a result of EM treatment. EM treatment resulted in a more aerobically stable PRG silage possibly as a result of the elevated VFA and alcohol concentrations [ethanol & propane-1,2-diol].

References

Merry, R.J., Davies, D.R.: Propionibacteria and their role in the biological control of aerobic spoilage in silage. Le Lait 79(1), 149–164 (1999)

Jones, R.: Understanding the Processes of Protein Degradation in Forage Crops Provides Opportunities for Improved Silage Quality and Enhanced Animal Production. Institute of Grassland and Environmental Research, UK (Courtesy of Alltech Inc.) (2007)

Pitt, E.R. and Shaver, R.D.: Proceedings of Dairy Feeding Systems Symposium, Harrisburg, USA (1990)

Hart, K.J.: Evaluation of Ensiled Whole-Crop Legumes for Ruminants. Open University (2005)

Taha, V.: Effect of Supplemental Tannin on Silage Quality and Animal Performance. Harper Adams University (2015)

Wilkinson, J., Davies, D.: The aerobic stability of silage: key findings and recent developments. Grass Forage Sci. 68(1), 1–19 (2013)

Salawu, M.B., Warren, E.H., Adesogan, A.T.: Fermentation characteristics, aerobic stability and ruminal degradation of ensiled pea/wheat bi-crop forages treated with two microbial inoculants, formic acid or quebracho tannins. J. Sci. Food Agric. 81(13), 1263–1268 (2001)

Duniere, L., Jin, L., Smiley, B., Qi, M., Rutherford, W., Wang, Y., McAllister, T.: Impact of adding Saccharomyces strains on fermentation, aerobic stability, nutritive value, and select lactobacilli populations in corn silage. J. Anim. Sci. 93(5), 2322–2335 (2015)

Amanullah, S., Kim, D., Lee, H., Joo, Y., Kim, S., Kim, S.: Effects of microbial additives on chemical composition and fermentation characteristics of barley silage. Asian-Australas. J. Anim. Sci. 27(4), 511 (2014)

Kim, D.H., Amanullah, S.M., Lee, H.J., Joo, Y.H., Han, O.K., Adesogan, A.T., Kim, S.C.: Effects of hybrid and bacterial inoculation on fermentation quality and fatty acid profile of barley silage. Anim. Sci. J. 89(1), 140–148 (2018)

Davies, D., Merry, R., Williams, A., Bakewell, E.L., Leemans, D., Tweed, J.: Proteolysis during ensilage of forages varying in soluble sugar content. J. Dairy Sci. 81(2), 444–453 (1998)

Lettat, A., Nozière, P., Silberberg, M., Morgavi, D.P., Berger, C., Martin, C.: Rumen microbial and fermentation characteristics are affected differently by bacterial probiotic supplementation during induced lactic and subacute acidosis in sheep. BMC Microbiol. 12(1), 142 (2012)

MAFF: The analysis of agriculture materials. In: Edition, r. (ed.) Food, Reference Book: Manual of Veterinary Parasitological Laboratory Techniques. Ministry of Agriculture and Fisheries, HMSO, London (1986)

Horwitz, W.: Official Methods of Analysis of AOAC International, 17th edn. Association of Analytical Chemists International, Gaithersburg, MD (2000)

Borreani, G., Tabacco, E.: Improving corn silage quality in the top layer of farm bunker silos through the use of a next-generation barrier film with high impermeability to oxygen. J. Dairy Sci. 97(4), 2415–2426 (2014)

Canale, A., Valente, M.E., Ciotti, A.: Determination of volatile carboxylic acids (C1–C5i) and lactic acid in aqueous acid extracts of silage by high performance liquid chromatography. J. Sci. Food Agric. 35(11), 1178–1182 (1984)

Cruwys, J., Dinsdale, R., Hawkes, F., Hawkes, D.: Development of a static headspace gas chromatographic procedure for the routine analysis of volatile fatty acids in wastewaters. J. Chromatogr. A 945(1–2), 195–209 (2002)

Mayne, C., Gordon, F.: Effect of harvesting system on nutrient losses during silage making. 2. In‐silo losses. Grass Forage Sci. 41(4), 341–351 (1986)

Wambacq, E., Latré, J.P., Haesaert, G.: The effect of Lactobacillus buchneri inoculation on the aerobic stability and fermentation characteristics of alfalfa-ryegrass, red clover and maize silage. Agric. Food Sci. 22(1), 127–136 (2013)

Reich, L.J., Kung Jr., L.: Effects of combining Lactobacillus buchneri 40788 with various lactic acid bacteria on the fermentation and aerobic stability of corn silage. Anim. Feed Sci. Technol. 159(3–4), 105–109 (2010)

Zahiroddini, H., Baah, J., McAllister, T.: Effects of microbial inoculants on the fermentation, nutrient retention, and aerobic stability of barley silage. Asian Australas. J. Anim Sci. 19(10), 1429–1436 (2006)

Baah, J., Addah, W., Okine, E., McAllister, T.: Effects of homolactic bacterial inoculant alone or combined with an anionic surfactant on fermentation, aerobic stability and in situ ruminal degradability of barley silage. Asian Australas. J. Anim. Sci. 24(3), 369–378 (2011)

Shah, A., Xianjun, Y., Zhihao, D., Siran, W., Tao, S.: Effects of lactic acid bacteria on ensiling characteristics, chemical composition and aerobic stability of king grass. J. Anim. Plant Sci. 3, 747–755 (2017)

Owens, V., Albrecht, K., Muck, R.: Protein degradation and fermentation characteristics of unwilted red clover and alfalfa silage harvested at various times during the day. Grass Forage Sci. 57(4), 329–341 (2002)

Zhang, L., Yu, C., Shimojo, M., Shao, T.: Effect of different rates of ethanol additive on fermentation quality of Napiergrass (Pennisetum purpureum). Asian Australas. J. Anim. Sci. 24(5), 636–642 (2011)

Pedroso, A.d.F., Nussio, L.G., Paziani, S.d.F., Loures, D.R.S., Igarasi, M.S., Coelho, R.M., Packer, I.H., Horii, J., Gomes, L.H.: Fermentation and epiphytic microflora dynamics in sugar cane silage. Sci. Agricola 62(5), 427–432 (2005)

Driehuis, F., Elferink, S.O., Van Wikselaar, P.: Fermentation characteristics and aerobic stability of grass silage inoculated with Lactobacillus buchneri, with or without homofermentative lactic acid bacteria. Grass Forage Sci. 56(4), 330–343 (2001)

Li, Y., Wang, F., Nishino, N.: Lactic acid bacteria in total mixed ration silage containing soybean curd residue: their isolation, identification and ability to inhibit aerobic deterioration. Asian Australas. J. Anim. Sci. 29(4), 516 (2016)

Holzer, M., Mayrhuber, E., Danner, H., Braun, R.: The role of Lactobacillus buchneri in forage preservation. Trends Biotechnol. 21(6), 282–287 (2003)

Schmidt, R., Hu, W., Mills, J., Kung Jr., L.: The development of lactic acid bacteria and Lactobacillus buchneri and their effects on the fermentation of alfalfa silage. J. Dairy Sci. 92(10), 5005–5010 (2009)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Taha, V.J. (2019). Using a Mix of Three Microbial Strains on Fermentation and Aerobic Stability of Grass Silage. In: Mustafa, Y., Sadkhan, S., Zebari, S., Jacksi, K. (eds) Recent Researches in Earth and Environmental Sciences. Springer Proceedings in Earth and Environmental Sciences. Springer, Cham. https://doi.org/10.1007/978-3-030-18641-8_7

Download citation

DOI: https://doi.org/10.1007/978-3-030-18641-8_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-18640-1

Online ISBN: 978-3-030-18641-8

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)