Abstract

Recent years, high power fiber lasers at the spectral region near 1550 nm attract a lot of attention as promising sources for numerous civil and military applications. There are four main type of lasers allowing to generate high power radiation at this spectral range: Er/Yb-co doped fiber lasers, Yb-free Er-doped fiber lasers cladding-pumped at 980 nm, Er-doped fiber lasers core-pumped by Raman lasers at 1480 nm, and Er-doped fiber laser in-band pumped at 1532 nm. In this chapter we review current states, limiting factors and future perspectives of all these approaches.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

8.1 Introduction

An emission band of erbium ions near 1.5 µm which coincides with the silica fibers minimum loss spectral range made Er-doped fibers (EDFs) indispensable for the telecom industry. These fibers were actively studied during 1990s in order to develop efficient high-gain optical amplifiers. The output power of such amplifiers required by telecom applications does not exceed 1 W. At the same time, there is large variety of applications with a great demand of the high power (1 W–1 kW) laser sources operating at 1.5 µm wavelength. There are three main reasons for that. First, this spectral range falls into the transparency window of the atmosphere, so a laser beam can be transmitted over a long distance with low loss. Second, a radiation at wavelengths longer than ~1400 nm is not focused by an eye lens on a retina. For this reason, 1.5 µm lasers are concerned to be so-called “eye-safe” type of light sources. Thus, for many applications high power Er-doped fiber lasers are much more preferable than e.g. Yb-doped counterparts operating near 1 µm due to safety reasons. Third, the active development of the optical communication industry at 1.55 µm during last decades resulted in the large amount of available high-quality low-cost optical components (isolators, wavelength division multiplexers (WDMs), circulators, couplers etc) operating at this wavelength range. This frequently makes the Er-doped fiber lasers (EDFLs) more attractive than Yb- and especially Tm-fiber sources from the commercial point of view. Therefore, high-power EDFLs are quite interesting for such applications as light detection and ranging, power beaming, illumination, free-space optical communications, remote sensing and bio-medical applications.

Despite the great demand of the high-power Er-doped fiber lasers for civil and military applications, demonstrated output power of such lasers are lower than that from any other commonly used rare-Earth-doped silica-based fiber laser. Thus, to date, 10 kW [1], 1 kW [2], and 400 W [3] power levels were demonstrated from Yb-, Tm- and Ho-doped fiber lasers respectively. At the same time, the highest power from a fiber laser at 1.55 µm is only 300 W [4]. The reasons for that are low Er3+ ions absorption and emission cross-sections and concentration effects caused by erbium ions clustering.

In this chapter we consider the main factors limiting manufacturing of the high power fiber lasers near 1.55 µm, present state of the art solutions, and discuss prospects of the power scaling of such systems.

8.2 Properties of Erbium Ions in Silica Glass

8.2.1 Spectroscopic Properties

There are several absorption bands of the Er-doped silica glass in the visible and near IR spectral ranges. Figure 8.1 demonstrates energy diagram of erbium ions in silica glass [5]. Transitions between the ground state 4I15/2 and higher-lying energy levels might be observed by absorption measurements. Figure 8.2 represents typical absorption spectrum of the Er-doped silica fiber measured by a cut-back technique [5].

Energy diagram of erbium ions in silica glass [5]

Experimentally measured loss spectrum of an Er-doped silica glass. The absorption at 400–600 nm region was divided by the factor of 10; the small oscillatory structure near 1100 nm corresponds to the cutoff of the second-order mode of the fiber [5]

The energy level 4I13/2 has a rather long lifetime of ~10 ms (it slightly varies with the glass composition). Electron transition from this level to 4I15/2 provides lasing in ~1530–1610 nm spectral range. Due to a large energy gap between 4I13/2 and the ground state a population of this level is almost equal to zero when not pumped. Population inversion might be achieved by an optical pumping into any upper energy levels (then ions quickly, mostly nonradiatively relax to the 4I13/2 level) or directly into short-wave edge of the absorption band 4I13/2. As the lower laser level is the ground state rather high population inversion (~50% depending on wavelength) is required to have a positive gain of Er-doped fiber.

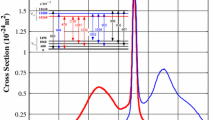

Absorption and emission spectra of EDFs as well as the lifetime slightly depend on the glass host. This is a result of different positions of Stark levels, intensities of transitions between them and their homogeneous and inhomogeneous broadening in different glass matrices. 4I13/2–4I15/2 transition absorption and emission cross sections of a widely used Al co-doped Er-doped glass are presented in Fig. 8.3 [6].

Absorption and emission cross section of an Al co-doped EDF [6]

8.2.2 Loss Mechanisms

One of the main reasons for the relatively low demonstrated maximum power of Er-doped fiber lasers is their low pump-to-signal conversion efficiencies. There are two main mechanisms that results in loss of pump and signal powers and, therefore, suppress the efficiency.

First mechanism is the background or so-called grey loss. This loss are weakly dependent on a wavelength and are sum of many factors: electron and photons absorption, Rayleigh scattering, impurities, glass non-uniformities, stresses etc Although grey loss less than 0.17 dB/km were demonstrated for telecom fibers typical loss of EDFs are 1–50 dB/km. This is caused by erbium and co-dopants precursors whose purity is often much worse than that of commercially available germanium and silicon chlorides used for the manufacturing of the telecom fibers. It should be noted, that loss of cladding-propagating light in state-of-the-art double-clad fibers is ~10–50 dB/km, which also affect the efficiency of the cladding-pumped lasers.

Second mechanism is up-conversion processes caused by a clustering of erbium ions. The thing is in rather low solubility of erbium ions in silica glass. It was shown [7, 8] that distribution of Er3+ in silica glass is not fully uniform and a noticeable amount of ions are much closer to each other than it can be expected from the statistics. In other words, erbium ions form clusters in the glass matrix. Short distance between ions within a cluster leads to a fast ion-ion energy exchange and cause an effect called up-conversion illustrated below.

Let’s consider cluster that consists from only two erbium ions. When both of ions are excited one of them transfers its energy to another and goes into a ground state. The other one simultaneously will go to the upper 4I9/2 state and then fast non-radiatively relaxes back to the 4I13/2 state (Fig. 8.4). Thus, up-conversion results in the loss of a signal or pump photon. For clusters of bigger size the up-conversion process proceeds in a similar manner.

Co-doping of the silica glass with aluminum or phosphorus oxides allows significantly decrease a number of clustered ions of rare earth elements [9]. For Er-doped silica glass it was shown that namely aluminum co-doped fibers demonstrates the best performances [10]. Thus, to date, Al2O3 is the most usable co-dopant for Er-doped fibers. Figure 8.5 shows dependences of part of clustered ions for fibers with low (<1.5 mol%) and high (>3 mol%) concentrations of the aluminum oxide [11]. It can be seen, that an addition of aluminum allows significantly decrease a number of the erbium clusters in the silica glass. However, it should be noted, that the clustering suppression saturates with the aluminum concentration at doping level near 3 mol%. Further increase of the aluminum content does not affect the clustered ions number [10].

Dependences of part of clustered ions on erbium concentration for glasses with high and low aluminum concentration [11]

Thus, up-conversion might be considered as a source of unbleachable loss at signal and pump wavelengths. The value of this loss depends on the erbium concentration, the population inversion and the glass composition.

8.3 Er-doped Yb-free Fiber Lasers Cladding Pumped at 980 nm

The erbium absorption band near 980 nm is often used for pumping due to the availability of efficient and cheap pump diodes at this wavelength. Worth to note that rather high—close to quantum limited—pump conversion efficiency could easily be reached in the Er-doped fiber lasers and amplifiers core-pumped at 980 nm [12]. However, the development of efficient cladding-pumped EDF lasers is much more challenging. The reason is in rather low pump absorption and emission cross-sections of Er3+ (~10 times lower than that of e.g. Yb3+). Thereby a relatively long fiber is required to absorb the pump and to have a sufficient gain. Exploiting of a cladding-pumped scheme even further reduce the pump absorption (approximately by the factor equal to the cladding to core areas ratio) and increase a fiber length. As a result, the influence of the background loss and the loss associated with clustering becomes considerable and leads to the significant efficiency drop. There were several attempts to realize high-power Er-doped lasers cladding-pumped fiber lasers [13,14,15,16,17], however efficiency of these lasers for a long time remained relatively low: less than 24% in a single-mode regime and less than 30% for multimode lasers. Accurate optimization of active fiber parameters was required in order to develop efficient high-power Er-doped fiber lasers cladding-pumped at 980 nm.

8.3.1 Optimization of a Double-Clad Er-doped Fiber Design

In 2013 an influence of double-clad Er-doped fibers parameters on their efficiencies was studied through a numerical modeling [11, 18]. It can be seen from Fig. 8.5 that fibers with high Al2O3 concentration exhibit a better Er3+ ions solubility. However, it worth to note that the high aluminum refractivity leads to a high core-to-clad index difference Δn, limiting the core diameter to 6–10 μm for a single mode regime. A simulation result for amplifiers based on the double-clad EDFs with high Al2O3 concentration and core diameter of 10 μm operating at 1550 nm are shown in Fig. 8.6 (curve (1)). It can be seen that the efficiency of the amplifiers based on this type of fibers does not exceed 5%. Reduction of the aluminum content in the core reduces Δn and allows increasing the core diameter. There are commercially available EDFs with 20 μm core (Δn ~ 0.002) which are operated singlemode by properly bending the fiber [15, 19]. Despite a poor solubility of erbium in such a glass (see Fig. 8.5), increasing the core-to-clad ratio enables the higher clad absorption and therefore the shorter active fiber. This reduces the influence of the up-conversion and grey loss per amplifier length. Calculations show significant increase of the slope efficiency for the 20 μm core fiber design (see curve (2) in Fig. 8.6). The maximum slope efficiency of 16% might be achieved with such fibers.

Calculated slope efficiencies of cladding pumped at 980 nm Er-doped fiber amplifiers with various Al2O3 concentration, core diameter and operating wavelength (clad diameter is 125 μm). 1: >3 mol%, 10 μm, 1550 nm; 2: >1.5 mol%, 20 μm, 1550 nm; 3: 1.5 mol%, 20 μm, 1585 nm; 4: 1.5 mol%, 35 μm, 1585 nm [11, 18]

In order to clearer demonstrate the influence of the background loss and the loss caused by the clustering calculations taking into account each effect separately were performed in [18]. The simulation was made for the same fiber parameters as for the curve (2) in Fig. 8.6. Results are presented in Fig. 8.7. As follows from it the up-conversion causes a significant degradation of the efficiency in heavily doped fibers. It is caused by the growth of the number of Er-ion pairs with erbium concentration. On the contrary, for fibers with low Er3+ content, their length reaches hundreds of meters and the efficiency decreases due to the high net value of background loss. Thereby, there is an optimal concentration of Er3+ where sum of clustering and background loss is minimized.

At longer wavelengths Er3+ ions and therefore clusters have a lower absorption cross-section. This decreases the number of ions in the excited state and therefore suppresses the up-conversion. So, growth of the efficiency can be obtained by operating at longer wavelengths. The curve (3) in Fig. 8.6 shows the efficiency for the same fibers as in (2) however operated at 1585 nm. The highest efficiency in this case is ~27% at the Er3+ content ~1025 m−3. This result is in a good agreement with [15] where 24% slope efficiency was obtained in an EDF with core and cladding diameters of 20 and 125 μm and slightly higher erbium concentration. Further increase of the wavelength (for example to 1600 nm) did not show more improvement of the efficiency due to very low Er3+ emission cross-sections at long wavelengths.

To date, stable manufacturing of fibers doped with ~1.5 mol% of Al2O3 and Δn ~ 0.001–0.0015 was achieved by co-doping with fluorine enabling the fabrication of singlemode fibers with a core diameter up to 35 μm [11]. The efficiency for these fibers is shown by a curve (4) in Fig. 8.6. Efficiency as high as 40% can be obtained with such a design. Thus, the maximum efficiency of an EDF cladding-pumped at 976 nm might be achieved for the large mode area fibers operating at long wavelengths.

8.3.2 Experimental Results

According to the calculations presented above a fiber with optimal parameters was fabricated in [11, 18]. The fiber core contained ~0.017 mol% Er2O3 (~7 · 1024 Er3+ ions/m3), ~1.5 mol% Al2O3 and ~1 wt% of F. The core diameter was 34 μm. The refractive index profile (RIP), calculated fundamental mode field distribution (mode field diameter: 24 μm) and microscope image of the fiber facet are shown in Fig. 8.8. The cutoff wavelength of the fiber was 1.7 μm, ensuring the singlemode operation in a gently bent fiber (Rb < 35 cm) operated at 1585 nm. The cladding of the fiber was square-shaped with a surface area of 110 × 110 μm2 (corresponding to that of a circular fiber with a diameter of 125 μm). The fiber was coated with a low index polymer providing NA = 0.46. The small-signal cladding absorption was 0.6 dB/m at 980 nm.

Manufactured fiber was tested as a gain medium in high power amplifier and oscillator laser schemes. Sketches of experimental setups are presented in Fig. 8.9. In both cases a pump radiation from pigtailed 980 nm multimode diodes (105/125 µm, 0.22 NA) was launched into the active fiber through a commercially available 6+1 to 1 pump combiner. A fiber laser with output power of 4 W at 1585 nm was used as a seed source for the amplifier. A cavity of the oscillator was formed by highly reflective fiber Bragg grating (FBG) and a straight cleaved output fiber facet providing 4% Fresnel reflection. The FBG was written in a passive fiber with 20/125 µm core/clad diameters (NA = 0.08/0.46). Output end of the amplifier was angle-cleaved. In both schemes a high-power cladding light stripper similar to that described in [20] was made near the output end of the active fiber. The combined available pump power was 275 W and 190 W in amplifier and oscillator experiments respectively. Dependences of output powers on launched signal powers for the amplifier and the oscillator are presented in Fig. 8.10. In both cases maximum output powers were limited only by available pump powers.

Maximum output powers of 100 and 75 W, and slope efficiencies of 37 and 40% were achieved. The output spectrum didn’t show any amplified spontaneous emission (ASE) over the emission band and the beam quality was close to the diffraction limit as presented in the insets of Fig. 8.10. Taking into account high electrical to optical (E–O) efficiency of 980 nm diodes (~50%), the E–O efficiency of the developed lasers was ~20%.

To date, the output power of 100 W and the slope efficiency of 40% are the highest demonstrated power and efficiency for the cladding-pumped at 980 nm Yb-free Er-doped fiber lasers. Concerning power scaling of such type of lasers, to date, 980 nm pump diode with 105/125 output fiber (0.22 NA) and power of 100 W are commercially available now. Thus, using a standard 7 to 1 pump combiner one can build 280 W Er-doped all-fiber laser. Moreover, recently 270 W diodes were reported as experimental samples [21]. Therefore power scaling of such Er-doped lasers to the ~850 W level might be performed in the near future.

8.4 Er-Yb Co-doped Fiber Lasers

8.4.1 Yb Sensitization of Er-doped Fibers

As it was shown above, the low value of Er3+ ions cross-sections results in the increase of the active fiber length and corresponding raise of net loss in laser/amplifier. One solution to this problem is to sensitize fiber by co-doping the EDF with ytterbium. The Yb3+ then absorbs most of the pump light and cross relaxation between adjacent ions of Er3+ and Yb3+ allows the absorbed energy to be transferred to the Er3+, thus providing another route for pumping the laser (see Fig. 8.11).

It should be noted that the absorption cross-section of ytterbium is order of magnitude higher than that of erbium. In addition, Yb3+ ions have only one energy transition in the near infrared region, thus clustering of ytterbium ions does not lead to up-conversion processes. Therefore, much higher ytterbium concentrations (up to several wt%) might be used comparing to that of erbium (~0.1 wt%) without impact on the efficiency. As a result, co-doping of an Er-doped fiber with Yb3+ allows increasing pump absorption by several orders of magnitude (see Fig. 8.11). It is also important that Yb co-doping increase solubility of the Er ions [22], which also allows one to increase pump-to-signal conversion efficiency.

Several groups successfully demonstrated low power (<1 W) Er-Yb lasers in the early 1990s [23, 24]. However, when more powerful pump diodes became available it turned out that power scaling of Er-Yb lasers to levels higher than several Watts is quite challenging. The main limiting factor for that is a parasitic emission (ASE or even lasing) of ytterbium ions near 1 µm. It results in an efficiency rollover at high powers and a self-pulsing near 1 µm causing the catastrophic damage of the fiber and optical components.

Reasons for the parasitic lasing are the back energy transfer from Er to Yb ions and the fact that there are some amount of isolated Yb3+ ions (i.e. not coupled with Er ions) that might emit light near 1 µm. Thus, careful core composition optimization is required to increase a threshold of the parasitic emission. Particularly, heavily phosphorous doping of the active core is usually used. The addition of phosphorous to the silica glass increase the phonon energy and ensure rapid multiphonon decay from the 4I11/2 level of Er3+ so minimizing back transfer of energy to the donor Yb3+ ion. Another way to avoid self pulsing near 1 µm is simultaneous operation at 1 and 1.55 µm. This might be realized by building additional cavity or seeding at 1 µm [25, 26].

8.4.2 High-Power Er-Yb Lasers

To date, the maximum power demonstrated with standard singlemode fibers with 5–10 µm core diameters is only ~10 W [24,25,26,27]. This level is limited by parasitic ASE and self-pulsing near 1 µm.

The best results in power scaling of Er-Yb fiber lasers were achieved by the group from Optoelectronic Research Center. The authors proposed exploiting of large-mode area active fibers. Increase of the core diameter allows reduction of the power density and, therefore, increasing the Yb lasing threshold. At the same time, the requirement of a high phosphorous concentration which increase refractive index of the glass leads to the fiber multimodeness.

In [29] an Er-Yb fiber with core/cladding diameters of 30/650 µm and the core NA of 0.2/0.45 was developed. The Er-Yb co-doped core provided a core absorption of 67 dB/m at 1535 nm (from the Er doping) and an inner cladding absorption for the pump light at 975 nm of 1.4 dB/m (from the Yb doping). The fiber was tested in a MOPA scheme presented in Fig. 8.12. The fiber was end-pumped from the signal output end by a free-space coupled diode stack at 975 nm with up to 470 W of launched pump power. Both fiber ends were angle cleaved to eliminate signal feedback. The signal from the preamplifier was launched via a free-space coupling arrangement, through a beam splitter and a dichroic mirror that were inserted to monitor the backscattered signal and to separate the residual pump and any spurious Yb emission at 1 µm from the signal beam path.

MOPA setup from [29]

The dependences of the signal power near 1.55 µm and the spurious lasing at 1 µm, and their spectra are presented in Figs. 8.13 and 8.14.

Signal power versus final-stage pump power. Inset: output spectra at 1563 nm [29]

Yb-emission power versus final-stage pump power. Inset: Yb-emission spectra [29]

The highest output power of 151 W at 1563 nm was achieved at a launched pump power of 457 W. The slope efficiency of 35% at low powers dropped to 29% at higher powers because of the onset of Yb emission. The maximum power of this emission exceeded 70 W at the maximum pump power. Despite the high value of V factor (V = 12) singlemode operation was achieved through the fiber bending and beam quality parameter M2 = 1.1 was measured.

In their following work the authors built a high-power oscillator schematically presented in Fig. 8.15 [4]. The fiber used in the experiment had a 30 µm core and a 600 µm cladding with NAs of 0.21 and 0.48. The absorption for light in the inner cladding from the Er and Yb ions are 0.11 dB/m at 1535 nm and 3.8 dB/m at 976 nm. The EYDF used for the laser is 6-m long, and both ends were cleaved perpendicularly to the fiber axis. The laser cavity was formed between the bare fiber facet at the pump launch end of the fiber and a dichroic mirror butt-coupled to the fiber at the rear end. The dichroic mirror had high reflection at 1.5–1.6 µm and high transmission for the pump and Yb emission wavelengths at ~1.07 µm.

Schematic of the Er:Yb codoped fiber laser system [4]

Figure 8.16 shows the laser performance at 1.56 µm (left) and 1.07 µm (right). As well as in the MOPA setup discussed above a significant rollover of efficiency (from 40 to 19%) associated with an Yb parasitic emission can be observed. 297 W of power at 1.56 µm and total 340 W of power at 1 µm were measured at the maximum pump power. The beam quality parameter for the output at 1.56 and 1.07 µm were 3.9 and 12.

Output power at 1.56 and 1.07 µm as functions of pump power [4]

The output power of 297 W, to date, is the highest power ever demonstrated for a laser operating near 1.55 µm. However, further power scaling of such systems looks challenging due to the serious impact of the parasitic Yb emission on the laser performance. The requirement of the 1 µm lasing control prevents building of all-fiber system and makes Er-Yb lasers rather complex and impractical. Significant improvement of a fiber design is required to overcome this issue.

8.5 Er-doped Fiber Lasers Cladding-Pumped at 1530 nm

In recent years in-band (or resonant) pumping has been the focus of attention as a promising approach for building high average power fiber lasers. For these lasers low quantum defect has allowed the demonstration of much higher optical-to-optical (O–O) efficiency and thus lower heat loads compare to their off-band pumped counterparts. For Er-doped fibers absorption peak near 1530 nm is often used for in-band pumping.

8.5.1 Pump Sources Near 1530 nm

There are commercially available InGaAsP/InP diode systems operating near 1535 nm that can be used for Er-doped fibers pumping. At the same time, to date, their parameters are much inferior to that of well-developed diodes at 915/980 nm. Available power of these diodes typically doesn’t exceed ~30 W (for 105/125 µm fiber), and efficiency is ~25%. To compare, 980 nm diodes available power and efficiency are ~100 W and 50%. In addition, a price of 1530 nm diodes is rather high. Another problem of diode pump sources is a thermal drift of the central wavelength. The point is in the rather small (several nanometers) spectral width of the erbium absorption peak near 1530 nm. Therefore, a pump wavelength variation with power or temperature can lead to a decrease of the pump absorption and, thus, efficiency reduction. Moreover, it is known that even diodes with wavelengths locked by a volume Bragg grating frequently generate significant amounts of out-of-band radiation when operated near the maximum current and/or at high heat sink temperatures. The highest demonstrated to date pump power from diode sources near 1535 nm in 125 µm fiber is 170 W [19]. It was obtained by combining of 6 multimode diodes through a commercially available 6+1 to 1 pump combiner.

In order to overcome disadvantages of diode sources fiber pump lasers were developed by several groups [28, 30,31,32]. For instance, in [30] single-mode 1535 nm an Er-Yb laser with 20 W of output power was used to core- and clad-pump Er-doped fiber. At the same time, as it was shown in Sect. 8.4 power scaling of Er-Yb lasers to 100 W and above power level is quite challenging due to the parasitic Yb lasing. To avoid this limitation Jebali et al. [28] proposed to combine several single-mode Er-Yb laser. The setup of the laser is schematically shown in Fig. 8.17. A radiation of 36 fiber lasers at 1535 nm was coupled into the cladding of an active double-clad fiber through specialty-developed combiner. Each Er-Yb pump laser was, in turn, pumped by 976 nm fiber coupled multimode diodes (see dashed box in Fig. 8.17). A commercially available (CoractiveDCF-EY-10/128) Er-Yb fiber was used as an active medium for these lasers. The fiber had relatively high Yb concentration that caused high heat load. As a result, the output power of each pump laser was thermal limited at level of ~10 W. The average efficiency of pump lasers was 35.6%.

Experimental setup from [28]

The outputs of these pump lasers were combined using a custom-made pump combiner that merges 37 standard single-mode fibers inputs (SMF28) into one coreless 125 μm fiber with a NA of 0.45. The manufacturing technique of the 37 → 1 fused fiber bundle combiner is described in [33] and [34]. The pump combiner losses was evaluated to be ~0.3 dB. As a result, ~370 W of multimode pump radiation at 1535 nm in 125 µm fiber was generated.

Another approach to build a high power pump laser at 1535 nm was demonstrated in [31]. It was proposed to use multimode Yb-free Er-doped fibers cladding-pumped at 980 nm. As it was shown in Sect. 8.3.1, increase of the core diameter of cladding-pumped Er-doped fibers results in significant improvement of their efficiency. It worth to note, that there is no need for a high beam quality of the 1535 nm pump source for cladding-pumped lasers. The parameters of the EDF core are limited only by the requirement to match them to the pump ports of standard pump combiners: a core/cladding diameter of 105/125 µm and a numerical aperture of 0.15. Therefore, the active fiber core could be multimode and has diameter up to 105 µm.

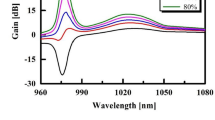

A numerical analysis similar to that described in Sect. 8.3.1 was performed in [31, 32] to define the optimum erbium concentration for a multimode Er-doped fiber. The slope efficiency of a co-pumped power amplifier based on 100/125 µm double-clad Er-doped fiber operating at 1535 nm was computed (Fig. 8.18a). It can be seen that the efficiency as high as 40% could be achieved.

a Computed slope efficiency of the amplifier at 1535 nm. b Refractive index profile and of the Er-doped preform and microscope image of the fiber facet 32

Based on the simulation results, a fiber preform with optimum parameters was produced [31, 32]. The refractive index profile of the preform core is presented in Fig. 8.18b. The preform was polished to an octagonal shape and a double clad fiber was drawn down from it. The resulting fiber had core/cladding diameters of 95/125 µm and was coated with a polymer providing a pump NA of 0.46. A microscope image of the fiber facet is presented in Fig. 8.18b.

The manufactured fiber was tested in an original laser scheme described below. It should be noted that, in addition to a high E–O efficiency, there are other important demands for the pump source: compactness, high long-term stability, small size and low cost. The simplest and therefore the cheapest scheme for a fiber laser consists of a gain fiber spliced between two FBGs. However, it is known that different modes have different reflection spectra from an FBG written in a multimode fiber. As a result, the spectrum of such a multimode laser has several peaks [13], leading to the effective spectral broadening. In addition, this effect could result in unstable operation because of the mode competition. To ensure a narrow spectrum of a multimode laser, a MOPA scheme could be used. However, the requirement of a seed laser that is powerful enough to saturate the amplifier increases the cost and footprint of the system and makes it more cumbersome.

In [31, 32] the new, simple multimode laser scheme was proposed (Fig. 8.19). A pump at 980 nm was launched into the cavity formed by 1.5 m of the single-mode double clad EDF developed in [11] and a pair of FBGs. Four multimode pump diodes at 980 nm and overall maximum power of 173 W were coupled through a commercially available 7 × 1 pump combiner into the laser resonator. The FBGs were written in a 20/125 passive fiber (NA~0.08/0.45) and had reflections of ~100 and 10% at 1535 nm with bandwidths <0.8 nm. The small-signal absorption from the cladding near 980 nm of the single-mode EDF was ~0.6 dB/m [11], so only ~5% of the overall pump power was absorbed in the single-mode laser cavity. It generated light at 1535 nm with a slope efficiency of ~45% with respect to the absorbed power. This signal was used as the seed radiation for the 12 m piece of the multimode EDF described above that was spliced to the 10% FBG of the single-mode cavity. A commercially available 105/125 µm multimode fiber was spliced at the output of the laser, and a cladding pump stripper similar to that described in [20] was built at the splice point. Therefore, the singlemode seed laser and the multimode amplifier were both pumped by the same pump diodes at 976 nm, and the spectral width of the laser was locked by the FBGs written in the single mode fiber, resulting in a relatively narrow output spectrum.

a Scheme of the multimode laser. b Output power of the multimode laser. Inset-spectrum at full power [32]

Figure 8.19b depicts the output power of the developed multimode laser. 60 W of output power, which was limited by the available pump power, was achieved. The slope efficiency of the laser was estimated to be 35%. The output spectrum measured near 1535 nm with 0.1 nm resolution is presented in the inset of Fig. 8.19b. A small part (~8% relative to the output power of the laser) of unabsorbed pump at 976 nm was propagated in the multimode laser core together with the signal near 1535 nm.

8.5.2 Er-doped Fiber Lasers Pumped at 1535 nm

The first high-power Er-doped fiber laser resonantly cladding-pumped near 1535 nm was demonstrated in [35]. Experimental setup from this work is presented in Fig. 8.20. It is comprised of a diode laser seeder, a preamplifier and a booster amplifier. The preamplifier provided a maximum output power of 0.4 W in order to maintain a signal level sufficiently close to saturating the booster gain. The Yb-free fiber booster amplifier was based on a 9.5 m Liekki Er 60-20/125 double-clad large mode area fiber with a core diameter and a numerical aperture of 20 and 0.07 respectively. The booster amplifier was cladding co-pumped by six 5–6 W fiber-coupled 105/125 µm, NA of 0.15 InGaAsP/InP laser diode modules coupled into the active fiber via a 6+1 to 1 pump combiner. The maximum combined launched power was 30.2 W.

Laser scheme from [35]

The maximum output signal power of 9.3 W at 1570 nm was obtained. The slope efficiency with respect to the absorbed pump power and O–O efficiency were 45 and 33%. In their following works the authors built high-power all-fiber oscillators with similar pump configuration and improved wavelength-stabilized diode sources [19]. As a result, the maximum output power of 88 W was achieved. The slope efficiency relatively to the absorbed pump power and O–O efficiency were increased to 69 and 52%.

It worth to note, that the highest achieved by the authors optical-to-optical of 52% efficiency is quite far from the quantum limit (96%). Thus, exploiting of a specialty optimized fiber instead of a commercially available one was required in order to increase the output power. Such optimization was done in [28]. As it was discussed above, first of all, erbium ions clustering should be suppressed. An alumino-phospho-silicate glass matrix with addition of Yb and Er was used as a material of the core. In contrast to Er-Yb lasers discussed above, Yb ions do not participate in the laser transition of in-band pumped EDFs. It was shown that addition of other rare earth elements such as lanthanum or ytterbium allows to increase efficiency of the Er-doped fiber lasers [22]. Apparently, a portion of the clusters that are consist of different rare earth ions, whose energy levels do not coincide, and Er3+ ions are separated inside the clusters by a second type of rare earth ions (e.g. Yb3+ or La3+). This effect may prevent up-conversion processes in these clusters. At the same time, aluminum and phosphorus oxides forms AlPO4 joints in silica glass. These structure units act as solvation shells for Er3+ ions and by this way also improve erbium solubility in the glass [10]. Both these approaches were applied by the authors of [28] to reduce up-conversion loss.

The manufactured in [28] active fiber had core and cladding diameters of 17 and 125 µm. Small signal absorption of the fiber from the cladding was 1.1 dB/m at 1535 nm. Er:Yb concentrations ratio was 1:3.3. The laser setup depicted in Fig. 8.17 was used. The cavity consisted of a FBG acting as the high reflector and 18 m of Er–Yb co-doped double-clad fiber with the cleaved end acting as the output coupler. The 1585 nm FBG, with a 3 dB bandwidth of 2 nm and a reflectivity of 30 dB, was UV written in a single-mode double-clad fiber having an 11 μm core diameter and a NA of 0.08. 264 W of output power was achieved with the slope efficiency of 75% with respect to the launched pump power in this experiment.

To date, 264 W [28] is a record demonstrated output power for the singlemode Er-doped fiber lasers. However, available pump power for the scheme demonstrated at Fig. 8.17 is quite limited by thermal effects and a parasitic emission of the singlemode Er-Yb fibers. Further power scaling might be achieved by combination of the fiber from [28] and multimode pump sources discussed above (Fig. 8.19). Indeed, the power of the described multimode fiber laser could be easily scaled. As it was already mentioned, 100 W multimode pump diode sources at 980 nm with a 105/125 µm fiber pigtail are commercially available now. Using these diodes together with 7-to-1 pump combiners ~250 W of power at 1535–1590 nm from 100 µm core output fiber (NA = 0.15) at the output of multimode laser. Finally, even this output power level from multimode fiber laser is not limited. It is shown in [31] that decrease of the pump conversion efficiency of multimode fibers is not very significant when core-to-cladding diameters ratio is decreased to 0.5. The efficiency of 100/200 µm core/cladding diameter with optimized erbium concentration and decreased background will have pump conversion efficiency of ~35% at 1535 nm. Currently pump combiners with 19 pump ports (105/125 µm, NA = 0.15) and output fiber with an outer diameter of 200 µm and a NA = 0.45 are commercially available. This means that there are no fundamental limitation to scale output power of multimode Er-doped lasers (output 105/125 µm fiber with NA = 0.15) to the level of 600 W of output power.

Utilization of such powerful sources instead of semiconductor pump diodes or Er-Yb fiber lasers could be very promising. In particular using of 7+1-to-1 pump combiner and 7 such pump sources with a highly efficient in-band pumped Er-doped fiber laser from [28] could allow one to scale output power of the single-mode laser to the unprecedented level of more than 3 kW. Therefore, to date tandem pumping of single-mode Er-doped fiber by the multimode fiber lasers is the most promising approach to build a multi-kW laser source at 1.55 µm.

8.6 Er-doped Fiber Lasers Core-Pumped at 1480 nm

As it was mentioned above Er-doped fibers demonstrated close to the quantum limited efficiency when core-pumped at 980 [12] or 1480 nm [36]. In this case, required length of the fiber is much smaller (approximately by factor of cladding-to-core areas ratio) compare to the cladding-pumped schemes. This significantly reduces the impact of clustering-induced loss on the efficiency. However, to date, the output power of the available singlemode pump diode sources at these wavelengths is less than few Watts. Similar to the pumping near 1530 nm good alternative to diode sources is a usage of fiber lasers.

There were some attempts to manufacture a high-power Yb-doped fiber laser operating at 980 nm [37,38,39]. However, efficient operation of Yb-doped fiber lasers at this wavelength is greatly obstructed by a competitive lasing near 1030 nm. As a result, proposed single-mode Yb-doped fiber lasers at 980 nm either demonstrated low efficiencies and powers [38, 39] or were too cumbersome and expensive for mass-production as a pump source [37]. As a result, no high-power Er-doped fiber lasers core-pumped by fiber lasers at 980 nm have been reported yet to the best of our knowledge. The development of fiber Raman lasers operating near 1480 nm was more successive and are discussed in the following section.

8.6.1 Raman Lasers at 1480 nm

Stimulated Raman scattering is an effective method to generate new wavelengths in optical fibers. Typical scheme of a Raman fiber laser at 1480 nm is presented in Fig. 8.21 [40]. Radiation of a single-mode high-power Yb-doped fiber laser is coupling into a cascaded Raman resonator. The resonator is formed by sets of Raman input gratings (RIG), Raman output gratings (ROG), and a Raman fiber. Wavelengths of grating sets are defined by a Stokes shift of the Raman fiber. For standard Ge-doped silica fibers the shift is ~440 cm−1, so five FBGs is required for each set to reach wavelength of 1480 nm. For instance for Yb-doped fiber laser operating at 1117 nm grating sets are consisting from FBGs at 1175, 1240, 1310, 1390 and 1480 nm [40]. All FBGs except output one at 1480 nm should be highly reflective. At the same time it was shown that the P-doped fibers have a Stokes shift of ~1300 cm−1. In this case only two FBGs per set (at 1240 and 1480 nm) are required.

Schematic of a typical Raman fiber laser [40]

Using setup described above and Ge-doped fiber as an active media the maximum of 41 W of output power at 1480 nm was achieved with 1117-to-1480 nm O–O efficiency of ~40% [41]. The power limitation for such a setup came from an unwanted scattering into the next Stokes order near 1580 nm. For 125 m of Raman fiber, the 1580 nm peak was only 15 dB below the 1480 nm peak at 41 W of output power (Fig. 8.22). The 1580 nm peak could be reduced to 30 dB below the 1480 nm peak by shortening the fiber length to 65 m, but with a negative impact on conversion efficiency. Furthermore, as the fiber length was shortened, a smaller fraction of light at the output was contained at 1480 nm with more residual radiation at the intermediate Stokes wavelengths [41].

Output spectrum of Raman laser at 41 W of output power [41]

Thereby, the lasing suppression at 1580 nm is required for further power scaling of Raman lasers at 1480 nm. In order to do that the specialty Raman filter fiber (RFF) was developed by the group from OFS Laboratories [42]. The RFF was a germanosilicate fiber that used a fundamental mode cutoff to achieve distributed loss at wavelengths longer than 1480 nm [42]. The RFF provided cascaded Raman gain up to 1480 nm and distributed loss at longer wavelengths. The measured loss curve is shown in Fig. 8.23.

Measured loss of RFF fiber [40]

Figure 8.24 shows the output power from the Raman laser as a function of 976 nm pump power. The maximum total output power measured was 88.1 W, with 81 W at 1480 nm, for a pump power of 250 W. The output of the 1117 nm, Yb fiber laser at this pump power was 162 W. The measured spectrum at full power is shown in Fig. 8.24b on a linear scale and on a decibel scale in the inset. At 1552 nm, the signal is 42 dB below the peak at 1480 nm, and more than 60 dB down at 1580 nm. The maximum output power was limited by the available pump power in this experiment.

a Output power as a function of 976 nm pump power (including both oscillator and amplifier pump power). b Output spectrum at maximum pump power on a linear and a log scale (inset) [42]

Further Raman fiber laser construction optimization was done in [40]. The main factors decreasing the efficiency of the Raman lasers were identified as follows [40]:

-

1.

Transmission loss in the Raman input grating set and output grating set.

-

2.

Two intra-cavity splices between low effective area (possibly dissimilar) fibers constituting the grating sets and the Raman gain fiber.

-

3.

Linear loss in the Raman fiber.

-

4.

Enhanced backward and forward light at the intermediate Stokes wavelengths due to their bandwidth being higher than the grating bandwidths.

-

5.

Splice loss between the Yb-doped fiber laser output and the low effective area Raman fiber.

Thus, a number of loss components are associated with the cascaded Raman resonator assembly. To eliminate the cascaded Raman resonator exploiting of a single pass cascaded Raman scheme was developed in [40]. Two key ingredients were necessary to make the single pass cascaded amplifier feasible. Firstly, a simple multi-wavelength source which can simultaneously provide sufficient powers at all the intermediate wavelengths. A lower power conventional cascaded Raman laser lends itself ideally for this purpose. Light present at the output at all the intermediate Stokes wavelengths provides sufficient seed power at the exact required wavelengths. Secondly, scattering of the output wavelength to the next Stokes order can be further enhanced in a single pass configuration. The use of Raman filter fiber eliminates this problem and provides a technique to terminate the cascade of wavelength conversion. The proposed in [40] laser design is presented in Fig. 8.25. A high power Yb-doped fiber laser was combined with a lower power Raman seed laser. The Yb-doped fiber laser was emitting at 1117 nm and the power was combined using an 1117/1480 nm fused fiber wavelength division multiplexer (WDM). This is then sent through a Raman filter fiber.

Figure 8.26 shows the total output power and components at each Stokes wavelength measured as a function of input power at 1117 nm to the cascaded amplifier. A progressive growth and decay of all the intermediate Stokes components with increasing power can clearly be observed. A rapid growth of the final output wavelength is seen beyond a power threshold.

Figure 8.27a shows the total output power and the 1480 nm component as a function of input power at 1117 nm. The maximum output power was ~204 W at 1480 nm. The conversion efficiencies were 65% from 1117 to 1480 nm (for a quantum limited value of 75%) and 43% O–O from 975 nm pump to 1480 nm. Figure 8.27b shows the measured output spectrum at full power (log scale in the inset). More than 95% of the power is in the 1480 nm band indicating the high level of wavelength conversion.

a Plot of total output power and output power at 1480 nm as a function of input power at 1117 nm. b Spectrum of the output in linear and log scale (inset) at maximum power [40]

In their following work with higher available pump power the authors realized 300 W single-pass cascaded Raman laser with output power of 300 W and similar efficiency [43].

8.6.2 Core-Pumped Er-doped Fiber Laser

Developed Raman fiber lasers were used for core-pumping of Er-doped fiber lasers. A backward pumped architecture was utilized in [44] (Fig. 8.28). 1554 nm FBG with a FWHM of 6 nm served as the high reflector and a flat cleave (which provides a 4% reflection) was used as the output coupler. An advantage of the backward pumped architecture was that no additional filtering was necessary for applications which might be sensitive to the power at the intermediate wavelengths. The output of the FBG was fusion spliced to 21 m of length of MP980 Er-doped fiber from OFS Specialty Photonics Division. The fiber had a peak absorption of approximately 6 dB/m at 1530 nm, 0.23 NA and a mode field diameter of approximately 5.6 µm.

Experimental setup from [44]

Figure 8.29a shows the forward output power at 1554 nm as a function of input 1480 nm pump power. The maximum power of 101 W was obtained with 142 W of pump power corresponding to a conversion efficiency of 71%. The output power was only limited by the availability of pump power. Figure 8.29b shows the output spectrum at maximum power. The laser FWHM is ~3.5 nm. No ASE was observed even at 50 dB below the emission peak.

a Output forward power at 1554 nm as a function of 1480 nm input. b Output spectrum of the laser [44]

It should be noted that the high power WDMs is a critical part of core-pumped high-power oscillators/amplifiers. It was shown above, these WDMs are used to build 1480 nm pump source, and to couple pump radiation into EDF. The intensity of the light in such WDMs are much higher than that in pump combiners used for cladding-pumped scheme. This makes the development of WDMs which are capable to handle multi-hundred of Watts or even kilowatts power level rather challenging. Moreover it was shown, that additional efforts should be taken to filter out intermediate Stokes waves that can cause long-term performance degradation of WDMs [45]. Thus, further power scaling of the core-pumped Er-doped fiber lasers will be probably limited by the availability of high-power multiplexors.

References

V. Fomin, M. Abramov, A. Ferin, A. Abramov, D. Mochalov, N. Platonov, V. Gapontsev, 10 kW single-mode fiber laser, in 5th International Symposium on High-Power Fiber Lasers and Their Applications, St. Petersburg, 28 June–1 July 2010

T. Ehrenreich, R. Leveille, I. Majid, K. Tankala, G. Rines, P.F. Moulton, 1-kW all-glass Tm:fiber laser, in Proceedings of the SPIE, vol. 7580 (2010), p. 112

N. Simakov, A. Hemming, J. Haub, A. Carter, High power holmium fiber lasers, in 2014 The European Conference on Optical Communication (ECOC), Cannes (2014), pp. 1–3

Y. Jeong, S. Yoo, C.A. Codemard, J. Nilsson, J.K. Sahu, D.N. Payne, R. Horley, R. Horley, P.W. Turner, L.M.B. Hickey, A. Harker, M.J. Lovelady, A.N. Piper, Erbium:ytterbium co-doped large-core fiber laser with 297 W continuous-wave output power. IEEE J. Sel. Top. Quantum Electron. 13, 573–579 (2007)

P.C. Becker, N.A. Olsson, J.R. Simpson, Erbium-Doped Fiber Amplifiers: Fundamentals and Technologies (Academic Press, San Diego, USA, 1999)

L.V. Kotov, A.D. Ignat’ev, M.M. Bubnov, M.E. Likhachev, Effect of temperature on the active properties. Quantum Electron. 46, 271 (2016)

P.F. Wysocki, J.L. Wagener, M.J.F. Digonnet, H.J. Shaw, Evidence and modeling of paired ions and other loss mechanisms in erbium-doped silica fibers, in Proceedings of the SPIE, vol. 1789 (1993), pp. 66–79

P. Myslinski, D. Nguyen, J. Chrostowski, Effects of concentration on the performance of erbium-doped fiber amplifiers. IEEE J. Lightwave Technol. 15, 112–120 (1997)

K. Arai, H. Namikawa, K. Kumata, T. Honda, Aluminium or phosphorous co-doping effects on fluorescence and structural properties of neodimium-doped silica glass. J. Appl. Phys. 59, 3430–3436 (1986)

M.E. Likhachev, M.M. Bubnov, K.V. Zotov, D.S. Lipatov, M.V. Yashkov, A.N. Guryanov, Effect of the AlPO4 join on the pump-to-signal conversion efficiency in heavily Er-doped fibers. Opt. Lett. 34(21), 3355–3357 (2009)

L.V. Kotov, M.E. Likhachev, M.M. Bubnov, O.I. Medvedkov, M.V. Yashkov, A.N. Guryanov, J. Lhermite, S. Février, E. Cormier, 75 W 40% efficiency single-mode all-fiber erbium-doped laser cladding pumped at 976 nm. Opt. Lett. 38, 2230–2232 (2013)

R.I. Laming, J.E. Townsend, D.N. Payne, F. Meli, G. Grasso, E.J. Tarbox, High-power erbium-doped-fiber amplifiers operating in the saturated regime. IEEE Photon. Tech. Lett. 3(3), 253–255 (1991)

A.S. Kurkov, V.M. Paramonov, M.V. Yashkov, S.E. Goncharov, I.D. Zalevskii, Multimode cladding-pumped erbium-doped fibre laser. Quantum Electron. 37(4), 343 (2007)

M. Dubinskii, V. Ter-Mikirtychev, J. Zhang, I. Kudryashov, Yb-free, SLM EDFA: comparison of 980-, 1470- and 1530-nm excitation for the core- and clad-pumping, in Proceedings of the SPIE, vol. 6952 (2008), p. 695205

V. Kuhn, D. Kracht, J. Neumann, P. Weßels, Yb-free Er-doped 980 nm pumped single-frequency fiber amplifier with output power of 54 W and near-diffraction limited beam quality, in CLEO/Europe and EQEC 2011 Conference Digest, CJ7_5 (2011)

V. Kuhn, D. Kracht, J. Neumann, P. Weßels, Er-doped photonic crystal fiber amplifier with 70 W of output power. Opt. Lett. 36, 3030–3032 (2011)

V. Kuhn, D. Kracht, J. Neumann, P. Wessels, 67 W of output power from an Yb-free Er-doped fiber amplifier cladding pumped at 976 nm. IEEE Photonics Technol. Lett. 23(7), 432 (2011)

L.V. Kotov, M.E. Likhachev, M.M. Bubnov, O.I. Medvedkov, M.V. Yashkov, A.N. Guryanov, S. Fevrier, J. Lhermite, E. Cormier, Yb-free Er-doped all-fiber amplifier cladding-pumped at 976 nm with output power in excess of 100 W, in Proceedings of the SPIE, vol. 8961 (2014), p. 89610X

J. Zhang, V. Fromzel, M. Dubinskii, Resonantly cladding-pumped Yb-free Er-doped LMA fiber laser with record high power and efficiency. Opt. Express 19, 5574–5578 (2011)

S. Aleshkina, T.A. Kochergina, K.K. Bobkov, L.V. Kotov, M.M. Bubnov, J. Park, M.E. Likhachev, High-power 125-μm-optical-fiber cladding light stripper, in Conference on Lasers and Electro-Optics, OSA Technical Digest (online), paper JTu5A.106 (2016)

J. Skidmore, M. Peters, V. Rossin, J. Guo, Y. Xiao, J. Cheng, A. Shieh, R. Srinivasan, J. Singh, C. Wei, R. Duesterberg, J.J. Morehead, E. Zucker, Advances in high-power 9XXnm laser diodes for pumping fiber lasers, in Proceedings of the SPIE, vol. 9733 (2016), p. 97330B

N.V. Kiritchenko, L.V. Kotov, M.A. Melkumov, M.E. Likhachev, M.M. Bubnov, M.V. Yashkov, A.Y. Laptev, A.N. Guryanov, Effect of ytterbium co-doping on erbium clustering in silica-doped glass. Laser Phys. 25(2), 025102 (2015)

E. Snitzer, H. Po. F. Hakimi, R. Tumminelli, B.C. McCollum, Erbium fiber laser amplifier at 1.55 μm with pump at 1.49 μm and Yb sensitized Er oscillator, in OFC’88 Optical Fibre Communications Conference, paper PD2-1 (1988)

J. Minelly, W. Barnes, R. Laming, P. Morkel, J. Townsend, S. Grubb, D. Payne, Diode-array pumping of Er/sup 3+//Yb/sup 3+/ Co-doped fiber lasers and amplifiers. IEEE Photon. Technol. Lett. 5(3), 301–303 (1993)

G. Sobon, P. Kaczmarek, A. Antonczak, J. Sotor, K.M. Abramski, Controlling the 1 μm spontaneous emission in Er/Yb co-doped fiber amplifiers. Opt. Express 19, 19104–19113 (2011)

Qun Han, Yunzhi Yao, Yaofei Chen, Fangchao Liu, Tiegen Liu, Hai Xiao, Highly efficient Er/Yb-codoped fiber amplifier with an Yb-band fiber Bragg grating. Opt. Lett. 40, 2634–2636 (2015)

E. Yahel, A. Hardy, Modeling high-power Er3+-Yb3+ codoped fiber lasers. J. Lightwave Technol. 21(9), 2044–2052 (2003)

M.A. Jebali, J.-N. Maran, S. LaRochelle, 264 W output power at 1585 nm in Er–Yb codoped fiber laser using in-band pumping. Opt. Lett. 39, 3974–3977 (2014)

Y. Jeong, J.K. Sahu, D.B.S. Soh, C.A. Codemard, J. Nilsson, High-power tunable single-frequency single-mode erbium:ytterbium codoped large-core fiber master-oscillator power amplifier source. Opt. Lett. 30(22), 2997–2999 (2005)

Ee-Leong Lim, Shaif-ul Alam, David J. Richardson, Optimizing the pumping configuration for the power scaling of in-band pumped erbium doped fiber amplifiers. Opt. Express 20, 13886–13895 (2012)

L. Kotov, O. Medvedkov, M. Bubnov, D. Lipatov, A. Guryanov, M. Likhachev, High brightness multi-mode fiber lasers—a novel sources for in-band cladding pumping of singlemode fiber lasers, in Proceedings of the 5th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS), vol. 1 (2017), pp. 99–105

L.V. Kotov, O.I. Medvedkov, M.M. Bubnov, D.S. Lipatov, N.N. Vechkanov, A.N. Guryanov, M.E. Likhachev, High power pump source at 1535 nm based on multimode Er-doped fiber, in Proceedings of the SPIE, vol. 10083 (2017), pp. 100831N-1

F. Gonthier, L. Martineau, N. Azami, M. Faucher, F. Seguin, D. Stryckman, A. Villeneuve, High-power all-fiber components: the missing link for high-power fiber lasers, in Proceedings of the SPIE, vol. 5335 (2004), p. 266

B. Wang, E. Mies, Review of fabrication techniques for fused fiber components for fiber lasers, in Proceedings of the SPIE, vol. 7195 (2009), p. 71950A

M. Dubinskii, J. Zhang, I. Kudryashov, Single-frequency, Yb-free, resonantly cladding-pumped large mode area Er fiber amplifier for power scaling. Appl. Phys. Lett. 93, 031111 (2008)

M. Dubinskii, J. Zhang, V. Ter-Mikirtychev, Record-efficient resonantly-pumped Er-doped singlemode fibre amplifier. Electron. Lett. 45(8), 400–401 (2009)

J. Boullet, Y. Zaouter, R. Desmarchelier, M. Cazaux, F. Salin, J. Saby, R. Bello-Doua, E. Cormier, High power ytterbium-doped rod-type three-level photonic crystal fiber laser, Opt. Express 16, 17891–17902 (2008)

M. Leich, M. Jäger, S. Grimm, D. Hoh, S. Jetschke, M. Becker, A. Hartung, H. Bartelt, Tapered large-core 976 nm Yb-doped fiber laser with 10 W output power. Laser Phys. Lett. 11, 045102 (2012)

S.S. Aleshkina, M.E. Likhachev, D.S. Lipatov, O.I. Medvedkov, M.M. Bubnov, A.N. Guryanov, All-fiber single-mode laser at 977 nm with 5.5 W output power, in CLEO/Europe-EQEC 2015, paper CJ-P.13 (2015)

V.R. Supradeepa, J.W. Nichsolson, C.E. Headley, M.F. Yan, B. Palsdottir, D. Jakobsen, A high efficiency architecture for cascaded Raman fiber lasers, Opt. Express 21, 7148–7155 (2013)

Y. Emori, K. Tanaka, C. Headley, A. Fujisaki, High-power cascaded Raman fiber laser with 41-W output power at 1480-nm band, in Conference on Lasers and Electro-Optics/Quantum Electronics and Laser Science Conference and Photonic Applications Systems Technologies, paper CFI2 (2007)

J.W. Nicholson, M.F. Yan, P. Wisk, J. Fleming, F. DiMarcello, E. Monberg, T. Taunay, C. Headley, D.J. DiGiovanni, Raman fiber laser with 81 W output power at 1480 nm. Opt. Lett. 35(18), 3069–3071 (2010)

V.R. Supradeepa, J.W. Nicholson, Power scaling of high-efficiency 1.5 μm cascaded Raman fiber lasers. Opt. Lett. 38, 2538–2541 (2013)

V.R. Supradeepa, J.W. Nicholson, K. Feder, Continuous wave Erbium-doped fiber laser with output power of >100 W at 1550 nm in-band core-pumped by a 1480 nm Raman fiber laser, in presented at CLEO, paper CM2N.8 (2012)

X. Peng, K. Kim, X. Gu, M. Mielke, S. Jennings, A. Rider, N. Fisher, T. Woodbridge, R. Dionne, F. Trepanier, Root cause analysis and solution to the degradation of wavelength division multiplexing (WDM) couplers in high power fiber amplifier system. Opt. Express 21, 20052–20061 (2013)

Acknowledgements

The authors are grateful to E. M. Dianov, the scientific director of the Fiber Optics Research Center, for his continuous interest in and support of this work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Kotov, L.V., Likhachev, M.E. (2019). High Power Continuous-Wave Er-doped Fiber Lasers. In: Ribeiro, P., Andrews, D., Raposo, M. (eds) Optics, Photonics and Laser Technology 2017. Springer Series in Optical Sciences, vol 222. Springer, Cham. https://doi.org/10.1007/978-3-030-12692-6_8

Download citation

DOI: https://doi.org/10.1007/978-3-030-12692-6_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-12691-9

Online ISBN: 978-3-030-12692-6

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)